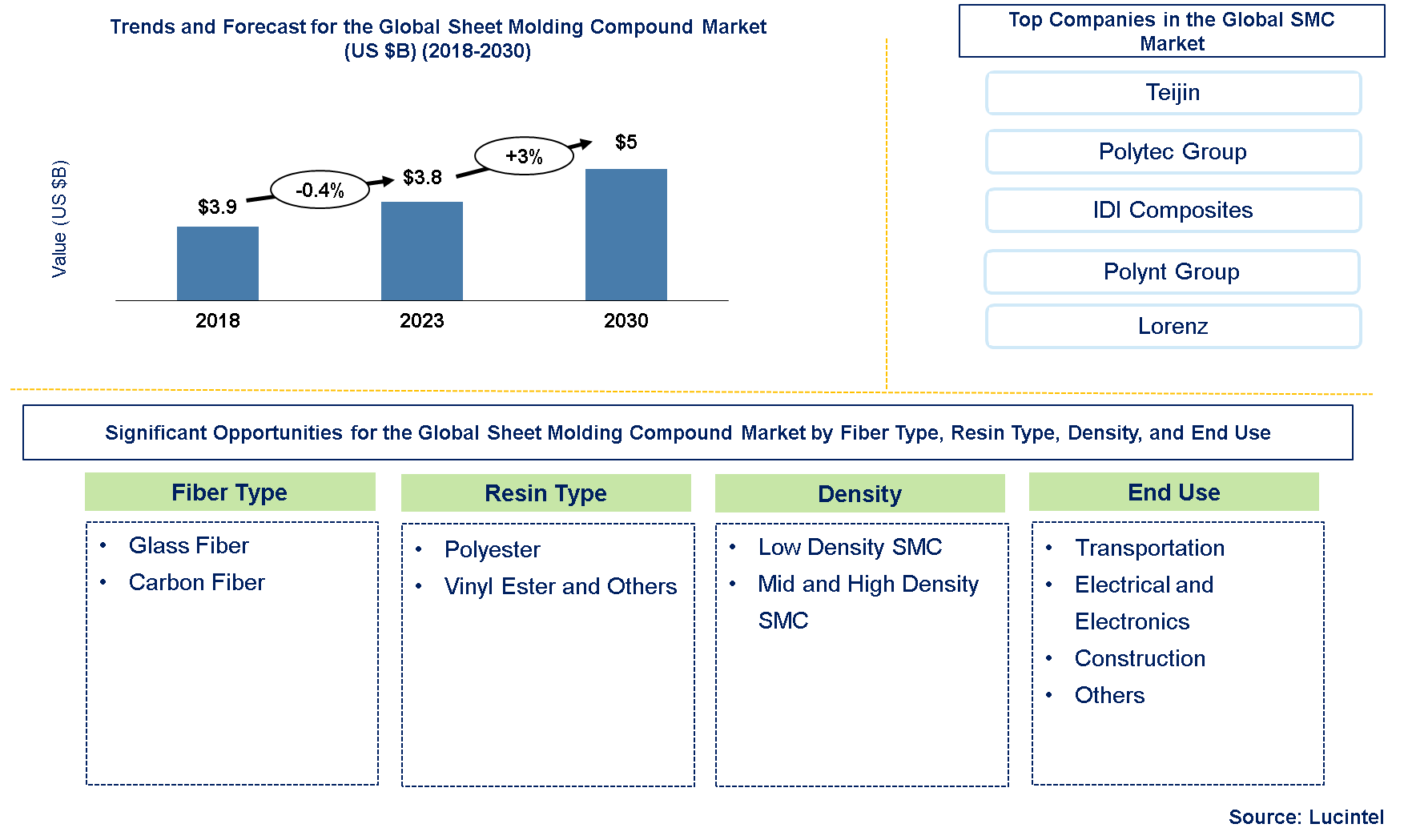

Sheet Molding Compound Market Trends and Forecast

The future of the global sheet molding compound intermediate material market looks promising with in the transportation, electrical & electronics, and construction industries. The global SMC market is expected to reach an estimated $5 billion by 2030 with a CAGR of 3% from 2023 to 2030. The major growth drivers for this market are increasing use of lightweight materials in transportation, and performance benefits, such as lower corrosion in construction and higher thermal resistance in E&E industries..

Fiberglass is mainly used in making sheet molding compound (SMC) to reinforce it for strength and rigidity. A matrix material such as unsaturated polyester or vinyl ester is usually resins. To improve properties and cut costs, fillers like calcium carbonate or talc are used. Curing agents, pigments and other additives are employed during the production of sheet molding compounds for influencing its curing process and achieving any required performance characteristics as well as coloring purposes. Sheet molding compound (SMC) generally has a higher price compared to traditional materials like steel or concrete due to its advanced manufacturing process and the cost of resins and fiberglass. However, it is often cost-competitive against other composite materials due to its superior strength, durability, and reduced need for maintenance. Pricing varies with material specifications and market conditions.

• Lucintel forecasts that in this market, transportation will remain the largest end use supported by growing automotive production and increasing focus on lightweight materials. Pickup truck boxes, deck lids, fenders, hoods, and bumpers are some of the major applications of SMC in the transportation industry. Construction is expected to witness the highest growth over the forecast period.

• Glass fiber based SMC will remain the largest segment over the forecast period supported by its high performance characteristics and it is also expected to witness the highest growth over the forecast period.

• Asia Pacific is expected to remain the largest market by value and volume. ROW is expected to witness the highest growth over the forecast period because of growing demand from construction and other end uses.

Country wise Outlook for the Sheet Molding Compound Market

The sheet molding compound market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major sheet molding compound producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends in the Sheet Molding Compound Market

Emerging trends in the sheet molding compound Market shaping its future applications and market dynamics:

• Advancements in Resin Technology: The mechanical properties, thermal stabilities and chemical resistances of sheet molding compounds (SMC) are being enhanced by the development of high-tech resin formulations that include vinyl ester and epoxy resins. These resins are helping to produce more durable high-performance composites for use in demanding situations. Manufacturers are increasingly focusing on low-volatile organic compound (VOC) resins that meet stringent environmental regulations as well as sustainability objectives. This kind of a resin helps reduce the environmental impact of SMC manufacturing through improved air quality.

• Increased Use in Automotive Applications: The lightweight nature of SMC has led to an increasing demand from the automobile industry owing to its ability to improve fuel efficiency and performance. In body panels, bumpers, and interior components, SMC is now used more extensively due to its higher strength and better impact resistance. Compression molding and automatic fiber placement among others process innovations have helped enhance the effectiveness levels as well as precision in SMC production. These advances make it easier for integration of SMCs into complex automotive designs.

• Growth in Aerospace and Defense: Aircrafts and military vehicles where weight reduction is paramount for improved performance, aerospace sector and defense sectors have rapidly embraced SMC because of its high strength-to-weight ratio. On the other hand, various aerospace components will be made using this material because it is highly durable against harsh conditions. Safety concerns underlie the need for these materials within aerospace applications or any other safety-sensitive industries such as defense. Meanwhile this material could conform with the toughest requirements set by both aeronautics industry and defense department by means of taking advantage over its formulation & processing advancements.

• Expansion into Consumer Goods: Another reason why SMC is becoming popular in consumer goods is because it produces durable and appealing products. For instance, SMC can be used to mold housings for electronics, appliances, and sporting goods since it feeds into complex shapes and surfaces well. To meet the demands of different consumers as well as specific product needs, SMC has the ability to be tailored or detailed. For instance, new developments in processing technology make it possible to design more innovative products using SMC.

• Sustainability and Recycling Innovations: New recycling technologies are being developed to address the environmental impact of SMC waste. This includes methods that restore or reuse materials from SMC so as to minimize waste generation as well as enhance cradle-to-cradle approach. Research is being conducted on bio-based substitute formulations for traditional type of material. Henceforth, this direction complies with global sustainability concerns by reducing reliance on fossil fuel resources towards creating a greener alternative material useful in conventional use of SMC.

A total of 140 figures / charts and 97 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below..

Recent Developments by the Sheet Molding Compound Market

Recent developments in sheet molding compound market by various companies highlight ongoing innovations and advancements across different sectors:

• Penetrating into Emerging Markets: SMC therefore should seek opportunities in growing infrastructure development that is taking place in emerging markets like Latin America and Asia Pacific, as there exists a demand for long-lasting construction materials that can be used for the projects of different types of infrastructures. Local manufacturing facilities are also very important as they reduce transportation costs, make your supply chains more efficient and meet local market demand better than ever before. Additionally, such a strategy would enable the company to increase its market penetration while remaining responsive to customers’ feedbacks.

• Innovation in Manufacturing Processes: Investing into automation and advanced manufacturing processes will result into more efficient and consistent production of SMC. As automated fiber placement or continuous molding techniques enhance product quality, so it helps to minimize production costs.Besides this, advanced manufacturing technologies that allow greater customization and complexity in SMC products have been developed for serving specific application areas or meeting special needs of individual customers. This includes innovation in mold design and processing techniques.

• Diversification of Applications: There are new growth avenues if SMC use is broadened to automotive and aerospace applications. This means that tailoring these products for use as lightweight structural components or high-performance parts will help address industry requirements hence increasing market share. Another approach entails identifying other uses where SMC properties give them an edge over others which include consumer goods as well electronics among others. In a similar vein, exploring untapped but highly productive niche markets would not only revolutionize the segments but also result in their capture through bespoke solutions.

• Sustainability Initiatives: Recycled and bio-based SMC materials should be developed since it supports global sustainability trends together with regulatory requirements around this area. Thus these initiatives could make more sustainable the eco-friendliness of SMC products in order to win the favor of green-minded consumers. It is important for SMC products to be certified as environmentally friendly or approved to follow some kind of sustainability requirements. Correspondingly, demonstrating compliance with environmental regulations and sustainability practices could attract customers and improve brand reputation.

Strategic Growth Opportunities for Global Sheet Molding Compound Market

Business Opportunities in Emerging Markets

• Infrastructure and Urbanization: Asian-Pacific, Latin America, and Africa are witnessing rapid infrastructural development and urbanization in emerging markets. These regions have a high potential for SMC applications in building construction, transport, and utilities that require durable materials that offer cost effectiveness.

• Local production facilities: When manufacturing plants are established in these areas, it decreases the costs of transportation; improves supply chain efficiency as well as enhances the capability to respond to customers’ needs. Additionally, local production can help adapt to regional regulations and standards more effectively.

Green Innovations

• SMC from Recycled and Bio-based Materials: Development of recycled and bio-based SMC materials is consistent with worldwide environmental trends as well as regulations. These eco-friendly materials attract conscientious consumers who may also be motivated by tightening environmental laws thereby improving companies` positioning on market.

• Circular Economy Initiatives: Recycling SMC waste into new products through inclusion of recycled content reduces environmental impacts while promoting circularity. In addition to achieving sustainability goals, this practice influences savings on material sourcing costs.

Advancement in Manufacturing Technology

• Automation and Digitalization: The integration of advanced manufacturing technologies such as automation, robots or digital twin simulations will enhance the productivity of output hence reducing wage bill alongside ensuring uniform quality. Such innovations will streamline processes thus raising competitiveness levels within SMC products.

• High Precision Molding Techniques: New molding techniques like automated fiber placement (AFP) or continuous compression molding (CCM) when invested upon result into better performing SMC products which are reliable than before. This enables greater flexibility while producing complex parts with high strength.

Product Diversification

• Automotive Sector: The automotive industry remains an important growth area for SMC due to its lightweight properties, high strengths including resistance against corrosion. Extending the use of SMCs to electric vehicles would support significant market expansion since their light weight is essential towards their performance.

• Aerospace and Defense: Venturing into aerospace and defense sectors where SMC gains value for its high strength to weight ratio besides durability under harsh conditions can create new market niches with higher value. Some potential applications might be in structures, panels and protective materials.

Sheet Molding Compound Market Drivers and Challenges

The sheet molding compound market is pivotal in industries requiring corrosion-resistant storage solutions. Driven by benefits like rising demand in automobile industry, advances in sustainable and green materials, and technological innovations in manufacturing, it faces challenges such as high initial cost and investment, and limited market awareness and acceptance.

The key drivers for the global sheet molding compound market include:

1. Rising Demand in Automobile Industry: The automotive industry is increasingly employing sheet molding compounds (SMC) because of their light weight, high strength, and resistance to corrosion. These materials enable the reduction of weight, causing better fuel efficiency and reduced emissions that align with strict environmental guidelines. Moreover, due to being capable of assuming complicated shapes during molding, SMC offers more design options when it comes to making different automobile parts like dashboards, body panels and rear bumpers.

2. Advances in Sustainable and Green Materials: More stringent environmental regulations and customers’ demand for greener products have caused an increase in the use of sustainable construction materials. In response to these requirements, SMC manufacturers are developing low-VOC and bio-based resin formulations. By doing this; SMC becomes a more marketable product by giving environmentally friendly alternatives that either keep or enhance its characteristics as far as performance is concerned hence helping contractors achieve sustainability goals while maintaining the quality.

3. Technological Innovations in Manufacturing: Improvements made on manufacturing techniques such as automated fiber placement as well as continuous compression molding have increased the efficiency, accuracy and scalability of SMC production. These changes lower costs of production, improve uniformity among products manufactured while enabling complex designs on high-performance composite parts. The result is that such technology improvements have helped make SMC become very competitive against traditional materials like metals and other composites thereby making their adoption across a number of industries in the sectors of automotive aerospace construction.

Challenges in the Sheet Molding Compound Market

1. High Initial Cost and Investment: Sheet molding compound manufacturing necessitates significant investment costs into special equipment and raw materials including high-performance resins & fibers. This can be prohibitive to new entrants hindering existing producers from expanding their output capacity necessarily. It’s also possible for potential buyers who are price-driven not to find it affordable purchasing SMC given its higher cost compared to conventional materials used in similar applications hence limiting market entry.

2. Limited Market Awareness and Acceptance: However, SMC is not well known or accepted by the target users in some regions and industries where traditional materials are widely used. Convincing people of the benefits of SMC as well as dispelling fears related to its performance quality compared to other conventional materials remains real challenges on its own. In order to gain wider acceptance, building trust and proving through case studies, certifications and successful applications that SMC has long-term value inherent within it is highly important.

The sheet molding compound (SMC) market is about to experience a period of growth due to technological improvements in sustainable materials and advanced manufacturing techniques. Nevertheless, there are still some challenges that need to be addressed such as high initial expense and lack of awareness in the market. However, applying technology innovations for reducing costs and educational campaigns can break through those barriers towards wider utilization which in turn will lead to more demand in the market.

Sheet Molding Compound Suppliers and Their Market Shares

In this globally competitive market, several key players such as Teijin Limited, Polytec Group, IDI Composites International, and Polynt Group etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies SMC companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the SMC companies profiled in this report includes.

• Teijin Limited

• Polytec Group

• IDI Composites International

• Polynt Group

• Lorenz

• Ningbo HAMC Group

• Core Molding Technologies

• Changzhou Jiang's Composite Materials Technology Co., Ltd.

• LyondellBasell

These companies have established themselves as leaders in the global sheet molding compound market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the sheet molding compound market are evolving, with the entry of new players and the emergence of innovative sheet molding compound market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Sheet Molding Compound Market by Segment

The world’s construction industry is experiencing robust growth in the following major segments: Infrastructure repair and strengthening; pipeline and utility rehabilitation; bridge and highway restoration; structural retrofitting, seismic upgrading. In this context, various factors drive those segments like the need to prolong the existence of building structures that are growing old, meeting tough regulatory rules or enhancing safety as well as longer existence of vital infrastructure. Additionally, this sector’s advancement depends on the way advanced composite materials are taken up by innovative repair techniques.

The study includes a forecast for the global SMC market by end use, fiber type, resin type, density, and region as follows:

SMC Market by End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Transportation

• Electrical and Electronics

• Construction

• Others

SMC Market by Fiber Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Glass Fiber

• Carbon Fiber

SMC Market by Resin Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Polyester

• Vinyl Ester and Others

SMC Market by Density [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Low Density

• Mid and High Density

SMC Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Sheet Molding Compound Market

• Market Size Estimates: SMC market size estimation in terms of value ($M) and (M lbs).

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by end use, fiber type, resin type, density, and region

• Regional Analysis: SMC market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different end use, fiber type, resin type, density, and region for the SMC market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the SMC market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

.

If you are looking to expand your business in sheet molding compound or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the SMC market size?

Answer: The global SMC market is expected to reach an estimated $5 billion by 2030.

Q2. What is the growth forecast for SMC market?

Answer: The SMC market is expected to grow at a CAGR of 3% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the SMC market?

Answer: The major growth drivers for this market are raising demand in automobile industry, advances in sustainable and green materials. and technological innovations in manufacturing.

Q4. What are the major applications or end use industries for SMC?

Answer: Transportation and Construction are the major end uses for SMC.

Q5. What are the emerging trends in SMC market?

Answer: Emerging trends which have a direct impact on the dynamics of the industry include advancements in resin technology, increased use in automotive applications, growth in aerospace and defense, expansion into consumer goods, and sustainability and recycling innovations.

Q6. Who are the key SMC companies?

Answer: Some of the key SMC companies are as follows:

• Teijin Limited

• Polytec Group

• IDI Composites International

• Polynt Group

• Lorenz

• Ningbo HAMC Group

• Core Molding Technologies

• Changzhou Jiang's Composite Materials Technology Co., Ltd.

• LyondellBasell

Q7.Which SMC fiber type segment will be the largest in future?

Answer: Lucintel forecasts that glass fiber based SMC will remain the largest segment and it is also expected to witness the highest growth over the forecast period supported by its high performance characteristics.

Q8. In SMC market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 7 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1. What are some of the most promising potential, high growth opportunities for the global SMC market by end use (transportation, electrical and electronics, construction, and others), fiber type (glass fiber and carbon fiber), resin type (polyester, vinyl ester and others), density (low density, and mid and high density), and region (North America, Europe, Asia Pacific and the Rest of the World)?

Q. 2. Which segments will grow at a faster pace and why?

Q.3. Which regions will grow at a faster pace and why?

Q.4. What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5. What are the business risks and threats to the market?

Q.6. What are the emerging trends in this market and the reasons behind them?

Q.7. What are the changing demands of customers in the market?

Q.8. What are the new developments in the market? Which companies are leading these developments?

Q.9. Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10. What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11. What M & A activities have taken place in the last five years in this market?