Low Density SMC Market Trends and Forecast

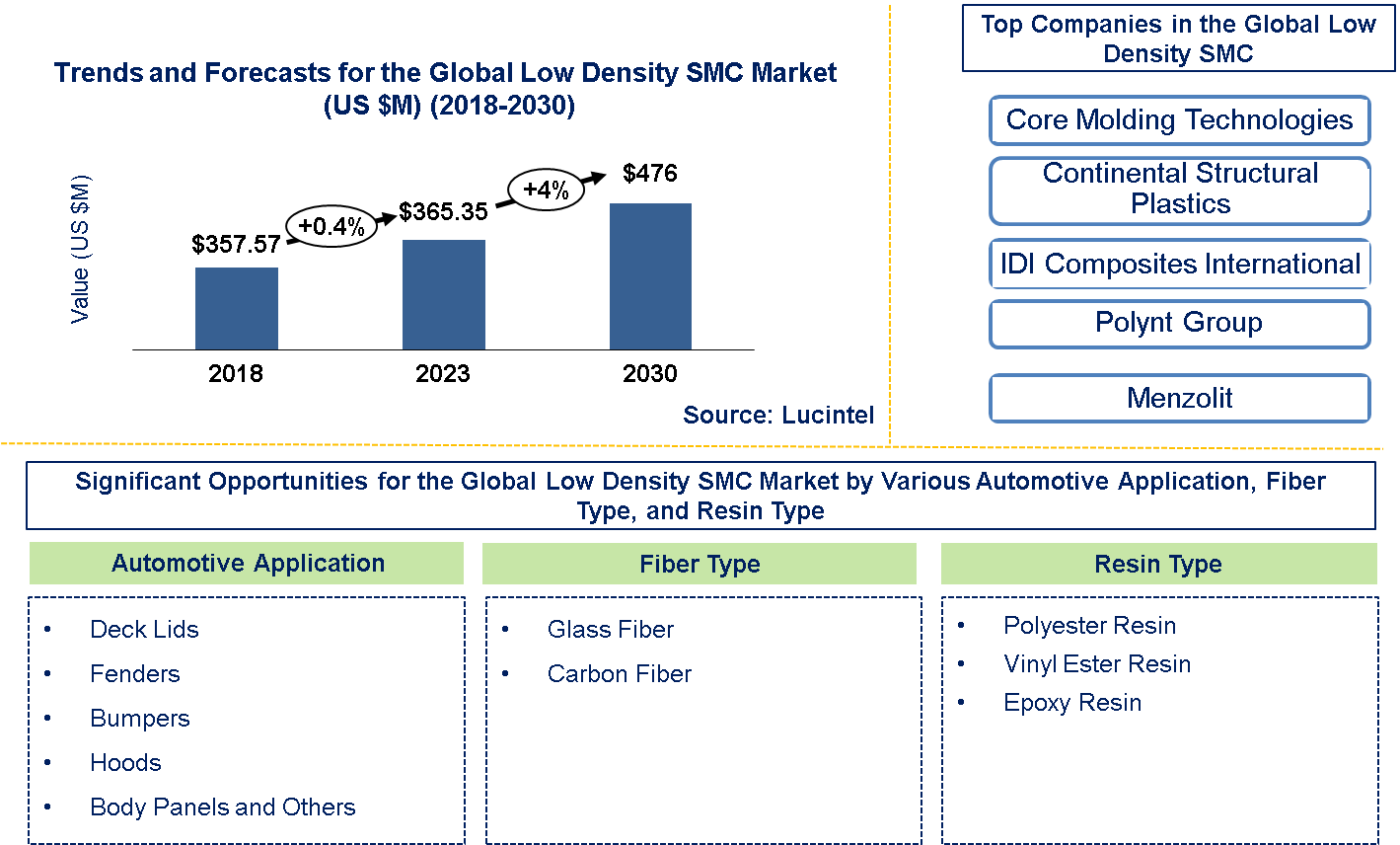

Lucintel finds that the future of the global low density SMC (Sheet Molding Compound) intermediate material market looks promising with opportunities in various hoods, deck lids, fenders, bumpers, and body panel applications. The global low density SMC market is expected to reach an estimated $391.4 million by 2030 with a CAGR of 4% 2023 to 2030. The major drivers for this market are growth in automotive production and increasing use of lightweight materials in different automotive applications.

Low density SMC is primarily made from raw materials such as thermoset resin, fiber, filler, and others. The price of low density SMC can vary based on factors like specific formulation; volume purchased, and market conditions. Generally, it tends to be competitive due to its lightweight properties and the ability to achieve high strength-to-weight ratios. Compared to traditional materials like metals (steel, aluminum) or higher density composites, low density SMC may offer cost advantages in terms of material efficiency, ease of manufacturing complex shapes, and reduced tooling costs. However, final pricing can also depend on application-specific requirements and the overall supply chain dynamics within the composite materials industry.

• Lucintel forecasts that hood will remain the largest automotive application and is also expected to witness the highest growth over the forecast period due to increasing demand for lightweight and non-corrosive materials. Hood is expected to witness the highest growth over the forecast period.

• Glass fiber will remain the largest segment over the forecast period due to its properties like high strength/weight, phenomenal impact resistance, good electrical properties, resistance to moisture, and excellent outdoor weathering.

• North America is expected to remain the largest region over the forecast period due to higher acceptance level of composites materials and growth in automotive application. APAC is expected to witness highest growth over the forecast period.

Country wise Outlook for the Low Density SMC Market

The low density SMC market is witnessing substantial growth globally, driven by increased demand from various industries such as deck lids, fenders, bumpers, hoods, body panels & others. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major low density SMC producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends in the Low Density SMC Market

Emerging trends in the low density SMC market shaping its future applications and market dynamics:

• Rising Demand for Lightweight Materials in Automotive: In order to increase fuel efficiency and lower emissions, the automotive industry is strongly moving toward lightweight materials. For automotive producers, low density SMC is appealing since it may save a lot of weight when compared to conventional materials like steel.

• Increasing Use of Electric Vehicles (EVs): The increasing use of electric vehicles has raised the need for materials that are lightweight and have a longer battery life. The lightweight properties of low density SMC help to maximize vehicle performance and range..

• Advanced Manufacturing Techniques: Automation and compression molding are two examples of manufacturing innovations that are increasing the productivity of low density SMC components. This lowers production costs and raises part quality uniformity..

• Customization and Design Flexibility: With low density SMC, manufacturers focus on offering individualized solutions and design flexibility. This makes it possible to create intricate pieces and forms that are suited to certain application requirements.

• Market Penetration in Emerging Economies: There is a rising demand for low density SMC in industries including transportation, renewable energy, and urban development as emerging economies continue to industrialize and modernize their infrastructure.

A total of 90 figures / charts and 122 tables are provided in this 192-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Low Density SMC Suppliers

Recent developments in low density SMC by various companies highlight ongoing innovations and advancements across different sectors:

• Material Innovation: Suppliers are continuously developing new formulations of low density SMC to enhance properties such as mechanical strength, impact resistance, and heat tolerance. This involves experimenting with different resin matrices, reinforcing fibers, and additives to achieve specific performance requirements.

• Sustainability Initiatives: ThereÄX%$%Xs a growing focus on sustainability within the SMC industry, with suppliers working to reduce the environmental impact of their products. This includes using recycled materials in SMC formulations, optimizing manufacturing processes to minimize waste and energy consumption, and obtaining certifications for eco-friendly practices.

• Advanced Manufacturing Technologies: Suppliers are adopting advanced manufacturing technologies to improve production efficiency and product quality. This includes automated mixing and molding processes, digital simulation tools for mold design optimization, and robotic handling systems for precise part manufacturing.

• Quality Assurance and Compliance: Suppliers are investing in stringent quality assurance measures and obtaining certifications to meet global standards and regulatory requirements. This ensures that their low density SMC products consistently meet customer expectations for performance, reliability, and safety.

• Collaborations and Partnerships: Suppliers are increasingly collaborating with customers, research institutions, and technology partners to co-develop innovative solutions. These collaborations help in addressing specific industry challenges, such as light weighting in automotive design or improving durability in construction materials.

Strategic Growth Opportunities for Low Density SMC Market

The low density SMC market is very dynamic due to its unique properties of being lightweight, strong and thermally stable. Some key strategic growth opportunities for this market include:

Expansion in Automotive Industry:

• Lightweight Components: Make use of low density SMC to fabricate light vehicle parts for high fuel efficiency and reduced emissions which is in line with demand for eco-friendly cars.

• Electrification: Design electric vehicle (EV)-specific lightweight SMC solutions that would allow lighter and energy efficient designs such as battery enclosures and structural components.

Growth in Consumer Goods:

• Innovative Designs: Make variety of consumer products from low density SMC that are highly attractive in terms of their shapes, many complex forms and better performance.

• Durability and Safety: Increase the resistance to impacts, longevity, safety etc. on consumer goods like home appliances, sports equipment etc. through the use of Low Density SMC

Advancements In Aerospace Sector:

• Weight Reduction: Use low-density sheet molding compound (SMC) in various aerospace applications so as to reduce aircraft component weight which improves fuel efficiency and general overall aircraft performance.

• Enhanced Performance: Develop advanced materials made from low-density sheet molding compounds (SMC) having improved mechanical or thermal characteristics that will meet demanding aerospace standards.

Development in Infrastructure and Construction:

• Building Materials: Capitalize on the light weight/high strength characteristics of low density SMC to broaden its usage on infrastructure projects including panels, cladding ,and structural components

Increase in Sustainability And Eco-Friendly Innovations:

• Recycled Materials: Develop technologies for incorporating recycled fibers and resins into LD-SMC systems to be consistent with environmental trends thus resulting in less environmental footprint among others

• Bio-Based Resins: However, a whole lot more companies are adopting bio-based resins meant for LD-SMC so as to reach environmentally concerned customers while abiding by the new regulations concerning chemical content control

Low Density SMC Market Drivers and Challenges

The market of SMC with low density is driven by its lightness, versatility and effectiveness in different industries. Nevertheless, difficulties such as expensive launching of production, shortcomings in quality uniformity and insufficient recycling facilities are stumbling blocks to overcome. It is necessary to balance these criteria for the development of the market and technology.

The factors responsible for driving the low density SMC market include:

1. Lightweight Benefits: Sheet Molding compounds of low density are highly praised for their lightness in the automotive industry, which enables fuel economy as well as decreasing the weight in aerospace parts, thus enhancing overall performance.

2. Adapted by Many Applications and Flexibility in Design: It can create different forms with high accuracy because it is a material that can be molded into complex shapes, thereby making it appropriate for use in various sectors including consumer goods, aerospace and automobiles.

3. Better Mechanical Properties: Modern-day materials have been used to improve the strength of low-density SMC products and their ability to withstand shocks, therefore making them suitable for demanding applications.

4. Economical Advantage: Its easy molding formability and processability, manufacturing with lightweight SMC can result in savings on costs due to reduced production time and wastage.

Challenges in the Low Density SMC Market:

1. High Initial Costs: The sum of money to invest in advanced production technologies and high quality raw materials for low-density SMC may be hefty, which can limit its adoption, especially in applications like cost-oriented.

2. Quality Consistency: To have a uniform quality and performance across different batches is not easy hence it requires strict control over the quality of the raw materials and specialized skills.

3. Limited Recycling Infrastructure: However, due to underdeveloped recycling infrastructure for low-density SMC there is an effect on the material’s ecological advantages and final disposal.

There are numerous emerging innovations that come with opportunities and challenges. For instance, these advances might improve performance and sustainability but they need much investment plus a lot of know-how in this area. Therefore, for the low-density SMC to be fully utilized there is need for market barriers be addressed.

Low Density SMC Suppliers and Their Market Shares

In this globally competitive market, several key players such as Core Molding Technologies, Teijin, IDI Composites International, Polynt Group, and Menzolit GmbH dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players Contact Us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies low density SMC companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the low density SMC companies profiled in this report include.

• Core Molding Technologies

• Teijin Limited

• IDI Composites International

• Polynt Group

• Menzolit GmbH

These companies have established themselves as leaders in the low density SMC industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the low density SMC market are evolving, with the entry of new players and the emergence of innovative low density SMC technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Low Density SMC Market by Segment

The low density SMC market is experiencing significant growth across several key segments. One notable area is automotive applications that are expanding due to the demand for lightweight materials that enhance fuel efficiency and reduce emissions. Finally, advancements in electric vehicles are boosting demand for SMC in battery enclosures and structural components.

This low density SMC market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including automotive application, fiber type, and resin type. The report offers insights into regional dynamics, highlighting the major markets for low density SMC and their growth potentials. The study includes trends and forecast for the global low density SMC market by automotive application, fiber type, and resin type, and region as follows:

Low Density SMC Market by Automotive Application [Value ($M) and Volume (KT) Shipment Analysis for 2018 – 2030]:

• Deck Lids

• Fenders

• Bumpers

• Hoods

• Body Panels and Others

Low Density SMC Market by Resin Type [Value ($M) and Volume (KT) Shipment Analysis for 2018 – 2030]:

• Polyester Resin

• Vinyl Ester Resin

• Epoxy Resin

Low Density SMC Market by Fiber Type [Value ($M) and Volume (KT) Shipment Analysis for 2018 – 2030]:

• Glass Fiber

• Carbon Fiber

Low Density SMC Market by Region [Value ($M) and Volume (KT) Shipment Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Low Density SMC Market

• Market Size Estimates: Global low density SMC market size estimation in terms of value ($M) and volume (KT)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by automotive application, fiber type, resin type, and region

• Regional Analysis: Global low density SMC market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different automotive application, fiber type, resin type, and region for the low density SMC market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the low density SMC market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in low density SMC or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

Frequently Asked Questions (FAQ)

Q1. What is the low density SMC market size?

Answer:The global low density SMC market is expected to reach an estimated $510 million by 2030.

Q2. What is the growth forecast for low density SMC market?

Answer:The low density SMC market is expected to grow at a CAGR of 4% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the low density SMC market?

Answer: The major drivers for this market are growth in automotive production and increasing use of lightweight materials in different automotive applications.

Q4. What are the major applications or end use industries for low density SMC?

Answer:Hood and deck lid are the major automotive applications for low density SMC

Q5. What are the emerging trends in low density SMC market?

Answer:Emerging trend, which has a direct impact on the dynamics of the industry, includes the development of ultra low density SMC and development of low density SMC for automotive structural applications.

Q6. Who are the key low density SMC companies?

Answer:Some of the key low density SMC companies are as follows:

• Core Molding Technologies

• Continental Structural Plastics

• IDI Composites International

• Polynt Group

• Premix Inc.

• Menzolit GmbH

Q7.Which low density SMC material segment will be the largest in future?

Answer: Lucintel forecasts that the glass fiber will remain the largest segment over the forecast period due to its properties like high strength/weight, phenomenal impact resistance, good electrical properties, resistance to moisture, and excellent outdoor weathering.

Q8: In low density SMC market, which region is expected to be the largest in next 7 years?

Answer: North America is expected to remain the largest region and APAC witness the highest growth over next 7 years.

Q9. Do we receive customization in this report?

Answer:Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following key questions

Q.1 How big the opportunities for global low density SMC market by automotive application (deck lids, fenders, bumpers, hoods and body panels & others), fiber type (glass fiber and carbon fiber), resin type (polyester, vinyl ester and epoxy), and region (North America, Europe, Asia Pacific and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?