Semiconductor Etching Agent Market Trends and Forecast

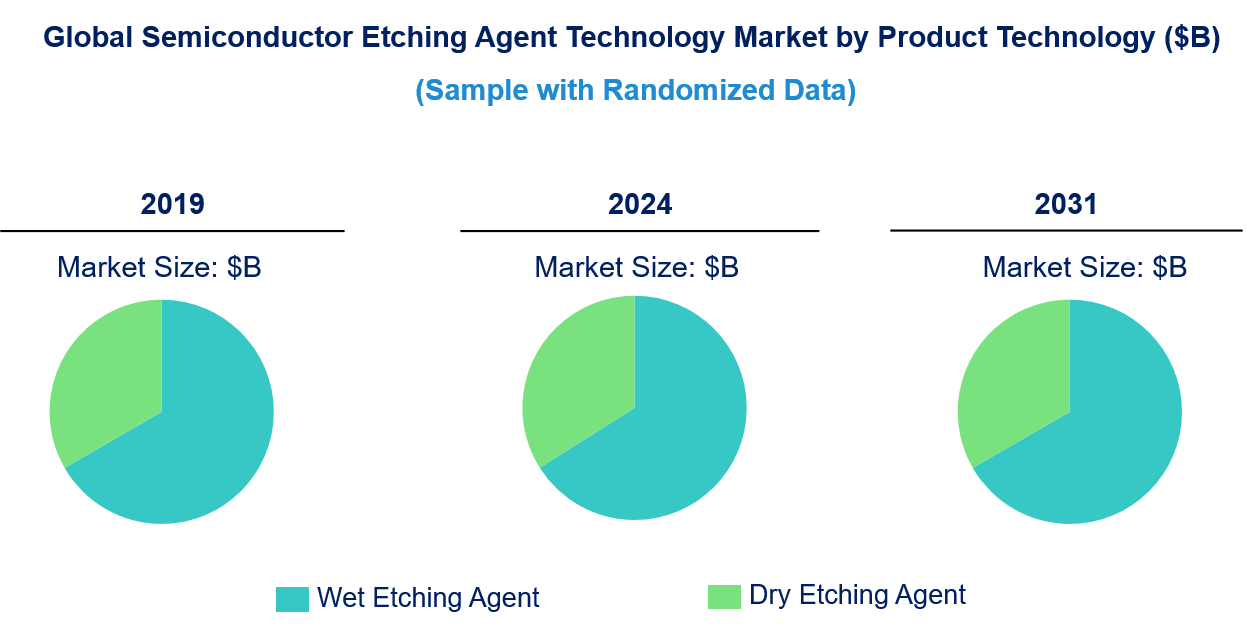

The technologies in the semiconductor etching agent market have undergone significant changes in recent years, with a shift from wet etching technology to dry etching technology. This change has been driven by the demand for finer and more precise etching in semiconductor manufacturing, particularly for advanced integrated circuits and smaller geometries. Wet etching agents were traditionally used to etch semiconductor materials using liquid chemicals, but dry etching, which involves gases and plasmas, offers more control and precision, enabling the creation of more complex and smaller features on chips. Additionally, advancements in plasma etching have further enhanced the capabilities of dry etching technologies, allowing for better resolution and material compatibility. As a result, dry etching has become more prominent in integrated circuit production, especially in processes like deep ultraviolet lithography. These technology shifts have led to improved etching precision, reduced material wastage, and better scalability for mass production in the semiconductor industry.

Emerging Trends in the Semiconductor Etching Agent Market

The semiconductor etching agent market is experiencing rapid evolution as the demand for smaller, faster, and more efficient semiconductor devices continues to grow. Technological advancements in etching techniques, combined with increased application in cutting-edge industries such as electronics, automotive, and renewable energy, are driving the market forward. Below are some of the emerging trends in the market, reshaping its future.

• Shift to Dry Etching Techniques: As semiconductor devices become more complex, the need for greater precision has led to a shift from traditional wet etching to dry etching techniques. Dry etching allows for better resolution and control, making it the preferred choice for smaller geometries in advanced integrated circuits and microchips.

• Advancements in Plasma Etching: Plasma etching technology, which uses ionized gases for material removal, is gaining traction in the semiconductor etching market. This method offers better material compatibility, enhanced resolution, and the ability to etch complex patterns, enabling manufacturers to produce smaller, more intricate features for high-performance chips.

• Increased Use of Atomic Layer Etching (ALE): Atomic layer etching is becoming increasingly popular due to its ability to achieve atomic-scale precision in etching. This technology allows for extremely fine control over material removal, supporting the creation of advanced, high-density integrated circuits used in next-generation devices like 5G and AI chips.

• Environmentally-Friendly Etching Agents: With increasing pressure to adopt sustainable practices, the semiconductor industry is focusing on the development of environmentally-friendly etching agents. This includes agents that are less toxic and have minimal environmental impact, contributing to cleaner manufacturing processes and reducing hazardous chemical waste.

• Integration with Advanced Lithography Technologies: The integration of etching agents with advanced lithography techniques, such as extreme ultraviolet (EUV) lithography, is enabling the production of even smaller semiconductor features. These combinations allow for the creation of intricate circuit patterns required in high-performance processors and memory chips, supporting the demand for more powerful electronics.

These emerging trends such as the shift towards dry etching, advancements in plasma and atomic layer etching, environmentally-friendly etching agents, and integration with advanced lithography are reshaping the Semiconductor Etching Agent Market. The continuous innovation in etching technologies is enabling semiconductor manufacturers to meet the growing demand for smaller, more efficient, and environmentally sustainable components across various industries.

Semiconductor Etching Agent Market : Industry Potential, Technological Development, and Compliance Considerations

The semiconductor etching agent market is experiencing significant technological evolution, driven by the growing demand for smaller, faster, and more efficient semiconductor devices.

• Potential in Technology:

The potential of etching technology lies in its ability to facilitate the manufacturing of intricate and high-performance components used in advanced applications like 5G, artificial intelligence, and memory storage. The shift from wet etching to dry etching and the increasing adoption of plasma etching have revolutionized the market, enabling greater precision and control over the etching process. Dry etching offers advantages such as better resolution, material compatibility, and scalability, which is crucial as device features continue to shrink to the atomic scale.

• Degree of Disruption:

The degree of disruption caused by these innovations is substantial, particularly in integrated circuit manufacturing where techniques like Atomic Layer Etching (ALE) are pushing the limits of precision. These technologies enhance chip performance and allow for the production of next-gen semiconductors.

• Current Technology Maturity Level:

As for the technology maturity, dry etching and plasma etching have reached a high level of maturity, while emerging techniques like ALE are still evolving but showing great promise.

• Regulatory Compliance:

Regulatory compliance in the semiconductor etching market focuses on minimizing the environmental impact of the chemicals used in etching processes, driving the development of safer and more eco-friendly etching agents. Overall, these technological shifts are crucial for enhancing semiconductor production while meeting the increasing demand for efficiency and miniaturization in modern electronics.

The semiconductor etching agent market is evolving rapidly, with advanced technologies offering greater precision and scalability. These innovations are driving efficiency in semiconductor manufacturing while addressing sustainability concerns.

Recent Technological development in Semiconductor Etching Agent Market by Key Players

The semiconductor etching agent market has witnessed significant advancements, driven by the growing demand for smaller, more efficient, and high-performance semiconductor devices. Key players in the market, such as Applied Materials, Hitachi High Technologies America, Lam Research, Tokyo Electron, and Plasma-Therm, have been at the forefront of these developments, pushing the boundaries of etching technologies to meet the needs of next-generation semiconductor manufacturing. Below are some of the recent developments from these industry leaders:

• Applied Materials: Applied Materials has made significant strides in the development of advanced plasma etching systems designed for 3D NAND flash memory and DRAM. Their technologies focus on improving the precision and uniformity of etching, enabling the production of smaller and more complex chips. These innovations are critical for meeting the demands of high-performance computing and mobile devices.

• Hitachi High Technologies America: Hitachi has been advancing atomic layer etching (ALE) technology to enable even finer etching precision in semiconductor manufacturing. This breakthrough improves the etching of complex materials with atomic-level control, allowing for smaller semiconductor features and better material compatibility, which is key for the latest logic and memory devices.

• Lam Research: Lam Research continues to enhance dry etching solutions with innovations in plasma etching for advanced nodes below 5nm. Their systems provide high etching precision, reduced material loss, and better integration with processes like extreme ultraviolet (EUV) lithography, which is essential for cutting-edge semiconductor production.

• Tokyo Electron: Tokyo Electron has been focusing on improving etching process technology for semiconductor integration. The company’s innovations in wet etching solutions, combined with improved post-etch cleaning, are enabling better yields and the manufacture of higher-performing semiconductor devices.

• Plasma-Therm: Plasma-Therm has been developing specialized dry etching solutions tailored for MEMS (Micro-Electro-Mechanical Systems) applications. Their technology provides higher etching precision for MEMS structures, which are critical for sensors, actuators, and various emerging applications in the automotive and healthcare sectors.

In conclusion, the recent developments in the Semiconductor Etching Agent Market are driven by advancements in plasma etching, atomic layer etching, and wet etching technologies, enabling semiconductor manufacturers to meet the demands of increasingly complex and smaller chip designs. These innovations enhance the performance, precision, and scalability of semiconductor production, positioning these key players as leaders in the market.

Semiconductor Etching Agent Market Driver and Challenges

The semiconductor etching agent market has been significantly shaped by evolving technological needs, with the increasing demand for smaller, more precise semiconductors. Innovations in etching technologies are driven by the rapid advancements in semiconductor manufacturing, especially as devices become more compact and performance requirements increase. However, these opportunities are accompanied by several challenges that impact market growth.

The factors responsible for driving the semiconductor etching agent market include:

• Technological Advancements: Continued innovations in plasma etching, atomic layer etching, and dry etching technologies are driving demand. These developments enable the creation of smaller semiconductor features with greater precision, which is critical for the production of advanced integrated circuits, memory devices, and processors.

• Increasing Demand for Smaller Devices: The trend towards miniaturization of semiconductor devices in industries such as consumer electronics, automotive, and telecommunications is driving the need for more advanced etching agents. This has led to higher demand for precision etching solutions that enable the production of smaller and more complex chip designs.

• Growth in Emerging Technologies: The rise of emerging technologies such as 5G, AI, and IoT has fueled the demand for advanced semiconductors, thus increasing the demand for specialized etching agents. These technologies require more intricate and precise etching processes, stimulating further innovation and market growth.

• Rising Demand for Semiconductor Devices in the Automotive Industry: The automotive industry’s growing reliance on semiconductors, especially for electric vehicles and autonomous driving technologies, has spurred the need for advanced etching agents that enable the manufacture of more complex chips for enhanced vehicle functionality.

• Increased Adoption of Advanced Packaging Technologies: As packaging technologies evolve, such as 3D packaging and system-on-chip (SoC) integration, there is a rising need for etching agents that can handle complex multi-layered semiconductor devices. This trend creates new growth opportunities in the semiconductor etching agent market.

Challenges in the semiconductor etching agent market are:

• Complexity of Advanced Etching Processes: As the demand for smaller and more complex devices increases, etching processes have become more intricate. Managing these advanced etching technologies requires specialized knowledge and equipment, which poses a challenge for companies looking to stay competitive.

• Material Compatibility and Waste Management: Ensuring that etching agents work effectively across a wide variety of semiconductor materials can be challenging. Additionally, managing waste from etching processes, including gases, liquids, and chemical residues, is a growing concern for the industry and a barrier to sustainability.

• Regulatory Compliance: As etching agents and their related processes often involve the use of hazardous chemicals, regulatory frameworks around chemical handling, disposal, and safety are stringent. Adhering to these regulations can impose significant costs on companies and limit their operational flexibility.

The semiconductor etching agent market is significantly impacted by advancements in technology, the demand for smaller devices, and the growth of emerging technologies like 5G and AI. While these opportunities present substantial growth potential, challenges such as complexity, material compatibility, waste management, and regulatory compliance must be navigated carefully to sustain long-term progress in the market.

List of Semiconductor Etching Agent Companies

Companies in the market compete based on product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies semiconductor etching agent companies cater to increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the semiconductor etching agent companies profiled in this report include.

• Applied Materials

• Hitachi High Technologies America

• LAM Research

• Tokyo Electron

• Plasma-Therm

Semiconductor Etching Agent Market by Technology

• Technology Readiness by Technology Type: Wet etching technology is mature and ready for mass production, especially in sectors like solar panel manufacturing and older semiconductor processes. However, it struggles to meet the demands of next-generation semiconductor nodes due to its lower precision. Dry etching technologies, such as plasma etching and atomic layer etching (ALE), are highly advanced and critical for the development of smaller, more complex semiconductor devices. Dry etching is ready for high-volume production, with its key applications in integrated circuits, memory devices, and logic chips at advanced nodes below 5nm. Wet etching is still competitive in less precision-demanding applications, but its ability to handle smaller geometries is limited. The regulatory compliance for dry etching is stringent, given the involvement of hazardous materials, while wet etching has fewer regulatory hurdles. Dry etching’s competitive intensity is high, as companies race to improve etching precision and scalability for the latest semiconductor technologies. Wet etching’s role is shrinking in advanced markets, with dry etching dominating the high-performance and miniaturized semiconductor applications critical to industries like AI, 5G, and automotive.

• Competitive Intensity and Regulatory Compliance: The competitive intensity in the semiconductor etching agent market is higher for dry etching technologies due to their critical role in advanced semiconductor manufacturing. Companies are heavily investing in innovations to meet the growing demand for smaller and more precise chips. Dry etching technologies, particularly those used for 5nm and smaller processes, are key to competitive differentiation in the market. Wet etching technologies, while still used in certain applications like solar energy and display manufacturing, face less competition but are becoming less relevant in high-end semiconductor applications. Regulatory compliance is stricter for dry etching, as it involves hazardous gases and chemicals, requiring rigorous safety measures and environmental management. Wet etching, being less chemically complex, faces fewer regulatory challenges but is increasingly seen as inadequate for the latest semiconductor processes, making dry etching the dominant force in the market moving forward. The stricter regulations surrounding dry etching contribute to higher entry barriers, intensifying competition among a smaller number of specialized players.

• Disruption Potential by Technology Type: The semiconductor etching agent market is undergoing significant disruption, primarily driven by the shift from wet etching agents to dry etching agents. Wet etching technologies are less precise and suitable for older, less complex processes, while dry etching technologies, particularly plasma etching, offer enhanced precision, scalability, and control, meeting the demands of modern semiconductor manufacturing. Dry etching, such as reactive ion etching (RIE) and atomic layer etching (ALE), enables the production of smaller, more complex devices, making it crucial for the advanced nodes used in high-performance applications. This disruption is accelerating as dry etching becomes integral to manufacturing processes for chips with smaller geometries, like 5nm and below. Consequently, dry etching’s potential to support innovations in AI, 5G, and IoT is greater, whereas wet etching’s role is diminishing in these high-precision sectors. As a result, wet etching’s disruption potential is limited, while dry etching is poised to revolutionize semiconductor production, driving further advancements in technology.

Semiconductor Etching Agent Market Trend and Forecast by Product Technology [Value from 2019 to 2031]:

• Wet Etching Agent

• Dry Etching Agent

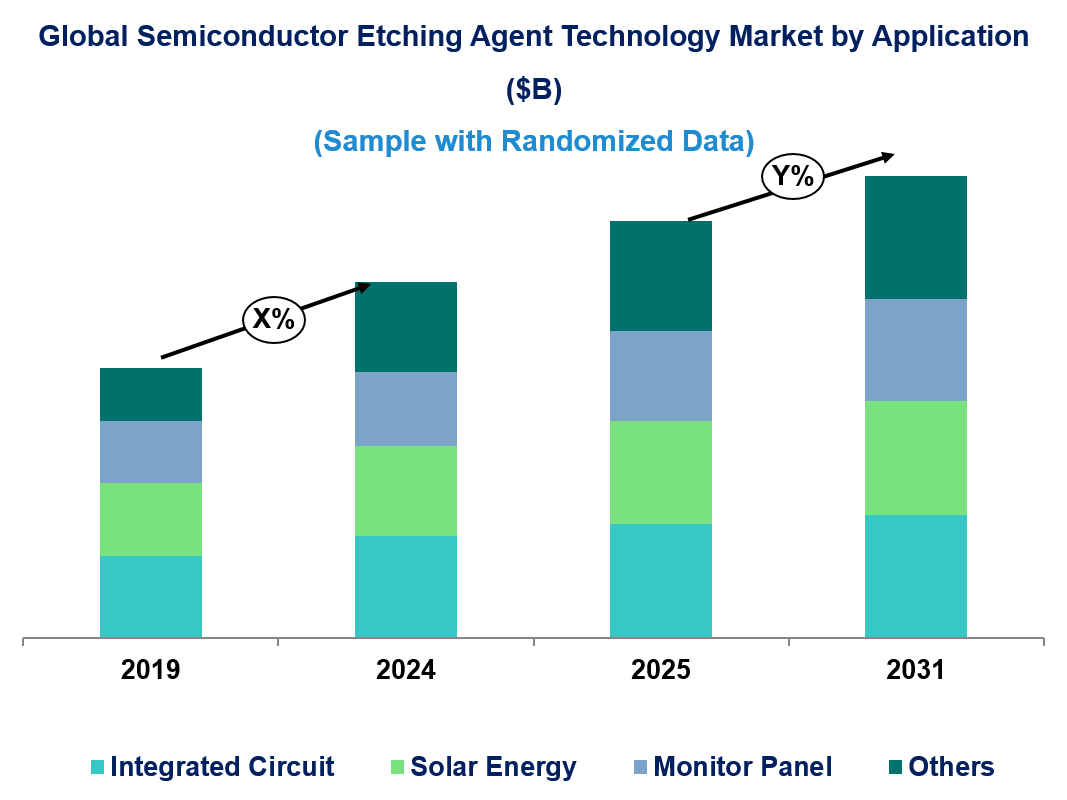

Semiconductor Etching Agent Market Trend and Forecast by Application [Value from 2019 to 2031]:

• Integrated Circuit

• Solar Energy

• Monitor Panel

• Others

Semiconductor Etching Agent Market by Region [Value from 2019 to 2031]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

• Latest Developments and Innovations in the Semiconductor Etching Agent Technologies

• Companies / Ecosystems

• Strategic Opportunities by Technology Type

Features of the Global Semiconductor Etching Agent Market

Market Size Estimates: Semiconductor etching agent market size estimation in terms of ($B).

Trend and Forecast Analysis: Market trends (2019 to 2024) and forecast (2025 to 2031) by various segments and regions.

Segmentation Analysis: Technology trends in the global semiconductor etching agent market size by various segments, such as application and product technology in terms of value and volume shipments.

Regional Analysis: Technology trends in the global semiconductor etching agent market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different applications, product technologies, and regions for technology trends in the global semiconductor etching agent market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for technology trends in the global semiconductor etching agent market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

This report answers following 11 key questions

Q.1. What are some of the most promising potential, high-growth opportunities for the technology trends in the global semiconductor etching agent market by product technology (wet etching agent and dry etching agent), application (integrated circuit, solar energy, monitor panel, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which technology segments will grow at a faster pace and why?

Q.3. Which regions will grow at a faster pace and why?

Q.4. What are the key factors affecting dynamics of different product technologies? What are the drivers and challenges of these product technologies in the global semiconductor etching agent market?

Q.5. What are the business risks and threats to the technology trends in the global semiconductor etching agent market?

Q.6. What are the emerging trends in these product technologies in the global semiconductor etching agent market and the reasons behind them?

Q.7. Which technologies have potential of disruption in this market?

Q.8. What are the new developments in the technology trends in the global semiconductor etching agent market? Which companies are leading these developments?

Q.9. Who are the major players in technology trends in the global semiconductor etching agent market? What strategic initiatives are being implemented by key players for business growth?

Q.10. What are strategic growth opportunities in this semiconductor etching agent technology space?

Q.11. What M & A activities did take place in the last five years in technology trends in the global semiconductor etching agent market?