Middle Eastern FRP Pipe Market Trends and Forecast

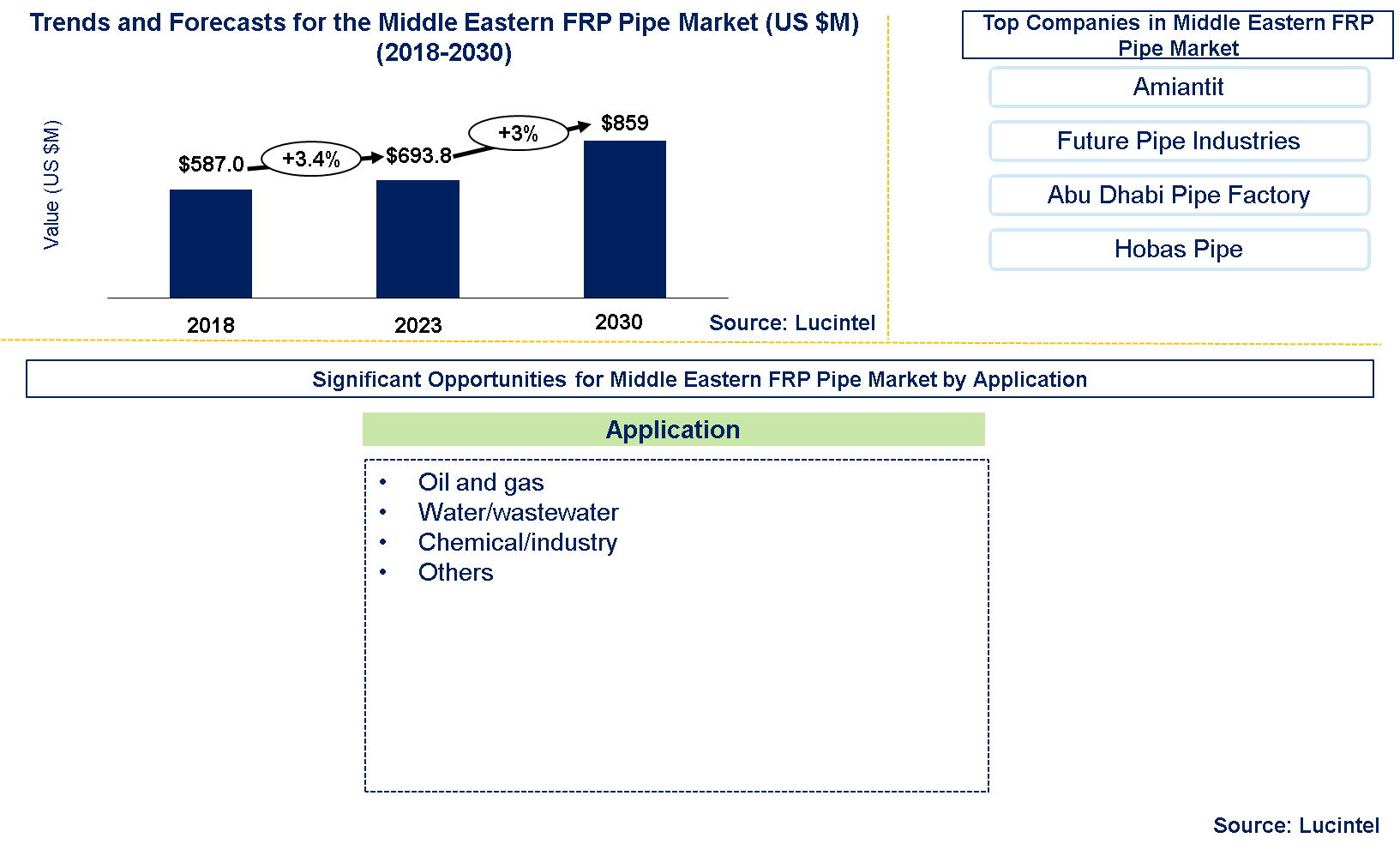

Lucintel finds that the future of the Middle Eastern FRP pipe market looks promising with opportunities in the oil and gas, water/waste water, chemical/industry, and others in application. Middle Eastern FRP pipe market is expected to reach an estimated $859 million by 2030 with a CAGR of 3% from 2024 to 2030. The major drivers of Middle East FRP pipe industry are growing investment towards urban infrastructure development, establishment and upgrade of airports, capacity expansion in petrochemical plants, and establishment of power plants. Increasing demand from replacement of existing metal pipe in oil and gas exploration activities to get rid of corrosion problems also drive the FRP pipe market in the Middle East..

Fiber Reinforced Plastic pipes are manufactured from raw materials such as resins (usually polyester, vinyl ester or epoxy), continuous glass fibers and additives (this includes fillers and curing agents). FRP pipes possess strength, corrosion resistance and durability due to the blending of these materials. In terms of pricing, FRP pipes are generally cost competitive when compared to traditional materials like steel, concrete and PVC. Because of a longer life cycle, reduced maintenance requirements and lower weight which translates to low installation costs, specific prices can vary with diameter size, pressure rating; supplier etc., but in many cases FRP pipes are found cheaper than most alternatives they compete against. Therefore FRP Pipes have become popular for use in any industries where corrosion resistant and structurally durable pipe solutions are required.

• Water/wastewater will witness strong growth during the forecast period. Establishment of water desalination plants to supply water for household and industrial applications, increasing awareness towards rainwater harvesting, and water recycling are the driving forces for this segment.

Country wise Outlook for the Middle Eastern FRP Pipe Market

Emerging Trends in Middle Eastern FRP Pipe Market

Emerging trends in Middle Eastern FRP pipe are shaping its future applications and market dynamics:

• Increased Adoption in Oil & Gas Sector: The oil and gas industry is now embracing the use of FRP pipes due to their resistance to corrosion and durability necessary for conveying different hydrocarbons and chemicals.

• Focusing on Infrastructure Development: The Middle East governments are heavily investing in infrastructure, including desalination plants, and water management systems where FRP pipes excel because of their ability to withstand harsh environmental conditions.

• Technological Advancements: Manufacturers are putting more efforts into research and development so as to improve FRP pipe properties such as mechanical strength, thermal resistance and ease of installation.

• Growing Environmental Awareness: Today’s construction projects are increasingly leaning towards sustainable practices. They prefer FRP pipes that can be recycled; have low carbon foot print, with longer life spans than traditional materials like steel or concrete.

• Expansion of Industrial Applications: In addition to its traditional sectors, FRP pipes also find applications in other areas such as agriculture, chemical processing, municipal water systems due to their versatility and cost-effectiveness.

These trends show that the Middle Eastern FRP pipe market is highly dynamic; evolving with great emphasis on innovative ideas, sustainability aspects and strategic collaborations aimed at tapping emerging opportunities in different sectors.

A total of 80 figures / charts and 20 tables are provided in this 110-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Middle Eastern FRP Pipe Market

Recent developments in Middle Eastern FRP Pipe by highlighting ongoing innovations and advancements across different sectors

• Innovative Product Launches: Advanced FRP pipe solutions have been introduced to the market by companies like Future Pipe Industries (FPI) and Amiantit. These products focus on sectors like oil and gas, water management, desalination and offer improved durability, resistance to corrosion and ease of installation.

• Expansion of Manufacturing Capacities: In order to meet the increasing demand, many major players in the Middle East have increased their manufacturing capacities. This includes setting up new production facilities as well as adopting modern manufacturing technologies that improve efficiency and product quality.

• Strategic Partnerships and Collaborations: Strategic partners with international technology providers and local stakeholders are being sought out by firms in the FRP pipe market. Therefore, these collaborations aim at utilizing expertise in material science, engineering as well as project management to provide holistic solutions for large-scale infrastructure projects.

• Shifting towards Sustainability: The Middle Eastern FRP pipe industry is witnessing a growing focus towards sustainability. Consequently, manufacturers are increasingly incorporating recycled materials into their products while improving product lifecycle assessments in a bid to minimize environmental footprints. This falls in line with regional sustainability drives as well as clients’ preferences concerning green items.

• Digital Transformation: There has been an uptake of digital technologies among FRP pipe manufacturers including IoT based monitoring systems and digital twins. These innovations enhance operational efficiency, asset management, and predictive maintenance thus offering reliability and cost-effectiveness for customers.

Strategic Growth Opportunities for Middle Eastern Glass Fiber

• Oil and Gas Sector Expansion: They need to seize the opportunity provided by growing oil and gas sector demand for FRP pipes, which are known for their higher resistance to rust and longer useful life. Upstream, midstream, and downstream segments that comprise of pipelines, refineries as well as petrochemical plants require tailor made solutions.

• Infrastructure Development Projects: The Middle East has invested heavily in infrastructure projects especially those related to water management like desalination plants and wastewater treatment plants hence creating an attractive market for FRP pipes. Ensure that this kind of requirement is met by concentrating on things such as high pressure rates, large bore sizes as well as harsh environmental conditions resistant materials.

• Investment in Research and Development: Ongoing investment in research and development is necessary to develop new products or improve on existing ones. Mechanical properties improvement, thermal stability upgrade and sustainability qualifications should be incorporated in FRP pipes. Further, inventiveness should also be extended to composites’ materials among others such the production technology as well as intelligent systems intended in monitoring use.

• Diversification into New Applications: Expanding the use of FRP pipes into emerging applications such as renewable energy infrastructure (e.g., wind farms, solar power plants) and smart city projects presents significant growth prospects.

• Geographical Expansion: Exploring opportunities in neighboring regions and countries with similar infrastructure development needs can broaden market reach and mitigate risks associated with regional economic fluctuations.

These opportunities reveal the growth potential through infrastructure spending, renewable energy targets, and technological advancements in manufacturing that can be achieved in the Middle Eastern glass-fiber market.

Middle Eastern FRP Pipe Market Drivers and Challenges

The Middle East’s FRP (Fiber Reinforced Plastic) pipe market is one of the key segments of the industrial and infrastructure landscape in the region, driven by different factors which are shaping its development. The paper looks at drivers that have led to rise in FRP pipes as well as challenges faced by industry players on how to maximize their potential. In recent times, there has been an increased preference for FRP pipes because of their outstanding corrosion resistance, durability and greenness among others. These features make them most appropriate for use in arduous situations such as water management; oil and gas as well as industrial processing within the Middle East. More so, manufacturing technologies advancements have led to improved capabilities and adaptability for FRP pipes which allows for customization according to specific project requirements

.

The key drivers for the Middle Eastern FRP pipe market include:

• Corrosion Resistance: Their excellent resistance to corrosion makes Fiber Reinforced Plastic (FRP) pipes popular in Middle East, which is ideal for transporting aggressive fluids such as oil and gas, chemical industry and desalination.

• Durability and Longevity: Durability is superior in FRP pipes compared to traditional materials like steel or concrete, making them serve longer. Consequently, these tubes have a lower needed maintenance cost as well as they can be relied on even in the harsh environmental conditions typical for the Middle East.

• Infrastructure Development: Investments into infrastructure projects such as water management systems; wastewater treatment plants; and desalination facilities drive demand for FRP pipes. For instance, projects of this magnitude need durable pipe networks that are affordable under varying operational pressures and environments.

• Advancements in Manufacturing Technology: Continuous advancements in composite materials as well as manufacturing processes contribute towards improved performance and versatility of FRP pipes. Therefore, manufacturers can produce FRP pipes at high pressures with larger diameters that exhibit better thermal stability among other specifications according to various project demands.

• Environmental Sustainability: The shift towards environmental sustainability has raised awareness about the use of fiberglass reinforced plastic (FRP) pipes. In addition to being lightweight and recyclable most of them made using eco-friendly methods thus conforming to local and international aspirations for sustainable development goals.

The challenges in the Middle Eastern FRP pipe market include:

• Expensive Initial Costs: The first cost of FRP pipes may be higher than that of conventional materials like bronze or cement. It is possible that this factor will make it difficult to apply, especially in projects with a limited budget.

• Perception and Awareness: Potential end users and decision makers might not be aware of or have wrong ideas on the performance and reliability of FRP pipes. These barriers can only be overcome through education and demonstration long-term benefits.

• Quality Control and Standards: Consistent quality as well as compliance with international standards while manufacturing FRP pipes is necessary. This however can vary greatly, which affects customer confidence in their safety and market acceptance.

• Installation and Maintenance Expertise: To maximize the life span as well as performance of FRP pipes; therefore, proper installation techniques are essential; moreover, maintenance practices play an important role too. Sometimes availability skilled workforce is a problem in some areas together with technical know-how.

• Competition from Alternative Materials: There are sections in the market still dominated by traditional materials such as steel, ductile iron or concrete pipes. For instance, one must prove better results than these well-known options providing for stronger results, cheaper rates and environmental advantages inherent to fiberglass tubes...

To sum up, the Middle East FRP pipe market is supported by two principal drivers such as, corrosion resistance and durability, infrastructure development on one hand while it faces high initial prices, skepticism of end users and competition from traditional materials on the other side. The last part calls for industry stakeholders to keep innovating, educating various actors on the long term advantages of using fiber glass reinforced polymers (FGRP) as well as ensuring there are no compromise on quality standards.

Middle Eastern FRP Pipe Suppliers and Their Market Shares

In this Middle Eastern FRP pipe market, several key players such as Amiantit, Future Pipe Industries, Abu Dhabi Pipe Factory, Farrasan, and Hobas Pipe etc. dominate the market and contribute to industry’s growth and innovation. These players capture maxim

Middle Eastern FRP Pipe Market by Segment

Numerous sections are responsible for the great growth that is being experienced today in the Middle East’s FRP (Fiber Reinforced Plastic) pipe market due to industrial and infrastructure demands. FRP pipes are becoming dominant in the oil and gas industry for both subsea and onshore applications because they have better resistance to corrosion than other materials used in these applications hence ensuring safe transportation of hydrocarbons. In water management and desalination, FRP pipes perform a critical role in desalination plants and municipal water distribution networks where their resistance to saline environments guarantees uninterrupted operation with minimal maintenance. Additionally, FRP pipes fulfill a great need in industries such as chemical processing which at times require transporting corrosive chemicals over long distances thus contributing towards effective material handling procedures that do not pose any health risks to employees. In this regard, lightweight properties of FRP pipes make them indispensable in infrastructure projects such as public transportation systems and renewable energy sources like solar and wind farms especially when considering efficient drainage systems within low-income areas or durable electricity suppliers through all seasons of the year. The aforementioned emerging segments reiterate the wide range of uses that can be found for FRP Pipes across diverse sectors throughout Middle East by highlighting their adaptability and dependability relevant to various regional needs.

Middle Eastern FRP Pipe Market by Application [Value ($M) and Volume (Million Pounds) Analysis for 2018 – 2030]:

• Oil and gas

• Water/wastewater

• Chemical/industry

• Others

Features of Middle Eastern FRP Pipe Market

• Market Size Estimates: Middle Eastern FRP pipe market size estimation in terms of value ($M) and volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various application.

• Segmentation Analysis: Market size by application.

• Growth Opportunities: Analysis on growth opportunities in different applications...

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the Middle Eastern FRP pipe composites market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in Middle Eastern FRP pipe market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ_

Q1. What is the Middle Eastern FRP pipe market size?

Answer: The Middle Eastern FRP pipe market is expected to reach an estimated $859 million by 2030

Q2. What is the growth forecast for Middle Eastern FRP pipe market?

Answer: The Middle Eastern FRP pipe market is expected to grow at a CAGR of 3% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the Middle Eastern FRP pipe market?

Answer: The major drivers of Middle East FRP pipe industry are growing investment towards urban infrastructure development, establishment and upgrade of airports, capacity expansion in petrochemical plants, and establishment of power plants.

Q4. What are the major applications or end use industries for Middle Eastern FRP pipe market?

Answer: Oil and Gas are the major end uses for Middle Eastern FRP pipe market.

Q5. What are the emerging trends in Middle Eastern FRP pipe market?

Answer: Emerging trends in the Middle Eastern FRP pipe market, which have a direct impact on the dynamics of Middle Eastern FRP pipe industry, are the increased adoption in oil & gas sector, focusing on infrastructure development.

Q6. Who are the key Middle Eastern FRP pipe market companies?

Answer: Some of the key Middle Eastern FRP pipe market companies are as follows:

• Amiantit

• Future Pipe Industries

• Abu Dhabi Pipe Factory

• Hobas Pipe

Q7. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the Middle Eastern FRP pipe market by application (oil and gas, water/waste water, chemical/industry, and others)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.4 What are the business risks and threats to the market?

Q.5 What are the emerging trends in this market and the reasons behind them?

Q.6 What are the changing demands of customers in the market?

Q.7 What are the new developments in the market? Which companies are leading these developments?

Q.8 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.9 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.10 What M & A activities have taken place in the last 5 years in this market?