Spray Foam Equipment Market Trends and Forecast

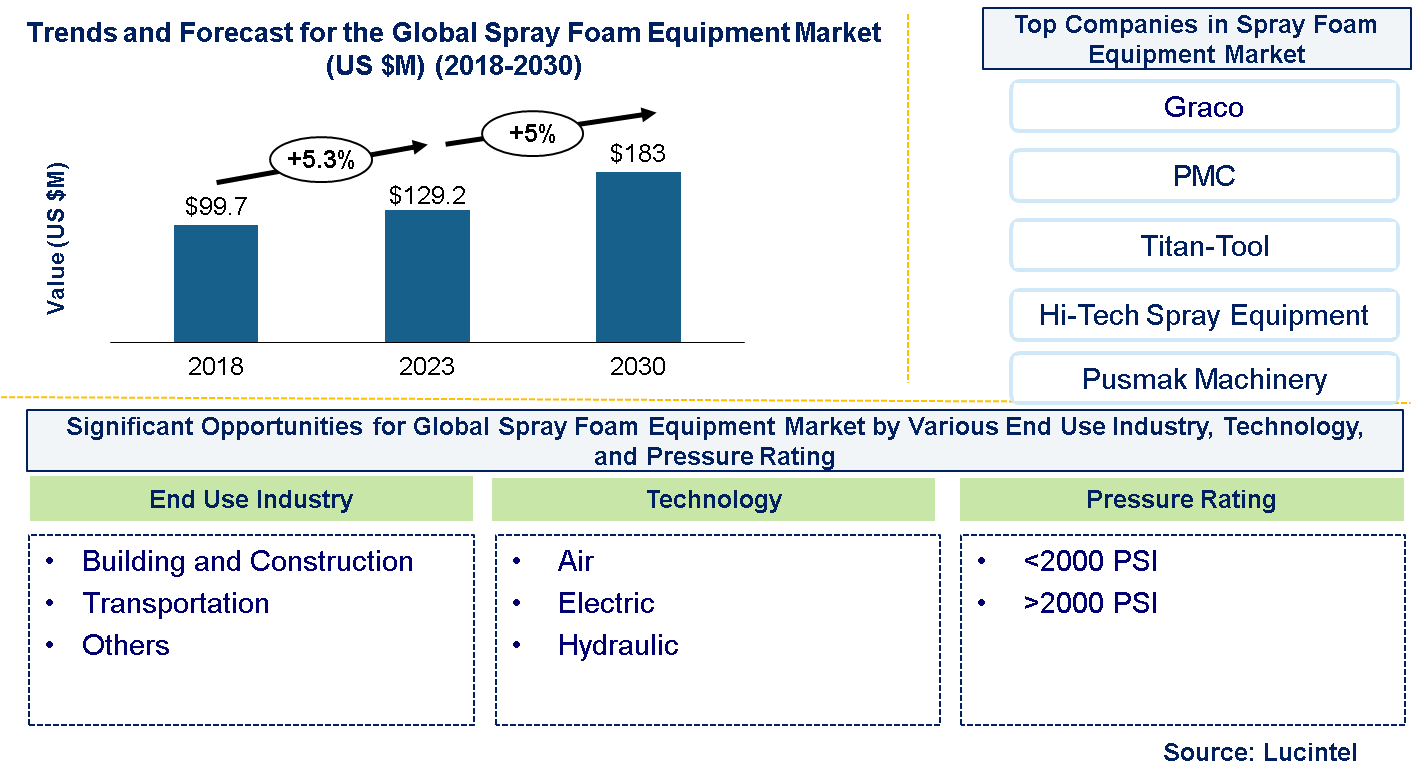

The future of the spray foam equipment market looks promising with opportunities in the residential, industrial, and commercial industry. The global spray foam equipment market is expected to reach an estimated $183 million by 2030 with a CAGR of 5% from 2024 to 2030. The major drivers for this market are the government regulations to support energy-efficient homes and building and growing demand for green building insulation in North America, APAC, and Europe.

Spray foam equipment typically utilizes materials such as stainless steel or aluminum for durability and corrosion resistance in the machinery components. Key raw materials also include high-pressure hoses and polyurethane or polyurea coatings for insulation and protection. Electrical components and pumps are made from various metals and polymers to ensure reliable operation. Insulation materials, like rubber or foam, are used to maintain temperature control. The price of spray foam equipment can vary significantly based on its type, capacity, and features. Generally, high-quality, industrial-grade spray foam systems are more expensive compared to entry-level or DIY models.

• Lucintel forecasts that building and construction is expected to remain the largest application segment, and this segment is projected to witness the highest growth over the forecast period,

• Electric is expected to remain the largest technology, and it will witness the highest growth in the forecast period.

• North America is expected to remain the largest market over the forecast period, supported by increasing residential construction and government regulations for energy efficiency.

Country wise Outlook for the Spray Foam Equipment Market

The spray foam equipment market is witnessing substantial growth globally. Below image highlights recent developments by major spray foam equipment producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends in the Spray Foam Equipment Market

Emerging trends in the spray foam equipment market shaping its future applications and market dynamics:

• Advancements in Equipment Technology: Innovations in spray foam machines, such as improved hydraulic systems, digital controls, and automated features, enhance efficiency, precision, and ease of use.

• Increased Focus on Energy Efficiency: Growing emphasis on energy-efficient solutions is driving demand for spray foam equipment that offers better insulation performance and reduced energy consumption in buildings.

• Integration with Smart Technologies: Integration with smart technologies, including IoT and real-time monitoring, allows for enhanced control, diagnostics, and performance tracking of spray foam applications.

• Expansion in Residential and Commercial Applications: Rising awareness of energy conservation is expanding the use of spray foam insulation in both residential and commercial buildings, leading to increased demand for versatile equipment.

• Development of Environmentally Friendly Foams: The market is seeing a shift towards eco-friendly spray foam formulations and equipment designed to minimize environmental impact and improve safety during application.

• Customization and Modular Equipment: Growing preference for customized and modular spray foam equipment allows for more flexible and scalable solutions to meet specific project requirements.

A total of 119 figures / charts and 113 tables are provided in this 210-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments Spray Foam Equipment Market

Ongoing innovations and advancements in various sectors of the spray foam equipment market which have been highlighted by recent developments:

• Advanced Technology Integration: New spray foam equipment now incorporates sophisticated digital controls, automation, and real-time monitoring systems, improving precision, consistency, and ease of operation.

• Energy-Efficient Designs: Recent models are designed with enhanced energy efficiency features, such as improved heat exchangers and optimized spray patterns, to reduce waste and improve insulation performance.

• Eco-Friendly Innovations: The development of environmentally friendly spray foam formulations and equipment focuses on reducing volatile organic compounds (VOCs) and using sustainable materials, aligning with green building practices and regulations.

• Improved Safety Features: Equipment advancements include enhanced safety features, such as better protective gear, automatic shut-off systems, and improved ventilation, to ensure safer application processes.

• Increased Portability and Flexibility: New equipment designs emphasize portability and modularity, allowing for easier transport and adaptation to various job sites, from residential to large commercial projects.

• Enhanced Training and Support: Companies are investing in comprehensive training programs and support services to help users better understand and effectively use the latest spray foam technologies.

• Smart Equipment Capabilities: Integration with IoT and smart technologies enables remote monitoring and diagnostics, offering real-time data and insights to optimize equipment performance and maintenance.

Strategic Growth Opportunities for Spray Foam Equipment Market

Some key strategic growth opportunities for this market include:

Residential Insulation:

• Energy Efficiency Upgrades: With increasing emphasis on energy-efficient homes, there is growth potential in residential insulation applications. Equipment that improves insulation quality and reduces energy costs can capture significant market share.

• Renovations and Retrofits: Older homes undergoing renovations or retrofits offer opportunities for spray foam equipment, as homeowners seek effective solutions for upgrading insulation and enhancing energy performance.

Commercial Construction:

• Green Building Initiatives: As commercial buildings increasingly pursue LEED and other green certifications, there is a demand for advanced spray foam solutions that contribute to energy efficiency and sustainable building practices.

• Large-Scale Projects: Equipment tailored for high-capacity applications in large commercial projects can address the growing need for effective insulation in offices, retail spaces, and industrial facilities.

Industrial Applications:

• Temperature Control and Energy Savings: In industrial settings, spray foam insulation is used for temperature control in piping, tanks, and equipment, providing opportunities for specialized equipment designed for harsh environments and large-scale applications.

• Industrial Facility Maintenance: As industries focus on reducing energy consumption and maintaining equipment, there is demand for spray foam solutions that offer durable insulation and protection.

By focusing on these strategic growth opportunities, companies can position themselves to meet the evolving needs of various sectors and capitalize on emerging trends in the spray foam equipment market.

Spray Foam Equipment Driver and Challenges

The spray foam equipment market is driven by the growing demand for energy-efficient building solutions and advancements in insulation technologies. As the construction and renovation industries seek better ways to enhance energy performance and reduce costs, spray foam equipment plays a crucial role. However, this market also faces several challenges that impact its growth and development.

The factors responsible for driving the spray foam equipment market include:

1. Increasing Demand for Energy Efficiency: The push for energy-efficient buildings and retrofits drives the demand for spray foam insulation, known for its superior thermal performance and air sealing properties.

2. Government Regulations and Incentives: Incentives and regulations promoting green building practices and energy conservation support the adoption of spray foam insulation in both new constructions and renovations.

3. Technological Advancements: Innovations in spray foam equipment, such as improved application techniques and digital controls, enhance efficiency and ease of use, attracting more customers.

4. Growing Awareness of Environmental Benefits: Rising awareness of the environmental benefits of spray foam insulation, including reduced energy consumption and lower carbon footprints, encourages its use.

Challenges in the spray foam equipment market are:

1. High Initial Costs: The initial investment in spray foam equipment can be high, which may deter some contractors or homeowners from adopting the technology despite its long-term benefits.

2. Regulatory Compliance: Navigating the various regulations and standards for spray foam applications, including environmental and safety regulations, can be complex and challenging.

3. Application Complexity: Proper application of spray foam requires skilled professionals and precise equipment operation, which can limit market growth due to the need for specialized training.

4. Market Competition: Intense competition in the spray foam equipment market can lead to price pressures and margin erosion, making it challenging for companies to differentiate themselves and maintain profitability.

These drivers and challenges shape the dynamics of the spray foam equipment market, influencing its growth prospects and the strategies companies must adopt to succeed.

Spray Foam Equipment Suppliers and Their Market Shares

In this globally competitive market, several key players such as Graco Inc., Polyurethane Machinery Corporation, Titan Tool Inc., Hi-Tech Spray Equipment, S.A., Pusmak Machinery Co., etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies spray foam equipment companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the spray foam equipment companies profiled in this report include.

• Graco Inc.

• Polyurethane Machinery Corporation

• Titan Tool Inc.

• Hi-Tech Spray Equipment

• Pusmak Machinery Co.

These companies have established themselves as leaders in the spray foam equipment industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the spray foam equipment market are evolving, with the entry of new players and the emergence of innovative spray foam equipment technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

0

Spray Foam Equipment Market by Segment

The residential insulation segment in the spray foam equipment market is experiencing significant growth. This surge is driven by increasing homeowner demand for energy-efficient solutions and home renovations. Enhanced awareness of energy savings and improved insulation performance fuels adoption, leading to greater investments in spray foam technologies for residential applications. The segment's expansion reflects a broader trend toward energy-efficient home improvements and retrofitting.

This spray foam equipment market report provides a comprehensive analysis of the market's current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including technology, pressure rating, and end-user industries. The report offers insights into regional dynamics, highlighting the major markets for spray foam equipment and their growth potentials. The study includes trends and forecast for the global spray foam equipment market by end use, technology, pressure rating, end use industry, and region as follows:

Spray Foam Equipment Market by Technology [Volume (M lbs) and $M analysis for 2018 – 2030]:

• Air

• Electric

• Hydraulic

Spray Foam Equipment Market by Pressure Rating [Volume (M lbs) and $M shipment analysis for 2018 – 2030]:

• <2000 PSI

• >2000 PSI

Spray Foam Equipment Market by End Use Industry [Volume (M lbs) and $M shipment analysis for 2018 – 2030]:

• Building and Construction

• Transportation

• Others

Spray Foam Equipment Market by Region [Volume (M lbs) and $M shipment analysis for 2018 – 2030]:

• North America

• USA

• Canada

• Mexico

• Europe

• Germany

• France

• United Kingdom

• Russia

• Spain

• Italy

• Asia Pacific

• China

• Japan

• India

• The Rest of the World

• Brazil

• UAE

Features of Spray Foam Equipment Market

• Market Size Estimates: Spray foam equipment market size estimation in terms of value ($M) and volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by technology, pressure rating, and end use industry

• Regional Analysis: Spray foam equipment market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different technologies, pressure ratings, end use industries, and regions for the spray foam equipment market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the spray foam equipment market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

FAQ

Q1. What is the spray foam equipment market size?

Answer: The global spray foam equipment market is expected to reach an estimated $183 billion by 2030.

Q2. What is the growth forecast for spray foam equipment market?

Answer: The global spray foam equipment market is expected to grow with a CAGR of 5% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the spray foam equipment market?

Answer: The major drivers for this market are the government regulations to support energy-efficient homes and building and growing demand for green building insulation in North America, APAC, and Europe.

Q4. What are the major applications or end use industries for spray foam equipment?

Answer: Building and construction and transportation are the major end use industries for spray foam equipment.

Q5. What are the emerging trends in spray foam equipment market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include the development of environmentally friendly foams and advancements in equipment technology.

Q6. Who are the key spray foam equipment companies?

Answer: Some of the key spray foam equipment companies are as follows:

• Graco Inc.

• Polyurethane Machinery Corporation

• Titan Tool Inc.

• Hi-Tech Spray Equipment

• Pusmak Machinery Co.

Q7.Which spray foam equipment end use industry segment will be the largest in future?

Answer: Lucintel forecasts that building and construction is expected to remain the largest end use industry over the forecast period.

Q8: In spray foam equipment market, which region is expected to be the largest in next 7 years?

Answer: North America is expected to remain the largest region in next 7 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the global spray foam equipment market by technology (air, electric, and hydraulic), pressure rating (<2000 PSI and >2000 PSI), end use industry (building and construction, transportation, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area, and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M&A activities did take place in the last five years in this market?