Southeast Asian Phenolic Resin Market Trends and Forecast

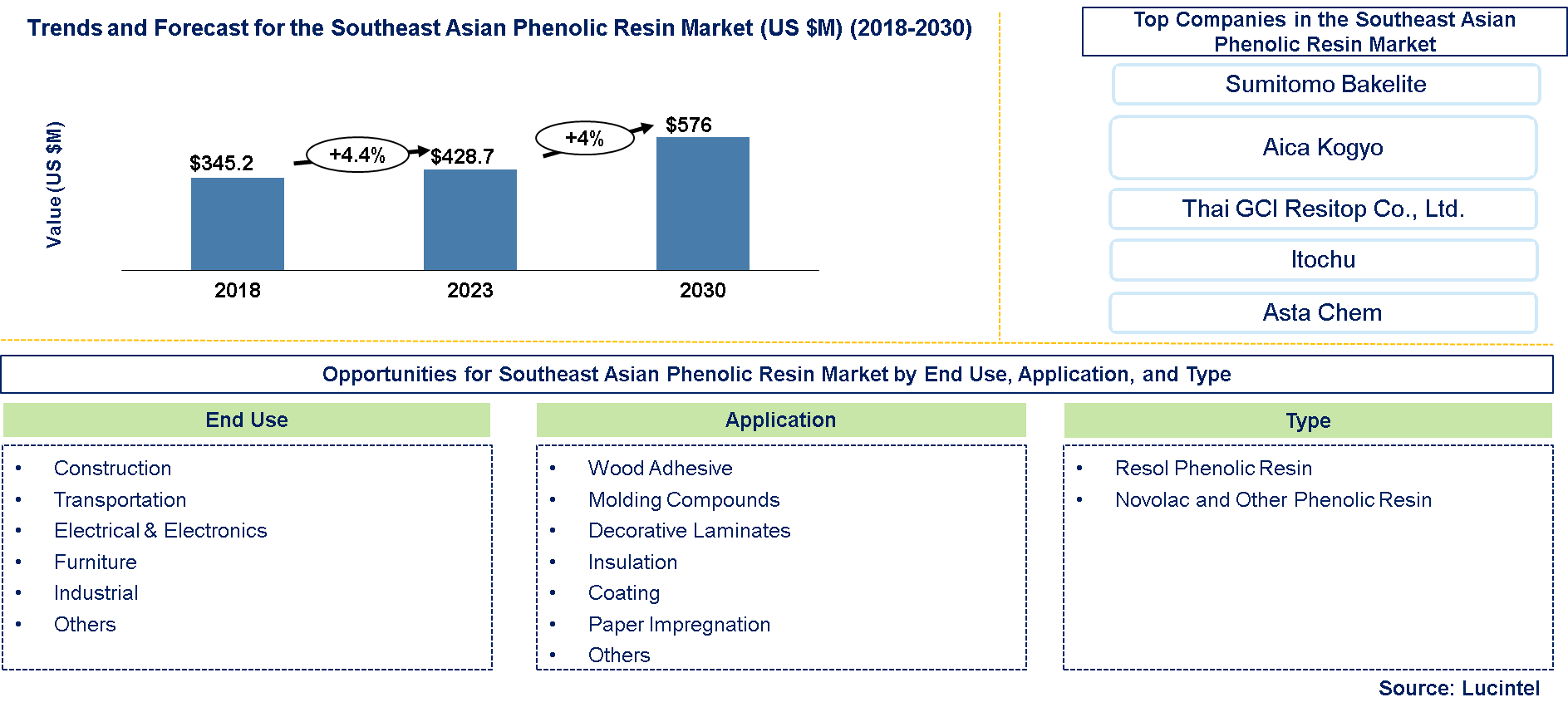

The future of the Southeast Asian phenolic resin market looks promising with growth opportunities in construction, transportation, electrical and electronics, furniture, and industrial end uses. The Southeast Asian phenolic resin market is expected to reach an estimated $576 million by 2030 with a CAGR of 4% from 2023 to 2030. The major drivers of growth for this market are increasing use of heat resistance, corrosion and chemical resistance materials in construction and transportation industry.

The primary elements used for making phenolic resin in Southeast Asia include phenol, formaldehyde and different additives. The two first-mentioned undergo polymerization with the help of catalysts which include alkaline compounds that hasten this process. To turn it into a material appropriate for industrial use, several fillers, stabilizers and modifiers are added to upgrade its heat resistance, durability and mechanical strength. Generally, Southeast Asia’s phenolic resin prices are competitive with those of epoxy and polyurethane resins, often even lower. Phenolic resins vary from $2 to $5 per kilogram, while epoxies may cost around 10 to 15 dollars per kilogram and polyurethanes between 5 and 10 dollars per kilogram. These factors: affordable price, excellent heat resistance as well as being fire retardant have contributed to making it the most preferable material for manufacturing in various industries.

• Lucintel forecasts that transportation will remain the largest end use segment over the forecast period due to increasing demand for heat resistant material, low-cost material, and manufacturing of high-performance composites. Electrical and electronics is expected to witness highest growth over the forecast period.

• Coating is expected to witness highest growth over the forecast period.

Country wise Outlook for the Southeast Asian Phenolic Resin Market

The Southeast Asian Phenolic Resin market is witnessing substantial growth. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major So

Emerging Trends in the Southeast Asian Phenolic Resin Market

Emerging trends in the Southeast Asian Phenolic Resin Market shaping its future applications and market dynamics:

• Increasing Demand in Construction: The fire resistance of phenolic resins in construction materials has been increasing safety standards for building projects.

• Expansion into Automotive Applications: To reduce fuel consumption and lower emissions, the automotive industry is turning to phenolic resins for lighter weight, high-performance parts.

• Electronics Sector Growth: Consumer electronics growth necessitates demand for phenolic resins in circuit boards as well as electrical insulation; this is because they are both thermally stable and durable.

• Sustainability Initiatives: Bio-based phenolic resin development would be a great way to meet environmental regulations and decrease dependence on petroleum-based feed stocks.

• Technological Advancements: New production processes look at refining resin quality and reducing manufacturing costs while making phenolic resins competitive with other substitutes.

A total of 82 figures / charts and 25 tables are provided in this 126-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Southeast Asian Phenolic Resin Market

Recent developments in Southeast Asian Phenolic Resin Market by various companies highlight ongoing innovations and advancements across different sectors:

• Expanding Production Facilities: Sumitomo Bakelite and Kolon Industries have increased their production capacities in Southeast Asia to cater for the growing demand from construction and automotive sectors.

• Partnerships and Joint Ventures: Mitsui Chemicals, among others, has been linked with regional producers, as local companies seek to tap into the global manufacturers’ innovation capabilities.

• Bio-based Resins Introduction: Companies investing in research and development on bio-based phenolic resins are ensuring that they come up with more sustainable products that are environmentally friendly.

• Advanced Resin Formulations: Phenol formaldehyde resin manufacturers have developed new phenolic resin formulations that exhibit superior heat resistance and mechanical properties, hence capable of withstanding high-performance electronics and aerospace applications.

• Market Penetration in Emerging Economies: Some firms are focusing on emerging markets like Vietnam and Indonesia within Southeast Asia because they have experienced rapid industrialization and infrastructure growth underpinning the rise in demand for phenolic resins.

Strategic Growth Opportunities for Global Southeast Asian Phenolic Resin Market

Construction Industry

• Better Fireproofing Materials: Develop and market phenolic resins with better fire-resisting characteristics for use in products such as insulation materials, roofings and wall panels. Increase demand due to more strict building codes and increased awareness of the importance of fire safety.

• Sustainable Construction Practices: To introduce bio-based phenolic resins that attracts green building initiatives and sustainable development. Catch the attention of environmentally conscious builders/developers and fit into sustainability trends.

Car Sector

• Lightweight Parts: Expand the employment of phenolic resin in lightweight automobile parts like brake pads, under-the-hood components and structural members. Better fuel economy, lower emissions to comply with stringent environmental regulations, which are increasingly important to customers buying eco-friendly cars.

• Thermal & Acoustic Insulation: Develop solutions based on phenolic resin for thermal and acoustic insulation in vehicles. Improve passenger comfort as well as vehicle performance in response to a rising desire among consumers for superior quality automotive interiors.

Electronics Industry

• High Efficiency Printed Circuit Boards (PCBs): Innovate in phenolic resin formulations to produce circuit boards with excellent electrical insulating capacity whilst maintaining desired thermal resistance properties during operation. Durable electronic appliances are now prevailing because people prefer such electronics tools like home appliances or laboratory equipment due to their long lasting nature while using it at the office or even at home they don’t have to worry that any time they might fail but rather focus on what they were intended for this is particularly true in portable consumer gadgets or industrial applications where durability is always a significant concern since it determines how long such an appliance can serve its purpose without malfunctioning.

• Miniaturization & Integration: Design advanced phenolic resins suitable for miniaturizing electronic components or integrated circuits (IC). This will go a long way in ensuring that the world is filled with smaller yet more powerful electronic devices thus targeting the consumer electronics market.

Aerospace Sector

• Heat-Resistant and Lightweight Materials: Develop phenolic resin composites for lightweight and heat resistant aerospace applications, where both structural and interior components are concerned. Fuel efficiency as well as aircraft performance can be enhanced by means of cost-effective durable materials, which meet industry needs.

• Advanced Composites: Innovate in phenolic resin composites to improve mechanical strength and durability for critical aerospace applications. This will contribute towards the development of next-generation aircrafts; ones that are not only faster but also come with better safety features.

Industrial Sector

• Highly Durable Industrial Coatings: Formulate high-durability chemical resistant thermal stable phenolic resin-based coatings for industrial machinery and equipment. Make industries like manufacturing, oil & gas etc. buy into products that can save them regular maintenance costs while extending the life span of their assets.

• Adhesives & Sealants: Expand application of phenolic resins in adhesives/sealants for industrial use providing stiff reliable bonding capabilities; Strong adhesive quality is very important as most industries require strong adhesive s when producing various products.

.Southeast Asian Phenolic Resin Market Drivers and Challenges

Southeast Asian Phenolic Resin market is pivotal in industries requiring corrosion-resistant storage solutions. Driven by benefits like rapid industrialization, rising demand for sustainable materials and technological advancements and innovation, it faces challenges such as high production costs and environmental and health concerns. This discussion explores key drivers propelling its growth and significant challenges hindering broader market adoption.

The key drivers for the Southeast Asian phenolic resin market include:

1. Rapid Industrialization and Urbanization: The Southeast Asian region is undergoing significant gains in industries and urban areas which drive the demand for construction materials, automotive parts, and electronic components. Phenolic resins have found increasing applications in these categories due to their heat resistance and flame retardancy for example as a result of which they are being used to develop durable fire resistant materials for such purposes. Therefore the phenolic resin manufacturers have an immense opportunity to grow using the expanding infrastructure and manufacturing activities experienced during this industrial boom.

2. Rising Demand for Sustainable Materials: Environmental rules and customer preferences are changing towards environment friendly products. The development and adoption of bio-based phenolic resins align with these trends, offering lower environmental impact compared to traditional petroleum-based resins. The construction, electronics and automotive industry is increasingly demanding greener alternatives; hence sustainable phenolic resin production can be one of the most promising areas of investment where firms may want to invest in order to take advantage of this market trend.

3. Technological Advancements and Innovation: Several technological improvements that have been made on phenolic resin production technology have improved polymerization processes as well as innovative resin formulations that improves both quality product quality as well performance. By so doing, productivity cost reduces as their uses increase making them more attractive therefore useful for a variety of high-performance applications. Corporations are able to come up with better products by adopting technologic progress tailored at satisfying needs coming from various sectors taking place within Asia’s leading producer of phenolic resins thereby stimulating marketing growth through innovation.

The challenges in the Southeast Asian phenolic resin Market include:

1. High Production Costs: Manufacturing of phenolic involves complicated chemical processes using expensive raw materials thus making it costlier as compared to other substitutes .Price sensitive sector can be jeopardized by such elevated costs. In order for each company presently involved in production business process need to carryout research and development to find the cost efficient methods of production raw material alternatives. However, this is can be a heavy burden in terms of financial.

2. Environmental and Health Concerns: The use of formaldehyde in the manufacture of phenolic resins poses environmental and health risks hence there have been stringent regulations governing it including possible restrictions on its use. The industry has had to invest heavily in safe production practices and equipment in order to comply with these regulations especially as they relate to formaldehyde. In addition, there is need for looking into issues such as disposal and re-cycling challenges related to phenolic resin so that its overall environment impact may be dealt with accordingly. Therefore, operational costs can rise due to these regulatory pressures and therefore complicating expansion efforts across borders.

In closing, Southeast Asian phenolic resin market expansion is precipitated by industrialization, green ideals and technological innovations. Nonetheless, it faces some difficulties such as high production expenses and environmental laws still exist. However, the use of bio-based substances and manufacturing techniques will create opportunities for the industry to expand; however, the complexity of regulatory frameworks and cost-effective procedures need to be addressed first before this can be achieved. Therefore, while ensuring compliance with regulations that promote innovation in order to remain competitive is essential for continued growth throughout the area.

Southeast Asian Phenolic Resin Suppliers and Their Market Shares

In this competitive market, several key players such as Thai GCI Resitop Co. Ltd, Malayan Adhesives and Chemicals Snd. Bhd, Formal Chemical (M) Snd. Bhd and Jowat Adhesives etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies Southeast Asian phenolic resin companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the Southeast Asian phenolic companies profiled in this report include.

• Thai GCI Resitop Co. Ltd

• Malayan Adhesives and Chemicals Snd. Bhd.

• Formal Chemical (M) Snd. Bhd.

• Jowat Adhesives

• Sumitomo Bakelite Co. Ltd

• DIC Corporation

• Asta Chem

• Pt. Intanwijaya International Tbk

• Itochu, Thailand

• Aica Kogy

These companies have established themselves as leaders in the Southeast Asian Phenolic Resin Market, with extensive product portfolios, presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the Southeast Asian phenolic resin market are evolving, with the entry of new players and the emergence of innovative Southeast Asian phenolic resin market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Southeast Asian Phenolic Resin Market by Segment

Construction materials used for fire resistant insulation and structural components are among the main parts of Southeast Asia’s phenolic resin seeing growth. For instance, lightweight composites in automotive applications for brake pads and under-the-hood components are expanding. Phenolic resin is also used by electronics sectors in circuit boards because of its thermal stability and insulation properties. Also industrial coatings and adhesives are registering growth as manufacturing a durable solution in infrastructure development across the region increases demand for them.

The study includes a forecast for the Southeast Asian phenolic resin market by application, type, end use, and country as follows:

Southeast Asian Phenolic Market by Application [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Wood Adhesive

• Molding Compounds

• Laminates

• Insulation

• Coating

• Paper Impregnation

• Others

Southeast Asian Phenolic Market by Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Resol Phenolic Resin

• Novolac Phenolic Resin

Southeast Asian Phenolic Market by End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Construction

• Transportation

• Electrical and Electronics

• Furniture

• Industrial

• Others

Southeast Asian Phenolic Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Thailand

• Singapore

• Malaysia

• Indonesia

• Philippines

• Vietnam

• Others

Features of Southeast Asian Phenolic Resin Market

• Market Size Estimates: Southeast Asian phenolic resin market size estimation in terms of value ($M) and volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments.

• Segmentation Analysis: Market size by application, type, end use, and country.

• Regional Analysis: Southeast Asian phenolic resin market breakdown by Thailand, Singapore, Malaysia, Indonesia, Philippines, Vietnam, Others.

• Growth Opportunities: Analysis of growth opportunities in different applications, type, end use and country for the Southeast Asian phenolic resin market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the Southeast Asian phenolic resin market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in Southeast Asian Phenolic Resin or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the Southeast Asian phenolic resin market size?

Answer: The Southeast Asian phenolic resin market is expected to reach an estimated $576 million by 2030.

Q2. What is the growth forecast for Southeast Asian phenolic resin market?

Answer: The Southeast Asian market is expected to grow at a CAGR of 4% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the Southeast Asian phenolic resin market?

Answer: The major drivers of growth for this market are rapid industrialization, rising demand for sustainable materials and technological advancements and innovation.

Q4. What are the major applications or end use industries for Southeast Asian phenolic resin?

Answer: Transportation and construction are the major end uses for Southeast Asian phenolic resin.

Q5. What are the emerging trends in Southeast Asian phenolic resin market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, the includes the increasing demand in construction, expansion into automotive applications, electronics sector growth, sustainability initiatives, and technological advancements.

Q6. Who are the key Southeast Asian phenolic resin companies?

Answer: Some of the key Southeast Asian phenolic resin companies are as follows:

• Thai GCI Resitop Co. Ltd

• Malayan Adhesives and Chemicals Snd. Bhd.

• Formal Chemical (M) Snd. Bhd.

• Jowat Adhesives

• Sumitomo Bakelite Co. Ltd

• DIC Corporation

• Asta Chem

• Pt. Intanwijaya International Tbk

• Itochu, Thailand

• Aica Kogyo

Q7. Which Southeast Asian phenolic resin segment will be the largest in future?

Answer: Lucintel forecasts that the molding compound segment will remain the largest segment and it is expected to witness the highest growth over the forecast period due to the growing use of phenolic resin in various applications where heat, pressure, water resistance, and other performance benefits are critical.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost

.

This report answers following 11 key questions

Q.1 What are some of the most promising, high-growth in Southeast Asian phenolic resin market by application (wood adhesive, molding compounds, laminates, insulation, coating, paper impregnation, and others), type (resol phenolic resin and novolac phenolic resin), end use (construction, transportation, electrical and electronics, furniture, and others), and country (Thailand, Singapore, Malaysia, Indonesia, Philippines, Vietnam and Others )?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.4 What are the business risks and threats to the market?

Q.5 What are the emerging trends in this market and the reasons behind them?

Q.6 What are the changing demands of customers in the market?

Q.7 What are the new developments in the market? Which companies are leading these developments?

Q.8 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.9 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.10 What M & A activities have taken place in the last 5 years in this market?