North American Automotive Composites Market Trends and Forecast

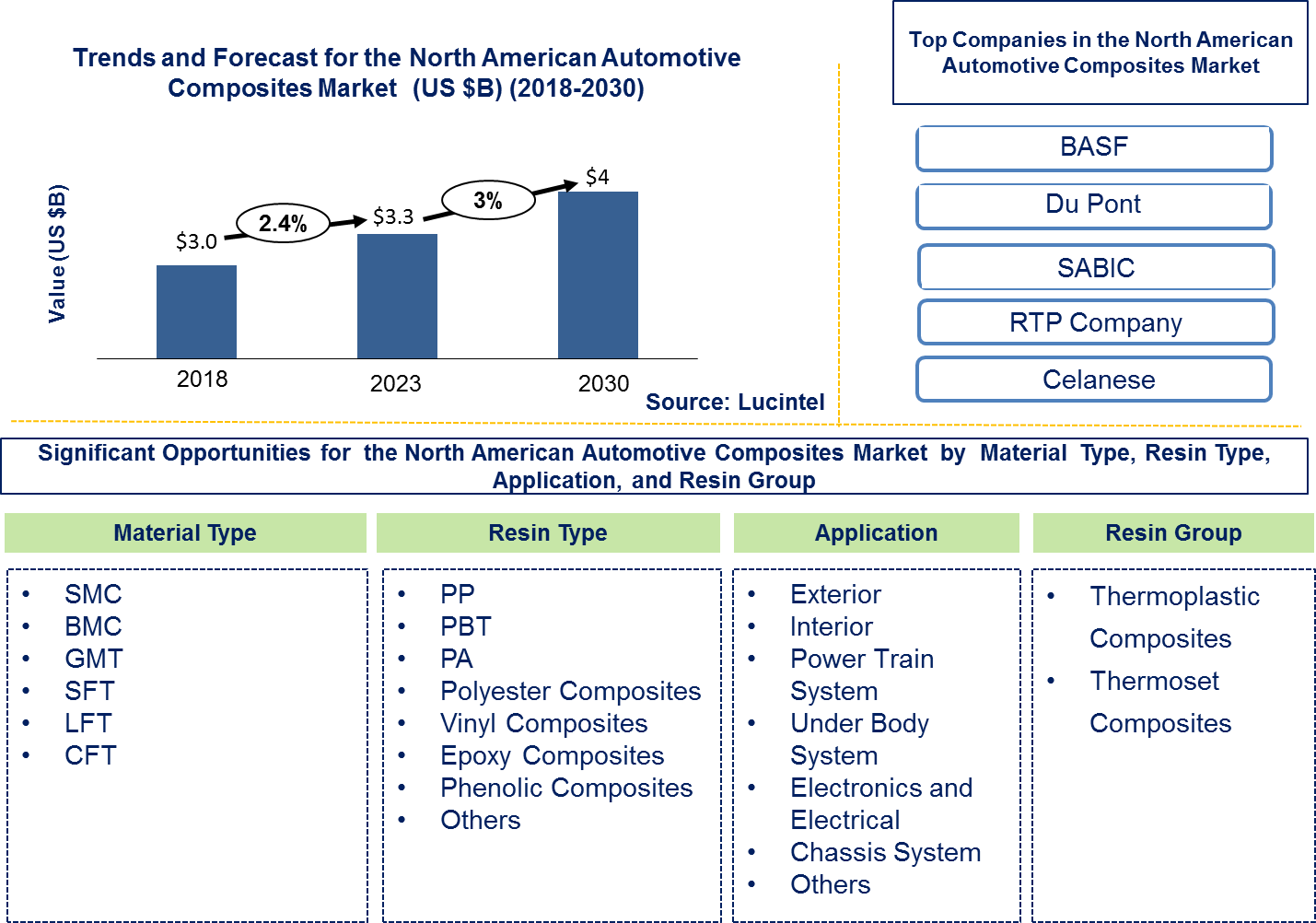

Lucintel finds that future of the North American automotive composites intermediate material market looks promising with opportunities in the exterior, interior, power train system, chassis system, under body system, electrical and electronics, and chasis system. The North American automotive composites market is expected to reach an estimated $4 billion by 2030 with a CAGR of 3% 2023 to 2030. The major growth drivers for this market are increase in production of passenger cars and light commercial vehicles are expected to boost composites material materials in the automotive industry in the next five years and increase usage of composites in chassis, insulating panels, casing, mufflers, and sound insulation parts of the vehicles.

Automotive composites are crafted from a diverse array of raw materials, primarily including resins such as unsaturated polyester resin (UPR), epoxy resin, and vinyl ester resin, which serve as binding agents. These resins are reinforced with materials like glass fibers, carbon fibers, natural fibers such as jute or hemp, and aramid fibers, providing strength and durability. Additionally, fillers like calcium carbonate, talc, or mica are often added to enhance mechanical properties and reduce costs. The pricing of automotive composites varies based on factors like raw material expenses, manufacturing complexity, and market demand dynamics. Generally, composites are competitive with traditional materials like metals due to their lightweight nature, which can contribute to improved fuel efficiency and performance, though specific price comparisons depend on application specifics and regional market conditions.

• Lucintel forecasts that short fiber thermoplastic (SFT) North American automotive composites is expected to remain the largest segment and continuous fiber thermoplastic (CFT) composites segment is expected to witness the highest growth in the forecast period.

• Exterior will remain the largest application segment and is also expected to witness the highest growth over the forecast period due to its increasing usage in automotive industry.

Country wise Outlook for the North American Automotive Composites Market

The North American automotive composites market is witnessing substantial growth. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major advance composite producers in key regions: the USA, Canada, and Mexico.

Emerging Trends in North American Automotive Composites Market

Emerging trends in North American automotive composites are shaping its future applications and market dynamics:

• Integration of Hybrid and Multi-material Composites: Merging different materials which are metals, polymers, ceramics etc. for the purpose of optimizing structural performance as well as cutting down on vehicle weight.

• Increasing uses of Lightweighting Initiatives: It is now becoming more evident that lightweight materials like carbon fiber reinforced composites will be very crucial in ensuring strict fuel efficiency regulations are met and at the same time help reduce vehicle weights.

• Adoption of Advanced Manufacturing Technologies: such processes include automated layup and resin transfer molding (RTM) that can improve production efficiency and lower costs.

• Recycling and Sustainability: Incorporating them into development of recyclable composites as well as bio-based resins would therefore serve to conform to environmental regulations and consumer preferences.

• Smart Materials: With an aim to enhance safety measures together with product ability researchers continue focusing on smart composites integrated with functions such as self-monitoring sensors or structural health monitoring systems.

• Functional Integration: Performance and passenger’s comfort for instance can largely be improved by inclusion of electrometric shielding, acoustic insulation, thermal management among other functional properties into composite materials.

These trends highlight a shift towards innovative, lightweight, sustainable, and technologically advanced composites in the North American automotive industry, driven by regulatory pressures, consumer demands, and advancements in manufacturing capabilities.

A total of 84 figures / charts and 44 tables are provided in this 176-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the North American Automotive Composites Market

Recent developments in North American Automotive Composites by highlighting ongoing innovations and advancements across different sectors

• Material Advancements: Introduction of new composite materials and formulations aimed at enhancing strength, reducing weight, and improving manufacturing efficiency.

• Electric Vehicle (EV) Integration: Increased usage of composite materials in this vehicle type to optimize battery capabilities, extend distances covered by the vehicle and improve energy use.

• Supply Chain Innovations: Streamlining of supply chains and logistics to support efficient production and distribution of composite materials across North America.

• Regulatory Compliance: Alignment with stringent environmental regulations by developing recyclable and sustainable composite solutions.

• Partnerships and Collaborations: Collaboration between automotive manufacturers, composite suppliers, and research institutions to accelerate innovation in materials, processes, and applications.

Strategic Growth Opportunities for North American Automotive Composites Market

The North American automotive composites market is set for high growth on the back of several strategic opportunities amid emerging industry trends and consumer preferences. Here are some key growth prospects for stakeholders in this dynamic sector:

1. Lightweighting Initiatives: The North American automotive market is increasingly leaning towards lightweight vehicles to enhance fuel economy and abate emissions. Materials such as carbon fiber reinforced polymers (CFRPs) and glass fiber reinforced polymers (GFRPs) save a lot of weight compared to traditional materials like steel and aluminum. Strategic alliances with material suppliers, car manufacturers and research institutions could help fast track the development of advanced composite materials specifically for automotive applications along with manufacturing processes.

2. Electric vehicles (EVs) / hybrid vehicles: Automotive composites play a vital role in the transition to electric and hybrid vehicles. Manufacturers of EVs are looking for lightweight materials that can improve battery efficiency and extend driving distance. Lightweight composites may be used to fabricate components like battery housings, chassis parts, structural elements etc., for EVs. Innovative composite materials need incorporation of superior strength, thermal stability and electrical insulation properties into them so that they meet the specificities of an EV platform today.

3. Advances in Composite Technologies: There have been continuous advances in composite manufacturing technologies including automated lay-up processes, resin infusion techniques, thermoplastic composites among others that result in better performance at lower costs of automotive composites. The whole North American auto industry will only shift if investments lead to improved material properties, reduced production cycle times or increased production capacity.

4. Customization/Design flexibility: Car makers prefer using composite material over other types because they make it easier for designers to make complex shapes geometeries than ever before hence more car manufactures are turning into it day by day.Some customized solutions made specifically for different types of automobile products such as interior parts’ exterior panels’ aerodynamic pieces can give an edge over rivals according to competitive markets.It is important therefore for designers engineers as well as composite suppliers collaborate on choosing the right materials , manufacturing processes and performance features based on application requirements.

5. Sustainable Materials: The automotive industry is witnessing increasing consumer demands for sustainable materials due to rising consumer awareness and regulatory pressures. Composites are more recyclable with low lifecycle environmental impacts and energy efficient compared to their traditional counterparts. By adopting bio-based resins from recycled fibers, end-of-life recycling programs or others in their composite supply chains, North American car manufacturers can take advantage of these sustainability trends.

The lightweighting initiatives, advances in composite technologies, EV shift in focus, customization capabilities and considerations regarding sustainability will make the North American automotive composites market experience rapid growth. Consequently, if these strategic choices in light of costs are resolved and addressed while making sure there is adherence to regulations then this sector will position itself as a place where innovation and competitiveness thrive among stake holders who will be at the forefront of change within the automobile landscape over the next few years hence. Because potential benefits from automotive composites throughout North America are not going to be realized unless material suppliers collaborate with OEMs and tech partners across the value chain

North American Automotive Composites Market Drivers and Challenges

The North American automotive composite market offers many opportunities due to regulatory requirements, technical advancements and changing consumer taste for eco-friendly and high performing vehicles. The adoption of lightweight composites has the potential to make a significant impact on the way automobiles are designed and manufactured with advantages in fuel economy, vehicle safety as well as customization capabilities. However, certain hurdles such as cost competitiveness, supply chain resilience, manufacturing scalability, regulatory compliance and sustainability must be resolved in unison across this sector. All these challenges can be overcome through innovation and investment in research and development while developing strategic alliances thereby advancing the North American Automotive Composites Market towards a sustainable growth path to take leadership in the global motor industry.

Key drivers of the North American automotive composites market include:

• Regulatory Requirements: Strict emissions standards and fuel efficiency regulations adopted by automakers in North America are forcing them to use lightweight materials like composites that assist in reducing vehicle weight while improving fuel economy as well as lowering emissions.

• Demand for Lightweighting: The average consumer nowadays is looking for a car that uses less fuel and gives better performance; hence, car makers are considering adopting light materials. Carbon fiber and glass fiber reinforced polymers such as composites significantly reduces the mass but still maintains strength and durability.

• Advancements in Composite Technologies: Innovations in resin systems, fiber reinforcements, and production techniques are enhancing the performance and cost-effectiveness of automotive composites. These advancements have resulted from intensive research and development on composite materials together with their manufacturing processes thereby widening their application on motor vehicle components.

• Electric Vehicles (EVs) & Hybrid Vehicles: Consequently, there has been an upsurge in electric vehicles (EVs) & hybrid vehicles sales within North America hence creating opportunities for composites to be used in battery housings, structural components, & lightweight body panels. To accomplish these objectives it will require adoption of various approaches such as usage of lighter materials such as carbon fibre among others that can help to increase efficiency and extend the range of EVs’ through vehicle’s weight reduction.

• Design Flexibility And Customization: In this way, complex shapes can be easily achieved using composites hence making it possible for automobile manufacturers to create functional integration into their designs. This is more particularly crucial for luxury cars plus sports where beauty comes first before anything else.

The key challenge in the North American automotive composites market include:

• Cost Considerations: On a bumpy road towards large scale implementation especially when dealing with low-cost markets where price competition is much higher than quality competition when compared with traditional alternatives including aluminum or steel because it could be expensive at times to make composite products.

• Supply Chain Complexity: However, it is difficult to establish a robust supply chain for composite raw materials including fibers and resin systems. Moreover, reliance on other countries can make these suppliers vulnerable to the disruptions that might impact on the production cycle.

• Manufacturing Scale-Up: Yet, huge investment should be made in equipment, facilities and training of personnel in order to facilitate mass production within automotive industry with regard to composites manufacturing processes. This creates production challenges since high quality outputs at scale still remain untapped by composite manufacturers & automakers yet there are opportunities for economies of scale.

• Material Performance and Standardization: Thus meeting stringent automotive safety & performance standards require extensive testing plus verification that can be complicated by material variability across various suppliers for integration into vehicles.

• Recycling and Sustainability: Nevertheless , the disposal and recycling of composites at their end-of-life poses difficulty despite its advantages such as weight reduction as well as energy conservation. Hence the need for a new environmental sound initiative towards composite recyclers, stateholders such as car manufacturers and others having major impact on environment.

North American automotive composites market experience growth propelled by regulatory mandates, lightweighting initiatives, technological advancements, as well as EV adoption among other drivers while it still faces challenges regarding cost competitiveness, supply chain complexities, manufacturing scalability; material performance standards & sustainability issues respectively that therefore need to be addressed for the complete realization of the benefits of this technology in the auto industry. These challenges can only be surmounted through teamwork among stakeholders within industry who must continue innovating to achieve sustainable growth throughout the entire global industrial sector.

North American Automotive Composites Suppliers and Their Market Shares

In this North American automotive composites market, several key players such as BASF, DuPont, SABIC, RTP Company, Celanese, Teijin, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players Contact Us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies North American automotive composites companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the North American automotive composites companies profiled in this report include.

• BASF

• DuPont

• SABIC

• RTP Company

• Celanese

• Teijin

• Lanxess

• Core Molding Technologies

• IDI Composites

• LyondellBasell

These companies have established themselves as leaders in North American automotive composites industry with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within North American automotive composites market are evolving, with the entry of new players and the emergence of innovative technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

North American Automotive Composites Market by Segment

Several segments of the North American Automotive Composites Market are experiencing notable growth. Carbon fiber composites are seeing increased demand due to their exceptional strength-to-weight ratio, particularly in luxury vehicles and high-performance sports cars where weight reduction is critical for enhancing performance. Glass fiber composites continue to expand in mainstream vehicles, valued for their cost-effectiveness, versatility, and ability to reinforce various automotive components. Thermoplastic composites, such as polypropylene (PP) and polyamide (PA), are gaining traction for their recyclability, impact resistance, and ease of processing, meeting the industryÄX%$%Xs sustainability goals. The electric vehicle (EV) segment is driving significant growth in composites usage to reduce vehicle weight and improve battery efficiency, supporting the burgeoning EV market across North America. Additionally, composites are increasingly utilized in interior applications like dashboards, door panels, and seating components, offering design flexibility, weight savings, and aesthetic benefits. These trends underscore a dynamic shift towards lightweight, sustainable, and technologically advanced materials in the North American automotive sector.

North American Automotive Composites Market by Material Type [Value ($M) and Volume (M lbs) analysis for 2018 – 2030]:

• SMC

• BMC

• GMT

• SFT

• LFT

• CFT

North American Automotive Composites Market by Resin Type [Value ($M) and Volume (M lbs) analysis for 2018 – 2030]:

• PP

• PBT

• PA

• Vinyl ester Composites

• Epoxy Composites

• Polyester Composites

• Phenolic Composites

• Other Composites

North American Automotive Composites Market by Application [Value ($M) and Volume (M lbs) analysis for 2018 – 2030]:

• Exterior

• Interior

• Under the body systems

• Electrical and Electronics

• Chassis System

• Power Chain System

• Others

North American Automotive Composites Market by Resin Group [Value ($M) and Volume (M lbs) analysis for 2018 – 2030]:

• Thermoplastic Composites

• Thermosets Composites

North American Automotive Composites Market by Fiber Type [Value ($M) and Volume (M lbs) analysis for 2018 – 2030]:

• Glass Fiber Composites

• Carbon Fiber Composites

• Natural Fiber Composites

Features of North American Automotive Composites Market

• Market Size Estimates: North American automotive composites market size estimation in terms of value ($M) and volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments.

• Segmentation Analysis: Market size by material type, resin type, application, resin group, fiber type, and countries

• Growth Opportunities: Analysis of growth opportunities in different material type, resin type, application, resin group, fiber type, and countries for the recycled carbon fiber market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the material type, resin type, application, resin group, fiber type, and countries market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in North American automotive composites market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the North American automotive composites market size?

Answer: The global North American automotive composites market is expected to reach an estimated $4 billion by 2030.

Q2. What is the growth forecast for North American automotive composites market?

Answer: The North American automotive composites market is expected to grow at a CAGR of 3% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the North American automotive composites market?

Answer: The major drivers for this market are increase in production of passenger cars and light commercial vehicles are expected to boost composites material materials in the automotive industry in the next five years and increase usage of composites in chassis, insulating panels, casing, mufflers, and sound insulation parts of the vehicles.

Q4. What are the major applications for North American automotive composites?

Answer: Power train system and exterior are the major applications for North American automotive composites.

Q5. What are the emerging trends in North American automotive composites market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, includes integration of hybrid and multi-material composites, increasing uses of lightweighting initiatives, adoption of advanced manufacturing technologies, recycling and sustainability, and smart materials

Q6. Who are the key North American automotive composites companies?

Answer: Some of the key North American automotive composites companies are as follows:

• Owens Corning

• Johns Manville Corporation

• Cytec Colay Group

Q7. Which North American automotive composites material type segment will be the largest in future?

Answer: Lucintel forecasts that short fiber thermoplastic (SFT) North American automotive composites is expected to remain the largest segment and continuous fiber thermoplastic (CFT) composites segment is expected to witness the highest growth in the forecast period.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 10 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the North American automotive composites market as by material type (SMC, BMC, LFT, SFT, GMT, CFT, phenolic composites, PU composites, natural composites, and other composites), resin type (PP composites, PBT composites, vinyl ester composites, polyester composites, PA composites, epoxy composites, phenolic composites, and other composites), application (interior, exterior, power chain system, chassis system, under the body systems, electrical and electronics, and others), resin group (thermoset composites, and thermoplastics composites), fiber type (glass fiber composites, carbon fiber composites, and natural fiber composites), and Country (US, Canada, and Mexico)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.4 What are the business risks and threats to the market?

Q.5 What are the emerging trends in this market and the reasons behind them?

Q.6 What are the changing demands of customers in the market?

Q.7 What are the new developments in the market? Which companies are leading these developments?

Q.8 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.9 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.10 What M & A activities have taken place in the last 5 years in this market?