North American Reinforced Thermoplastic Pipe Market Trends and Forecast

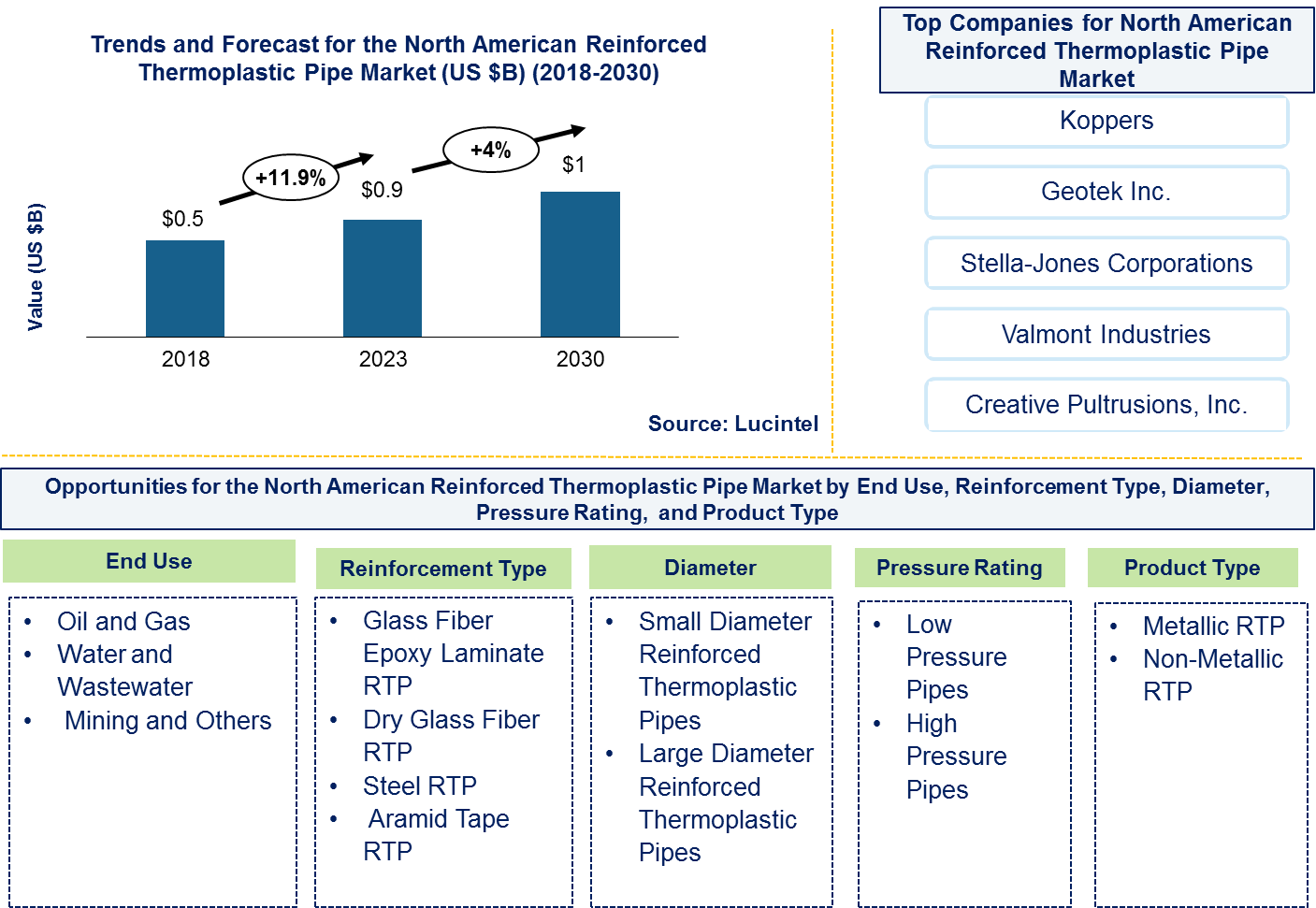

The future of the North American reinforced thermoplastic pipe market looks promising with opportunities in the oil and gas, water and wastewater, and mining & other applications. The North American reinforced thermoplastic pipe market is expected to reach an estimated $1 billion by 2030 with a CAGR of 4% from 2023 to 2030. The major drivers for this market are increasing old pipeline replacement, growing oil and gas industry, and new pipeline construction activities.

The basic raw materials employed in the North American reinforced thermoplastic pipe (RTP) market are usually polymers such as polyethylene (PE), polypropylene (PP) and PVDF, which are reinforced with materials such as glass fiber or aramid fiber. In various industrial applications, these substances help in overcoming harsh conditions through their durability, chemical resistance, and flexibility. The North American RTP market generally sells at comparable prices when comparing it to traditional steel and concrete piping systems due to its lightweight nature, ease of installation and corrosion resistant properties. However prices depend on specific project requirements but more often than not RTP offers cost benefits compared to rivals based on lifecycle costs and installation expenses.

• Lucintel forecasts that glass fiber epoxy laminate reinforced RTP will remain the largest reinforcement type segment over the forecast period due to their cost advantages and high performance in extreme conditions of high pressure and high temperature.

• Within this market, oil and gas will remain the largest application segment over the forecast period due to increasing old pipeline replacement with reinforced thermoplastic pipes.

Country wise Outlook for the North American Reinforced Thermoplastic Pipe Market

The North American reinforced thermoplastic pipe market is experiencing significant global growth, driven by increasing demand across various industries such as oil and gas, water treatment, and mining. This expansion is driven by the pipe's advantages including corrosion resistance, lightweight design, and ease of installation, which contribute to reduced operational costs and enhanced environmental sustainability. Below image highlights recent developments by major North American reinforced thermoplastic pipe market producers in key regions: Canada and USA

Emerging Trends in the North American Reinforced Thermoplastic Pipe Market

Emerging trends in the North American reinforced thermoplastic pipe market shaping its future applications and market dynamics:

• Oil and Gas Expansion: RTP is increasingly becoming the preferred choice for oil and gas pipelines because of its rust resistance, lightness, and ease of installation mainly under extreme conditions such as offshore fields.

• Composite materials development: Continual improvement in resin formulations and reinforcement materials has made RTP more pressure tolerant, thermally stable and durable than before thus increasing its applications in different sectors of the economy.

• Sustainability Initiatives: The focus on sustainability is driving the increased use of recyclable, eco-friendly materials for RTP. This reflects current environmental regulations and corporate commitments towards sustainability goals.

• Digitalization and IoT Integration: The integration of digital solutions like IoT sensors along with predictive analytics allows improved monitoring capabilities for RTP which enhance maintenance schedules optimization while improving overall operational efficiency.

A total of more than 150 page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments in the North American Reinforced Thermoplastic Pipe Market

Recent developments in North American reinforced thermoplastic pipe market which highlights ongoing innovations and advancements across different sectors:

• RTP in Several Applications: In oil and gas transportation, water and wastewater management, mining operations, and chemical processing among others, RTP is increasingly been used. This development demonstrates the flexibility and dependability of RTP in many industries.

• Technological Developments: Manufacturers are constantly improving RTP through new materials, manufacturing processes, and design capabilities. For example improved resins formulation, carbon fiber as reinforcement material and new ways of manufacturing to ensure higher performance and longer life of products.

• Environmental Friendliness: The use of recyclable materials has increased within the RTP industry. Some manufacturers have also started using bio-based resins while others have initiated measures to reduce carbon footprints both during production and operation. These actions conform to environmental targets set at large as well as regulatory rules governing all sectors.

• Digital Integration: There is a growing trend where digitalization has affected the RTP industry since IoT sensors are being used for real-time monitoring purpose; there is predictive maintenance using digital twin technology; plus advanced data analytics enables decisions making process. Thus these technologies make an improvement on operational efficiency as well as reliability of the entire system of RTP.

Strategic Growth Opportunities for North American Reinforced Thermoplastic Pipe Market

The North American reinforced thermoplastic pipe market is very dynamic due to its role in addressing infrastructure needs, advancements in materials and manufacturing technologies, and increasing demand across diverse industries such as oil and gas, water management, and industrial applications.

Some key strategic growth opportunities for this market include:

Increasing Demand in Oil and Gas Industry:

• Corrosion resistance, durability, and ability to withstand harsh environments are among the reasons why RTPs are gaining traction in the oil and gas industry. As oil and gas exploration moves to deeper waters and challenging terrains, there is a need for reliable pipeline solutions that can reduce maintenance costs while guaranteeing long-term performance. Manufacturers can grab tremendous growth opportunities by using RTPs offshore or onshore.

Infrastructure Renewal and Replacement Projects:

• There is an increasing demand for tough pipes resistant to corrosion as old infrastructure in North America decays especially in water distribution, wastewater management, as well as industrial sectors. These lightweight built pipes provide easy installation, resist chemical corrosion hence fit for replacing age-long pipes alongside modernizing prevailing systems. The market growth rate is also influenced through governmental investments into infrastructure renewal projects.

Advancements in Composite Materials and Manufacturing Technologies:

• The performance attributes of RTPs are improved by technological breakthroughs in composite materials, resin formulations, as well as manufacturing processes. For example; innovations made on reinforcement fibers like carbon fibers, glass fiber or aramid fibers help to enhance the strength, flexibility or even the corrosion resistance of RTPS products. It will only be through intense R&D investment from manufacturers who want to develop high-performance RTP’s that meet strict industry standards and regulatory requirements that they can differentiate themselves from others.

Focus on Environmental Sustainability:

• When pipeline projects are undertaken environmental issues have become more significant now than before. Environmentally friendly conscious industries including regulatory bodies prefer recyclable lower carbon footprint compared to traditional materials like steel which makes them appealing towards RTPs. Companies that make these eco-friendly RTPs available together with those that engage in sustainable manufacturing practices will be able to take advantage of this trend thereby gaining competitive edge.

Expansion in Water and Wastewater Management:

• RTPs are being adopted by water and wastewater management industry in North America for use in water supply pipelines, sewer systems and stormwater management. This is because they are resistant to corrosion, abrasion, chemicals hence it makes them the most suitable pipes for various fluid and wastewater effluent applications. The demand for RTPs is expected to rise as municipalities and utilities upgrade their infrastructure to meet increasing water demands as well as regulatory standards.

Emerging Applications in Industrial and Mining Sectors:

• Applications of RTPs are increasing in industrial sectors such as mining, chemical processing or even power generation. These industries need pipes that can be used against corrosive chemicals, high temperatures and abrasive materials. Such demanding conditions can only be answered using RTPS offering versatility and customizability. Conversely, it is only those manufacturers tailoring their RTP solutions according to specific requirements of a particular sector that thrive through accessing niche markets.

Strategic Partnerships and Market Expansion:

• In the North American RTP market; strategic alliances with engineering firms, contractors or end-users will foster market expansion. These partnerships facilitate product development, project execution together with market penetration efforts by these companies. Also having regional manufacturing facilities or distribution networks may help in improving efficiency along supply chain including quick response time on local demands.

By taking advantage of these strategic growth opportunities, the North American reinforced thermoplastic pipe market can realize its full potential and transform numerous industries through enhanced durability, cost-effectiveness, and environmental sustainability in sectors such as oil and gas, water management, and industrial applications.

North American Reinforced Thermoplastic Pipe Market Driver and Challenges

North American Reinforced Thermoplastic Pipe Market plays a pivotal role across industries such as oil and gas, water distribution, and chemical processing, leveraging its lightweight, corrosion-resistant properties to enhance infrastructure durability and efficiency.

The key drivers for the North American reinforced thermoplastic pipe market include:

1. Cost Effectiveness: RTP has cost advantages compared to conventional materials like steel and concrete due to lower costs of installation, maintenance, shorter downtime periods and long life span.

2. Corrosion Resistance: Being resistant to corrosion as a natural characteristic of the material makes it an ideal choice in industries such as oil & gas, water treatment and chemical processing where the pipe is exposed to conditions that eat away at traditional pipe materials.

3. Light Weight and Easy Installation: The lightweight nature of RTP simplifies transportation, handling and installation leading to faster project completion times and reduced labor costs.

4. Flexibility and Durability: The flexibility of RTP allows it to endure harsh operating environments including temperature fluctuations or pressure changes while still maintaining its structural integrity over time.

The challenges facing the North American reinforced thermoplastic pipe market include:

1. Material Selection and Performance: It can be difficult to choose the right combination of materials (resins/reinforcement) aimed at addressing specific application requirements because different surrounding conditions necessitate tailor-made answers.

2. Perception and Market Education: One obstacle may be educating end-users and stakeholders about the benefits and abilities of RTP compared with traditional materials especially when certain industries have strong preferences for steel or concrete.

3. Competitive Market Landscape: Therefore, as a result of competition from other piping materials, alternative solutions therefore make it important for manufacturers of RTPs continually improve their product positioning by innovating new products that will differentiate them on performance basis but also cost-effective ones.

4. Regulatory Compliance: Adhering to regulatory standards and certifications for RTP materials and installation practices can pose challenges, especially as regulations evolve and vary across different jurisdictions.

Innovations in material science and manufacturing processes have spurred strong demand for the North American reinforced thermoplastic pipe market, showcasing advancements like enhanced composite materials and improved manufacturing techniques. These developments offer lightweight, corrosion-resistant solutions ideal for diverse applications in oil and gas, water management, and industrial sectors.

North American Reinforced Thermoplastic Pipe Market Suppliers and their Market Shares

In this globally competitive market, several key players such as Bakers Hughes Company, Techinp FMC PLC, National Olivewell Varco Inc., Shawcor Ltd., Weinerberger Inc., etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies, North American reinforced thermoplastic pipe market companies cater to increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the North American reinforced thermoplastic pipe market companies profiled in this report include-

• Bakers Hughes Company

• Techinp FMC PLC

• National Olivewell Varco Inc.

• Shawcor Ltd.

• Weinerberger Inc.

These companies have established themselves as leaders in the North American reinforced thermoplastic pipe market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the North American reinforced thermoplastic pipe market are evolving, with the entry of new players and the emergence of innovative North American reinforced thermoplastic pipe technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

North American Reinforced Thermoplastic Pipe Market by Segment

Major segments of the North American reinforced thermoplastic pipe market experiencing growth include applications in the oil and gas industry, where RTPs are valued for their corrosion resistance and durability, particularly in offshore drilling and pipeline projects. Additionally, the water management sector is seeing increased adoption of RTPs due to their ability to withstand harsh environmental conditions and provide reliable performance in water distribution networks and wastewater treatment facilities.

This North American reinforced thermoplastic pipe market report provides a comprehensive analysis of the market's current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including North American reinforced thermoplastic pipe market end use, reinforcement type, diameter, pressure rating and product type. The report offers insights into regional dynamics, highlighting the major markets for North American reinforced thermoplastic pipe market and their growth potentials. The study includes trends and forecast for the North American reinforced thermoplastic pipe market by end use, reinforcement type, diameter, pressure rating, product type and country as follows:

By End Use [Value ($ Million) and Volume (Thousand Meters) for 2018 – 2030]:

• Oil and Gas

• Onshore

• Offshore

• Water and Wastewater

• Mining and Others

By Reinforcement Type [Value ($ Million) and Volume (Thousand Meters) for 2018 – 2030]:

• Glass Fiber Epoxy Laminate-Reinforced Thermoplastic Pipes

• Dry Glass Fiber-Reinforced Thermoplastic Pipes

• Steel-Reinforced Thermoplastic Pipes

• Aramid Tape-Reinforced Thermoplastic Pipes

By Diameter [Value ($ Million) and Volume (Thousand Meters) for 2018 – 2030]:

• Small Diameter Pipes

• Large Diameter Pipes

By Pressure Rating [Value ($ Million) and Volume (Thousand Meters) for 2018 – 2030]:

• Low Pressure Pipes

• High Pressure Pipes

By Product Type [Value ($ Million) and Volume (Thousand Meters) for 2018 – 2030]:

• Metallic Reinforced Thermoplastic Pipes

• Non-Metallic Reinforced Thermoplastic Pipes

By Country [Value ($ Million) for 2018 – 2030]:

• United States

• Canada

• Mexico

Features of the North American Reinforced Thermoplastic Pipe Market

• Market Size Estimates: North American reinforced thermoplastic pipe market size estimation in terms of value ($M) and volume (Thousand Meters).

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments.

• Segmentation Analysis: North American reinforced thermoplastic pipe market size by various segments, such as application, reinforcement type, diameter, pressure rating, and product type in terms of value and volume.

• Country Analysis: North American reinforced thermoplastic pipe market breakdown by the United States, Canada, and Mexico.

• Growth Opportunities: Analysis of growth opportunities in different application, reinforcement type, diameter, pressure rating, and product type for the North American reinforced thermoplastic pipe market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape of the North American reinforced thermoplastic pipe market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in North American reinforced thermoplastic pipe market, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the North American reinforced thermoplastic pipe size?

Answer: The North American reinforced thermoplastic pipe market is expected to reach an estimated $4 billion by 2030.

Q2. What is the growth forecast for North American reinforced thermoplastic pipe market?

Answer: The North American reinforced thermoplastic pipe market is expected to grow at a CAGR of 1% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the North American reinforced thermoplastic pipe market?

Answer: The major drivers for this market are increasing old pipeline replacement, growing oil and gas industry, and new pipeline construction activities.

Q4. What are the major segment for North American reinforced thermoplastic pipe?

Answer: Oil and gas segment are the major end use segments for North American reinforced thermoplastic pipe.

Q5. What are the emerging trends in North American reinforced thermoplastic pipe market?

Answer: Emerging trends, which have a direct impact on the dynamics of the North American reinforced thermoplastic pipe industry, includes expansion in oil and gas, advancements in composite materials, integration of digitalization solution, and growing emphasis on sustainability initiatives.

Q6. Who are the key North American reinforced thermoplastic pipe companies?

Answer: Some of the key North American reinforced thermoplastic pipe companies are as follows:

• Bakers Hughes Company

• Techinp FMC PLC

• National Olivewell Varco Inc.

• Shawcor Ltd.

• Weinerberger Inc.

Q7.Which North American reinforced thermoplastic pipe product segment will be the largest in future?

Answer: Lucintel forecasts that oil and gas segment will remain the largest segment due to its critical role in global energy supply, ongoing exploration and production activities, and the need for advanced technologies to enhance extraction efficiency.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the North American reinforced thermoplastic pipe market by end use (oil & gas, water & wastewater, and mining & others), reinforcement type (glass fiber epoxy laminate RTP, dry glass fiber RTP, steel RTP, and aramid tape RTP), diameter (small diameter pipes and large diameter pipes), pressure rating (low pressure pipes and high pressure pipes), and product type (metallic and non-metallic reinforced thermoplastic pipes)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which country will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the North American reinforced thermoplastic pipe market?

Q.5 What are the business risks and threats to the North American reinforced thermoplastic pipe market?

Q.6 What are emerging trends in this reinforced thermoplastic pipe market and the reasons behind them?

Q.7 What are some changing demands of customers in this reinforced thermoplastic pipe market?

Q.8 What are the new developments in this reinforced thermoplastic pipe market?

Which companies are leading these developments?

Q.9 Who are the major players in this reinforced thermoplastic pipe market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this reinforced thermoplastic pipe market, and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M&A activities did take place in the last five years in the North American reinforced thermoplastic pipe market?

For any questions related to North American reinforced thermoplastic pipe market or related to North American reinforced thermoplastic pipe companies, North American reinforced thermoplastic pipe market size, North American reinforced thermoplastic pipe market share, North American reinforced thermoplastic pipe market growth, North American reinforced thermoplastic pipe market research, write Lucintel analyst at email: helpdesk@lucintel.com we will be glad to get back to you soon.