Polypropylene Resin Market in Thailand Trends and Forecast

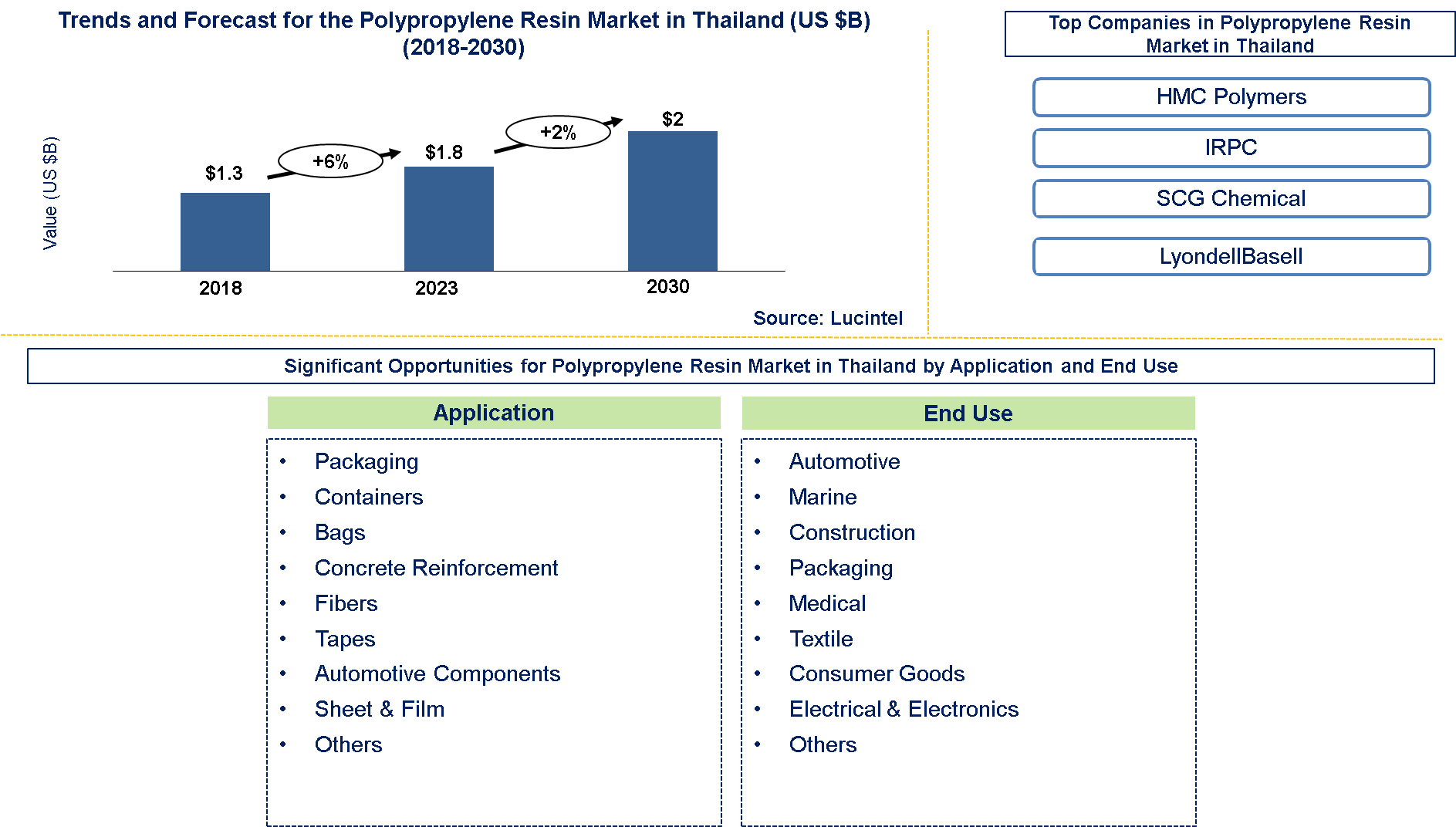

Lucintel finds that the future of the polypropylene resin market in Thailand is expected to reach an estimated $2 billion by 2030 with a CAGR of 2% from 2023 to 2030. The major drivers in this market are increasing demand of polypropylene resin from packaging end use and the rising need of lightweight materials in the automotive components such as such as bumpers, instrument panels, and door trim.

In Thailand, polypropylene resin production depends on propylene sourced from petroleum refining and natural gas processing. Catalysts like Zeigler-Natta or metallocene are used in polymerization for controlling properties while enhancing performance by way of having additives such as antioxidants and stabilizers. Hydrogen or solvents can also be used. Global pricing is competitive largely influenced by propylene costs, production efficiency, and local demand. Polyethylene and polystyrene prices compete with these products. Competitiveness is also affected by the availability of feedstock as well as technological advancements. Resin prices are driven by market factors such as supply disruptions or regulatory changes which impact Thailand’s position among the global players in polymer resins.

• Lucintel forecast that packaging will remain the largest end use segment over the forecast period because it is the most cost-effective and safer material for packaging. Packaging is also expected to witness the highest growth over the forecast period.

• Packaging will remain the largest application over the forecast period due to the increasing use of polypropylene resin in packaging for its various properties such as; good mechanical properties at ambient temperature, low absorption of water, low density, and special grades for food contact etc.

Country wise Outlook for the Polypropylene Resin Market in Thailand

The polypropylene resin market in Thailand is witnessing substantial growth globally, driven by increased demand from various industries such as packaging, automotive, electrical and electronics, and construction. Major players in the market are expanding

Emerging Trends in the Polypropylene Resin Market in Thailand

Emerging trends in the polypropylene resin market in Thailand shaping its future applications and market dynamics:

1. Customization and Specialty Grades: Responding to specific industry requirements, Thai manufacturers have started providing customized and specialist polypropylene resin grades. Examples comprise of flame retardant grades, UV-resistant grades, compounds with antimicrobial properties etc.

2. Digital Transformation: The application of digital platforms or tools in supply chain management customer engagement or product development has revolutionized the polypropylene resin market in Thailand by making it possible for firms to be more agile responsive and transparent on the value chains across all sectors.

3. Bio-based Polypropylene: Thailand is no exception to global trends of an increasing interest in bio-based polypropylene. This has been through research efforts aimed at using renewable feed stocks and biodegradable additives in developing sustainable polypropylene products.

4. Smart Manufacturing: Industry 4.0 concepts such as automation, artificial intelligence (AI), robotics or Internet of Things (IoT) have found their way into Thai’s manufacturing processes involving polypropylene resin. These applications are meant to make production schedules optimized, produce quality control enhanced and operational efficiency improved.

5. Advanced Production Technologies: The world is moving towards the application of advanced production technologies that help to increase efficiency, reduce electricity use and enhance product value. Notably, metallocene catalysts and reactor improvements are gaining momentum as they allow for the creation of high-performance polypropylene resins.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Polypropylene Resin Market in Thailand

Recent developments in polypropylene resin market in Thailand by various companies highlight ongoing innovations and advancements across different sectors:

• Capacity Expansions: A number of large petrochemical companies in Thailand are expanding their polypropylene manufacturing capabilities including investing in new facilities and modernizing old ones in order to take care of the rising regional and global demand.

• Technological Innovations: These improvements include enhanced polymerization processes, catalyst technologies, and recycling technologies which reduce environmental impact and increase sustainability. Such advances are enhancing efficiency and product quality in polypropylene production.

• Market Diversification: Polymer resin made of polypropylene has many applications like packaging, automobile manufacturing, building construction, and medical needs. Research is now focused on development of custom-designed grades of polypropylenes for specific uses such as high performance automotive parts (HPAP), light weight packages (LWP) or even medical grade plastics (MGP).

• Sustainability Initiatives: There is a focus on promoting use of recycled Polypropylene and consequently reducing the environmental burden during its manufacture. Some firms are investing heavily in post-consumer waste recycling technologies that churn out resins containing recycled polyethylene terephthalate at high quality levels.

• Strategic Partnerships and Investments: Collaborations between Thai enterprises and international partners aim at harnessing technical know-how, market entry strategies as well as capital requirements. This leads to the creation of new alliances, sharing knowledge with foreign entities where jointly developed products can be sold abroad or simply accelerating innovation or penetrating markets through partnerships with other research institutions.

• Regulatory Compliance: Complying with international standards regarding quality assurance alongside environmental regulations is an absolute necessity. To maintain competitiveness on the market companies are investing into regulatory changes concerning safety-related issues about products, environmental impact assessments alongside sustainability certifications.

• Market Dynamics: Market fluctuations stem from price volatility, supply chain interruptions among other geopolitical aspects leading to market dynamics. Therefore firms adopt various strategic approaches like risk management strategies, diversifying supply chains while others try to make predictions about future developments in order to best deal with these challenges.

Strategic Growth Opportunities for Polypropylene Resin Market in Thailand

• Geographical Location and Advantage: It is best for Thailand that it is strategically placed in Southeast Asia allowing it to be utilized as a manufacturing and trading center thus offering several logistical benefits which can be used in exporting PP resin to other neighboring countries and beyond. In the world market, this geographical advantage has made Thailand to be more competitive than any other country especially in the Asia Pacific region where there is a steady increase in demand of PP resin across various industries.

• Well-established Industrial Base and Manufacturing Capabilities: Thai people have already developed their industrial base well with the established manufacturing capabilities found in automobile packaging, consumer goods, and electronics sectors among others. The automotive, packaging, consumer goods sectors are some amongst the many sectors where there is increased demand on PP resin because of its versatility, durability and cost-effectiveness. This has encouraged growth of PP resin industry through the presence of major multinational companies as well as local manufacturers who encourage technology advancement and product innovations.

• Rising Demand from Automotive and Packaging Sectors: Due to its lightweight characteristics and resistance to shock impact properties, interior components, bumpers as well as exterior trims made from PP resin are widely used within Thailand’s automotive sector. With an increasing consumer base coupled with government push factors resulting into constant growth experienced by the region’s automobile industry; this implies that demand for PP resin shall raise further more. Similarly, changing customer preferences, sustainability targets and e-commerce trends drive consumption of PP resin by packaging firms which manufacture flexible or rigid packing material.

• Emphasis on Sustainability and Circular Economy: As an outcome of increased global consciousness regarding ecological issues plastics industry circles now concentrate on sustainability along with the circular economy theme. There are efforts by Thailand towards promotion of sustainable practices alongside investments in recycling infrastructure meant to enhance recycling rates for plastics including those made from polypropylene (PP) resin. Through such concentration areas apart from supporting environmental objectives these might lead into new market spaces and compliance with environmental standards that are stringent for export destinations.

• Government Support and Infrastructure Development: This is because the Thai government has supportive policies, provides incentives to foreign investors and has embarked on infrastructure development initiatives aimed at fostering industrial growth among them the PP resin sector. For example, Thailand’s infrastructure investments such as ports, industrial parks, transportation networks etc. have created an enabling environment for manufacturing PP resin hence attracting FDI and enhancing industry competitiveness.

Polypropylene Resin Market in Thailand Drivers and Challenges

The polypropylene resin market in Thailand drives industrial growth with its versatility in packaging, automotive, construction, and consumer goods. Despite growth prospects fueled by industrial advancements, challenges like raw material price volatility and regulatory pressures pose significant considerations for stakeholders navigating this dynamic market landscape.

The key drivers for the polypropylene resin market in Thailand include:

1. Growing Demand in Packaging Industry: In packaging sectors, Polypropylene resin is extensively used due to its qualities like lightness, sturdiness and resistance to humidity. Its demand is driven by the growth of e-commerce and food packing sectors.

2. Expansion of the Automotive Sector: Thailand’s automotive industry which serves as a huge consumer of polypropylene resin for production of bumper and interior components makes substantial contribution to market demand.

3. Increasing Construction and Infrastructure Projects: Thailand’s ongoing infrastructure development initiatives make polypropylene resin applicable for pipes, fittings, insulation materials, etc., used in construction and infrastructure projects.

4. Growing Consumer Goods Manufacturing: Polypropylene resin is used in manufacturing consumer goods such as appliances and household items because it offers versatility for molding at reasonable costs.

The challenges facing the polypropylene resin market in Thailand include:

1. Volatility in Raw Material Prices: Thai manufacturers of polypropylene resin are affected by fluctuations inherent in crude oil prices since the product is petroleum based translating into higher costs of production which may impact on profit margins.

2. Environmental Regulations: There has been an increased push towards sustainable practices among producers due to rising regulatory pressures on plastic use and recycling standards that have added operational costs associated with investments made toward recycling technologies.

3. A Competitive Market Landscape: This implies that pricing strategies as well as market share dynamics are influenced by competition from global manufacturers or alternative materials present within the Thai polypropylene resin market.

4. Technological Advancements: New types of materials can be invented through innovations in chemistry of polymers and methods of their manufacture that might become alternatives or more efficient modes of production thus posing difficulties for old-style suppliers of polypropylene resins.

The market for polypropylene resin in Thailand is ready to grow due to an increase in demand from the packaging, automobiles, buildings, and consumer product industries. These sectors gain immensely from being able to use polypropylene resin because of its versatility and low cost. Nevertheless, environmental regulations, price fluctuations for raw materials, competition in the market as well as technological dislocation should make the participants reinvent themselves strategically. This will help them avoid or reduce risks and also benefit from new opportunities by focusing on sustainability programs, technological advances and market diversification strategies that are resilient to change in Thailand’s polypropylene resin industry.

Polypropylene resin Suppliers and Their Market Shares

In this Thailand competitive market, several key players such as HMC Polymers, IRPC, Asahi Kasei Corporation, SCG Chemical, and LyondellBasell etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at helpdesk@lucintel.com.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies polypropylene resin cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the polypropylene resin companies profiled in this report include.

• HMC Polymers

• IRPC

• SCG Chemical

• LyondellBasell

These companies have established themselves as leaders in the polypropylene resin market in Thailand, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations. The market share dynamics within the polypropylene resin market are evolving, with the entry of new players and the emergence of innovative polypropylene resin market in Thailand technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Polypropylene Resin Market in Thailand by Segment

The polypropylene resin market in Thailand is experiencing growth in a number of key sectors. Initially, this can be seen in the demand for packaging applications due to the expansion of the food and beverage industry. Second, it is apparent that there is growth in the automotive sector especially in lightweight parts and interior materials production. Thirdly, polypropylene resin used in pipes, fittings and insulation materials indicates a significant growth within building industry. Further still, electrical and electronic industries are using polypropylene resin as an insulator against electricity. Finally, medical packaging and devices are increasingly being made from polypropylene resins for use by health professionals.

Polypropylene Resin Market in Thailand by Application [Value ($M) and Volume (Kilotons) Analysis for 2018 – 2030]:

• Packaging

• Containers

• Bags

• Concrete Reinforcement

• Fibers

• Tapes

• Automotive Component

• Sheet & Film

• Others

Polypropylene Resin Market in Thailand by End Use [Value ($M) and Volume (Kilotons) Analysis for 2018 – 2030]:

• Automotive

• Marine

• Construction

• Packaging

• Medical

• Textile

• Consumer Goods

• Electrical & Electronics

• Others

Features of Recycled Carbon Fiber Market

• Market Size Estimates: polypropylene resin market in Thailand market size estimation in terms of value ($M) and volume (M Lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments.

• Segmentation Analysis: Market size by application and end use.

• Growth Opportunities: Analysis of growth opportunities in different applications and end uses for the polypropylene resin market in Thailand.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the polypropylene resin market in Thailand.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in polypropylene resin or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the polypropylene resin market in Thailand market size?

Answer: The polypropylene resin market in Thailand is expected to reach an estimated $2 billion by 2030.

Q2. What is the growth forecast for polypropylene resin market in Thailand?

Answer: The polypropylene resin market in Thailand is expected to grow at a CAGR of 2% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the polypropylene resin market in Thailand?

Answer: The major drivers in this market are increasing demand of polypropylene resin from packaging end use and the rising need of lightweight materials in the automotive.

Q4. What are the major applications for polypropylene resin market in Thailand?

Answer: Packaging and containers are the major applications of polypropylene resin market in Thailand.

Q5. What are the emerging trends in polypropylene resin market in Thailand?

Answer: Emerging trends, which have a direct impact on the dynamics of the polypropylene resin market in Thailand, includes customization and specialty grades, digital transformation, bio-based polypropylene, smart manufacturing, and advanced production technologies.

Q6. Who are the key polypropylene resin companies in Thailand?

Answer: Some of the key polypropylene resin companies in Thailand are as follows:

• HMC Polymers Co. Ltd.

• IRPC Public Co. Ltd.

• SCG Chemical Public Co. Ltd.

• LyondellBasell

Q7.Which polypropylene resin market in Thailand application segment will be the largest in future?

Answer: Lucintel forecast that packaging will remain the largest segment over the forecast period due to the increasing use of polypropylene resin in packaging for its various properties such as; good mechanical properties at ambient temperature, low absorption of water, low density, and special grades for food contact etc.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the polypropylene resin market in Thailand by application (packaging, containers, bags, concrete reinforcement, fibers, tapes, automotive component, sheet & film, and others) and end use (automotive, marine, construction, packaging, medical, textile, consumer goods, electrical & electronics, and others)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.4 What are the business risks and threats to the market?

Q.5 What are the emerging trends in this market and the reasons behind them?

Q.6 What are the changing demands of customers in the market?

Q.7 What are the new developments in the market? Which companies are leading these developments?

Q.8 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.9 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.10 What M & A activities have taken place in the last 5 years in this market?