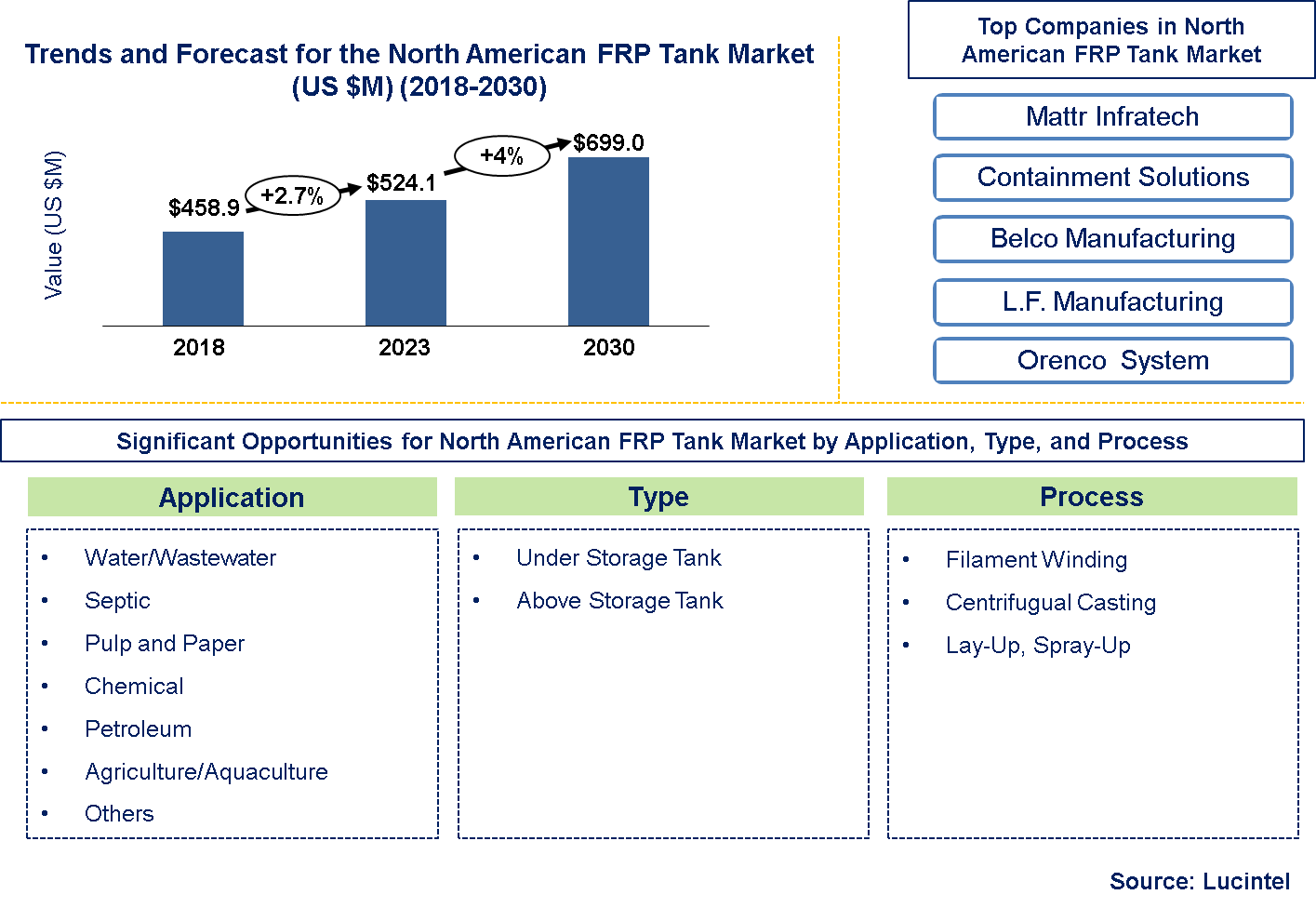

North American FRP Tank Market Trends and Forecast

Lucintel finds that the future of composite product of the North American FRP tank market looks promising with opportunities in water/wastewater, septic, pulp and paper, chemical, petroleum, and agriculture/aquaculture applications. The North American FRP tank end product market is expected to reach an estimated $699 million by 2030 with a CAGR of 4% 2023 to 2030. The major drivers of growth for this market are increasing use of composites products over metals, steel, and concrete made tanks due to high strength, greater corrosion resistance, and faster manufacturing process.

FRP (Fiber Reinforced Plastic) tanks are made from raw materials such as resin, fiberglass, fillers and additives. Typically polyester or vinyl ester or epoxy; binds the fiberglass together to provide strength and rigidity. Fillers like calcium carbonate improve mechanical properties while lowering costs whereas additives like UV inhibitors and flame retardants enhance performance and durability. Comparatively, FRP tanks are less expensive than concrete or steel thereby cost effective due to low maintenance, long life span and resistance to corrosion. However, lifecycle costs are lower despite higher initial costs. Market pricing varies based on size, design and application in order to balance performance with cost effectiveness.

• Lucintel forecasts that water/wastewater segment will remain the largest application by value and volume during the forecast period due to infrastructural development. Septic is expected to witness highest growth over the forecast period.

• Above storage tank is expected to remain the largest segment due to its increasing use in the chemical and water/wastewater application. Under storage tank is expected to witness highest growth over the forecast period.

Country wise Outlook for the North American FRP Tank Market

The North American FRP Tank market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major North American FRP Tank producers in key regions: the USA, Mexico, and Canada.

Emerging Trends in the North American FRP Tank Market

Emerging trends in the North American FRP tank Market shaping its future applications and market dynamics:

1. Expansion in Industrial Applications: FRP tanks have become popular in industrial fields of chemicals, wastewater treatment and oil & gas because of their durability, chemical resistance and ability to meet ever stringent regulatory requirements.

2. Customization and Modular Solutions: Nowadays there is increasing request for custom built or modularly created FRP tanking solutions which can be designed, sized and located specifically according to project requirements and space constraints.

3. Sustainability Initiatives: The trend towards more sustainable materials and manufacturing processes has made FRP tanks a preferred choice due to their corrosion resistance over traditional materials with longer lifecycle.

4. Advanced Manufacturing Technologies: There has been an increasing adoption of advanced manufacturing methods such as automated filament winding as well as resin infusion techniques so that efficiency, quality plus customization capabilities are enhanced for FRP tanks.

A total of 72 figures / charts and 52 tables are provided in this 148-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the North American FRP Tank Market

Recent developments in North American FRP tank Market by various companies highlight ongoing innovations and advancements across different sectors:

• Technological Advancements: Companies like ZLC Composites and Augusta Fiberglass, for instance, have come up with new ways of fabricating materials hence improving durability and performance of FRP tanks hence widening their scope in usage.

• Expansion in Industrial Sectors: In the chemical industry, wastewater treatment plants and oil drilling sites there is an increasing use of fiberglass reinforced plastic (FRP) tanks which are known to be corrosion resistant, light weight and meet stringent regulatory standards.

• Sustainability Initiatives: Manufacturers are adopting measures to increase recyclability of materials used in FRP tanks and minimize the effects on environment by optimizing production processes.

• Market Consolidation and Acquisitions: The industry discussions lately have been about mergers and acquisition. This will help consolidate the market shares, reach wider geographical locations as well as product diversification..

• Innovative Product Offerings: Companies are launching new products such as larger capacity FRP tanks, modular systems, and tanks integrated with IoT technologies for improved monitoring and maintenance.

Strategic Growth Opportunities for North American FRP Tank

The North American tank market offers a number of strategic growth opportunities driven through diverse industrial requirements and regulatory developments as discussed below

Industrial Expansion and Replacement Demand:

• Market Demand: Aging infrastructure and expanding industrial sectors such as chemicals, oil & gas, and water treatment drive replacement and new tank installations.

• Opportunities: There is significant market for tanks that offer corrosion resistance, durability, and compliance to stringent regulatory standards especially among industries upgrading their storage capacities.

Focus on Environmental Regulations:

• Regulatory Landscape: Increasing environmental regulations necessitate tanks that meet emissions standards, leak prevention requirements, and sustainable material criteria.

• Opportunities: Innovations in tank coatings, materials (such as fiberglass and stainless steel), and leak detection systems cater to compliance needs and offer competitive advantages.

Water and Wastewater Treatment Sector:

• Industry Applications: Tanks play a crucial role in water storage, wastewater treatment, as well as industrial process water management.

• Opportunities: Expansion in municipal projects, storm water management initiatives, and industrial wastewater treatment facilities create demand for durable and efficient tank solutions.

Residential and Commercial Construction Projects:

• Building Sector: Tanks are used in residential developments for water storage, fire suppression systems, and HVAC applications.

• Opportunities: With urbanization and infrastructure upgrades, there is a growing market for tanks that optimize space, integrate with green building certifications, and offer cost-effective solutions.

North American FRP Tank Market Drivers and Challenges

There are several factors that drive and affect the growth of the North American market for FRP (Fiber-Reinforced Plastic) pipes. In such a way, the increasing need for anti-corrosive piping across industries like water management, chemical processing, and infrastructure development is one of these drivers. Supportively, they are long-lived, weightless in effect and do not corrode as well making them suitable in harsh environments. Additionally, technological advancement of production processes and environmental friendly campaigns also boost the market’s growth rate. However, there are numerous challenges to overcome including high initial costs, technical expertise requirements, market perception barriers as well as stiff competition from traditional materials like steel and concrete encountered by industry players in FRP pipe sector.

The key drivers for the North American FRP tank market include

1. Corrosion resistivity: FRP pipes are highly resistant to corrosion from chemicals and environmental elements, making them ideal for applications in water treatment, chemical processing and wastewater management.

2. Durability and Longevity: These types of pipes have a longer lifespan compared to traditional materials like steel or concrete, which helps reduce maintenance costs and downtime.

3. Lightweight and Ease of Installation: Being lightweight, FRP pipes are easier to transport, handle and install than many heavier alternatives leading to possible cost savings and quicker project completion.

4. Versatility in Applications: These types of FRP pipes can be tailored into different industrial or municipal settings such as oil & gas industry, infrastructure projects or desalination plants thereby offering adaptability with flexibility being insured.

5. Environmental Sustainability: The sector’s increased focus on environmental sustainability boosts the demand for non-corrosive FRP pipes that can contain recycled materials in line with green building initiatives.

The key challenges in the North American FRP tank market include

1. High Initial Prices: FRP pipes’ first payment can be greater than conventional materials, and this might discourage its early adoption notwithstanding that it provides a long-term means of saving on maintenance and replacement.

2. Technical Expertise: the installation and maintenance of FRP pipes need specialized knowledge and training; thus, there may be difficulties in ensuring proper handling and optimal performance.

3. Market Perception and Awareness: On the other hand, lack of awareness among consumers as regards to the benefits as well as applications of FRP pipes compared with traditional materials such as steel or concrete could slow down their market entry.

4. Material Quality Assurance: In spite of being challenging, it is necessary to ensure equal quality and performance across different manufacturers’ batches in the FRP pipe industry.

5. Competitive Market: To keep its market share amid stiff competition from other materials and alternative composite solutions for piping industry requires constant innovation as well as differentiation.

The North American FRP pipes market has immense opportunities for expansion due to a rising demand for reliable, long-lasting and cost-friendly conduits needed in different sectors. However, even with these positive drivers, its success depends on how it manages some hurdles such as price limitations, intricacies involved during manufacturing processes and techniques adopted by consumers as well as competition forces. The changing demands of this dynamic market can therefore be tapped into by stakeholders who can come up with new solutions that are compliant with the legal requirements while at the same time driving growth through sustainability fostered by joint ventures.

North American FRP Tank Suppliers and Their Market Shares

In this North American competitive market, several key players such as Mattr (Shawcor), Containment Solutions, Belco Manufacturing Co.Inc. and L.F Manufacturing Inc. etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players Contact Us. Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies North American FRP Tank cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the North American FRP Tank companies profiled in this report include.

• Mattr Infratech (Shawcor)

• Containment Solutions

• Belco Manufacturing Co.Inc

• L.F. Manufacturing, Inc.

• Orenco Systems Inc.

• Zurn Green Turtle

• Fabricated Plastic Limited

• Diamond Fiberglass

These companies have established themselves as leaders in the North American FRP Tank Market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the North American FRP Tank market are evolving, with the entry of new players and the emergence of innovative North American FRP Tank market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

North American FRP Tank Market by Segment

The FRP (Fiber Reinforced Plastic) tank market is seeing growth across several key segments. The first one is the growth in industrial applications like chemical processing and water treatment because of its corrosion resistant and long lasting nature. Secondly, the municipal water and wastewater sectors are increasingly embracing FRP tanks due to their lightness as well as their resistance to various chemicals. Thirdly, the oil and gas industry is increasingly using FRP tanks for storage and transportation of various fluids due to their cost-effectiveness and longevity. Besides that, there is growth in agricultural sector which utilizes FRP tanks for storing fertilizers and chemicals due to their non-corrosive nature. Finally, the automotive industry considers fuel storage tanks made from FRPs owing to their lightness and strength superiority.

North American FRP Tank Market by Application [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Water/wastewater

• Septic

• Pulp and paper

• Chemical

• Petroleum

• Agriculture and aquaculture

• Others

North American FRP Tank Market by Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Under Storage Tank

• Above Storage Tank

North American FRP Tank Market by Process [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Filament Winding

• Centrifugal Casting

• Lay-Up, Spray-Up

North American FRP Tank Market by Country [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Eastern Canada

• Eastern US

• Central US

• Western US

• Western Canada

• Texas, OK, LA

Features of North American FRP Tank Market

• Market Size Estimates: North American FRP tank market size estimation in terms of value ($M) and volume (M lbs).

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments.

• Segmentation Analysis: Market size by application, type, manufacturing process, and country.

• Growth Opportunities: Analysis of growth opportunities in different application, type, manufacturing process, and country for the North American FRP tank market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the North American FRP tank market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in North American FRP Tank or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

FAQ

Q1. What is the North American FRP tank market size?

Answer: The North American FRP tank market is expected to reach an estimated $699 million by 2030.

Q2. What is the growth forecast for North American FRP tank market?

Answer: The North American FRP tank market is expected to grow at a CAGR of 4% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the North American FRP tank market?

Answer: The major drivers of growth for this market are increasing use of composites products over metals, steel, and concrete made tanks due to high strength, greater corrosion resistance, and faster manufacturing process.

Q4. What are the major applications or end use industries for North American FRP tank?

Answer: Petroleum and water/wastewater are the major end uses for North American FRP tank.

Q5. What are the emerging trends in North American FRP tank market?

Answer: Emerging trends, which have a direct impact on the dynamics of the North American FRP Tank industry, includes expansion in industrial application, customization and modular solution, sustainability initiatives, and advanced manufacturing technologies.

Q6. Who are the key North American FRP tank companies?

Answer: Some of the key North American FRP tank companies are as follows:

• Mattr Infratech

• Containment Solutions

• Belco Manufacturing Co. Inc.

• L.F. Manufacturing, Inc.

• Orenco Systems Inc.

• Zurn Green Turtle

• Fabricated Plastic Limited

• Diamond Fiberglass

Q7. Which North American FRP tank type segment will be the largest in future?

Answer: Lucintel forecasts that above storage tank is expected to remain the largest segment due to its increasing use in the chemical and water/wastewater application.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the North American FRP tank market by application (water/wastewater, septic, pulp and paper, chemical, petroleum, agriculture/aquaculture, and others), type (under storage tank, and above storage tank), process (filament winding, centrifugal casting, lay-up and spray-up), and Country (Eastern Canada, Eastern US, Central US, Western US, Western Canada, and Texas, OK, LA)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?