Spray Polyurea Coating Equipment Market Trends and Forecast

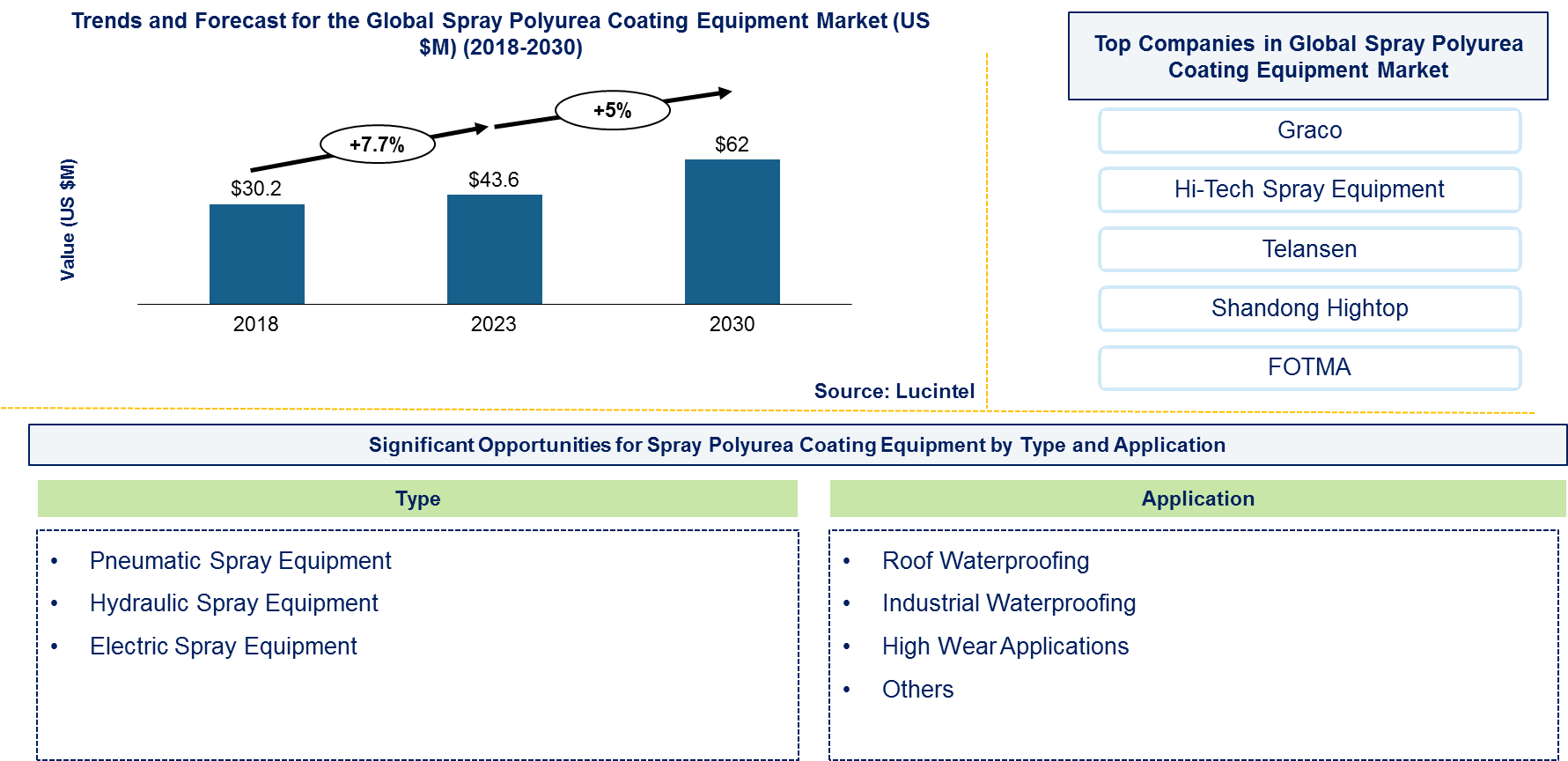

The future of the global spray polyurea coating equipment market looks promising with opportunities in the roof waterproofing, industrial waterproofing, and high wear applications . The global spray polyurea coating equipment market is expected to reach an estimated $62 million by 2030 with a CAGR of 5% from 2023 to 2030. The major drivers for this market are growth of superior durability, rapid curing times, and advancements in equipment technology, which enhance efficiency and application quality, Increased demand for customizable coatings and eco-friendly solutions also boost adoption and economic factors like long-term cost savings.

Spray polyurea coating equipment primarily uses polymeric resins such as polyols and isocyanates, which are the main reactants in the polyurea reaction. Solvents are used to adjust the viscosity of the coating for proper spraying. Catalysts accelerate the curing process of polyurea coatings. Additives like pigments, stabilizers, and surfactants are included to enhance performance characteristics and appearance. The equipment itself also includes components like spray guns and mixing chambers for precise application and mixing of these materials. The price of spray polyurea coating equipment generally falls within a mid-to-high range compared to competitors, influenced by factors such as brand, features, and technology. Equipment with advanced features, like automated mixing and high-efficiency spray systems, can command a premium price. While it is often more expensive than basic spray equipment or manual applicators, it is typically less costly than specialized industrial-grade systems or large-scale coating machines.

• Lucintel forecasts that hydraulic spray equipment will remain the largest market over the forecast period.

• roof waterproofing will remain the largest end use industry over the forecast period

• North America will remain the largest region over the forecast period.

Country wise Outlook for Spray Polyurea Coating Equipment Market

The spray polyurea coating equipment market is witnessing substantial growth globally, driven by increased demand from various application such as roof waterproofing, industrial waterproofing, and high wear applications. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major spray polyurea coating equipment producers in key regions: the USA, China, India, Japan, and Germany.

Emerging Trends in the Spray Polyurea Coating Equipment Market

Emerging trends in the spray polyurea coating equipment market shaping its future applications and market dynamics:

• Increased Automation: Advances in automation are driving the development of spray polyurea coating equipment with automated mixing, application, and control systems. Automation improves precision, consistency, and efficiency, reducing manual labor and minimizing errors.

• Enhanced Material Compatibility: Newer equipment is being designed to handle a wider range of polyurea formulations and other high-performance coatings. This versatility allows for more flexible applications across different industries, including construction, automotive, and industrial.

• Improved Efficiency and Energy Use: Modern equipment is focusing on energy efficiency and reduced material waste. Innovations in spray technology and equipment design are enhancing the utilization of coatings, leading to cost savings and reduced environmental impact.

• Smart Technology Integration: The integration of smart technologies, such as IoT connectivity and real-time monitoring, is becoming more common. This allows for remote diagnostics, predictive maintenance, and data collection to optimize performance and streamline operations.

• Advanced Application Techniques: New developments in spray techniques and nozzle designs are improving the quality and uniformity of coatings. These advancements help achieve better adhesion, coverage, and finish, catering to specialized applications and demanding environments.

A total of 75 figures / charts and 58 tables are provided in this 129-page report to help in your business decisions. Sample figures with some insights are shown below.

Recent Development in the Spray Polyurea Coating Equipment Market

Ongoing innovations and advancements in various sectors of the spray polyurea coating equipment market which have been highlighted by recent developments:

• Advanced Automation: The latest equipment integrates sophisticated automation systems that handle mixing, application, and curing processes with minimal human intervention. This enhances precision, reduces labor costs, and ensures consistent coating quality.

• Improved Material Handling: New equipment designs accommodate a broader range of polyurea formulations, including those with varying viscosities and cure times. Enhanced material handling systems improve mixing accuracy and reduce waste.

• Enhanced User Interfaces: Modern equipment features intuitive digital controls and user-friendly interfaces, including touchscreens and programmable settings. These advancements simplify operation, reduce setup time, and allow for easier adjustments to coating parameters.

• Energy Efficiency: Innovations in spray technology focus on reducing energy consumption and optimizing the use of polyurea materials. Equipment with energy-efficient heating systems and improved spray mechanisms contributes to lower operational costs and reduced environmental impact.

• Smart Technology Integration: The incorporation of IoT and real-time monitoring technologies enables remote diagnostics, performance tracking, and predictive maintenance. This helps in maintaining equipment efficiency, minimizing downtime, and improving overall reliability.

• Enhanced Application Techniques: Recent developments include advanced nozzle designs and spray patterns that ensure more uniform coverage, better adhesion, and superior finish quality. This is particularly beneficial for complex or large-scale coating projects.

Strategic Growth Opportunities for Spray Polyurea Coating Equipment Market

The field of spray polyurea coating equipment is ripe with strategic growth opportunities as industries increasingly focus more on sustainability, efficiency and autonomy. Here are some key areas to consider:

• Expansion into Emerging Markets: As industrialization and infrastructure development accelerate in emerging markets, there is growing demand for advanced coating solutions. Spray polyurea coatings offer superior durability, chemical resistance, and versatility, making them ideal for new construction projects, infrastructure rehabilitation, and protective coatings in these regions. Companies can capitalize on this growth by targeting markets in Asia, Latin America, and Africa where infrastructure and industrial activity are expanding.

• Technological Innovation: Continuous advancements in technology present opportunities for innovation in spray polyurea equipment. Incorporating features such as automated mixing systems, IoT connectivity, and smart controls can enhance equipment performance and user experience. Automation reduces labor costs and improves coating consistency, while smart technology allows for real-time monitoring and predictive maintenance, increasing equipment reliability and operational efficiency.

• Customization and Versatility: Developing equipment that can handle a broader range of polyurea formulations and other coating materials expands its applicability across different industries. Customized solutions that cater to specific requirements, such as varying viscosities or specialized coatings, can attract a wider customer base. Versatile equipment that can be easily adapted for different applications, including automotive, construction, and industrial uses, can tap into diverse market segments.

• Energy Efficiency and Sustainability: There is increasing emphasis on energy-efficient and environmentally friendly technologies. Innovations that reduce energy consumption and minimize waste are highly valued. Equipment designed to optimize material use and lower energy costs aligns with global sustainability goals and appeals to environmentally conscious customers. Companies can differentiate themselves by focusing on eco-friendly solutions and demonstrating their commitment to reducing environmental impact.

• Enhanced Training and Support Services: Providing comprehensive training and support services can enhance customer satisfaction and loyalty. Offering training programs that help users maximize the potential of their equipment, coupled with robust technical support and maintenance services, can set a company apart from competitors. Support services also ensure that customers achieve optimal performance and longevity from their equipment.

• Expansion of Application Areas: Exploring new application areas for polyurea coatings, such as advanced protective coatings for electronics or specialized industrial components, can open new revenue streams. Identifying niche markets where polyurea’s properties offer distinct advantages can drive growth and innovation.

By taking advantage of these strategic growth opportunities, the spray polyurea coating equipment market can realize its full potential and transform numerous industries through strength, lightness, versatility.

Spray Polyurea Coating Equipment Driver and Challenges

Spray polyurea coating equipment has a very important role in many application like roof waterproofing, industrial waterproofing, and high wear applications. The changing market dynamics are being driven by the growing demand for durable coatings, advancements in technology, expansion of infrastructure projects and expansion of infrastructure projects. however, challenges like high production costs, complexity in application, and complexity in application.

The factors responsible for driving the spray polyurea coating equipment market include:

1. Growing Demand for Durable Coatings: The increasing need for highly durable, protective coatings across various industries, including construction, automotive, and industrial applications, drives demand for spray polyurea coating equipment. Polyurea coatings are known for their superior resistance to wear, chemicals, and environmental conditions, making them a popular choice.

2. Advancements in Technology: Innovations in equipment technology, such as automated mixing and application systems, improve efficiency, consistency, and ease of use. These advancements reduce labor costs and enhance the quality of the applied coatings, encouraging more widespread adoption.

3. Expansion of Infrastructure Projects: Large-scale infrastructure projects and industrial applications are fueling demand for polyurea coatings. These coatings provide long-lasting protection for surfaces exposed to harsh conditions, making them ideal for infrastructure repair and maintenance.

4. Increased Focus on Environmental Protection: The growing emphasis on sustainability and environmental protection is driving the use of polyurea coatings. These coatings are often designed to be eco-friendly, with low volatile organic compound (VOC) content, aligning with regulatory requirements and environmental standards.

5. Rising Construction and Renovation Activities: Increased construction and renovation activities globally boost the demand for high-performance coatings. Polyurea coatings offer rapid curing times and excellent adhesion, making them suitable for various construction and renovation applications.

Challenges facing the spray polyurea coating equipment market are:

1. High Initial Cost: The cost of advanced spray polyurea coating equipment can be high, which may be a barrier for smaller businesses or those with limited budgets. The initial investment in high-quality equipment and associated materials can be significant.

2. Complexity in Application: Proper application of polyurea coatings requires skilled operators and precise control of equipment settings. The complexity of the application process can lead to variability in coating quality if not managed correctly, necessitating comprehensive training and expertise.

3. Maintenance and Calibration: Maintaining and calibrating spray equipment to ensure consistent performance can be challenging. Regular maintenance is crucial to avoid equipment malfunctions and ensure optimal operation, adding to operational costs.

4. Material Handling and Storage: Polyurea coatings often require specific handling and storage conditions to maintain their properties and ensure effective application. Managing the logistics of materials, including temperature control and shelf life, can be demanding.

Innovation in spray polyurea coating equipment includes advanced automation for precise and efficient application, and smart technology integration for real-time monitoring and predictive maintenance. Improved material handling systems accommodate various formulations and reduce waste, while enhanced user interfaces and energy-efficient designs simplify operation and lower costs. New spray technology and customizable systems offer better coating quality and flexibility. These advancements enhance equipment performance, durability, and adaptability for diverse applications.

Spray Polyurea Coating Equipment Suppliers and Their Market Share

The spray polyurea coating equipment is highly competitive, with several key players such as Graco Inc., Hi-Tech Spray Equipment, S.A., Telansen Coating Machinery Co., Ltd, Shandong Hightop Machinery, Hubei Fotma Machinery Co., Ltd have established their presence in the market and hold a significant market share. To know the current market share of each of major players Contact Us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies spray polyurea coating equipment companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Spray polyurea coating equipment companies profiled in this report includes.

• Graco Inc.

• Hi-Tech Spray Equipment

• S.A., Telansen Coating Machinery Co., Ltd

• Shandong Hightop Machinery

• Hubei Fotma Machinery Co., Ltd

These companies have established themselves as leaders in the spray polyurea coating equipment industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the spray polyurea coating equipment market are evolving, with the entry of new players and the emergence of innovative spray polyurea coating equipment. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Spray Polyurea Coating Equipment by Segment

The market for spray polyurea coating equipment is expanding significantly in key segments such as roof waterproofing, industrial waterproofing, and high wear applications. In roof waterproofing, polyurea coatings are favored for their excellent durability and quick curing properties, which ensure long-lasting protection against leaks and weathering. For industrial waterproofing, the equipment is used to create robust, chemical-resistant barriers that protect infrastructure and machinery from harsh environments. In high wear applications, polyurea coatings provide superior abrasion and impact resistance, making them ideal for surfaces subject to heavy use and stress. This growth is driven by the demand for reliable, high-performance coatings across these critical sectors.

This spray polyurea coating equipment market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments type, and application. The report offers insights into regional dynamics, highlighting the major markets for energy harvesting system and their growth potentials. The study includes trends and forecast for the semiconductor spray polyurea coating equipment market type, application, and region as follows:

By Type [$M Analysis from 2018 – 2030]:

• Logic

• Memory

• Analog

• Others

By Application [$M Analysis from 2018 – 2030]:

• Consumer Electronics

• Telecommunication

• Automotive

• Others

By Region [$B Analysis from 2018 – 2030]:

• North America

• United States

• Canada

• Mexico

• Europe

• Germany

• UK

• France

• Russia

• Spain

• Italy

• Asia Pacific

• China

• Japan

• India

• Rest of the World

• Brazil

• UAE

Features of Spray Polyurea Coating Equipment Market

• Market size estimates: Global spray polyurea coating equipment market size estimation in terms of value ($M) shipment.

• Trend and forecast analysis: Market trend (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation analysis: Market size by various segments such as by type, application, and region.

• Regional analysis: Global spray polyurea coating equipment market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth opportunities: Analysis on growth opportunities in different type, application, and region for global spray polyurea coating equipment market.

• Strategic analysis: This includes M&A, new product development, and competitive landscape of the global spray polyurea coating equipment market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in spray polyurea coating equipment or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the spray polyurea coating equipment market size?

Answer: The global spray polyurea coating equipment market is expected to reach an estimated $62 million by 2030

Q2. What is the growth forecast for spray polyurea coating equipment market?

Answer: The spray polyurea coating equipment market is expected to grow at a CAGR of 5% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the spray polyurea coating equipment market?

Answer: The major drivers for this market are growth of superior durability, rapid curing times, and advancements in equipment technology, which enhance efficiency and application quality, Increased demand for customizable coatings and eco-friendly solutions also boost adoption and economic factors like long-term cost savings.

Q4. What are the major applications or end use industries for spray polyurea coating equipment market?

Answer: roof waterproofing, industrial waterproofing, high wear applications are the major end use industry for spray polyurea coating equipment market.

Q5. What are the emerging trends in spray polyurea coating equipment market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include the increased automation and enhanced material compatibility.

Q6. Who are the key spray polyurea coating equipment companies?

Answer: Some of the key spray polyurea coating equipment companies are as follows:

• Graco Inc.

• Hi-Tech Spray Equipment

• S.A., Telansen Coating Machinery Co., Ltd

• Shandong Hightop Machinery

• Hubei Fotma Machinery Co., Ltd

Q7. Which spray polyurea coating equipment type segment will be the largest in future?

Answer: Lucintel forecasts that hydraulic spray equipment will remain the largest market over the forecast period.

Q8. In spray polyurea coating equipment market, which region is expected to be the largest in next 7 years?

Answer: North America is expected to remain the largest region and witness the highest growth over next 7 years

Q9. Do we receive customization in this report?

Answer:Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1. What are some of the most promising potential, high-growth opportunities for the global spray polyurea coating equipment market by type (pneumatic spray equipment, hydraulic spray equipment, and electric spray equipment), applications (into roof waterproofing, industrial waterproofing, high wear applications, and others), and region (North America, Europe, Asia Pacific, and Rest of the World (ROW))?

Q. 2. Which segments will grow at a faster pace and why?

Q.3. Which regions will grow at a faster pace and why?

Q.4. What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5. What are the business risks and threats to the spray polyurea coating equipment market?

Q.6. What are the emerging trends in spray polyurea coating equipment market and the reasons behind them?

Q.7. What are some changing demands of customers in the spray polyurea coating equipment market?

Q.8. What are the new developments in the spray polyurea coating equipment market? Which companies are leading these developments?

Q.9. Who are the major players in the spray polyurea coating equipment market? What strategic initiatives are being implemented by key players for business growth?

Q.10.What are some of the competitive products and processes in the spray polyurea coating equipment market, and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11. What M&A activity has occurred in the last 7 years?