Tablet Coating Market Trends and Forecast

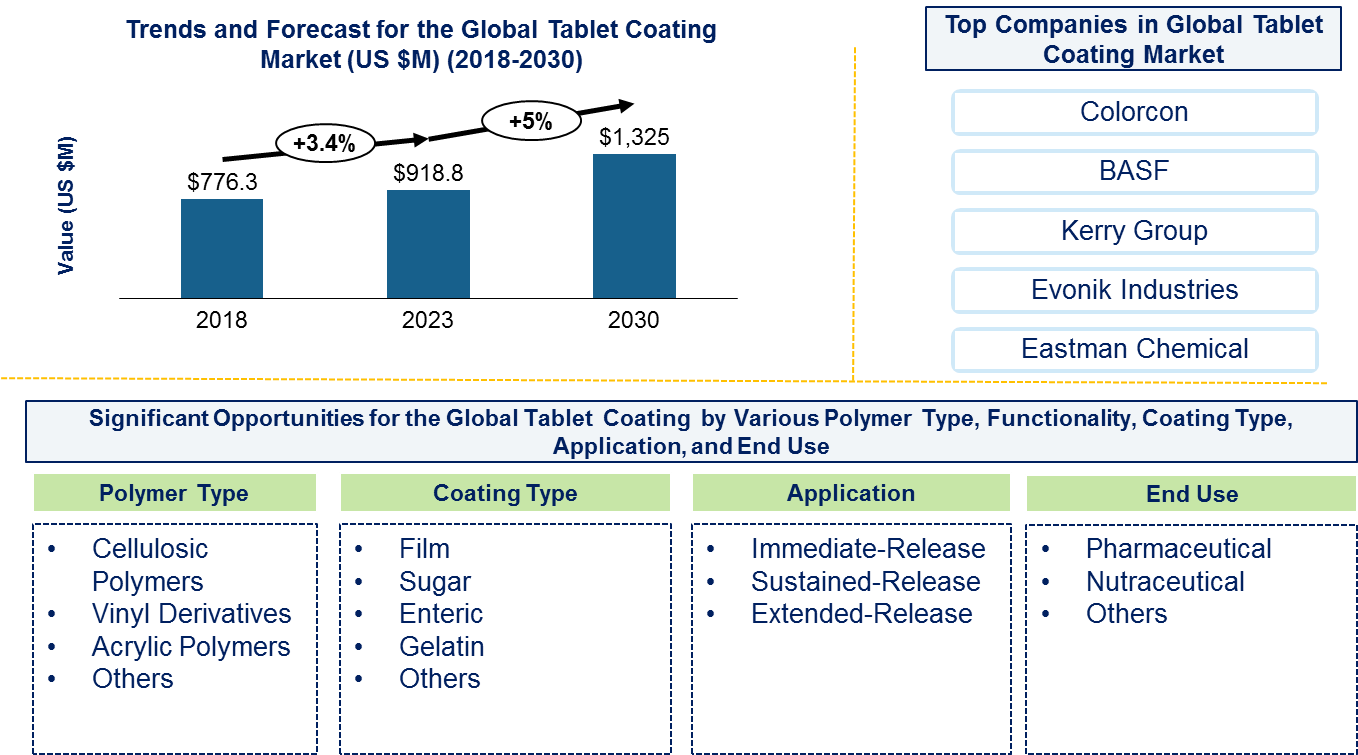

Lucintel finds that the future of the global tablet coating market looks promising with opportunities in pharmaceutical and nutraceutical end uses. The global tablet coating market is expected to reach an estimated $1,325 million by 2030 with a CAGR of 5% from 2024 to 2030. The major drivers for this market are significant growth in the pharmaceutical industry, advancement in coating technology, and increasing research and development (R&D) investment activities.

Tablet coating is a pharmaceutical process where a thin layer of film is applied to the surface of a tablet core. This coating serves several purposes, including improving the tabletÄX%$%Xs appearance, taste masking, protecting the active ingredient from environmental factors (such as moisture or light), controlling the release of the drug, and facilitating swallowing. Cellulose derivatives such as, hydroxypropyl methylcellulose (HPMC), hydroxypropyl cellulose (HPC), ethyl cellulose (EC), and methyl cellulose (MC) are commonly used. They provide film strength, flexibility, and adhesion. Acrylic polymers such as, polyacrylates like poly(meth)acrylate copolymers which offer pH-dependent release properties and improved stability.

• Lucintel forecast that cellulosic polymers will remain the largest segment over the forecast period because of its strong properties, such as compressibility, flowability, soluble, and less sensitivity to wet granulation.

• Pharmaceutical is expected to remain the largest end use segment due to the increasing frequency of various diseases and growing demand for innovative drug delivery formulation.

• North America will remain the largest region due to increasing awareness of treatment among population and growing demand for innovative pharmaceutical products and biosimilars in the region.

Country wise Outlook for Tablet Coating Market

The tablet coating market is witnessing substantial growth globally, driven by increased demand from pharmaceutical and nutraceutical end uses. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major tablet coating producers in key regions: the USA, Germany, China, India, Japan, and Brazil.

Emerging Trends of Tablet Coating Market

The tablet coating marketÄX%$%Xs size has been expanding rapidly, driven by the increasing adoption of tablet coating in various applications. The market size is influenced by factors such as development of advanced coating technology and usage of tablets with functional coatings for controlled release. The market size is estimated to continue its upward trajectory as industries across the globe seek to improve performance, efficiency, and sustainability.

Emerging trends in tablet coating market are shaping its future applications and market dynamics:

• Advanced Coating Technologies: The advanced coating technologies that provide better functionalities are becoming increasingly popular. The trend encompasses the use of nanotechnology in the production of nano-coatings, which enable accurate control of drug release profiles, increased bioavailability, and targeted delivery of active substances.

• Functional Coatings for Controlled Release: The market for tablets with controlled release capacities has grown in recent times. This includes such emerging trends as the development of functional coatings that will permit modified-release formulations like enteric coatings for delayed-release or film coatings with pH dependent dissolution attributes.

• Multifunctional Coatings: Multifunctional coatings have gained popularity over time because they serve more than one purpose other than just aesthetics. These include taste masking, moisture protection, stability enhancement and improved patient compliance among other functions that may be incorporated into the coatings to meet the versatile needs of pharmaceutical formulations.

• Environmentally Friendly Coating Materials: There is a move towards eco-friendly and sustainable coating materials due to environmental concerns and regulatory pressures. Biodegradable polymers, natural cellulose derivatives as well as water-based coating systems are being tested as substitutes for traditional solvent-based coatings.

• Personalized Medicine and Patient-Centric Coatings: Recent developments in personalized medicine are affecting tablet coating industry too. More emphasis is laid on developing coatings designed specifically for particular patients’ requirements including customized dosage regimens, combination therapies or pediatric formulations. Palatability-enhancing and swallowability improving coats are also required by this type of market audience.

• Continuous Manufacturing and Process Efficiency: The tablet coating industry has been adopting continuous manufacturing techniques at an increasing rate. In contrast to conventional batch processing methods, continuous coating processes offer an array of benefits such as efficiency, shorter production cycle times and enhanced quality control. Thus, this trend enables pharma companies optimize their production lines against customer requirements.

A more than 150-page report is developed to help in your business decisions. A sample figure with some insights is shown below.

Recent Developments in Tablet Coating Market

Recent developments in the tablet coating market reflect ongoing advancements in technology, expanding applications across industries, and evolving consumer needs.

• Advanced Coating Formulations: The number of developed progressive coating formulations is increasingly higher in the pharmaceutical companies, which offer better features and functions. This involve stable coatings, sustained release capacity and greater bioavailability of active pharmaceutical ingredients (APIs). Advanced polymers alongside excipients are being employed to attain specific coating properties in conformance to diverse curative needs.

• Continuous Manufacturing Technologies: Tablet coating processes are rapidly embracing continuous manufacturing technologies. Continuous systems for coatings possess process control improvements over conventional batch methods, thus leading to reduced production cycles, increased efficiency as well as quality improvement. These applications enable acquirement of higher throughput compared to traditional batch processes, significant cost savings as well as consistent product quality.

• Biodegradable and Eco-Friendly Coatings: Sustainability has been a key driver in the development of degradable and eco-friendly substrates used in film coatings. Companies are seeking alternatives such as natural biodegradable polymer-based systems that do not require use of solvents during their preparation or application stages which include water-based films-modifiers as well cellulose derivatives besides others instead of traditional solvent based ones. Bio-degradation helps reduce impact on a surrounding due to environmentally friendly methods used in manufacturing drugs.

• Personalized Medicine and Patient-Centric Coatings: Customized tablet coats that can be manufactured so as to meet individual patient requirements are now required due to the rise of personalized medicine. Customized releases profile taste masking capabilities and patient-centric attributes are among other things being integrated into these types of medicines by many companies who have released them in market with an aim increasing adherence rates enhancing patient outcomes whereas at time supporting new niche medications designed for particular groups of sick people. It is only through this way that drug makers will have been able foster the growth of specialty pharmaceutical products.

• Digitalization and Quality Assurance: In tablet coating processes digital technologies have been deployed for purposes of enforcing regulatory standards while also improving quality assurance mechanisms within firms dealing with tablets’ production. Real-time monitoring systems, data analytics and digital documentation platforms are used to optimize coating parameters, monitor critical process parameters, and ensure batch-to-batch consistency. These undertakings help improve efficiency in operations, decrease costs of doing business as well as compliance with strict regulatory frameworks.

Strategic Growth Opportunities for Tablet Coating Market

Technological advances, regulatory changes and evolving consumer preferences will create strategic growth opportunities for the tablet coating market. Below are the key strategic growth opportunities for tablet coating:

• Advanced Coating Technologies: Adoption of advanced coating technologies like nanocoatings, biodegradable polymers and functional coatings shows a great potential. As far as the pharmaceutical sector is concerned, developments in coating materials and processes enable improved bioavailability of tablets, controlled release profiles or enhanced patient adherence. Manufactures can differentiate themselves based on therapeutic needs and overall drug efficacy with coatings designed to meet those demands.

• Personalized Medicine & Patient-Centric Coatings: Demand for personalized solutions that specifically meet a patients’ unique requirements drives this market. There are strategic opportunities in developing coatings which improve taste for better palatability as well as customized dosing regimens and modified release formulations aimed at optimizing therapeutic outcomes. Niche markets, speciality drugs, and patient-specific treatment strategies can be supported by customizable coatings thus help in enhancing market penetration and competitiveness.

• Sustainability & Green Coatings: Growing concerns over environment friendliness has seen an increase in eco-friendly coating materials and techniques. There’s room for growth in developing biodegradable polymers, natural-based coatings as well as solvent-free formulations that reduce environmental implications along the product lifecycle. Pharmaceutical companies may gain competitive edge through promoting sustainable practices, meeting regulatory requirements or attracting environmentally conscious consumers and stakeholders.

• Digitalization & Smart Coatings: The integration of digital technologies such as real-time monitoring systems and data analytics into tablet coating processes improves operational effectiveness as well as product quality. It would be strategic to employ smart coatings to facilitate remote monitoring of critical variables during film-coating thus ensuring batch-to-batch consistency thereby adhering to regulatory requirements that include Quality-by-Design (QbD). By going digital throughout its operations process optimization time will be reduced enabling quick time-to-market while also giving an overall improvement to manufacturing agility.

• Emerging Markets Expansion: The tablet coating manufactures have found emerging markets to be very lucrative. For instance, strategic initiatives may involve expanding into regions with fast-growing pharmaceutical industries, increasing healthcare spending as well as rising demand for generic drugs. Developing coatings materials that meet local regulatory requirements, cost constrictions and specific medical needs of some segments in such developing countries can assist a firm to expand its market and generate more revenues.

• Collaborations & Partnerships: Partnering with technology vendors, research institutions and pharmaceutical companies is one way of gaining access to innovative coating technologies, expertise and market insights. Strategic partnerships facilitate joint research and development efforts, accelerate product innovation, and enhance capabilities in niche applications such as pediatric medicines, geriatric formulations, and specialty drugs. Collaborative initiatives strengthen market positioning, mitigate risks and capitalize on emerging opportunities in the global tablet coating market.

• Regulatory Compliance & Quality Assurance: For sustained growth in the tablet coating industry it is essential to adhere to global regulatory standards while enhancing quality assurance processes. This entails strategic investments in strong quality management systems (QMS), compliance with good manufacturing practices (GMP) as well as proactive risk management tactics which ensure that products are safe, efficacious and approved by the relevant authorities. Having high levels of quality and compliance helps build a good rapport with all stakeholders thus supporting global activities that help grow the business for commercial purposes.

Tablet Coating Market Driver and Challenges

Tablet coating play a crucial role in a wide range of industries and applications due to their unique properties and versatile functionalities. The changing market dynamics are being driven by increasing demand for controlled release formulations and enhanced aesthetic appeal and patient acceptance. However, challenges like complexity in formulation & process optimization and cost & manufacturing efficiency to sustain growth and innovation in tablet coating market. The factors responsible for driving the tablet coating market include:

• Increasing Demand for Controlled Release Formulations: Tables with controlled release properties are increasingly in demand to increase drug efficacy and improve patient adherence. This permits precise control over the rate of drug release, as well as providing sustained or targeted modes of administration for active substances. Technological developments in drug delivery systems have brought about this trend.

• Enhanced Aesthetic Appeal and Patient Acceptance: Tablet coatings enhance the appearance, taste and texture of tablets improving patients’ adherence and acceptance to dosing regimens. To make their products palatable, reduce dysphagia and be unique in a competitive environment, pharmaceutical firms make use of such coatings too. Enhanced aesthetic appeal is also associated with branding and customer demand.

• Technological Advancements in Coating Materials and Processes: Advances on coating materials such as polymers or excipients result into functional coatings that have distinct characteristic like pH dependent ones, moisture barrier or modified surface attributes. Innovations in coating processes including continuous manufacturing and automation bring about efficiency improvements, reduced production costs as well as uniformity of coating.

• Rising Pharmaceutical Industry Investments: This enhances tablet coat technologies by means of increased investments into R&D by pharmaceutical companies. Companies are now looking at novel formulations or enhanced existing methods for coating to meet changing regulations; which optimize therapeutic outcomes; while enhancing patient safety.

• Regulatory Requirements And Quality Standards: Meeting strict quality requirements such as good manufacturing practices (GMP), pharmacopeial specifications, among others influence the market dynamics surrounding tablet coating significantly. In order to comply with regulatory expectations regarding product quality as well as production process stability, safety and performance characteristics must be guaranteed through proper coating mechanisms.

Challenges facing the tablet coating market are:

• Complexity in Formulation and Process Optimization: It can be challenging to develop effective coating formulations for obtaining desired release profiles & other performance features along with optimizing these processes accordingly. Issues such batch-to-batch variation, uniformity within coats & compatibility when it comes to variations amongst different drugs require careful process validation and formulation development.

• Cost and Manufacturing Efficiency: The overall cost of production is influenced by the cost of materials used in coating, machinery and processes that are considered to be labor intensive. Pharmaceutical companies face the challenge of developing cost-effective coating solutions that comply with quality standards and meet regulatory requirements. Cost pressures must be mitigated through investments in efficient manufacturing technologies and process optimization.

• Technology Integration And Innovation Barriers: This calls for considerable expertise & capital investment so as to incorporate advanced technologies like continuous manufacturing, digital monitoring systems, smart coatings among others into tablet coating processes. A major challenge facing pharmaceutical manufacturers is how they are able to overcome technological obstacles, scale up their innovations; at the same time ensuring compatibility with existing infrastructure.

In conclusion, while drivers such as technological advancements, regulatory compliance, and patient-centric formulations propel the tablet coating market forward; challenges related to formulation complexity, cost management, and technological integration must be effectively addressed to sustain growth and innovation in the global pharmaceutical industry.

Tablet Coating Suppliers and their Market Shares

In this globally competitive market, several key players such as Colorcon, BASF, Kerry, Eastman, Evonik, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at helpdesk@lucintel.com. Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies, tablet coating companies cater to increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the tablet coating companies profiled in this report include:

• Colorcon

• BASF SE

• Kerry

• Eastman

• Evonik Industries AG

These companies have established themselves as leaders in tablet coating industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within tablet coating market are evolving, with the entry of new players and the emergence of tablet coating technologies. Additionally, collaborations between raw material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Tablet Coating Market by Segment

Major segments of tablet coating experiencing growth include pharmaceutical and nutraceutical applications, contribute to enhancing the properties of tablet coating in terms of strength, durability, chemical resistance, and other specialized characteristics. This advancement is crucial in meeting the increasingly complex demands of environmental protection, waste containment, and industrial applications.

This tablet coating market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including polymer type, functionality, coating type, formulation, application, and end use,. The report offers insights into regional dynamics, highlighting the major markets for tablet coating and their growth potentials. The study includes trends and forecast for tablet coating market through 2030, segmented by polymer type, functionality, coating type, formulation, application, end use, and region as follows:

Tablet Coating Market by Polymer Type [Value ($M) Shipment Analysis from 2018 to 2030]:

• Cellulosic Polymers

• Vinyl Derivatives

• Acrylic Polymers

• Others

Tablet Coating Market by Functionality [Value ($M) Shipment Analysis from 2018 to 2030]:

• Non-Functional Non-Modifying Coatings

• Functional Modifying Coatings

• Functional Non-Modifying Coatings

Tablet Coating Market by Coating Type [Value ($M) Shipment Analysis from 2018 to 2030]:

• Film

• Sugar

• Enteric

• Gelatin

• Others

Tablet Coating Market by Formulation [Value ($M) Shipment Analysis from 2018 to 2030]:

• Plasticizer

• Colorant

• Solvent

Tablet Coating Market by End Use [Value ($M) Shipment Analysis from 2018 to 2030]:

• Pharmaceutical

• Nutraceutical

• Others

Tablet Coating Market by Region [Value ($M) Shipment Analysis from 2018 to 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Tablet Coating Market

Market Size Estimates: Tablet coating market size estimation in terms of value ($M)

Trend And Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

Segmentation Analysis: Tablet coating market size by various segments, such as by polymer type, functionality, coating type, formulation, application, end use, and region

Regional Analysis: Tablet coating market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis on growth opportunities in different polymer types, functionalities, coating types, formulations, applications, end uses, and regions for the tablet coating market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for the tablet coating market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

FAQ

Q1. What is the tablet coating market size?

Answer: The global tablet coating market is expected to reach an estimated $1,3245 million by 2030.

Q2. What is the growth forecast for tablet coating market?

Answer: The global tablet coating market is expected to grow with a CAGR of 5% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the tablet coating market?

Answer: The major drivers for this market are growing adoption of orphan drugs, significant growth in the pharmaceutical industry, and increasing research and development (R&D) investment activities.

Q4. What are the major segments for tablet coating market?

Answer: The future of the tablet coating market looks promising with opportunities in pharmaceutical and nutraceutical end uses.

Q5. Who are the key tablet coating companies?

Answer: Some of the key tablet coating companies are as follows:

• Colorcon

• BASF SE

• Kerry

• Evonik Industries

• Eastman

Q6. Which tablet coating segment will be the largest in future?

Answer: Lucintel forecast that cellulosic polymers will remain the largest polymer type segment over the forecast period because of its strong properties, such as compressibility, flowability, soluble, and less sensitivity to wet granulation.

Q7. In tablet coating market, which region is expected to be the largest in next 7 years?

Answer: North America will remain the largest region due to increasing awareness of treatment among population and growing demand for innovative pharmaceutical products and biosimilars in the region.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1. What are some of the most promising, high-growth opportunities for the tablet coating market by polymer type (cellulosic polymers, vinyl derivatives, acrylic polymers, and others), functionality (non-functional non-modifying coatings, functional modifying coatings, and functional non-modifying coatings), coating type (film, sugar, enteric, gelatin, and others), formulation (plasticizer, colorant, and solvent), application (immediate-release, sustained-release and extended-release), end use (pharmaceutical, nutraceutical, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which segments will grow at a faster pace and why?

Q.3. Which region will grow at a faster pace and why?

Q.4. What are the key factors affecting market dynamics? What are the key challenges and business risks in this market?

Q.5. What are the business risks and competitive threats in this market?

Q.6. What are the emerging trends in this market and the reasons behind them?

Q.7. What are some of the changing demands of customers in the market?

Q.8. What are the new developments in the market? Which companies are leading these developments?

Q.9. Who are the major players in this market? What strategic initiatives are key players pursuing for business growth?

Q.10. What are some of the competing products in this market and how big of a threat do they pose for loss of market share by material or product substitution?

Q.11. What M&A activity has occurred in the last five years and what has its impact been on the industry?

For any questions related to tablet coating market or related tablet coating companies, tablet coating market size, tablet coating market share, tablet coating analysis, write Lucintel analyst at email: helpdesk@lucintel.com we will be glad to get back to you soon.