North American FRP Pipe Market Trends and Forecast

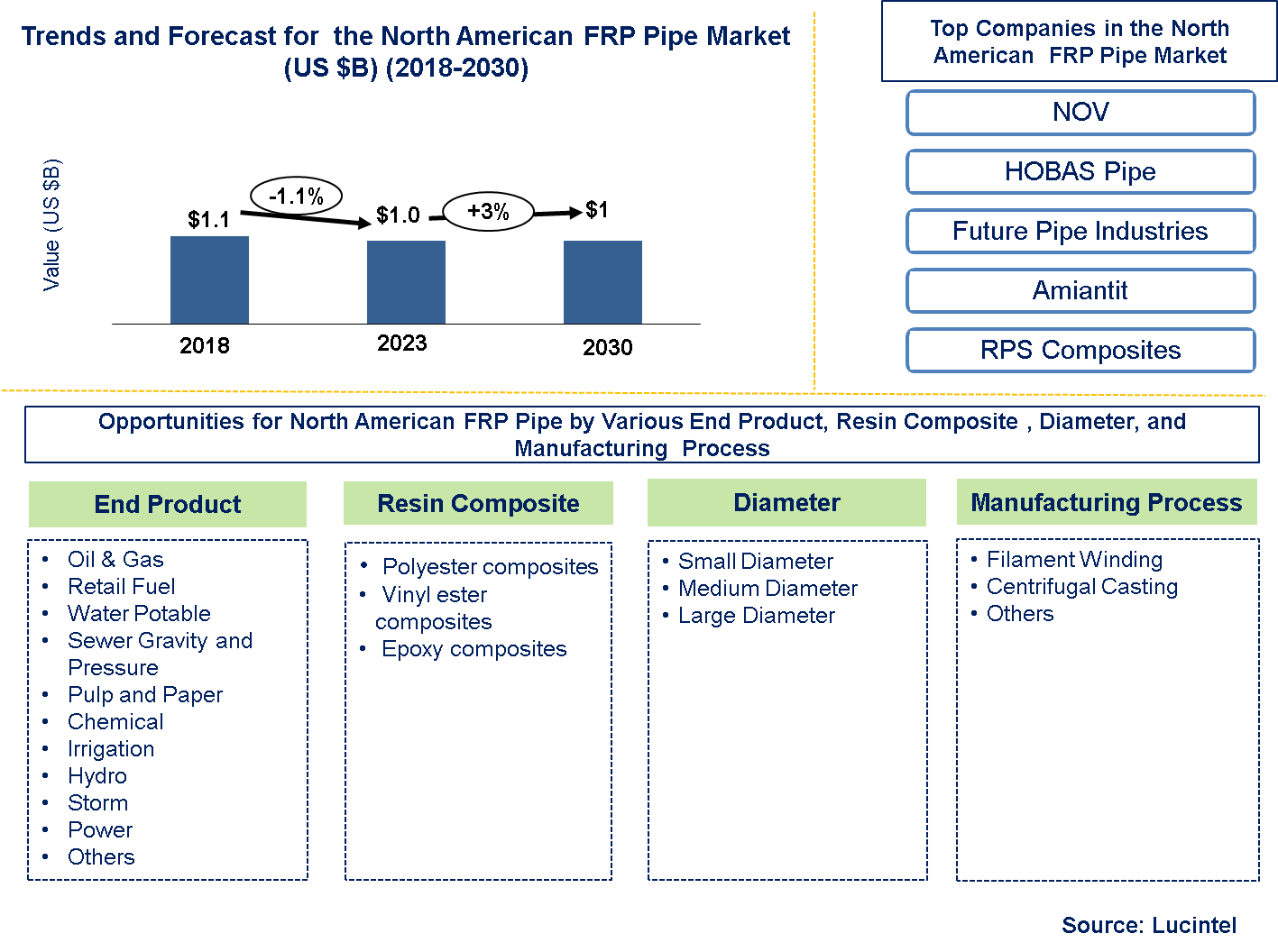

Lucintel finds that the future of composite product of the North American FRP pipe market looks promising with opportunities in the sewer gravity and pressure, water potable, irrigation, storm, hydro, oil and gas, retail fuel, pulp and paper, chemical, and power. The North American FRP pipe end product market is expected to reach an estimated $1 billion by 2030 with a CAGR of 3% from 2023 to 2030. The major drivers for this market are increasing construction of water supply systems, further development of sewage treatment systems, and increasing oil and gas exploration activities.

Fiber Reinforced Plastic (FRP) pipes are made using a blend of raw materials like resins such as polyester, vinyl ester or epoxy that act as matrix providing corrosion resistance and structural integrity. These resins are stiffened by glass fibers which is the main contributor to strength and stiffness in composites. Some fillers like calcium carbonate or silica can be used to improve specific characteristics such as resistance to abrasion or retardation of fire. Catalysts and initiators are utilized in resin cure system for manufacturing processes. Mold release agents assist separation of cured FRP pipe from molds. When it comes to cost, pricing for FRP pipes is competitive with traditional materials like steel and concrete especially when the longer service life, reduced maintenance costs and their light weightness are taken into account. Because of different factors like diameter, wall thickness, resin type and project specifications the pricing is not fixed hence making FRP pipes more suitable choice for long lasting durability and corrosion resistance in various industrial applications.

• Lucintel forecasts that oil and gas will remain the largest end use segment and it is also expected to witness the highest growth over the forecast period due to the growth in rig count.

• Epoxy resin will remain the largest segment by value and volume and polyester resin is expected to witness the highest growth over the forecast period.

Country wise Outlook for the North American FRP Pipe Market

The North American FRP Pipe market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major North American FRP Pipe producers in key regions: the USA, Mexico, and Canada.

Emerging Trends in the North American FRP Pipe Market

Emerging trends in the North American FRP Pipe Market shaping its future applications and market dynamics:

1. Development of Advanced Materials: Continued development of new resin formulations and fiber reinforcements to enhance the strength, durability, and corrosion resistance of FRP tanks, making them suitable for a wider range of applications and harsh environments..

2. Integration of Smart Technologies: Integrate smart sensors and IOT enabled monitoring systems in FRP tanks that give real-time tank conditions data, better maintenance scheduling, and enhanced efficiency in operations.

3. Customization and Modular Solutions: Customer demand for customized FRP tank products responding to the specific project needs including modular designs for flexible installation as well as options of future expansion.

4. Environmental Sustainability: Innovations aimed at lowering the environmental impact associated with FRP tanks such as use of recyclable materials, eco-friendly ways of making them among other strategies which promote efficient utilization of resources over a long period.

5. Safety and Compliance: Advancements in tank design and manufacturing processes to comply with strict regulations on safety within the industry leading to reliability and performance in critical applications like chemical storage or wastewater treatment plants..

A total of 72 figures / charts and 52 tables are provided in this 148-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the North American FRP Pipe Market

Recent developments in North American FRP Pipe Market by various companies highlight ongoing innovations and advancements across different sectors:

• Expansion in Infrastructure Projects: The use of FRP pipes for infrastructure projects has grown notably, due to corrosion resistance, lightweight properties and long-term cost savings compared to traditional materials such as steel and concrete. This also includes municipal water systems, industrial pipelines, and marine installations.

• Sustainability Initiatives: Manufacturers are adopting sustainability by creating environment-friendly FRP pipe solutions that reduce environmental impact through their life cycle. They achieve this by using recycled materials, optimizing production processes to minimize waste, and promoting energy-efficient manufacturing techniques.

• Strategic Partnerships and Acquisitions: Market coverage increase, technology enrichment and product differentiation are among the strategic partnerships and acquisitions taking place within the industry. These collaborations are aimed at enhancing competitiveness as well as meeting rising customer needs for innovative pipe solutions.

• Regulatory Compliance and Safety Standards: The adoption of FRP pipes in critical applications where corrosion resistance, reliability, longevity is important is driven by increased adherence to strict regulatory requirements as well as safety standards. Manufacturers have invested in certifications and quality assurance measures to ensure reliable products that satisfy customers’ demands.

• Technological Advancements: NOV Fiber Glass Systems such Future Pipe Industries have up-scaled their manufacturing capabilities in order to cope with an increasing demand in sectors like oil & gas; water; wastewater; chemical processing. Examples include advanced resin formulations or automated manufacturing processes towards better product performances with improved durability.

Strategic Growth Opportunities for North American FRP Pipe Market

The North American FRP pipe market is very dynamic due to its unique properties of being lightweight, strong and thermally stable. Some key strategic growth opportunities for this market include:

Rehabilitation of Infrastructure and Replacement:

• Market Demand: Aging water and wastewater infrastructure in North America necessitates its rehabilitating and replacing it.

• Opportunities: However, other materials like steel and concrete which are commonly employed during repairs have shorter life spans than those of FRP pipes making them suitable for upgrading the infrastructure.

Growth in Oil and Gas Industry:

• Applications: Their use is increasing in oil and gas pipelines, refineries, and offshore platforms due to resistance to corrosive fluids or environments.

• Opportunities: However, demand for lightweight, high-strength FRP pipes that result in reduced installation and maintenance costs will increase with the growth of shale gas exploration and production.

Water & Wastewater Treatment Facilities:

• Market Segment: They are made to be used as FRP pipes, this material being applied for their chemical resistance as well as smooth inner surfaces in water treatment plants; desalination facilities; industrial wastewater treatment plants.

• Opportunities: Nevertheless , demand for FRP pipes with superior hydraulic performance is driven by the expansion of municipal and industrial projects requiring reliable low maintenance piping solutions.

Infrastructure Development in Construction:

• Building Sector: For instance such building works as drainage systems, cooling towers or HVAC (Heating Ventilation Air Conditioning) installations can involve composite materials such as fiber reinforced plastic (FRP) pipes.

• Opportunities: These include ease of installation, lightweight construction among others which indeed make them stand out especially when considering sustainable building practices from other options available because they are easy to install compared to metal substitutes like carbon steels hence less labor intensive during building work, also corrosion resistance forms one acceptable advantage amongst many others like light weight construction including ease of use leading to good serviceability factor keeping it at top position among its competitors. 5. Renewable Energy Projects.

By taking advantage of these strategic growth opportunities, the NA FRP pipe market can realize its full potential and transform numerous industries through strength, lightness, versatility.

North American FRP Pipe Market Drivers and Challenges

Superior corrosion resistance and durability propelled North American FRP pipe market demand in sectors such as water infrastructure and chemical processing. Nonetheless, obstacles like higher initial costs and perceptions about material strength vis-a-vis conventional options such as steel still remain.

The key drivers for the North American FRP pipe market include

1. Corrosion Resistance: FRP pipes are known for their superior resistance to corrosion, which make them appropriate for use in water and wastewater management, chemical processing and marine applications.

2. Longevity and Durability: These pipes live a longer life than conventional materials such as steel or concrete thereby reducing maintenance costs and downtime.

3. Light Weightiness and Ease of Installation: The lightweight characteristic of FRP pipes makes it easy to transport, handle and install them thus resulting in saved money on project timelines.

4. Versatility in Applications: The market has multiple applications that FRP pipes can be customized into including industrial processes pipe system, oil & gas transportation lines, infrastructure projects among others.

5. Environmental Compliance: Due to rising environmental regulations there is preference for FRP pipes since they are not corrosive and can be made from recycled material meeting the tenets of sustainability.

The key challenges in the North American FRP pipe market include

• High Initial Costs: Even though there may be long-term savings from their use, the upfront costs of FRP pipes can exceed those associated with traditional materials thereby deterring their initial adoption

• Technical Expertise: Proper handling and performance are challenging when installing and maintaining FRP pipe because it requires specific knowledge and training

• Perception And Awareness: The understanding among users regarding the benefits or application areas where these kinds of pipes can be used as opposed to conventional products like steel or concrete is low hence a limited market growth

• Material Quality Assurance: However, an essential requirement still poses significant challenges because ensuring consistent quality as well as reliability across various batches from different manufacturers is not an easy task

• Competitive Market: This means that continuous innovation as well as differentiation is required due to intense competition coming from other materials along with alternative composite solutions in the piping industry.

The North American FRP (Fiber-Reinforced Plastic) tanks market has various main drivers that define its growth path and specific challenges. For example, there is increasing demand for fiber reinforced plastic tank from the sectors of water treatment, chemicals and oil & gas due to their durability properties as well as cost affectivity. Furthermore, technological improvements in manufacturing procedures along with environmental friendliness assist in enhancing the market’s coverage area. Nevertheless, major obstacles facing stakeholders in FRP tank industry include high setup costs, requirement for skilled personnel and resistance by potential customers against using such tanks over other materials such as concrete or steel due to safety concerns.

North American FRP Pipe Suppliers and Their Market Shares

In this North American competitive market, several key players such as National Oilwell Varco (NOV), HOBAS Pipe, Future Pipe Industries, Amiantit, RPS Composites, Ershigs Inc. etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players Contact Us. Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies North American FRP Pipe cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the North American FRP Pipe companies profiled in this report include.

• National Oilwell Varco (NOV)

• HOBAS Pipe

• Future Pipe Industries

• Amiantit

• RPS Composites

• Ershigs Inc.

• Colney Composites LLC

• Belco Manufacturing Co.Inc

These companies have established themselves as leaders in the North American FRP Pipe Market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the North American FRP Pipe market are evolving, with the entry of new players and the emergence of innovative North American FRP Pipe market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

North American FRP Pipe Market by Segment

Within the North American market for Fiber Reinforced Plastic (FRP) pipes, a number of segments are experiencing remarkable growth. FRP pipes are increasingly used in water and wastewater systems due to their durability and corrosion-resistance that is beneficial in modernizing aging infrastructures as well as handling severe environmental conditions. In oil and gas industry, FRP pipes are gradually opted for as they stand against corrosive fluids and environments that make them reliable for offshore platforms, pipelines and refinery applications. For instance, FRP pipes can be employed in chemical processing operations which handle a broad spectrum of chemicals thus enhancing safety and operational efficiency with respect to corrosives. Furthermore, FRP pipes have been increasingly used in building bridges, marine installations and other infrastructure projects due to their lightweight design coupled with longevity that ensures cost-effective solutions. On the other hand, renewable energy industry makes use of FRP pipes in cooling systems and wastewater management associated with solar energy facilities and wind farms respectively. All these trends reveal why FRP pipe is so versatile in its application across different industries and infrastructure sectors throughout North America.

North American FRP Pipe Market by End Product [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Oil and Gas

• Sewer Gravity and Pressure

• Water Potable

• Irrigation

• Storm

• Hydro

• Non-circular

• Retail Fuel

• Pulp and Paper

• Chemical

• Power

• Others

North American FRP Pipe Market by Resin Composites [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Polyester resin based FRP pipe

• Epoxy resin based FRP pipe

• Vinyl ester resin based FRP pipe

North American FRP Pipe Market by Diameter [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Small Diameter

• Medium Diameter

• Large Diameter

North American FRP Pipe Market by Pressure Rating [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Less than 150 psi

• 150 to 300 psi

• More than 300 psi

North American FRP Pipe Market by Manufacturing Process [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Filament Winding

• Centrifugal Casting

• Others

Features of North American FRP Pipe Market

• Market Size Estimates: North American market size estimation in terms of value ($M) and Volume (M lbs).

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and country.

• Segmentation Analysis: Market size by end product, resin composites, diameter, pressure rating, and manufacturing process.

• Growth Opportunities: Analysis of growth opportunities in different end product, resin, diameter, pressure rating, manufacturing process, and country for the North American FRP market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the North American FRP pipe market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in North American FRP Pipe or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the North American FRP pipe market size?

Answer: The North American FRP pipe market is expected to reach an estimated $1 billion by 2030.

Q2. What is the growth forecast for North American FRP pipe market?

Answer: The North American FRP pipe market is expected to grow at a CAGR of 3% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the North American FRP pipe market?

Answer: The major drivers for this market are increasing construction of water supply systems, further development of sewage treatment systems, and increasing oil and gas exploration activities.

Q4. What are the major end products for the North American pipe market?

Answer: Oil and gas and chemical are the major end products for the North American pipe market.

Q5. What are the emerging trends in North American FRP pipe market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, includes development of advanced material, integration of smart technologies, customization and modular solution, environmental sustainability, and safety and compliance.

Q6. Who are the key North American FRP pipe companies?

Answer: Some of the key North American FRP pipe companies are as follows:

• National Oilwell Varco (NOV)

• HOBAS Pipe

• Future Pipe Industries

• Amiantit

• RPS Composites

• Ershigs Inc.

• Colney Composites LLC

• Belco Manufacturing Co. Inc.

Q7. Which North American FRP pipe product segment will be the largest in future?

Answer: Lucintel forecasts that the epoxy resin will remain the largest segment by value and volume and polyester resin is expected to witness the highest growth over the forecast period.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q1. What are some of the most promising, high-growth areas of the North American FRP pipe market by end product (sewer gravity and pressure, water potable, irrigation, storm, hydro, oil and gas, retail fuel, pulp and paper, chemical, power and others), resin composites (epoxy, polyester and vinyl ester), diameter(small, medium, and large), pressure rating (less than 150 psi, 150 to 300 psi, and more than 300 psi), manufacturing process (filament winding, centrifugal casting, and others), and country (The US, Canada and Mexico)?

Q2. Which segments will grow at a faster pace and why?

Q3. What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q4. What are the business risks and threats to the market?

Q5. What are the emerging trends in this market and the reasons behind them?

Q6. What are the changing demands of customers in the market?

Q7. What are the new developments in the market? Which companies are leading these developments?

Q8. Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q9. What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q10. What M & A activities have taken place in the last 5 years in this market? big of a threat do they pose for loss of market share via material or product substitution?