Unsaturated Polyester Resin Market Trends and Forecast

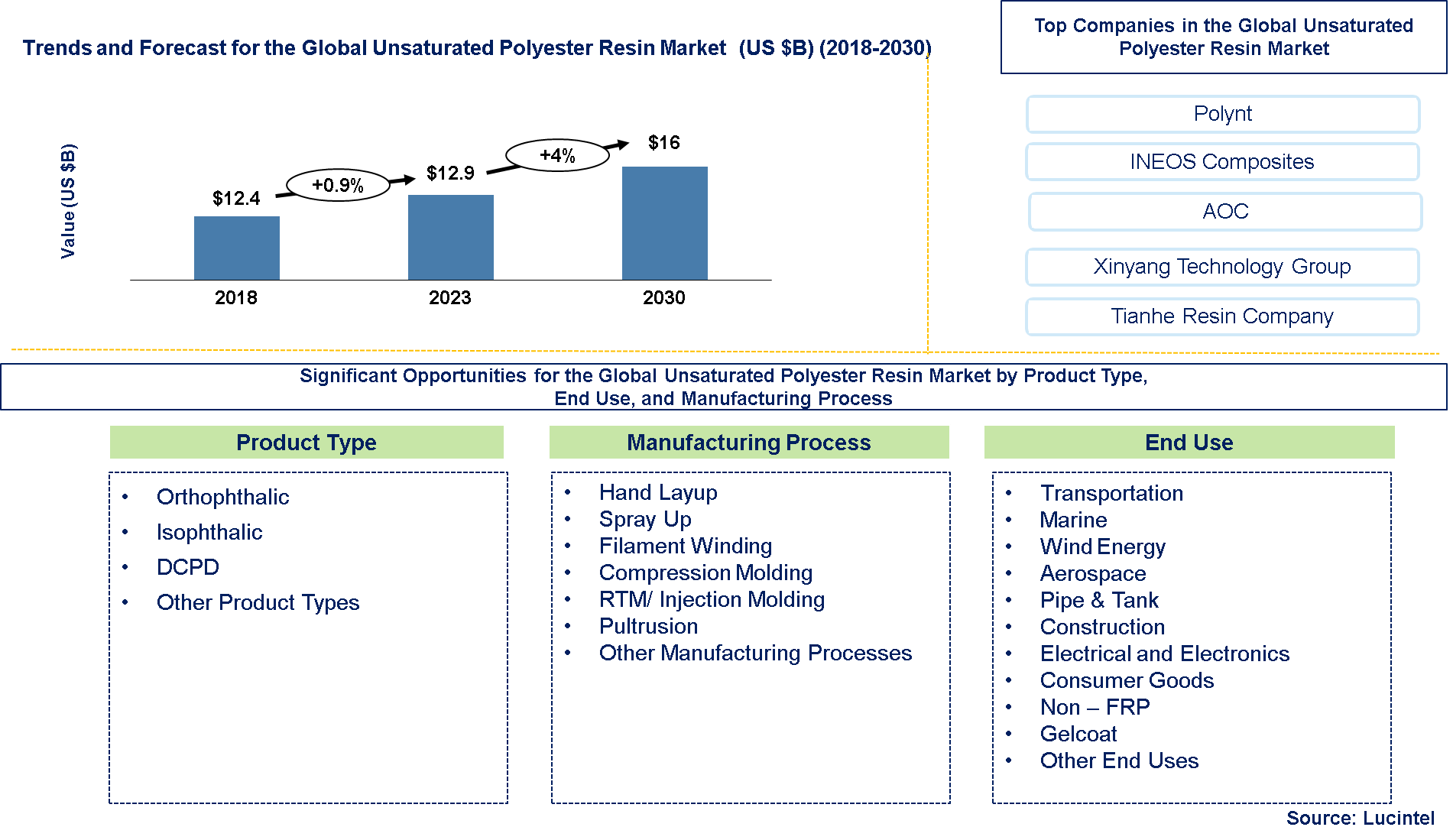

The future of the global unsaturated polyester resin looks promising with opportunities in the unsaturated polyester resin market. The global unsaturated polyester resin is expected to reach an estimated $16 billion by 2030 with a CAGR of 4% from 2023 to 2030. The major drivers for this market are growing infrastructural investments and rehabilitation of old infrastructural projects and increasing need for lightweight products with ease of handling, transportation, and installation.

UPRs are manufactured primarily from glycols (such as propylene glycol), unsaturated acids or anhydrides (e.g. maleic anhydride) and saturated acids or anhydrides (e.g. phthalic anhydride). To adjust its viscosity and support cross-linking, styrene monomer is employed as a reactive diluent. The polymerization process is controlled by inhibitors such as hydroquinone whereas fillers and additives boost the properties of resins. UPRs are generally priced competitively with market rates across the globe. This is because of cheaper production and local raw material availability in India, which give Indian UPRs an edge over others in terms of cost. But still, there are different prices dictated by the kind of resin used, its grade and what it applies to. In addition, final price can be determined by market dynamics and international competition as well.

• Lucintel forecasts construction will remain the largest end use by value and volume due to increasing residential and commercial construction and growth in remolding activities. Aerospace is expected to witness highest growth over the forecast period.

• Hand layup is expected to remain the largest manufacturing process segment because it is the most basic and versatile process among all the fabricating processes. Other manufacturing processes is expected to witness highest growth over the forecast period.

• APAC will remain the largest region and it is also expected to witness highest growth over the forecast period due to rapid industrialization, increasing urbanization, and growing per capita income in the emerging countries is giving rise to residential and commercial construction and growing investment in water and wastewater infrastructure.

Country wise Outlook for the Unsaturated Polyester Resin Market

The unsaturated polyester resin market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major Unsaturated Polyester Resin producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends in the Unsaturated Polyester Resin Market

Emerging trends in the unsaturated polyester resin Market shaping its future applications and market dynamics:

• Resins That are Sustainable and Eco-Friendly: The popularity of bio-based unsaturated polyester resins (UPR) is increasing. By doing this, reliance on petroleum based raw materials is reduced with resin coming from renewable sources thus aligning them to global sustainability objectives. It is being emphasized that there should be an easier way of recycling UPR formulations. When new technologies for recycling and practices for circular economy are considered, waste generation will be minimized, which in turn will make it easy to prolong the lifecycle of UPR items.

• Advanced Manufacturing Techniques: Efficiency and exactitude in making UPR have been improved through integration of automation as well as digital technologies into the manufacturing processes. This includes employment of AI as well as IoT for production parameter monitoring & optimization. The utilization of 3D printing technologies is progressively expanding among UPR. It allows for complexly designed high precision parts which are significant improvements in design and scope of application.

• Enhanced Performance Characteristics: Better tensile strength, thermal stability, chemical resistance among others are some mechanical property improvements witnessed by advances made regarding Un-Saturated polyester resin (UPR). As a result these types of resins find uses in demanding applications such like aerospace, automotive or construction industries. Increasing desire to meet very stringent safety standards across different applications has led to development fire retardant UPR. These ones maintain other important characteristics while they offer superior flame resistance.

• Market Expansion into Emerging Economies: Demand for unsaturated polyester resin (UPR) is being fueled by rapid urbanization alongside infrastructure development in emerging countries. Activities in construction industry especially Asia-Pacific as well as Latin America have been major growth drivers for unsaturated polyester resins (UPRs). Additionally, there is increased demand of unsaturated polyester resins (UPRs) largely based on the thriving automotive industry in developing countries. The light weight, durability and cost friendliness of UPR components are increasingly used to make motor vehicles that save fuel and emit less.

• Regulatory and Compliance Trends: Manufacturers are being pushed by governments across the globe to adopt more sustainable practices hence materials by way of putting into place stringent environmental regulations. This conformance to such rules has contributed towards coming up with environmentally friendly formulation which is utilized in UPRs. In these cases a lot of emphasis is currently being put on health as well as safety while manufacturing & using UPR since these techniques have had VOC emissions incidences in products such like volatile organic compounds (VOCs) reduced tremendously.

A total of 116 figures / charts and 156 tables are provided in this 233-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Unsaturated Polyester Resin Market

Recent developments in unsaturated polyester resin market by various companies highlight ongoing innovations and advancements across different sectors:

Advances in Bio based Resins

• Raw Material Renewables: Substantial headway has been achieved in the production of UPRs from renewable raw materials such as oils from plants and bio-wastes. These alternative products are eco-friendly and reduce dependency on petroleum based products hence they align with the increasing global demand for sustainable solutions.

• Improved Performance: The performance of the bio-based UPRs is now being enhanced to either match or surpass those of the traditional UPRs. This includes various innovations like better mechanical properties, thermal stability, and chemical resistance making them useful across a broad range of applications.

Technological Innovation in Manufacturing

• Automation and Digitalization: The incorporation of digital technologies and automation in UPR manufacturing processes has brought about improved efficiency, lowered production costs, and consistency in product quality. Employing IoTand AI for real-time monitoring as well as optimization of production parametersis increasingly gaining popularity.

• Advanced Composite Materials: The use of UPRs is expanding with development of new composite materials. Such composites exhibit great strength yet lightweight features that make them ideal for the automobile industry, aerospace uses as well as construction purposes.

Extension into Other Areas

• Building Industry: There have been sizeable increases in the adoption of composites made from UPRs within the building industry because they offer good mechanical properties and can withstand environmental factors. As such, products like panels, pipes or coatings made from URPs are commonly used during infrastructure constructions due to their excellent mechanical power and resistance towards environmentals’ factors.

• Automotive Segment: In automotive sector lightweight high-performance components are made from UP resins. This market trend is driven by both eco-friendly cars which aim at reducing fuel consumption by producing fewer emissions alongside extremely light cars intended to be electric vehicles.

Regulation Compliance And Environmental Safety

• Low Emission Of VOC: Currently, there is a drive to produce UPRs with low volatile organic compound (VOC) content so as to comply with strict environmental legislations. Low VOC resins contribute to better indoor air quality and less environmental impact.

• Recycling Initiatives: There’s a need for sustainable disposal and reusability in UPR products recycling technology advancements. The industry is focusing on closed-loop recycling systems that allow for the recovery and reuse of UPR materials, promoting a circular economy.

Collaborative Deals And Strategic Partnerships

• University – Industry Collaborations: Partnerships between manufacturers of UPRs and the academic world are enabling new resin formulation research as well as innovation. This is critical since market collaborations enable development of future generation UPRs those having enhanced properties.

• Joint Ventures: These alliances between major producers of UPRs and end user sectors which are also strategic joint ventures will help in expanding their markets. Through such partnerships, one could develop customized UPR solutions that meet specific industry requirements thereby opening up new markets opportunities.

Market Expansion And Geographical Diversification

• Emerging Markets: Asia-Pacific and Latin America are emerging markets for the production of unsaturated polyester resin (UPR) where infrastructure development, population growth rate, and industrialization rates are highest. As a result, local manufacturing and distribution networks have become a key priority for UPR manufacturers in this region.

• Localized Production: Enterprises have established localized facilities to cater to regional demand while streamlining supply chain issues. Besides improving supply chain efficiency, localization helps in meeting local regulatory needs plus customers’ preferences.

Innovative Product Formulations

• High-Performance Unsaturated Polyester Resins (UPRs): The latest improvements include high-performance UPRs that display dedicated features like improved fire resistance or heightened thermal durability or increased strength against impacts among others. They also vary across various end-use applications hence designed accordingly.

• Stir in Additives: Current trends indicate that UPR formulations are now increasingly incorporating functional additives for resin property customization. This is achieved by adding such things as stabilizers, flame retardants, and impact resistors to the mix so as to improve performance of the respective products thereby elongating their life span.

Strategic Growth Opportunities for Global Unsaturated Polyester Resin Market

Product Portfolio Diversification

• Specialized UPR Formulations: Producing a broad range of specialized UPR formulations for various sectors like motor vehicles, boat construction or building can help to infiltrate niche markets. Adapting UPR products to precise demands of application will offer the competitive advantage.

• Innovative Composites: Investing in R&D of new UPR-based composites with improved properties may open up new market segments. These materials are highly preferred by the advanced manufacturing sector since they have high tensile strength, durability, and lightweight features.

Geographic Expansion

• Penetrating Emerging Markets: Entering unexplored markets experiencing rapid growth in Asia-Pacific, Latin America and Africa is likely to result in substantial sales increase. Putting up local manufacturing bases as well as distribution networks enhances market presence while achieving low logistics costs.

• Strategic Alliances and Partnerships: Working together with local firms through strategic alliances and partnerships helps in penetrating markets. When looking for a partner to work with during this process, it makes sense to search for common interests that your two firms share.

Investment in Research and Development

• Innovation Hubs and R&D Centers: Creating dedicated innovation hubs and R&D centers focused on UPR could lead to constant improvement of quality and ground-breaking improvements. This investment is aimed at producing next-generation UPRs with better performance characteristics as well as being environmentally friendly.

• Collaborative R&D Projects: Engaging in joint ventures involving universities, research institutions or even other players within the industry is one way through which innovation can be easily achieved. It is through such collaborative efforts that novel uses of this material can be discovered besides coming up with superior technology on UPRs.

Sustainability Initiatives

• Green Manufacturing Practices: To increase the sustainability profile of their products, UP producers must adapt green manufacturing practices which comprise energy-saving technologies, waste reduction measures including the use of renewable raw materials. These actions may lure eco-sensitive customers and meet the demands of regulators.

• Lifecycle Assessment and Circular Economy: Sustainable development can be promoted through conducting a lifecycle analysis in order to determine the environmental impacts associated with UPR applications. This includes developing recycling UPR products as well as others that can be easily be recycled which makes them more marketable.

Enhancing Customer Engagement and Support

• Technical Support and Services: Offering extensive technical support services to clients is likely to enhance adoption of UPR products. For example, one could provide assistance on how best to use UP resins, general troubleshooting advice, and customization guidelines that would guarantee long term customer satisfaction.

• Training and Education Programs: Training programs targeted at customers and partners will help create awareness about the benefits of using UPRs. In addition, it is important to involve these stakeholders in workshops and other platforms where one can present information.

Unsaturated Polyester Resin Market Drivers and Challenges

The global unsaturated polyester resin market is driven by benefits like growing demand in construction and infrastructure, advancements in automotive and transportation industries, and sustainability and environmental regulations, it faces challenges such as fluctuating raw material prices, and technological and quality consistency issues. This discussion explores key drivers propelling its growth and significant challenges hindering broader market adoption.

The key drivers for the global unsaturated polyester resin market include:

1. Growing Demand in Construction and Infrastructure: The UPR market is driven by construction and infrastructure sectors, which are increasingly urbanizing and developing their infrastructures all over the world. For building applications such as pipes, tanks, panels, etc., UPR is needed due to its excellent properties like corrosion strength, long life, cost-effectiveness among others. Additionally, there is an increasing demand for refurbishment and upgrading of current facilities more so in emerging countries.

2. Advancements in Automotive and Transportation Industries: The automotive industry today has embraced UPR technology while producing lightweight components with high strength that enhance fuel efficiency thereby reducing emissions. Due to growing adoption of electric vehicles in the automobile sector, UPR material has become a priority as it is light. It can be molded into highly complex shapes so it is popularly used in making various car parts like body panels, interiors among others.

3. Sustainability and Environmental Regulations: Adoption of environmentally friendly UPR formulations is being driven by strict environmental regulations as well as sustainability push. There are also low-VOC and bio-based types of unsaturated polyester resins being developed by manufacturers to meet green materials requests demanded upon by rules governing environment issues underpinning these products’ production process growth rates. The emphasis on minimizing carbon footprints and promoting sustainable construction practices has led to an increased use of eco-friendly UPR with lower environmental footprints during manufacture processes that make them amenable to recycling.

The challenges in the global unsaturated polyester resin Market include:

1. Fluctuating Raw Material Prices: The global market for unsaturated polyester resins (UPRs) encounters fluctuations in raw material costs mainly petroleum derivatives whose prices are unstable. Variations witnessed include styrene, glycol alongside other primary inputs triggering notable effects on earnings margins along with manufacturing expenses not considering pricing strategy stability by producers hence supply chain shortfalls due to market shifts.

2. Technological and Quality Consistency Issues: One of the main challenges is ensuring consistency in quality and performance of UPR products across different applications or production batches. This leads to inconsistency in the final product due to variations in material quality as well as differences in manufacturing processes. Besides, growing technological advancements and need for improved solutions necessitate huge R&D investments that poses a challenge to smaller firms trying to keep up with larger competitors.

In conclusion, the UPR market is boosted by modern technologies upgrading its products and opening new areas of application that create demand. Nonetheless, the industry is faced with the problem of quality control and managing costs of production. To beat this challenge and keep on growing, it is important to continuously introduce innovative eco-friendly compositions as well as improve production methods.

Unsaturated Polyester Resin Suppliers and Their Market Shares

In this globally competitive market, several key players such as Polynt Group, AOC, INEOS Composites, and BASF etc, dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies unsaturated polyester resin companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the unsaturated polyester resin companies profiled in this report include

• Polynt Group

• AOC

• INEOS Composites

• BASF

• Covestro

• Xinyang Technology Group

• Tianhe Resin Company Ltd.

These companies have established themselves as leaders in the global unsaturated polyester resin market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the unsaturated polyester resin market are evolving, with the entry of new players and the emergence of innovative unsaturated polyester resin market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Unsaturated Polyester Resin Market by Segment

The major growing sections of the UPR market include construction which utilizes durable, cost-effective building materials; automotive that is used for lightweight and high-performance parts which aid in fuel efficiency; marine for corrosion-resistant components; electrical and electronics for robust insulation materials; and consumer goods where UPR’s versatility and customization potential are responsible for the production of various everyday products.

The study includes a forecast for the global unsaturated polyester resin by end use, product type, manufacturing process, and region as follows:

Unsaturated Polyester Resin Market by End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Transportation

• Marine

• Wind Energy

• Aerospace

• Pipe and Tank

• Construction

• Electrical and Electronics

• Consumer Goods

• Non-FRP

• Gelcoat

• Other End Uses

Unsaturated Polyester Resin Market by Product Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Orthophthalic

• Isophthalic

• DCPD

• Other Product Types

Unsaturated Polyester Resin Market by Manufacturing Process [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Hand Layup

• Spray-Up

• Filament Winding

• Compression Molding

• RTM/Injection Molding

• Pultrusion

• Other Manufacturing Processes

Unsaturated Polyester Resin Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• US

• Canada

• Mexico

• Europe

• Germany

• The United Kingdom

• Italy

• France

• Spain

• Asia Pacific

• China

• Japan

• India

• The Rest of the World

• Brazil

Features of Unsaturated Polyester Resin Market

• Market Size Estimates Global unsaturated polyester resin market size estimation in terms of value ($M) shipment and volume (M lbs).

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by end use, product type, manufacturing process, and region.

• Regional Analysis: Unsaturated polyester resin market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis on growth opportunities in different end use, product type, manufacturing process, and regions for the global unsaturated polyester resin market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the global unsaturated polyester resin market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in Unsaturated Polyester Resin or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the unsaturated polyester resin size?

Answer: The global unsaturated polyester resin is expected to reach an estimated $16 billion by 2030.

Q2. What is the growth forecast for unsaturated polyester resin?

Answer: The unsaturated polyester resin is expected to grow at a CAGR of 4% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the unsaturated polyester resin?

Answer: The major drivers for this market are growing demand in construction and infrastructure, advancements in automotive and transportation industries, and sustainability and environmental regulations.

Q4. What are the major end uses for unsaturated polyester resin?

Answer: Construction and non-FRP use are the major end uses for unsaturated polyester resin.

Q5. What are the emerging trends in unsaturated polyester resin?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, includes resins that are sustainable and eco-friendly, advanced manufacturing techniques, market expansion into emerging economies, regulatory and compliance trends and enhanced performance characteristics.

Q6. Who are the key unsaturated companies?

Answer: Some of the key unsaturated companies are as follows:

• Polynt Group

• AOC

• INEOS Composites

• BASF

• Covestro AG

• Xinyang Technology Group

• Tianhe Resin Company Ltd

Q7. Which unsaturated polyester resin manufacturing process segment will be the largest in future?

Answer: Lucintel forecasts that hand layup is expected to remain the largest manufacturing process segment because it is the most basic and versatile process among all the fabricating processes.

Q8. In unsaturated polyester resin, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 7 years.

Q9. What is the Price of Unsaturated Polyster Resin?

Answer: Typically, average UPR prices ranges between $1 to $1.5 per pound depending on the availability of raw materials. The prices of raw materials used in UPR production, such as glycols, maleic anhydride, and styrene fluctuate based on supply and demand, impacting the final price of the resin.

Q10. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the global unsaturated polyester resin market by end use (transportation, marine, wind energy, aerospace, pipe and tank, construction, electrical and electronics, consumer goods, non-FRP, gelcoat, and others), product type (orthophthalic, isophthalic, DCPD, and others), manufacturing process (hand layup, spray-up, filament winding, compression molding, RTM/injection Molding, pultrusion, and others), and by region (North America, Europe, Asia Pacific, and Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?