Semiconductor Wafer Cleaning Equipment Market Trends and Forecast

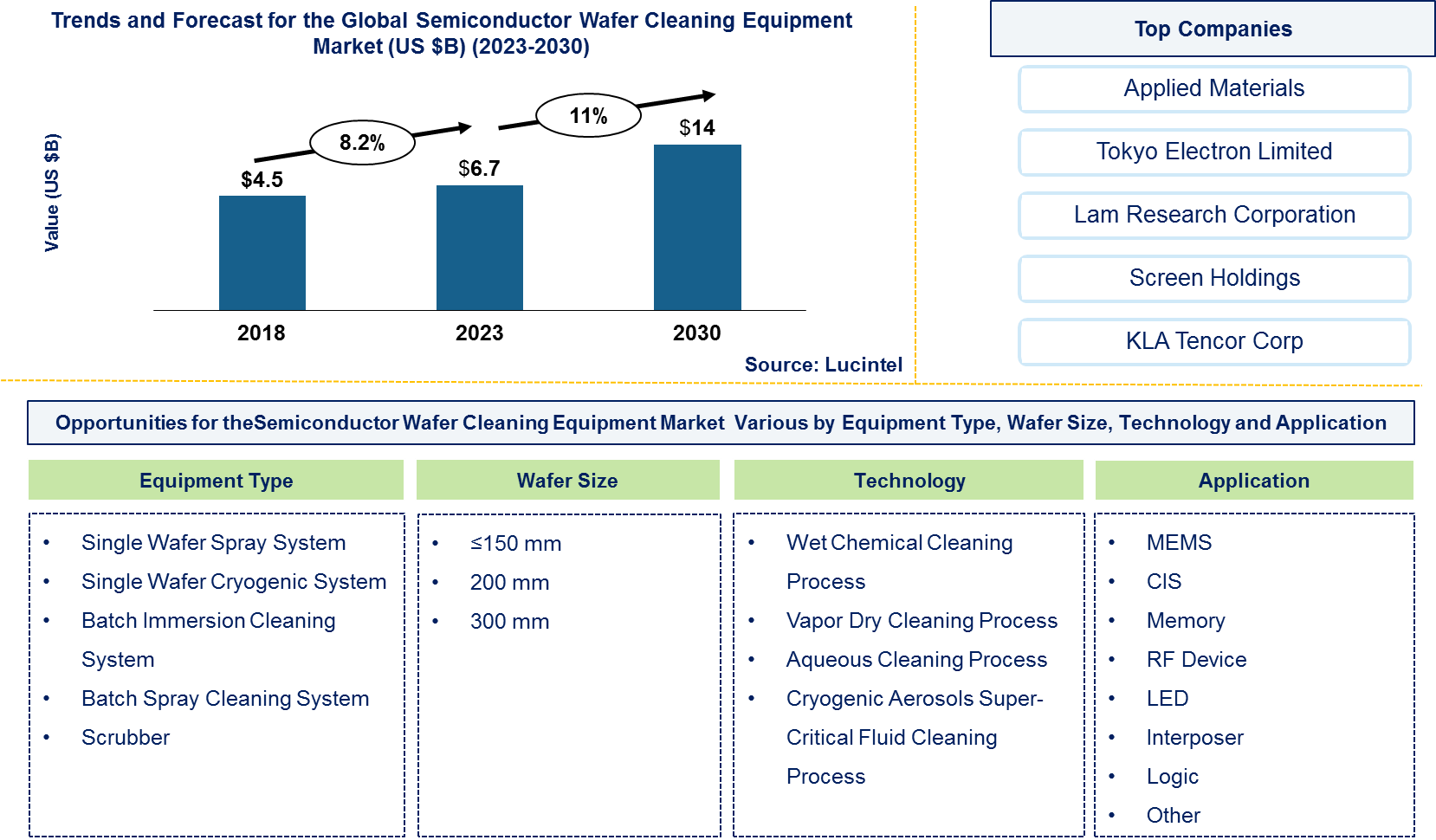

Lucintel finds that the future of the global semiconductor wafer cleaning equipment market looks promising with opportunities in the MEMS, CIS, Memory, RF device, LED, interposer, and logic applications. The global semiconductor wafer cleaning equipment market is expected to reach an estimated $14.1 billion with a CAGR of 11.2% from 2023 to 2030. The major drivers for this market are increasing usage of MEMS technology, increasing number of critical steps in the wafer cleaning sequence, and rising demand for wafers in 3D structure and increasing adoption of silicon-based sensors, chips, and diodes in IoT applications.

The semiconductor wafer cleaning equipment are used to remove contaminants from semiconductor surfaces, chemicals such as acids, bases, solvents and DI water are used in these pieces of equipment. Nitrogen or oxygen gases are meanwhile used to aid the drying and purging processes. The equipment has for accurate monitoring and control purposes, pumps, valves, filters and automation components. Controlled environments need cleaning brushes pads and cleanroom supplies. In manufacturing processes these components and materials are essential for guaranteeing reliability and performance of semiconductor wafers. The pricing of the semiconductor wafer cleaning equipment differ significantly due to factors such as brand name, capacity, technology features, and type among others. The efficiency and capability of the high-throughput and advanced technology models justify their higher prices. The market demand and competitive environment determine the selling price of these machines which may range between tens of thousands to several hundred thousand dollars. In evaluating equipment alternatives, customers consider total cost of ownership with regard to maintenance efficiency and operational effectiveness.

• Lucintel forecasts that single wafer spray system will remain the largest equipment type segment and expected to witness highest growth over the forecast period.

• LED remain the largest segment and RF is expected to witness the highest growth over the forecast period.

• APAC is expected to remain the largest market and NA expected to witness the highest growth over the forecast period due to rise in the demand of MEMS, RF device and LEDs.

Country wise Outlook for the Semiconductor Wafer Cleaning Equipment Market

The semiconductor wafer cleaning equipment market is witnessing substantial growth globally, driven by increased demand from various application such as MEMS, CIS, memory, RF device, LED. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major semiconductor wafer cleaning equipment producers in key regions: the USA, China, India, Japan, and Germany.

Emerging Trends in the Semiconductor Wafer Cleaning Equipment Market

Emerging trends in the semiconductor wafer cleaning equipment market shaping its future applications and market dynamics:

• Development of Wafer Back-Side Cleaning System: Semiconductor wafer cleaning equipment removes particles and residues from semiconductor wafers. A wafer back side cleaning system was developed by Screen with function like chemical and brush cleaning which uses scrubber technique. The new product has chemical etching/ cleaning function.

• Introduction of Single Wafer Cleaning Tool for 3D NAND: Single wafer cleaning tool for 3D NAND was introduced to meet the demand. The production capacity becomes due to unprecedented demand for semiconductor chips. They can be used for polymer removal, tungsten (W) loop or back-end copper process, pre-deposition clean, post-etch and post-chemical mechanical polishing (CMP) clean, deep trench clean, and RCA standard clean.

• Automation and Robotics: The cleaning process can be improved through the integration of automation, artificial intelligence (AI), and robotics.

• Compatibility with New Materials: The development of cleaning equipment that can handle new semiconductor materials such as gallium nitride (GaN) and silicon carbide (SiC) that require special cleaning protocol.

• Dual-Side Cleaning: Development of equipment capable of cleaning both sides of wafers simultaneously, improving throughput and operational efficiency.

A total of 88 figures / charts and 82 tables are provided in this 184-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Development in the Semiconductor Wafer Cleaning Equipment Market

Ongoing innovations and advancements in various sectors of the semiconductor wafer cleaning equipment market which have been highlighted by recent developments:

• Improving Cleaning Technology: Introduction of enhanced cleaning techniques for smaller node sizes and more complicated semiconductor structures to ensure higher accuracy and cleanliness.

• Automation and Robotics Integrated: Increased adoption of automation and robotics for wafer handling, cleaning, and process control improving efficiency while reducing manual labor

• Focus on Green Cleaning Solutions: Creating environmentally sustainable cleaning processes and chemicals that meet regulatory standards with reduced environmental impacts.

• Enhanced Particle Monitoring and Control: Implemented advanced systems for detecting particles in order to reduce contamination as well as increase yields during wafer cleaning.

• Smart Manufacturing Integration: Integrating wafer cleaning equipment with smart manufacturing, resulting in real-time monitoring, predictive maintenance, data analytics for optimized production processes.

• Customized and Flexible Solutions: Demand for modular & customizable cleaners that can be adjusted to different semiconductor materials/ sizes/ production requirements.

Strategic Growth Opportunities for Semiconductor Wafer Cleaning Equipment Market

The semiconductor wafer cleaning equipment market is poised for strategic growth opportunities driven by several key factors that are shaping the semiconductor industry landscape:

Technological Advancements: Continuous advancements in semiconductor manufacturing technologies, including smaller node sizes and complex structures, necessitate more advanced cleaning solutions. Developing equipment capable of handling these technological advances while maintaining high precision and efficiency presents an opportunity to innovate.

Emerging Semiconductor Materials: The increasing adoption of new materials such as gallium nitride (GaN) and silicon carbide (SiC) requires specialized cleaning processes. There is a chance to develop cleaning equipment with innovations tailored for the unique properties and challenges associated with these materials.

Demand for Higher Yield and Quality: To improve yield rates of semiconductors and ensure they are high-quality products, manufacturers have to enhance their cleaning equipment for increased reliability, cleanliness, etc. which directly improves both yield and quality metrics.

Environmental Sustainability: In order to reduce chemical usage during manufacture, generation of wastes as well as energy consumption, sustainability issues must be considered even in this field. Therefore, a significant opportunity for growth exists in creating environmentally safe technology along with green washing solutions that would minimize chemical waste production whilst at the same time minimizes energy consumption.

Automation and Industry 4.0 Integration: It is through automation systems, robotics as well as AI-driven technologies that today’s semiconductor manufacturing processes are being improved in terms of efficiency hence operational capabilities are being transformed. Manufacturers of Semiconductor wafer cleaning equipment can leverage on this trend by providing automated smart-cleaning solutions that will enhance process control thereby reducing labor costs.

Market Expansion in Emerging Economies: Emerging economies are witnessing increased investment in semiconductor manufacturing infrastructure. The lucrative growth opportunities exist when companies expand into such markets catering to advanced cleansing tools needs by local population.

By taking advantage of these strategic growth opportunities, the semiconductor wafer cleaning equipment market can realize its full potential and transform numerous industries through strength, lightness, versatility.

Semiconductor Wafer Cleaning Equipment Market Driver and Challenges

Semiconductor wafer cleaning equipment has a very important role in many applications including MEMS, CIS, memory, RF device and LED. The changing market dynamics are being driven by the technological advancements, demand for higher yield and quality and stringent manufacturing standards. However, semiconductor wafer cleaning equipment market faces challenges like complexity of semiconductor structures, environmental concerns, and cost pressures.

The factors responsible for driving the semiconductor wafer cleaning equipment market include:

1. Technological Advancements: It is the rapid advancements in semiconductor technology that necessitate for more capable wafer cleaning equipment to deal with smaller node sizes and complex structures.

2. Demand for Higher Yield and Quality: The manufacturers towards cleaner wafers to improve their yield rates and guarantee high-quality semiconductor products, hence increasing demand for efficient cleaning solutions.

3. Stringent Manufacturing Standards: To this end, increased regulatory standards and industry requirements make the market for advanced cleaning equipment grow.

4. Emerging Semiconductor Materials: Indeed, the adoption of materials such as gallium nitride (GaN) and silicon carbide (SiC) has led to the need for specialized cleaning processes, thus driving equipment innovation.

5. Automation and Industry 4.0: A mix of automation, robotics and AI can provide an avenue through which process control in wafer cleaning is improved upon while reducing manual labor thereby enhancing efficiency.

Challenges facing the semiconductor wafer cleaning equipment market are:

1. Complexity of Semiconductor Structures: Cleanliness should be done on increasingly intricate semiconductor structures but without causing any damage to delicate features.

2. Environmental Concerns: Use of chemicals in cleaning processes poses environmental as well as regulatory challenges, which call for ecological solutions and waste management practices.

3. Cost Pressures: High initial financial outlays and running costs linked to sophisticated equipment for cleaning may discourage its adoption, particularly by small companies.

4. Particle Contamination: Adhering to cleanliness standards in cleanrooms and minimizing particle contamination during the cleaning process is still a major challenge.

Innovations in semiconductor wafer cleaning equipment include advanced techniques such as plasma and cryogenic cleaning, alongside eco-friendly chemical solutions. Automation and robotics enhance precision and efficiency, while real-time monitoring and data analytics optimize processes. Improvements in ultrasonic cleaning, spin-rinse-dry systems, and water recycling contribute to higher efficiency and sustainability. Compact and modular designs offer flexibility and adaptability for various manufacturing needs.

Semiconductor Wafer Cleaning Equipment Suppliers and Their Market Share

The market for semiconductor wafer cleaning equipment is highly competitive, with several key players such as Applied Materials, Tokyo Electron Limited, Lam Research Corporation, Screen Holdings, KLA Corp have established their presence in the market and hold a significant market share. To know the current market share of each of major players Contact Us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies semiconductor wafer cleaning equipment companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the semiconductor wafer cleaning equipment companies profiled in this report includes.

• Applied Materials

• Tokyo Electron Limited

• Lam Research Corporation

• Screen Holdings

• KLA Corp

These companies have established themselves as leaders in the semiconductor wafer cleaning equipment industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the semiconductor wafer cleaning equipment market are evolving, with the entry of new players and the emergence of innovative semiconductor wafer cleaning equipment technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Semiconductor Wafer Cleaning Equipment Market by Segment

The semiconductor wafer cleaning equipment market includes key segments such as MEMS, CIS, memory, RF devices, LEDs, interposers, and logic devices. Each segment has unique cleaning needs: MEMS require precise cleaning for delicate structures, CIS and memory need high cleanliness to ensure performance, RF devices focus on signal integrity, LEDs demand residue-free surfaces for optimal light emission, interposers require contamination-free connections, and logic devices need rigorous cleaning for reliable function. Specialized cleaning technologies are essential for meeting these diverse requirements.

This semiconductor wafer cleaning equipment market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including semiconductor wafer cleaning equipment type, size, technology, and application. The report offers insights into regional dynamics, highlighting the major markets for semiconductor wafer cleaning equipment and their growth potentials. The study includes a forecast for the global semiconductor wafer cleaning equipment market by equipment type, wafer size, technology, application, and region, as follows:

Semiconductor Wafer Cleaning Equipment Market by Equipment Type [Value ($M) Analysis from 2018 to 2030]:

• Single Wafer Spray System

• Single Wafer Cryogenic System

• Batch Immersion Cleaning System

• Batch Spray Cleaning System

• Scrubber

Semiconductor Wafer Cleaning Equipment Market by Wafer Size [Value ($M) Analysis from 2018 to 2030]:

• ≤150 mm

• 200 mm

• 300 mm

Semiconductor Wafer Cleaning Equipment Market by Technology [Value ($M) Analysis from 2018 to 2030]:

• Wet Chemical Cleaning Process

• Vapor Dry Cleaning Process

• Aqueous Cleaning Process

• Cryogenic Aerosols Super-Critical Fluid Cleaning Process

Semiconductor Wafer Cleaning Equipment Market by Application [Value ($M) Analysis from 2018 to 2030]:

• MEMS

• CIS

• Memory

• RF Device

• LED

• Interposer

• Logic

• Others

Semiconductor Wafer Cleaning Equipment Market by Region [Value ($M) Shipment Analysis from 2018 to 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Semiconductor Wafer Cleaning Equipment Market

• Market Size Estimates: Semiconductor wafer cleaning equipment market size estimation in terms of value ($M)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Semiconductor wafer cleaning equipment market size by various segments, such as by equipment type, wafer size, technology, application, and region

• Regional Analysis: Semiconductor wafer cleaning equipment market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis on growth opportunities in different by equipment type, wafer size, technology, application, and regions for the semiconductor wafer cleaning equipment market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the semiconductor wafer cleaning equipment market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in semiconductor wafer cleaning equipment or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the semiconductor wafer cleaning equipment market size?

Answer: The global semiconductor wafer cleaning equipment market is expected to reach an estimated $14 billion by 2030.

Q2. What is the growth forecast for semiconductor wafer cleaning equipment market?

Answer: The global semiconductor wafer cleaning equipment market is expected to grow with a CAGR of 11.2% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the semiconductor wafer cleaning equipment market?

Answer: The major drivers for this market are increasing usage of MEMS technology, increasing number of critical steps in the wafer cleaning sequence, and rising demand for wafers in 3D structure and increasing adoption of silicon-based sensors, chips, and diodes in IoT applications.

Q4. What are the major segments for semiconductor wafer cleaning equipment market?

Answer: The future of the semiconductor wafer cleaning equipment market looks promising with opportunities in the MEMS, CIS, Memory, RF device, LED, interposer, and logic applications.

Q5. Who are the key semiconductor wafer cleaning equipment companies?

Answer: Some of the key semiconductor wafer cleaning equipment companies is as follows:

• Applied Materials

• Tokyo Electron

• Lam Research Corporation

• Screen Holdings

• KLA Corp

Q6. Which semiconductor wafer cleaning equipment segment will be the largest in future?

Answer: Lucintel forecast that batch spray cleaning systems will remain the largest segment over the forecast period as it helps in processing multiple wafers all at a time, while saving time as well as cleaning cost.

Q7. In semiconductor wafer cleaning equipment market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to witness the highest growth during the forecast period due to growing demand for portable consumer electronics along with advancements in capabilities of the semiconductor equipment manufacturing industry, and increasing investments and business expansion in this region.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1. What are some of the most promising, high-growth opportunities for the semiconductor wafer cleaning equipment market by equipment type (single wafer spray system, single wafer cryogenic system, batch immersion cleaning system, batch spray cleaning system, and scrubber), wafer size (<150 mm, 200 mm, and 300 mm), technology (wet chemical cleaning process, vapor dry cleaning process, aqueous cleaning process, and cryogenic aerosols super-critical fluid cleaning process), application (MEMS, CIS, memory, RF device, LED, interposer, and logic), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which segments will grow at a faster pace and why?

Q.3. Which region will grow at a faster pace and why?

Q.4. What are the key factors affecting market dynamics? What are the key challenges and business risks in this market?

Q.5. What are the business risks and competitive threats in this market?

Q.6. What are the emerging trends in this market and the reasons behind them?

Q.7. What are some of the changing demands of customers in the market?

Q.8. What are the new developments in the market? Which companies are leading these developments?

Q.9. Who are the major players in this market? What strategic initiatives are key players pursuing for business growth?

Q.10. What are some of the competing products in this market and how big of a threat do they pose for loss of market share by material or product substitution?

Q.11. What M&A activity did occur in the last five years and how did they impact the industry?

For any questions related to semiconductor wafer cleaning equipment market or related to semiconductor wafer cleaning equipment companies, semiconductor wafer cleaning equipment market size, semiconductor wafer cleaning equipment market share, semiconductor wafer cleaning equipment analysis, write Lucintel analyst at email: helpdesk@lucintel.com we will be glad to get back to you soon.