Masterbatch in South Korea Market Trends and Forecast

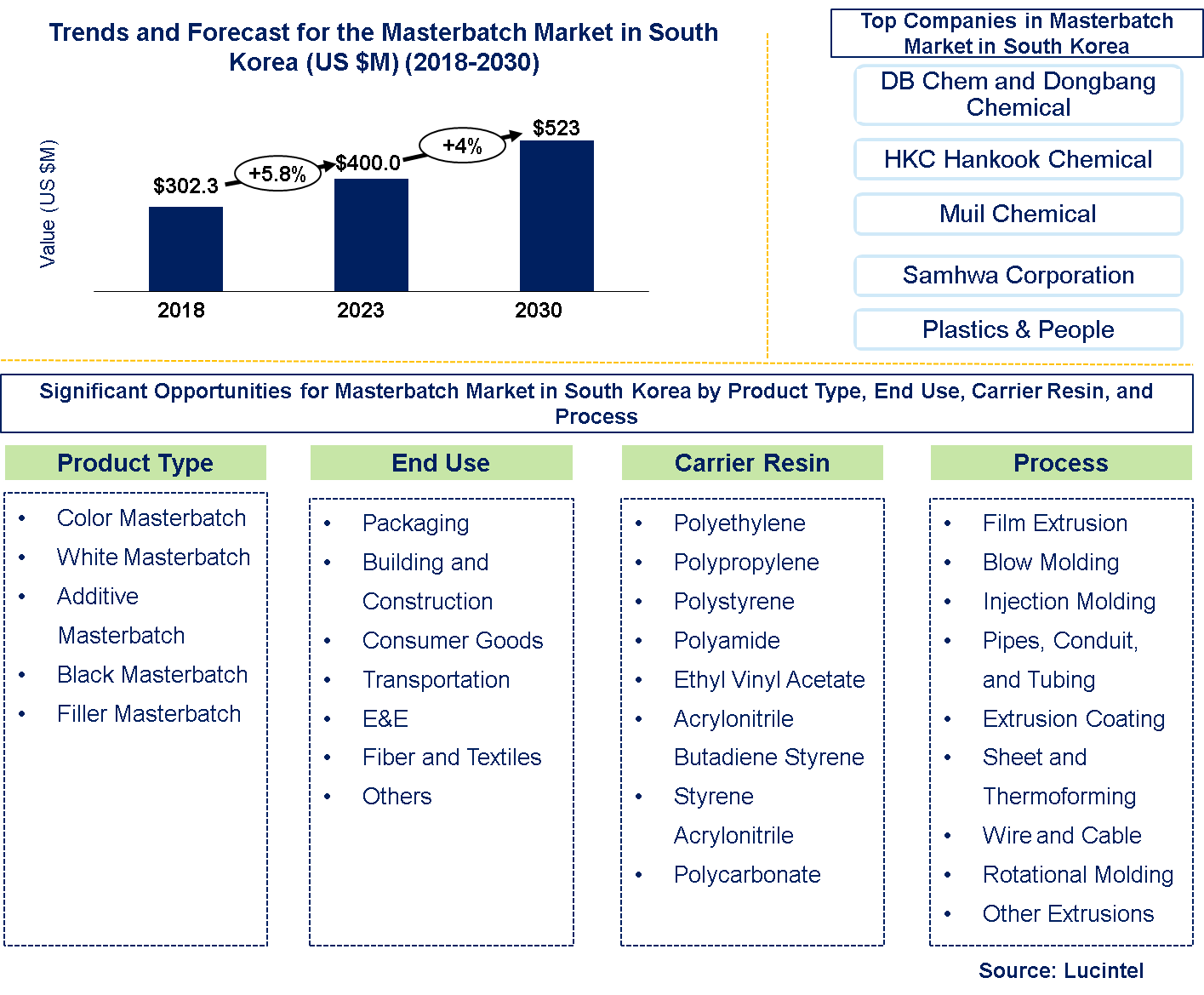

Lucintel finds that the future of the masterbatch market in South Korea is attractive with opportunities in various end use, including packaging, building and construction, consumer goods, transportation, electrical and electronics, and textiles industries. The masterbatch market in South Korea is expected to reach an estimated $523 million by 2030 with a CAGR of 4% from 2023 to 2030. The major driver for growth of this market is increasing demand for plastic as substitutes for various materials like metal, concrete, and steel in various end uses.

Comprising of pigments and dyes, the masterbatch also includes carrier resins such as polyethylene or polypropylene and additives like UV stabilizers and antioxidants, which help to enhance the weather resistant properties while giving color. Prices of these raw materials range from low cost to high depending on quality, volume bought and type since there are production efficiencies as well as raw materials costs. With polymer manufacturing and use comes the need for satisfying several needs by addressing markets competing around quality of raw materials, customization services, service delivery rather than pricing alone..

• Lucintel forecasts that the packaging is expected to remain the largest segment by value and volume over the forecast period supported by increasing consumption of packaged consumer goods.

• By product type, color, black, white, and additives are the major masterbatch utilized to manufacture plastic products. Color masterbatch is expected to be the largest market by value and volume because it’s used for special effect and colors to distinguish products.

Country wise Outlook for Masterbatch in South Korea Market

Emerging Trends in the Masterbatch in South Korea Market

Emerging trends in carbon fiber are shaping its future applications and market dynamics:

1. High Performance Additives: The scorching demand of the masterbatches having functional additives like fire retardants, biocides and anti-static is on the increase. These additives enhance final products’ performance and durability for different applications.

2. Customization and Application Specific Solutions: Recently, there is a growing trend where companies are customizing their masterbatch solutions to meet individual customer expectations and application needs. This has seen the niche markets within industries such as healthcare, electronics or other sectors.

3. Color and Special Effects: Current market trends indicate that there is an increasing need for masterbatches that provide bright colors, special effects (e.g., metallic or pearlescent finishes), as well as UV protection properties. Specific technologies can be used in packaging industry, consumer goods amongst others automotive.

4. Technological Advancements: To improve product quality, consistency and efficiency in masterbatch processes; business organizations invest in advanced manufacturing technologies and process innovations.

5. Focus on Sustainability: Today’s emphasis on sustainable masterbatch solutions stems from regulatory pressures and the desire by customers for eco-friendly items. There are company-specific initiatives aimed at reducing environmental impact through developing bio-based/recycled content masterbatches as well.

The South Korean market for masterbatches is undergoing a dynamic evolution driven by technological advancements, regulatory compliance and changing consumer preferences towards sustainable & high-performance materials.

A total of 25 figures / charts and 12 tables are provided in this 60-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Masterbatch in South Korea

Recent developments in masterbatch in South Korea by highlighting ongoing innovations and advancements across different sectors

• Progress of Technologies: The technology behind masterbatch has continuously been advancing so as to make product performance better, efficient as well as compatibility with different kind of polymer resins. Some developments have resulted in the emergence of high-performance masterbatches that support better dispersion, UV stabilization, flame retardancy, and antibacterial properties.

• Sustainable Development Focus: Like other global markets, South Korea’s masterbatch industry is increasingly prioritizing sustainability. There is a growing demand for eco-friendly masterbatch solutions that reduce carbon footprint, utilize recycled materials and meet stringent environmental regulations. Companies are investing in research and development to develop bio-based and biodegradable masterbatch products to meet these sustainability goals.

• Application Areas Expanding: The South Korean market for masterbatches has grown beyond packaging into automotive parts, electrical and electronic devices, agriculture films and construction materials. In each sector there are specific requirements for colorants or additives necessary for improving its performance together with functional masterbatches which can be customized to suit the various forms of processing required by them as well as end uses.

• Technological Integration: Digitalization as well as integration of smart technologies are influencing the landscape of the Master batch industry in South Korea. Data analytics, IoT (Internet of Things), and automation enable companies optimize manufacturing processes while product quality is upgraded at customer service levels; this also improves supply chain efficiency.

• Strategic Partnerships/ Collaborations : Collaboration between manufacturers of masterbatch weighers, polymer processors besides end-users plays an essential role in propelling innovation along with growth within the market. These partnerships concentrate on creating tailor-made solution providers hence exploring new application areas domestically or internationally thereby widening its domestic or international reach.

Strategic Growth Opportunities for Masterbatch in South Korea Market

The masterbatch in South Korea market is very dynamic due to its unique properties of being lightweight, strong and thermally stable. Some key strategic growth opportunities for this market include

Plastic Industry Growth:

• Market Demand: A strong manufacturing sector for plastics in South Korea, including packaging, electronics, automotive and consumer goods has generated a significant demand for masterbatch.

• Opportunities: Opportunities exist for specialty masterbatch formulations tailored to specific applications in sectors like flexible packaging and consumer electronics where growth is witnessed.

Trends in Masterbatch Formulation Technology:

• Innovation: Continuous research and development on masterbatch technology is focused on improving features such as UV stabilization, antimicrobial properties among others.

• Opportunities: To differentiate themselves from the competitors, manufacturers can offer high performance master batches solutions that meet strict quality standards and environmental regulations.

Eco-Friendly and Sustainable Masterbatch:

• Environmental Awareness: Sustainability is gaining more weight thereby increasing demand of eco-friendly masterbatches such as bio-based or recycled content ones.

• Opportunities: Investing in sustainability could enable companies benefit from the current inclination towards greener products among consumers and regulators within South Korea.

Potential Opportunities in the Automotive Sector:

• Applications: In enhancing color & functional additives of automotive interior & exterior components (dashboards door panels bumpers) amongst other factors a crucial role is played by masterbatches.

• Opportunities: With its well-established car industry base there are chances for customized formulation suppliers to provide unique products that adhere to all automotive industry requirements.

Finally, the South Korean masterbatch market is defined by various expansion chances fuelled by industry growth, technological progress, eco-friendliness and joint ventures. Therefore, firms that are about to invest in sophisticated technologies, ecological activities and diversification of a market will exploit these opportunities for an incessant development in the fast changing South Korean market.

Masterbatch in South Korea Market Drivers and Challenges

The growth and development of the masterbatch market in South Korea are determined by a number of factors. Growth factors encompass increasing industrial applications in such areas as packaging, automotive, electronics, and consumer goods propelled by technology advancement as well as customization pressure. Regulatory compliance and the drive for sustainable solutions also foster expansion of the market. They include cost pressures, recyclability related environmental concerns, competitive dynamics, technological complexities, and supply chain vulnerabilities that pose difficulties to the market.

The factors responsible for driving the masterbatch in South Korea market include:

1. Advantages of Industrial Growth: Increased usage of masterbatch in a wide range of sectors including consumer goods, electronics, packaging and vehicles has fuelled the market.

2. Technology Progression: Product functionality improvement through use of more advanced masterbatch formulas for color control and other features.

3. Being Conformist with Regulations: There also is government’s move towards green and environment friendly masterbatches because such products comply with their stringent guidelines thus discouraging other types.

4. Creativity and Personalization: The demand for custom-made masterbatch formulations that fit specific applications needs as well as aesthetic tastes.

5. More End-Use Segments Expansion: Specialized Master batch is preferred by industries like construction, healthcare, agriculture due to its growing demands.

The key challenges for the masterbatch in South Korea market include:

1. Cost Pressures: The extent to which manufacturers and consumers are price-sensitive may affect their acceptance of high-priced special masterbatch.

2. Environmental Concerns: Masterbatch producers face tough times in developing sustainable solutions because of growing concern about reducing carbon footprint and improving recyclability.

3. Competitive Landscape: Intensive competition among worldwide and local firms in the masterbatch industry necessitates distinguishing one’s products through novelty and service mastery.

4. Technological Complexity: Rapid technological changes mean that firms need to continue investing heavily in research and development for market superiority.

5. Supply Chain Disruptions: Material cost uncertainty coupled with supply chain glitches, can increase production costs as well as lead time.

In conclusion, the South Korean masterbatch market is poised for growth driven by technological innovation and strategic partnerships. However, navigating challenges such as regulatory compliance and intense competition requires continuous adaptation and investment. The marketÄX%$%Xs evolution hinges on innovative solutions that meet environmental standards while maintaining cost-efficiency, fostering a dynamic landscape for future advancements and sustainable growth.

Masterbatch in South Korea Suppliers and Their Market Shares

In this South Korea competitive market, several key players such as ,DB Chem and Dongbang Chemical, HKC Hankook Chemical, Muil Chemical, Samhwa Corporation etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players Contact Us. Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies carbon fiber companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the masterbatch in South Korea companies profiled in this report include.

• DB Chem and Dongbang Chemical

• HKC Hankook Chemical

• Muil Chemical

• Samhwa Corporation

• Plastics & People

• SAM-A C&I Co,Ltd.

• HN Platec

• SM Chemical

• Samjin Polytech

These companies have established themselves as leaders in the masterbatch in South Korea industry with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the masterbatch in South Korea market are evolving, with the entry of new players and the emergence of innovative technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Masterbatch in South Korea Market by Segment

There has been a remarkable surge in the masterbatch industry in South Korea that embraces key sectors. Packaging is leading with increasing need for masterbatches to improve product appearance and protection. For instance, the automotive sector is expanding its production using masterbatches as many of their interior and exterior parts are produced from these materials. Masterbatches are being utilized in consumer goods such as electronics and appliances among others, for appearance improvement and good performance. Moreover, building & construction is one of the sectors where there are increased usage of masterbatching agents in durable products like pipes and profiles. Masterbatches influence agricultural production by increasing crop yields through films used to protect crops and enhance environmental sustainability indicating how diverse this market is becoming.

By End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Packaging

• Building and Construction

• Consumer Goods

• Transportation

• Electrical and Electronics

• Fiber and Textiles

• Others

By Product Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Color Masterbatch

• White Masterbatch

• Additive Masterbatch

• Black Masterbatch

• Filler Masterbatch

By Carrier Resin [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Polyethylene (PE)

• Polypropylene (PP)

• Polystyrene (PS)

• Polyamide (PA)

• Ethylene-vinyl acetate (EVA)

• Acrylonitrile butadiene styrene (ABS)

• Styrene Acrylonitrile Resin (SAN)

• Polycarbonate (PC)

By Process [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Film Extrusion

• Blow Molding

• Injection Molding

• Pipe, Conduit, and Tubing

• Extrusion Coating

• Sheet and Thermo foaming

• Wire and Cable

• Rotational Molding

• Other Extrusion

Features of Masterbatch in South Korea Market

• Market Size Estimates: Masterbatch in South Korea market size estimation in terms of value ($M) and Volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Masterbatch in South Korea market size by various segments, such as end use, product type, carrier resin, process, and regions in terms of value and volume.

• Growth Opportunities: Analysis on growth opportunities in different end use, product type, carrier resin, process, and regions for the masterbatch in South Korea market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the masterbatch in South Korea market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in composites in the masterbatch in South Korea market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the masterbatch in South Korea size?

Answer: The masterbatch in South Korea is expected to reach an estimated to $523 million by 2030.

Q2. What is the growth forecast for masterbatch in South Korea market?

Answer: The masterbatch in South Korea market is expected to grow at a CAGR of 4% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the masterbatch in South Korea market?

Answer: The major drivers for growth in this market are increasing demand for light weight plastic as substitutes for various materials like metal, concrete, and steel in various end uses.

Q4. What are the major applications or end use of masterbatch in South Korea?

Answer: Packaging and construction end use are the major end uses for masterbatch in South Korea market.

Q5. What are the emerging trends of masterbatch in South Korea market?

Answer: Emerging trends, which have a direct impact on the dynamics of the masterbatch industry, include high performance additives, customization and application specific solutions, and color and special effects..

Q6. Who are the masterbatch in South Korea companies?

Answer: Some of the key masterbatch in South Korea companies are as follows:

• DB Chem and Dongbang Chemical

• HKC Hankook Chemical

• Muil Chemical

• Samhwa Corporation

• Plastics & People

• SAM-A C&I Co.,Ltd.

• HN Platec

• SM Chemical

• Samjin Polytech

Q7.Which masterbatch in South Korea product segment will be the largest in future?

Answer: Lucintel forecasts that color product type masterbatch in South Korea will remain the largest segment.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the masterbatch market in South Korea by product type (color, white, black, additive, and filler), function type (PE, PP, PS, PC, EVS, SAN, and ABS), end use industry (packaging, consumer goods, electrical and electronics, transportation, fiber and textiles, building and construction, and others), and by process (film extrusion, blow molding, injection molding, pipe, conducit and tubing, extrusion coating, sheet and thermoforming, wire and cable, rotational molding, and other extrusion)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 What are the key factors affecting market dynamics? What are the drivers and challenges of the masterbatch market?

Q.4 What are the business risks and threats to the masterbatch market?

Q.5 What are emerging trends in this masterbatch market and the reasons behind them?

Q.6 What are some changing demands of customers in the masterbatch market?

Q.7 What are the new developments in the masterbatch market? Which companies are leading these developments?