Global Masterbatch Market Trends and Forecast

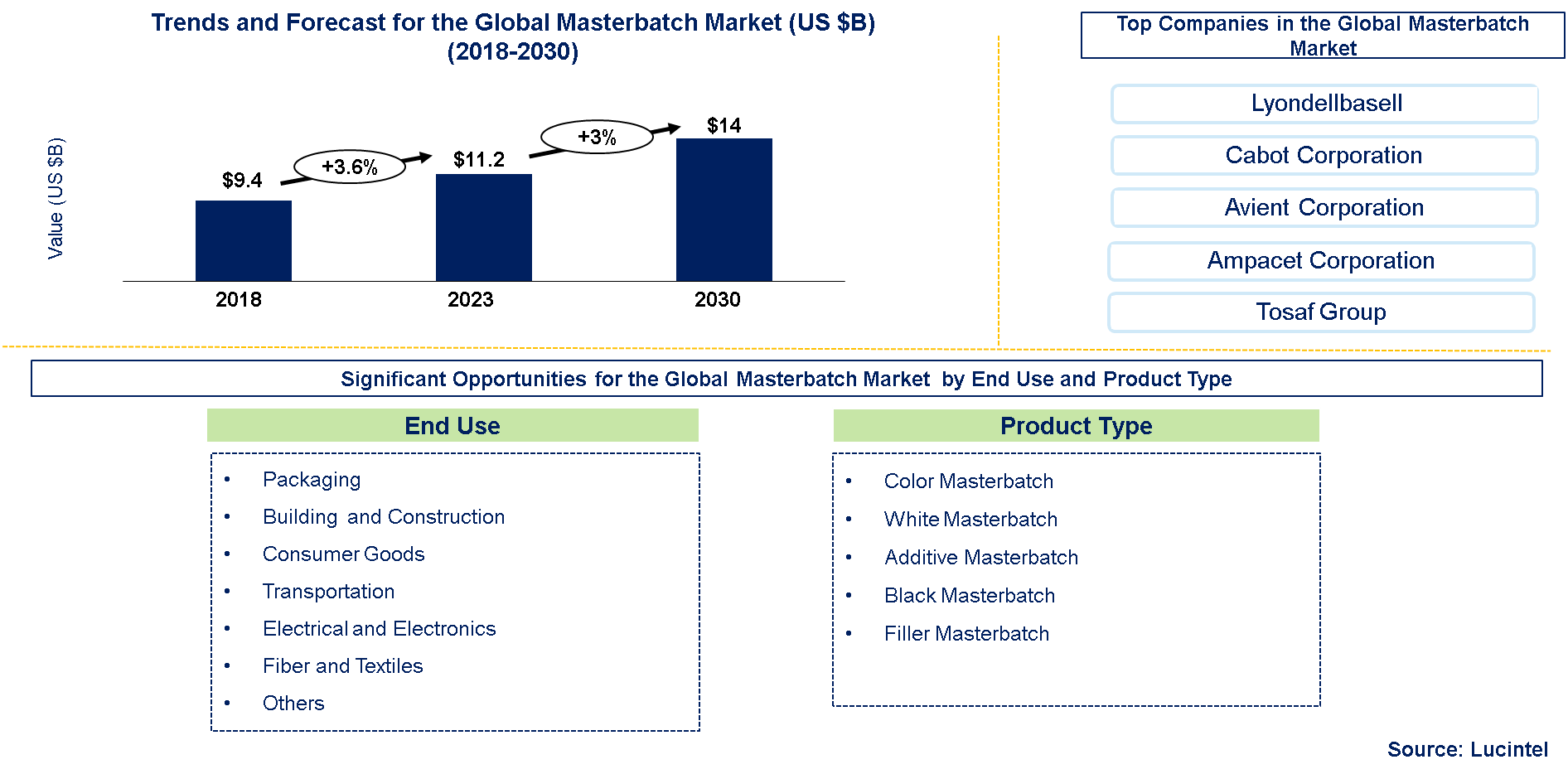

Lucintel finds that the future of the global masterbatch market looks promising with opportunities in packaging, building and construction, consumer goods, transportation, electrical and electronics, and fiber & textiles end uses. The global masterbatch market is expected to reach an estimated $14 billion by 2030 with a CAGR of 3% 2023 to 2030. The major drivers for growth in this market are increasing demand for light weight plastic as substitutes for various materials like metal, concrete, and steel in various end use industries.

Masterbatch is composed of pigments or dyes, carrier resins like polyethylene or polypropylene, and additives such as UV stabilizers and antioxidants. These components impart color and enhance properties like weather resistance. Prices vary based on type, quality, and volume purchased, influenced by raw material costs and production efficiencies. Competition in the market emphasizes product quality, customization options, and service excellence over price alone, catering to diverse polymer manufacturing needs and applications.

• Lucintel forecasts packaging will remain the largest end use by value and volume due to increasing consumption of packaged consumer goods. Fibers/textile is expected to witness highest growth over the forecast period.

• Color masterbatch is expected to be the largest market by value and volume and it is also expected to witness fastest growth over the forecast period because it’s used for special effect and colors to distinguish products.

• Asia Pacific (APAC) is expected to remain the largest region by value and volume and it is also expected to experience the highest growth over the forecast period due to growth in end uses and increasing urbanization, rising construction and infrastructure activities, changing consumer lifestyles, economic development, and demand for plastic products especially in China and India

Country wise Outlook for the Global Masterbatch Market

The masterbatch market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major advance composite producers in key regions: the USA, Germany, Brazil, China, and Japan

Emerging Trends in the Composites in the Global Masterbatch Market

1. Integrating Industry 4.0: Integration of advanced industry 4.0 technologies like IoT (Internet of Things) into smart manufacturing in order to enhance productivity levels during production processes as well as quality controls and customization in the manufacture of master batch.

2. Environmental Conservation: The demand for sustainable and environmentally friendly masterbatch solutions is increasing due to regulatory requirements that call for recyclable and biodegradable items from customers’ perspective.

3. Value added Masterbatches: The ever increasing number of functional additives like flame retardants, antimicrobials, conductive additives being added to specialized areas such as automotive, healthcare sector electronics indicates a growing interest in this segment.

4. Plastics Colours and Special Effects: Advancements in color matching technologies supported by consumer preferences towards product aesthetics have resulted into increased demand for customized plastic coloring agents and special effects.

These trends indicate a shift towards more sustainable, innovative, and technologically advanced solutions in the masterbatch industry to meet evolving consumer and regulatory demands globally.

A total of 124 figures / charts and 98 tables are provided in this 207-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Masterbatch Market

Recent developments in global masterbatch by various companies highlight ongoing innovations and advancements across different sectors

• Technological Advances: The utilization of smart technologies such as Internet of Things (IoT) sensors and RFID tags for instant tracking and quality assurance. Creation of nano- and micro-sized masterbatch for exact color matching improved dispersion. Introduction of functional additives which include antimicrobial agents and UV stabilizers.

• Initiatives on Sustainability: The rise in the use of bio-based or biodegradable masterbatches to meet the environmental requirements. Recycling materials used in production of masterbatch in line with circular economy objectives. Manufacturing, supply chain operations taking actions to reduce carbon footprint.

• Market Expansion & Application Diversification: Increasing demand for packaging applications such as food, pharmaceuticals, consumer goods. Availability in automotive interiors, exteriors and building materials is on increase. Construction materials also offer properties like UV protection factor, weather resistance and durability.

• Regulatory Compliance & Certification: Complying stringently with regulations on food contact, health safety and environmental friendliness. Investment into compliance processes; quality assurance for meeting global standards.

• Industry Cooperation & Partnership: Manufacturers collaborating with processors are united to develop custom-made solutions accessible to end-users. Strategic partnerships aimed at expanding market coverage and enhancing technical abilities.

• Digitalization & Industry 4.0 - – Employing artificial intelligence (AI), machine learning (ML) and data analytics (DA) for process optimization. Predictive maintenance and product design through digital twins and simulation tools.

Strategic Growth Opportunities for Global Masterbatch Market

There are several strategic growth opportunities in the masterbatch market. These trends include technological developments, end-use industry patterns and changes in market dynamics. Here is a list of strategic opportunities that are available in masterbatch space;

1. Expansion in Emerging Markets

Opportunity: Make use of fast growing economies as witnessed in regions such as Asia-Pacific, Latin America and Africa where industrialization, urbanization and rising consumer demands have given rise to packaging, automotive and consumer goods sectors.

Rationale: In these areas there is fast economic growth rates coupled with rapid infrastructure development implying increased demand for quality plastic products thus increasing for masterbatches.

2. Growth in Packaging Industry

Opportunity: Concentrate on packaging sector which is the largest user of masterbatches to have bright colors, high qualities and functional solutions towards packaging.

Rationale: Demand for functional characteristics like UV resistance, barrier properties, biodegradability as well as enhanced visual attractiveness of packaging materials has led to requirement of specialized masterbatches.

3. Advances in Sustainable and Eco-Friendly Masterbatches

Opportunity: Develop and promote environmental friendly products through product designs using sustainable materials; produce Masterbatches that utilize recycled or biodegradable components.

Rationale: Demands for an eco-friendly solutions has been driven by increase in regulatory pressures and consumers’ concern towards environment.

4. Innovation in Functional Masterbatches

Opportunity: Conduct R&D into advanced performance attributes including flame retardancy, anti-microbial features or thermal stability properties among others.

Rationale: End-use industries require special capabilities from their master batches to improve safety and performance such as automotive construction electronics markets which need specific performances from their Master batches

5. Expansion of Applications in Automotive and Consumer Goods

Opportunity: Focus more on the automotive industry and consumer goods sector because they take advantage of masterbatches which used both for design purposes but also filled them with essence of functionality for several components or final goods.

Rationale: The automotive industry’s emphasis on lightweight materials and customizable components, coupled with the consumer goods sector’s desire to differentiate products, necessitates innovative masterbatch solutions.

6. Growth in 3D Printing

Opportunity: Create masterbatches for 3D printing applications that improve color consistency and material properties.

Rationale: With a growing use of 3-dimensional technology in multiple industries, there is an increasing demand for high quality Masterbatches that can provide the needed performance and aesthetics in printed parts.

Global Masterbatch Market Drivers and Challenges

Various drivers and challenges are responsible for shaping the global masterbatch market, which encompasses incorporation of color or functional additives into polymers. An understanding of these can enable stakeholders navigate the market and spot strategic opportunities.

The key drivers for the global advance composites market include

• Rising Packaging Industry: Masterbatches are in demand to improve the aesthetics, functionality, and durability of packaging materials due to the expanding packaging industry majorly in food & beverage, consumer goods and healthcare.

• Increase in Customization and Personalization Demand: There is a growing requirement for personalized and customized products across multiple industries including consumer goods, automotive and electronics.

• Advances in Technology: Innovations in colorants, additives as well as manufacturing processes are leading to improved efficiency, performance as well as versatility of masterbatches.

• Trends on Sustainability: Stringent regulations coupled with increased concerns from customers regarding environmental friendly products have resulted to sustainable and recyclable masterbatches.

• Emerging Markets Expanding: There has been an escalating need for masterbatches among developing countries such as Africa, Latin America, and Asia-Pacific because of their applications like packaging or consumer goods driven by rapid industrialization process coupled with economic boom.

• Growth in Automotive and Consumer Goods Sectors: The demand for specialized masterbatches arises from the automotive industry’s focus on utilizing lightweight materials and consumer goods sector which emphasizes on aesthetics and functionality.

The key challenges for the global advance composites market include

High Production Costs: Manufacturing technologies for producing top quality raw materials and advanced manufacturing technologies result to high production costs in the case of masterbatches.

Complexity in Manufacturing Processes: The manufacture of such additives is very complex involving precise blending, dispersion as well as quality controls.

Regulatory and Compliance Issues: There are stringent safety requirements governing the formulation of any given masterbatch related to environmental impact as well as industrial standards.

Limited Recycling Options: Complex additives containing masterbatch materials are not easily recyclable due to logistical as well as environmental challenges associated with this process.

Fluctuating Raw Material Prices: Price volatility is experienced due to market dynamics together with supply chain problems concerning key raw materials like pigments or polymers (polymerization).

Intellectual Property and Innovation Risks: Proprietary formulations development together with rapid advancements of masterbatch technology poses threats which are linked to intellectual property and innovation risks.

The masterbatch market worldwide is driven by reasons like customizing that is in high demand; technology related improvements and sustainability trends as well as having wider applications in packaging, automobile and consumer goods sectors. Nevertheless, such challenges as high production costs complicated manufacturing processes and regulatory compliance should be tackled. If a company can overcome these hurdles while also exploiting the drivers of growth, it may succeed in the evolving masterbatch industry.

.

Global Masterbatch Suppliers and Their Market Shares

In this globally competitive market, several key players such as, Lyondell Basell, Cabot Corporation, Avient Corporation, Ampacet Corporation, Tosaf Group etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at helpdesk@lucintel.com.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies carbon fiber companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the global masterbatch companies profiled in this report include.

• Lyondell Basell

• Cabot Corporation

• Avient Corporation

• Ampacet Corporation

• Tosaf Group

• Polyplast

• Podder Pigments Ltd

• Gabriel Chemic GmbH

These companies have established themselves as leaders in the global masterbatch industry with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the global masterbatch market are evolving, with the entry of new players and the emergence of innovative technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Composites in Masterbatch Market by Segment

Major segments of the masterbatch industry experiencing growth include color masterbatches driven by customization demands, additive masterbatches for enhanced functionality across industries like electronics and healthcare, and white masterbatches valued for their opacity and cost-effectiveness in packaging. Specialty masterbatches are expanding in niche applications such as biodegradable polymers and high-temperature plastics, while bio-based and sustainable masterbatches are gaining traction amid regulatory pressures and increasing consumer preference for eco-friendly products. These trends highlight a shift towards specialized, functional, and environmentally conscious solutions in the masterbatch market.

This masterbatch market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including end use, product type, process, and carrier resin. The report offers insights into regional dynamics, highlighting the major markets for global masterbatch and their growth potentials. The study includes trends and forecast for the composites in global masterbatch market by end use, product type, process, and carrier resin and region as follows:

By End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Packaging

• Building and Construction

• Consumer Goods

• Transportation

• Electrical and Electronics

• Fiber and Textiles

• Others

By Product Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Color Masterbatch

• White Masterbatch

• Additive Masterbatch

• Black Masterbatch

• Filler Masterbatch

By Carrier Resin [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Polyethylene (PE)

• Polypropylene (PP)

• Polystyrene (PS)

• Polyamide (PA)

• Acrylonitrile butadiene styrene (ABS)

• Ethylene-vinyl acetate (EVA)

• Styrene Acrylonitrile Resin (SAN)

• Polycarbonate (PC)

• Others

By Process [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Film Extrusion

• Blow Molding

• Injection Molding

• Pipe, Conduit, and Tubing

• Extrusion Coating

• Sheet and Thermo foaming

• Wire and Cable

• Rotational Molding

• Other Extrusion

By Region [Value ($M) and Volume (M lbs) shipment analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• Rest of the World

Features of Global Masterbatch Market

• Market Size Estimates: Masterbatch market size estimation in terms of value ($M) and Volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Masterbatch market size by various segments, such as end use, product type, carrier resin, process, and regions in terms of value and volume.

• Regional Analysis: Masterbatch market breakdown by North America, Europe, and Asia Pacific & the Rest of the World.

• Growth Opportunities: Analysis on growth opportunities in different end use, product type, carrier resin, process, and regions for the global masterbatch market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the global masterbatch market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in composites in the global masterbatch market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the global masterbatch size?

Answer: The global masterbatch is expected to reach an estimated to $14 billion by 2030.

Q2. What is the growth forecast for global masterbatch market?

Answer: The masterbatch market is expected to grow at a CAGR of 3% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the global masterbatch market?

Answer: The major drivers for growth in this market are increasing demand for light weight plastic as substitutes for various materials like metal, concrete, and steel in various end use industries.

Q4. What are the major applications or end use industries global masterbatch?

Answer: Packaging and building & construction use are the major end uses for masterbatch.

Q5. What are the emerging trends of global masterbatch market?

Answer: Emerging trends, which have a direct impact on the dynamics of the masterbatch industry, include smart and intelligent masterbatches, industry 4.0 integration, sustainability, functional additives, color and special effects.

Q6. Who are the global masterbatch companies?

Answer: Some of the key global masterbatch companies are as follows:

• Lyondell Basell

• Cabot Corporation

• Polyone

• Ampacet Corporation

• Plasti Blends

• Tosaf Group

• Polyplast

• Podder Pigments

• Gabriel Chemic GmbH

Q7.Which global masterbatch product segment will be the largest in future?

Answer: Lucintel forecasts that color product type global masterbatch will remain the largest segment.

Q8: In global masterbatch, which region is expected to be the largest in next 7 years?

Answer: APAC is expected to remain the largest region and witness the highest growth over next 7 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global masterbatch market by end use (packaging, consumer goods, electrical and electronics, transportation, fiber and textiles, building and construction, and others), product type (color, white, black, additive, and filler) resin carrier type (PE, PP, PS, PA, EVA, ABS, SAN, and PC), process (film extrusion, blow molding, injection molding, pipe, conduit and tubing, extrusion coating, sheet and thermoforming, wire and cable, rotational molding, and other extrusion), and region (North America, Europe, and Asia Pacific & Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?