The technologies in the global 3D printing material in the aerospace market have undergone significant changes in recent years, with a shift from traditional methods like Fusion Deposition Modelling (FDM) to more advanced techniques such as Direct Metal Laser Sintering (DMLS) and Continuous Liquid Interface Production (CLIP). Initially dominated by Single-Level Cell (SLC) technology, the market has progressively transitioned to more advanced methods, including Multi-Level Cell (MLC) and Triple-Level Cell (TLC) technologies. This shift is driven by the need for higher performance, greater storage density, and enhanced reliability. MLC and TLC technologies offer improved efficiency and cost-effectiveness compared to SLC, allowing for the production of more complex and detailed ceramic components. As these advanced technologies become more prevalent, they are enabling innovations in various applications, from intricate industrial parts to customized consumer products. This progression highlights the ongoing advancements in the 3D printing sector and its growing impact on the ceramics industry.

Emerging Technology in the 3D Printing Material in Global Aerospace Market

Emerging technology trends, which have a direct impact on the dynamics of the industry include the advancement of high-temperature resistant materials, the development of multi-material 3D printing technologies, the integration of advanced composites such as carbon fiber and metal alloys, and the implementation of improved software algorithms for optimized design and manufacturing processes.

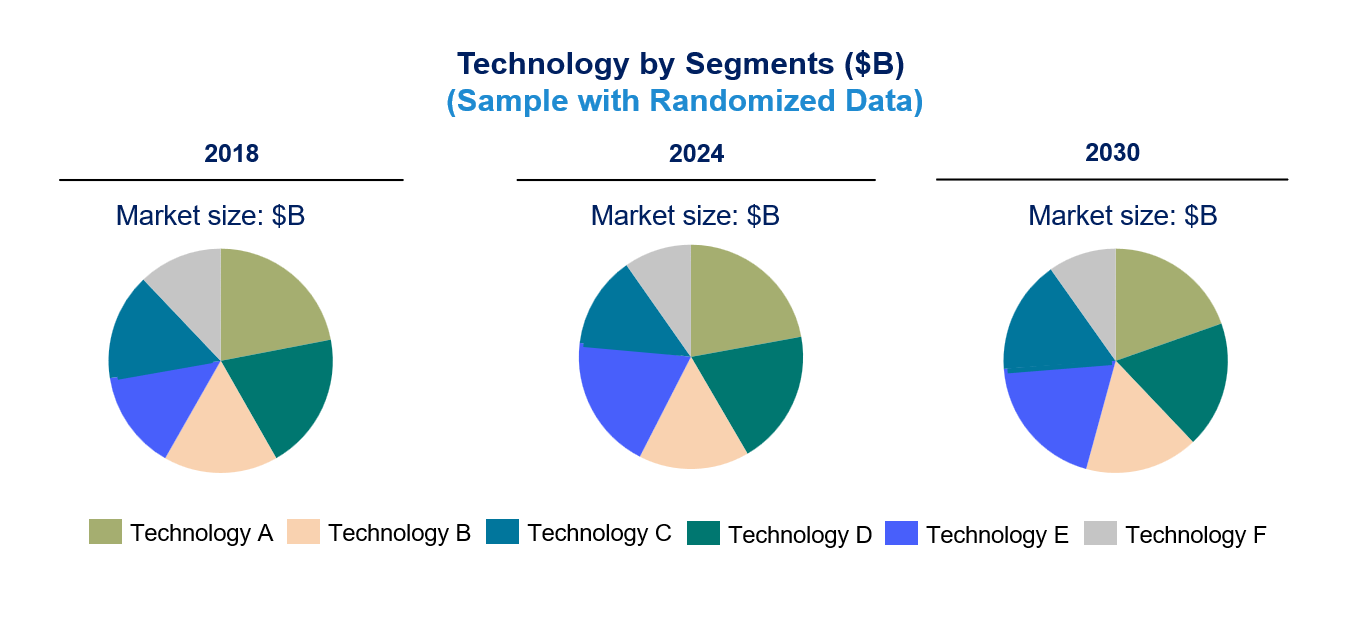

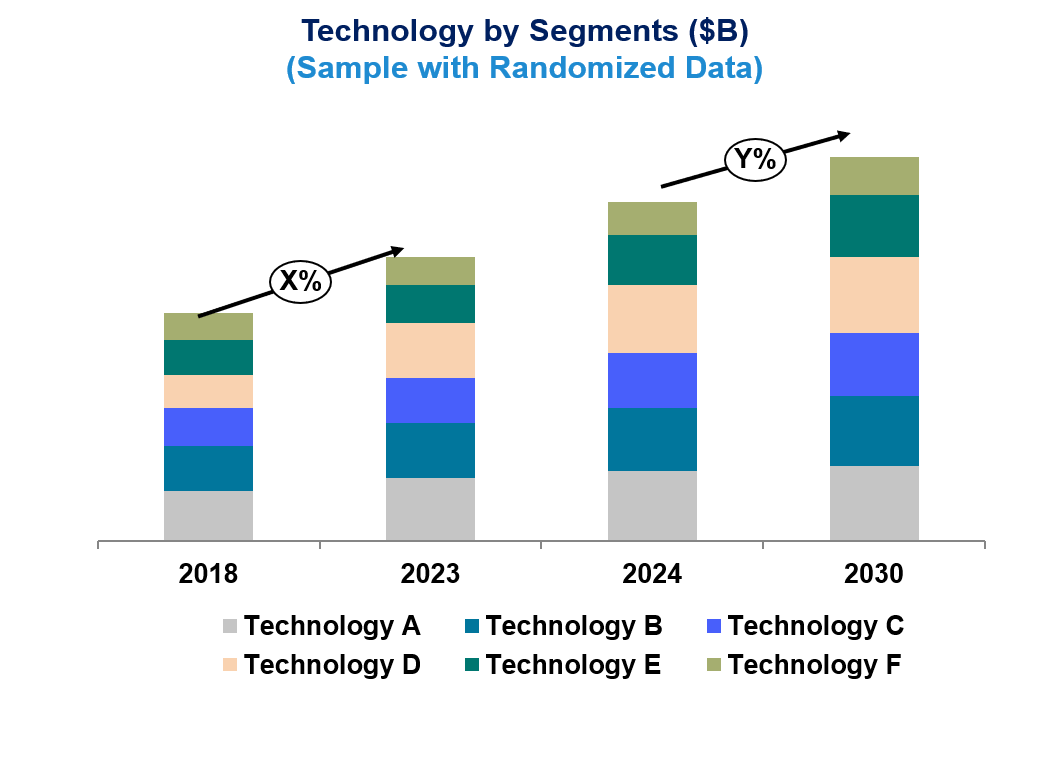

3D Printing Material in Global Aerospace Market by Technology

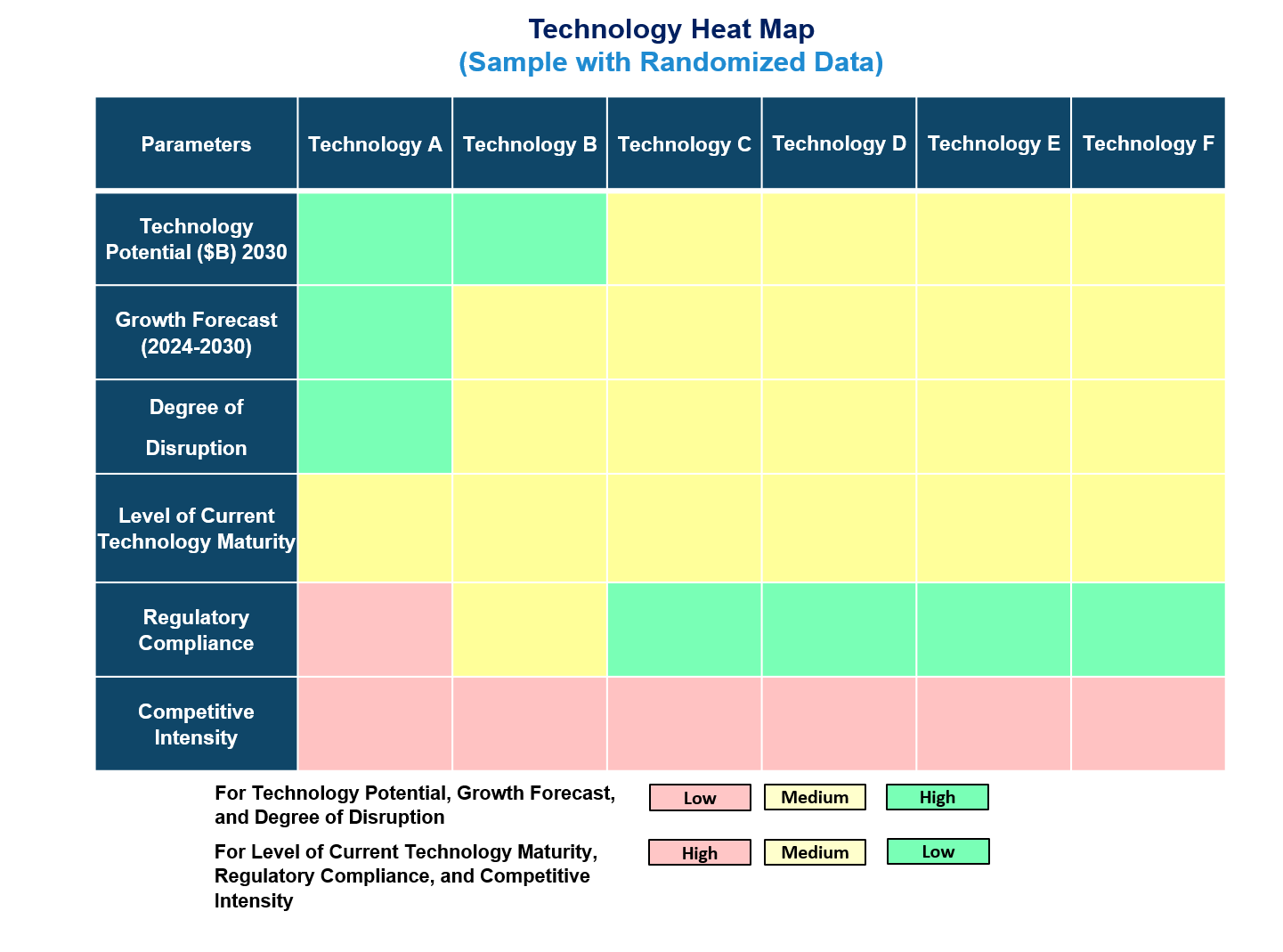

This report analyzes technology maturity, degree of disruption, competitive intensity, market potential, and other parameters of various technologies in the 3D printing material in aerospace technology market. The study includes trends and forecast for the technology trends in the 3D printing material in aerospace market by printing technology, end use, and region as follows:

Technology Readiness by Technology Type

Competitive Intensity and Regulatory Compliance

Disruption Potential by Technology Type

3D Printing Material In Aerospace Market Trend and Forecast by Printing Technology [Value from 2018 to 2030]:

• Stereolithography (SLA)

• Fusion Deposition Modelling (FDM)

• Direct Metal Laser Sintering (DMLS)

• Selective Laser Sintering (SLS)

• Continuous Liquid Interface Production (CLIP)

• Others

3D Printing Material In Aerospace Market Trend and Forecast by End Use [Value from 2018 to 2030]:

• Aircraft

• Spacecraft

3D Printing Material In Aerospace Market by Region [Value from 2018 to 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Latest Developments and Innovations in the 3D Printing Material In Aerospace Technologies

Companies / Ecosystems

Strategic Opportunities by Technology Type

List of 3D Printing Material Companies in Aerospace Market

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies 3D printing material companies in aerospace market cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the 3D printing material companies in aerospace market profiled in this report includes.

• Stratasys

• 3D Systems

• GE

• ExOne

• Höganäs AB

• EOS

3D Printing Material in Global Aerospace Market Insight

Lucintel forecasts that plastics will remain the largest material segment over the forecast period due to its affordable price and light weight. Moreover, this material is greatly preferred by the aircraft sector.

Aircraft is expected to remain the larger end use industry segment due to the growing stringent emission regulations and increasing inclination towards light weight, fuel efficient aircraft.

North America will remain the largest region due to the presence of key aerospace companies and growing demand for complex and lightweight 3D components in the region.

If you are looking to expand your business in this or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

Features of the 3D Printing Material in Global Aerospace Market

Market Size Estimates: 3D printing material in aerospace market size estimation in terms of ($B).

Trend and Forecast Analysis: Market trends (2018 to 2023) and forecast (2024 to 2030) by various segments and regions.

Segmentation Analysis: Technology trends for 3D printing material in global aerospace market size by various segments, such as printing technology and end use in terms of value and volume shipments.

Regional Analysis: Technology trends for 3D printing material in global aerospace market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different printing technologies, end uses, and regions for technology trends for 3D printing material in global aerospace market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for technology trends for 3D printing material in global aerospace market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

This report answers following 11 key questions

Q.1. What are some of the most promising potential, high-growth opportunities for the technology trends for 3D printing material in global aerospace market by printing technology (stereolithography (SLA), fusion deposition modelling (FDM), direct metal laser sintering (DMLS), selective laser sintering (SLS), continuous liquid interface production (CLIP), and others), end use (aircraft and spacecraft), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which technology segments will grow at a faster pace and why?

Q.3. Which regions will grow at a faster pace and why?

Q.4. What are the key factors affecting dynamics of different printing technologies? What are the drivers and challenges of these printing technologies for 3D printing material in global aerospace market?

Q.5. What are the business risks and threats to the technology trends for 3D printing material in global aerospace market?

Q.6. What are the emerging trends in these printing technologies for 3D printing material in global aerospace market and the reasons behind them?

Q.7. Which technologies have potential of disruption in this market?

Q.8. What are the new developments in the technology trends for 3D printing material in global aerospace market? Which companies are leading these developments?

Q.9. Who are the major players in technology trends for 3D printing material in global aerospace market? What strategic initiatives are being implemented by key players for business growth?

Q.10. What are strategic growth opportunities in this 3D printing material in aerospace technology space?

Q.11. What M & A activities did take place in the last five years in technology trends for 3D printing material in global aerospace market?

For any questions related to 3d printing material in aerospace market, 3d printing material in aerospace market Size, 3d printing material in aerospace market Growth, 3d printing material in aerospace market Analysis, 3d printing material in aerospace market Report, 3d printing material in aerospace market Share, 3d printing material in aerospace market Trends, 3d printing material in aerospace market Forecast, 3d printing material in aerospace companies write Lucintel analyst at email: helpdesk@lucintel.com. We will be glad to get back to you soon.