Piezo Film Sensor Market Trends and Forecast

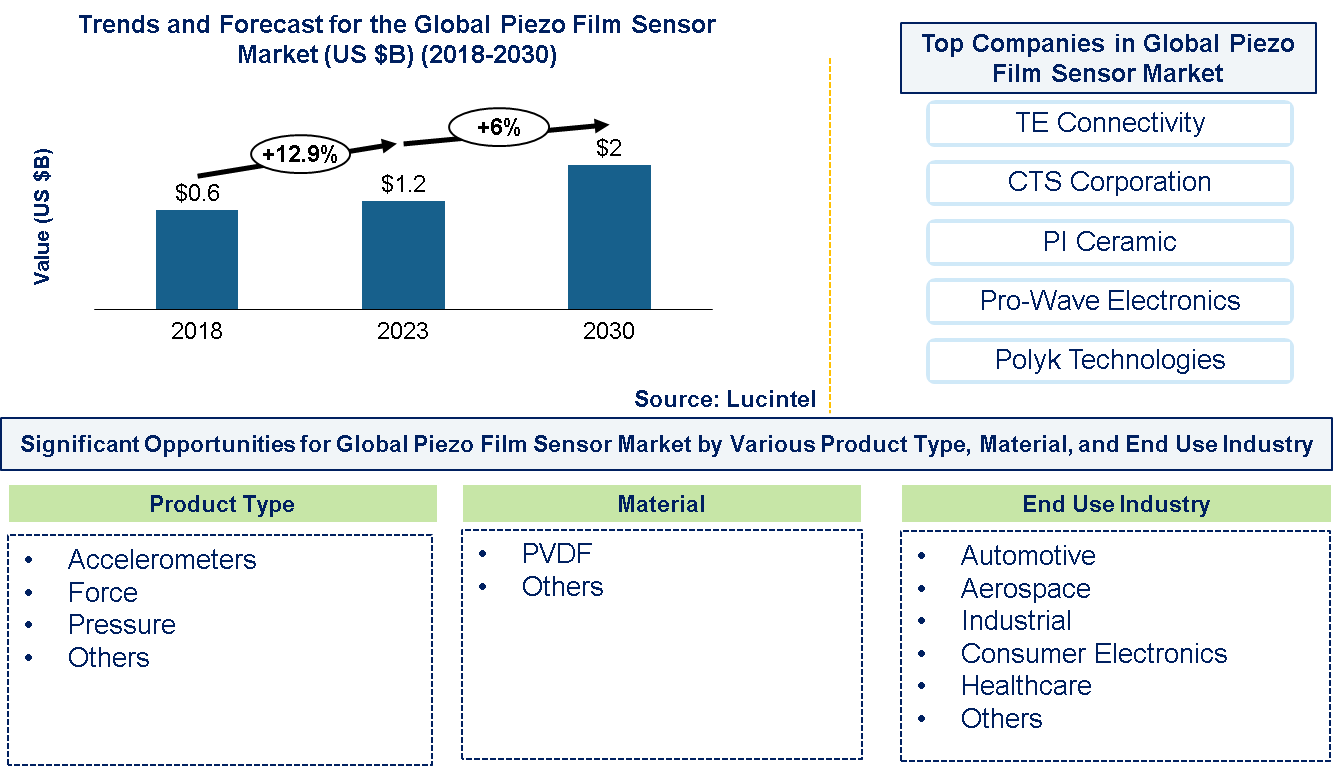

Lucintel finds that the future of the global piezo film sensor market looks promising with opportunities in the automotive, aerospace, industrial, consumer electronics, and healthcare industries. The global piezo film sensor market is expected to reach an estimated $2 billion by 2030 with a CAGR of 6% from 2024 to 2030. The major growth drivers for this market are growing usage of piezo film sensor in the microelectronics and semiconductor industries and growing demand in the medical and automotive sectors.

Piezo film sensors are primarily made from polyvinylidene fluoride (PVDF), a highly sensitive polymer that exhibits strong piezoelectric properties. This material is often processed into thin, flexible films that can detect mechanical changes and convert them into electrical signals. Additional raw materials include electrodes made from conductive metals such as silver, copper, or gold, which are deposited onto the PVDF film to facilitate signal transmission. Other components may include protective layers or coatings to enhance durability and performance in various environments. The price of piezo film sensors generally falls in the mid to high range compared to other sensor technologies. While they tend to be more expensive than traditional mechanical or capacitive sensors, their unique properties, such as flexibility, high sensitivity, and durability, justify the cost for many applications. Competing technologies like MEMS (Micro-Electro-Mechanical Systems) sensors may offer lower prices but lack the specific advantages of piezo film sensors in terms of form factor and performance in dynamic environments.

• Lucintel forecasts that consumer electronics will remain the largest end use industry segment over the forecast period, as it exhibits higher piezoelectricity than other polymers and produces electrical signals in response to temperature variations.

• PVDF will remain the largest material segment over the forecast period, as it exhibits higher piezoelectricity than other polymers and produces electrical signals in response to temperature variations.

• Asia Pacific will remain the largest region over the forecast period due to growth in the consumer electronics and automotive industries and rising adoption of piezo film sensor as tilt sensor and pressure sensor in consumer electronics.

Country wise Outlook for the Piezo Film Sensor Market

The piezo film sensor market is witnessing substantial growth globally, driven by increasing demand in consumer electronics and rising integration of piezo film sensors in automotive applications including engine management. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major piezo film sensor producers in key regions: the USA, China, Germany, Japan, and South Korea.

Emerging Trends in the Piezo Film Sensor Market

Emerging trends in piezo film sensor are shaping its future applications and market dynamics:

• Miniaturization and Integration: Manufacturers of piezo film sensors are focusing on miniaturization and integration to meet the demands of compact electronic devices and IoT applications. This trend involves shrinking sensor sizes while maintaining or improving sensitivity and performance.

• Advancements in Sensing Technology: Ongoing research and development efforts are leading to advancements in piezo film sensing technology, resulting in sensors with improved sensitivity, reliability, and accuracy. These developments enable piezo film sensors to be used in a wider range of applications, including medical devices, industrial equipment, and consumer electronics.

• Application in Healthcare Monitoring: Piezo film sensors are increasingly being used in healthcare monitoring devices for applications such as heart rate monitoring, respiratory rate monitoring, and movement detection. The flexibility and conformability of piezo film sensors make them suitable for wearable and non-invasive medical devices.

• Emerging use in Structural Health Monitoring: Piezo film sensors are finding applications in structural health monitoring (SHM) systems for monitoring the integrity and performance of civil infrastructure, such as bridges, buildings, and pipelines. These sensors can detect changes in vibration, strain, and pressure, providing valuable data for maintenance and safety purposes.

• Incorporation in Touch and Haptic Feedback Devices: Piezo film sensors are being integrated into touch-sensitive and haptic feedback devices, such as touchscreens, touchpads, and tactile feedback systems. The ability of piezo film sensors to detect pressure and touch gestures enables enhanced user interaction and immersive experiences in consumer electronics and gaming applications.

• Focus on Energy Harvesting: Piezo film sensors have the capability to convert mechanical energy into electrical energy through the piezoelectric effect. As a result, thereÄX%$%Xs growing interest in using piezo film sensors for energy harvesting applications, where they can capture ambient vibrations and movements to generate power for low-power electronic devices and wireless sensor networks.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by Piezo Film Sensor

Recent developments in piezo film sensor market which highlights ongoing innovations and advancements across different sectors:

• Consumer Electronics: Companies like Murata Manufacturing and TDK Corporation are developing piezo film sensors for enhanced touchscreens and haptic feedback in smartphones and wearable devices, improving user experience and device functionality.

• Automotive Industry: Piezo film sensors are being integrated into advanced driver assistance systems (ADAS) and autonomous vehicles for applications such as gesture recognition, seat occupancy sensing, and tire pressure monitoring, contributing to vehicle safety and efficiency.

• Healthcare: Advancements in piezo film sensor technology are enabling applications in medical devices for non-invasive diagnostics, ultrasound imaging, and smart prosthetics, offering precise and reliable patient monitoring and treatment solutions.

• Industrial Automation: Piezo film sensors are increasingly used in industrial automation for vibration monitoring, precision measurement, and ultrasonic sensing in machinery and equipment, enhancing operational efficiency and predictive maintenance capabilities.

• Robotics: Innovations in piezo film sensors are facilitating tactile sensing and force feedback in robotics, improving robotic interaction capabilities in manufacturing, healthcare, and service robotics applications.

Strategic Growth Opportunities for Piezo Film Sensor Market

The piezo film sensor market is poised for promising growth, driven by its unique properties and expanding applications. Some key strategic growth opportunities for this market include:

Technological Advancements:

• Enhanced Sensitivity and Miniaturization: Developing piezo film sensors with higher sensitivity will open doors to new applications requiring precise pressure or vibration detection. Additionally, miniaturized sensors will cater to the growing demand for compact and integrated devices in wearables, robotics, and Internet of Things (IoT) applications.

• Material Innovation: Research into novel materials with improved piezoelectric properties can lead to sensors with wider operating temperature ranges, better durability, and potentially lower costs. This will broaden their applicability in harsh environments and cost-sensitive sectors.

• Integration with Electronics: Developing seamless integration of piezo film sensors with microcontrollers and wireless communication modules will create smart sensor systems. These systems can offer real-time data collection, analysis, and transmission, expanding their value proposition across various industries.

Diversification of Applications:

• Medical Diagnostics: Piezo film sensors hold potential for wearable health monitoring devices for tracking vital signs like heart rate and respiration. Additionally, they can be integrated into diagnostic tools for pressure mapping in wound care or tremor detection in neurological disorders.

• Structural Health Monitoring: These sensors can be embedded in structures like bridges, buildings, and aircraft to monitor stress and strain levels, enabling preventative maintenance and early detection of potential failures.

• Smart Agriculture and Environmental Monitoring: Piezo film sensors can be used in smart irrigation systems to optimize water usage based on soil moisture content. Additionally, they can be employed in environmental monitoring applications to track parameters like wind speed and direction.

• Consumer Electronics: The touch screens in modern smartphones and tablets often utilize piezo film technology. Further advancements can lead to more responsive and pressure-sensitive touchscreens, enhancing user experience in various consumer electronics.

Regional Expansion:

• Focus on Emerging Markets: The Asia Pacific region, with its rapid industrial growth and increasing automation adoption, is a promising market for piezo film sensors. Manufacturers can target this region by establishing local production facilities or partnerships to cater to the growing demand.

• Investment in Infrastructure: Developing countries often lack the infrastructure for advanced sensor technology adoption. Strategic partnerships with governments or private companies can help establish the necessary infrastructure and create new market opportunities.

Collaboration and Partnerships:

• Cross-industry Collaboration: Collaboration between piezo film sensor manufacturers and companies in various end-use industries can accelerate innovation and application development. This can lead to the creation of customized sensor solutions tailored to specific industry needs.

• Academia-Industry Partnerships: Partnerships between research institutions and sensor manufacturers can foster research and development in novel materials and applications for piezo film sensors. This collaborative approach can drive technological advancements and accelerate market growth.

By capitalizing on these strategic growth opportunities, the piezo film sensor market can unlock its full potential and become an even more vital component in various industries, contributing to technological advancements, improved efficiency, and innovative product development.

Piezo Film Sensor Market Driver and Challenges

The piezo film sensor market is influenced by various drivers and faces specific challenges that impact its growth and adoption.

The factors responsible for driving the piezo film sensor market include:

1. Growing Demand in Consumer Electronics: Piezo film sensors are increasingly used in consumer electronics such as touchscreens, wearables, and mobile devices for applications like touch sensing and haptic feedback. The proliferation of smartphones and wearable devices drives the demand for sensitive, reliable, and cost-effective sensing technologies.

2. Expansion in Healthcare Applications: The healthcare industry utilizes piezo film sensors in medical devices for applications such as diagnostic tools, patient monitoring, and biomedical imaging. The sensorsÄX%$%X ability to accurately detect physiological signals like heartbeat, respiration, and pressure supports advancements in telemedicine, remote patient monitoring, and healthcare diagnostics.

3. Advancements in Industrial Automation: Piezo film sensors play a vital role in industrial automation for sensing applications in robotics, machinery vibration monitoring, and precision control systems. The sensorsÄX%$%X capability to detect minute changes in pressure, force, and acceleration contributes to enhancing operational efficiency, reducing downtime, and ensuring product quality in manufacturing environments.

4. Emerging Applications in Automotive Sector: The automotive industry utilizes piezo film sensors for various applications, including automotive safety systems (e.g., airbag deployment), tire pressure monitoring, and engine performance monitoring. As vehicle manufacturers focus on enhancing vehicle safety, comfort, and efficiency, the demand for reliable and durable sensing technologies continues to grow.

5. Advances in Material and Manufacturing Technologies: Continuous advancements in piezo film materials, fabrication techniques, and integration methods enhance sensor performance, reliability, and cost-effectiveness. These advancements drive innovation in sensor design, enabling new applications and expanding market opportunities.

Challenges facing the piezo film sensor market are:

1. Complex Integration Requirements: Integrating piezo film sensors into complex electronic systems or structures requires specialized expertise and precise calibration to ensure accurate and reliable sensor performance. Challenges may arise in achieving consistent sensor response across different environmental conditions and operating environments.

2. Cost Considerations: The initial cost of piezo film sensors and associated electronics may be higher compared to conventional sensing technologies, impacting adoption in price-sensitive markets. Manufacturers face challenges in balancing sensor performance, durability, and cost-effectiveness to meet diverse customer requirements and competitive market pricing.

3. Environmental Factors: Piezo film sensors may be sensitive to environmental factors such as temperature fluctuations, humidity, and mechanical stress, which can affect sensor accuracy and reliability over time. Addressing environmental stability and robustness is crucial to ensuring long-term sensor performance in various applications and operating conditions.

4. Competition from Alternative Technologies: Alternative sensing technologies, such as capacitive sensors, optical sensors, and MEMS sensors, pose competitive challenges to piezo film sensors. Manufacturers must differentiate their offerings based on unique sensor capabilities, performance advantages, and specific application requirements to maintain market competitiveness.

5. Regulatory and Standards Compliance: Compliance with industry standards and regulatory requirements, particularly in sectors such as healthcare and automotive, poses challenges for piezo film sensor manufacturers. Adhering to stringent safety, reliability, and performance standards is essential to gaining market acceptance and securing long-term partnerships with industry stakeholders.

Navigating these drivers and challenges requires ongoing investment in research and development, collaboration with industry partners, and adaptation to evolving market demands. Piezo film sensor manufacturers and stakeholders must innovate continuously to capitalize on growth opportunities, address market challenges effectively, and drive adoption across diverse applications and industries.

Piezo Film Sensor Suppliers and Their Market Shares

The piezo film sensor market is dominated by several key suppliers, including TE Connectivity, Kureha Corporation, APC International, Noliac AS. These companies hold significant market shares due to their continuous innovation, strategic partnerships, and expansion efforts in various high-demand applications such as medical devices, consumer electronics, automotive systems, and industrial monitoring. To know the current market share of each of major players contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies piezo film sensor companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the piezo film sensor companies profiled in this report includes.

• TE Connectivity

• Kureha Corporation

• APC International

• Noliac AS

• Measurement Specialties Inc.

• PI Ceramic GmbH

These companies have established themselves as leaders in the piezo film sensor industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the piezo film sensor market are evolving, with the entry of new players and the emergence of innovative piezo film sensor technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Piezo Film Sensor Market by Segment

The major segments of the piezo film sensor market experiencing significant growth include wearable technology, medical devices, and industrial monitoring. In wearable technology, the demand for flexible, lightweight sensors is driving adoption for health monitoring and fitness tracking applications. Medical devices benefit from piezo film sensorsÄX%$%X high sensitivity and reliability, essential for diagnostic and therapeutic equipment. Industrial monitoring is also expanding, with piezo film sensors being used for precision measurements and real-time data acquisition in various industrial processes. Additionally, the automotive sector is seeing increased use of these sensors for applications like vibration monitoring and safety systems.

This piezo film sensor market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including product type, material, and end use industries. The report offers insights into regional dynamics, highlighting the major markets for piezo film sensor and their growth potentials. The study includes trends and forecast for the global piezo film sensor market by product type, material, end use industry, and region as follows:

Piezo Film Sensor Market by Product Type [Value ($B) Analysis for 2018 – 2030]:

• Piezoelectric Accelerometers

• Piezoelectric Force Sensor

• Piezoelectric Pressure Sensor

Piezo Film Sensor Market by Material [Value ($B) Analysis for 2018 – 2030]:

• Ceramic Crystal Films

• PVDF Films

Piezo Film Sensor Market by End Use Industry [Value ($B) Analysis for 2018 – 2030]:

• Automotive

• Aerospace

• Industrial

• Healthcare

• Consumer Electronics

• Others

Piezo Film Sensor Market by Region [Value ($B) Analysis for 2018 – 2030]:

• North America

o US

o Canada

o Mexico

• Europe

o Germany

o The United Kingdom

o Italy

• Asia Pacific

o China

o Japan

o India

o South Korea

• The Rest of the World

Features of Piezo Film Sensor Market

• Market Size Estimates: Piezo film sensor cleanser market size estimation in terms of value ($B)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by product type, material, and end use industry.

• Regional Analysis: Piezo film sensor market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different product type, material, and end use industry, and regions for the piezo film sensor market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the piezo film sensor market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

FAQ

Q1. What is the piezo film sensor market size?

Answer: The global piezo film sensor market is expected to reach an estimated $2 billion by 2030.

Q2. What is the growth forecast for piezo film sensor market?

Answer: The piezo film sensor market is expected to grow at a CAGR of 6% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the piezo film sensor market?

Answer: The major growth drivers for this market are growing usage of piezo film sensor in the microelectronics and semiconductor industries and growing demand in the medical and automotive sectors.

Q4. What are the major applications or end use industries for piezo film sensor?

Answer: Consumer electronics and automotive are the major end use industries for piezo film sensor.

Q5. Who are the key piezo film sensor companies?

Answer: Some of the key piezo film sensor companies are as follows:

• TE Connectivity

• Kureha Corporation

• APC International

• Noliac AS

• Measurement Specialties Inc.

• PI Ceramic GmbH

Q7. Which piezo film sensor product segment will be the largest in future?

Answer: Lucintel forecasts that PVDF will remain the largest material segment over the forecast period, as it exhibits higher piezoelectricity than other polymers and produces electrical signals in response to temperature variations.

Q8. In piezo film sensor market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 7 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global piezo film sensor market by product type (piezoelectric accelerometers, piezoelectric force sensor, and piezoelectric pressure sensor), material (ceramic crystal films and PVDF films), end use industry (automotive, aerospace, industrial, healthcare, consumer electronics, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 7 years in this market?