Lead Frame Market Trends and Forecast

The future of the global lead frame market looks promising with opportunities in the consumer electronics, industrial & commercial electronics, and automotive markets. The global lead frame market is expected to reach an estimated $6 billion by 2030 with a CAGR of 9% from 2024 to 2030. The major drivers for this market are the strong demand for consumer electronics, increasing use of technology in healthcare, pharmaceutical, and industrial automation, and growing demand for compact and high-performance semiconductor packaging, lead frames are essential components in products like smartphones, automotive sensors, and iot devices.

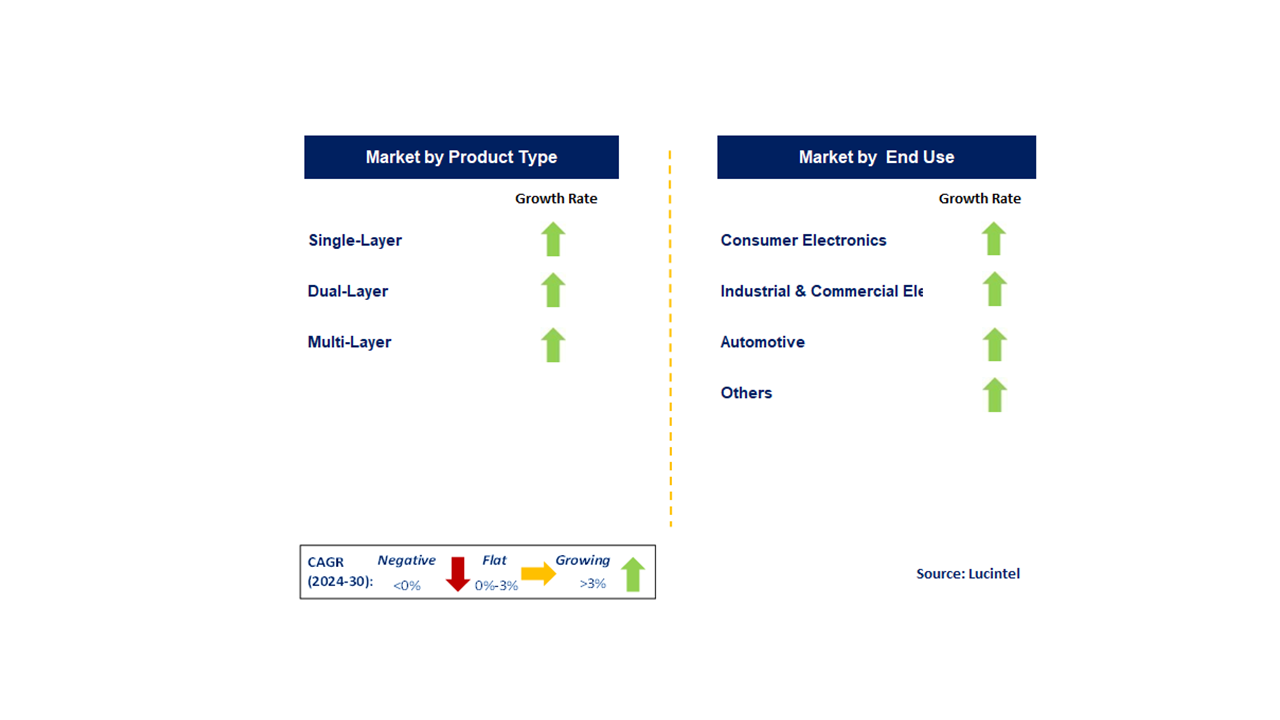

• Lucintel forecasts that dual-layer will remain the largest segment over the forecast period.

• Within this market, automotive is expected to witness the highest growth.

• APAC will remain the largest region over the forecast period.

Country Wise Outlook for the Lead Frame Market

Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major lead frame producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends

Emerging trends in the lead frame market shaping its future applications and market dynamics:

• Increasing Use of Advanced Packaging: One of the crucial roles of lead frames is to become part of advanced packaging technologies like SiP (System-in-Package) and 3D packaging that are very critical in terms of integration density and performance.

• Using Alternative Materials: Environmental issues as well as superior electrical performance have made traditional lead frames which are using copper and several other alloys to be substituted with alternative materials gain a lot of popularity.

• Integration into Emerging Technologies: It is envisaged that the lead frames, such as those used in 5G systems, Internet of Things (IoT), connected vehicles will have to be adapted for use in new applications thereby creating demand for specialized designs and improved performance.

• More Efficient Thermal Management: With increased capacity for electronic devices and their miniaturization, there is a tendency towards choosing better thermal conductivity/heat dissipation features in lead frames.

• Smart Manufacturing and Industry 4.0: The industry expects to see further adoption of smart manufacturing processes along with Industry 4.0 technologies in order to streamline production cycles for lead frame manufacturing resulting in an increase in efficiency, flexibility, quality control.

Ongoing innovations and advancements in various sectors of the lead frame market which have been highlighted by recent developments:

• Miniaturization and Complexity: To produce miniature electronic components, lead frames are gradually becoming smaller in size and more complex. Technological advances in semiconductors and consumer electronics drive this trend.

• Material Innovations: Improvements have been made in lead frame materials to enhance their performance, thermal management, as well as reliability. These include using alloys that have improved conductivity and increased durability.

• Advanced Manufacturing Processes: There has been an improvement in the manufacturing processes such as precision stamping, plating methods, assembly techniques that we have seen recently. The purpose of these improvements is to improve the quality and consistency of the lead frames.

• Customization and Flexibility: Manufacturers are increasingly making customised lead frame options available to them for meeting specific requirements of electronic devices with unique designs. This customization involves various sizes, shapes and configurations.

• Quality Control and Testing: Recently there has been a focus on improving quality control measures along with testing protocols in order to ensure adherence to strict industry standards for reliability and performance by lead frames.

Strategic Growth Opportunities for Lead Frame Market

The lead frame market, which is important in semiconductor packaging, provides a number of strategic growth opportunities through technological advances, industry trends and changing consumer preferences.

• Technological Trends in Semiconductor Packaging: The demand for smaller and more efficient electronic devices continues to drive what is happening in the field of semiconductor packaging. A great contribution in interconnecting semiconductor devices and external circuits would be played by lead frames. Thinner profiles, improved thermal management capabilities, as well as better electrical performance are required to meet the needs of next-gen electronics like 5G connectivity, IoT devices and automobile electronic equipment.

• Growth in Automotive Electronics: The transition to electric vehicles (EVs) and autonomous driving technologies by the automotive sector necessitates strong semiconductor packaging solutions. Lead frames are used for power management, sensor connection as well as vehicle control systems among other things in automotive electronics. There is a huge opportunity for growth when it comes to high-performance reliable lead frames that will withstand harsh conditions when on use such as those demanded by automotive environment.

• Increased Demand from Consumer Electronics: It is consumer electronics that continue to drive the necessity for smaller yet more powerful semiconductors. Smartphones, tablets, portable computing devices and wearables commonly use leadframes since their sizes have been compressed due to the need for space-saving features with high reliability at low or normal costs respectively. On top of this, there has been an expansion into wearable health monitors including smart home appliances and portable electronics propelling advanced leadframe technology markets

• Move towards Advanced Materials and Manufacturing Processes: Recently sourced materials like copper alloys from alternative materials that have better electrical conductivity properties have been introduced into those used on leadframes such as copper alloys. These include higher effectiveness heat dissipation ability than older materials like iron-based cobalt-iron-nickel alloys other than environmental sustainability benefits such as energy savings stand out after comparisons between them have been made against conventional ones that release many pollutants in the atmosphere. The application of advanced stamping techniques as well as automation revolutionize production rates and quality that meet rapid demands from a semiconductor industry.

• Emphasis on Sustainability and Environmental Regulations: In line with this, companies in the semiconductor industries including manufacturers of lead frames are increasingly taking up green initiatives to comply with global environmental rules. This is done through minimizing the carbon footprints in their manufacturing process, using recyclable materials, and adhering to international environmental standards. These businesses distinguish themselves by prioritizing sustainability and developing environmentally lead frame friendly solutions that appeal to both eco-conscious consumers and firms operating for profit.

By taking advantage of these strategic growth opportunities, the lead frame market can realize its full potential and transform numerous industries by technological advancements, expanding applications in automotive and consumer electronics, advancements in materials and manufacturing processes, sustainability initiatives, and geographic expansion.

Lead Frame Market Driver and Challenges

Lead Frame has a very important role in many industries including aerospace, automotive and renewable energy. The changing market dynamics are being driven by the growing semiconductor industry, rising demand for consumer electronics and rising demand for consumer electronics. however, challenges cost pressure, complexity in design and supply chain risks.

The factors responsible for driving the lead frame market include:

1. Growing Semiconductor Industry: The demand for lead frames depends on the growth of the semiconductor industry that has continued to expand due to technological advances and increase in use of electronics, automobiles, industrial sectors.

2. Rising Demand for Consumer Electronics: The uptake of semiconductors by consumer electronic products like smartphones, tablets, wearables among others increases the need for semiconductor devices thus leading to more demand of lead frames.

3. Automotive Electronics: Changing preference by automobile manufacturers towards electric cars alongside increased integration of advanced drivers assistance system (ADAS) into vehicles have led to a rise in semiconductor content thereby driving up demand for lead frames used in such applications.

4. Miniaturization and Performance Requirements: As electronic devices continue shrinking and becoming more efficient, there is a need for lead frames that can meet high performance requirements at an affordable cost without compromising on reliability.

5. Technological Advancements: Improved performance and enlarged application space in high-performance electronic devices are brought about by innovations in lead frame materials as well as designs and manufacturing processes such as fine pitch leads and advanced plating technologies.

6. Environmental Regulations: Increasing reliance on green technology initiatives such as RoHS compliance demands that hazardous substance be replaced with non-toxic ones which has invigorated innovation and investments in new technologies around the issue.

Challenges in the lead frame market are:

1. Cost Pressure: The manufacturers of semiconductors are constantly pressured to reduce the cost, improve performance, reliability and efficiency of lead frames which demands continuous innovation and optimization of manufacturing processes.

2. Complexity in Design and Manufacturing: It requires advanced engineering capabilities and precise manufacturing processes to design and manufacture increasingly complexly-geometrized lead frames with tight tolerances.

3. Supply Chain Risks: For example, geopolitical factors often disrupt the supply chain, raw material shortages impact on production schedules alongside demand fluctuations thus affecting lead times in this industry of making lead frame products.

4. Environmental Concerns: However, despite advances made towards alternatives which do not contain traces of leads, environmental sustainability throughout the life cycle of a lead frame still remains a major challenge especially when it comes to recycling as well as waste management.

Lead Frame Suppliers and Their Market Shares

In this globally competitive market, several key players such as Ningbo Hualong Electronics Co.,Ltd., Mitsui High-tec, Inc., Dynacraft Industries Sdn. Bhd., Precision Micro Ltd., SDI Group, Inc., etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players contact us.

• Stats ChipPAC Pte. Ltd

• Possehl Electronics Deutschland GmbH

• Ningbo Hualong Electronics Co.,Ltd.

• Mitsui High-tec, Inc.

• Dynacraft Industries Sdn. Bhd.

• Ningbo Kangqiang Electronics Co., Ltd.

• Enomoto Co.,Ltd.

These companies have established themselves as leaders in the lead frame industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the lead frame market are evolving, with the entry of new players and the emergence of innovative lead frame technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Lead Frame Market by Segment

Lead frames are experiencing growth across diverse segments such as automotive, consumer electronics, and industrial & commercial electronics. In automotive applications, lead frames support crucial electronic components in vehicles, ensuring reliability and performance. Consumer electronics utilize lead frames for integrated circuits and semiconductor packaging, driven by demand for smaller, more efficient devices. In industrial and commercial electronics, lead frames enable the production of robust electronic modules used in various machinery and equipment. This growth reflects ongoing advancements in technology and the expanding use of electronic components across different sectors.

This lead frame market report provides a comprehensive analysis of the market's current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including type, manufacturing process, end use industry. The report offers insights into regional dynamics, highlighting the major markets for lead frame and their growth potentials.

Lead Frame Market by Product Type [Value from 2018 to 2030]:

• Single-Layer

• Dual-Layer

• Multi-Layer

Lead Frame Market by Manufacturing Process [Value from 2018 to 2030]:

• Photo Etching

• Stamping

• Others

Lead Frame Market by End Use [Value from 2018 to 2030]:

• Consumer Electronics

• Industrial & Commercial Electronics

• Automotive

• Others

Lead Frame Market by Region [Value from 2018 to 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of the Global Lead Frame Market

Market Size Estimates: Lead frame market size estimation in terms of value ($B).

Trend and Forecast Analysis: Market trends (2018 to 2023) and forecast (2024 to 2030) by various segments and regions.

Segmentation Analysis: Lead frame market size by product type, manufacturing process, end use, and region in terms of value ($B).

Regional Analysis: Lead frame market breakdown by North America, Europe, Asia Pacific, and Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different product type, manufacturing process, end use, and regions for the lead frame market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape of the lead frame market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in carbon fiber or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the lead frame market size?

Answer: The global lead frame market is expected to reach an estimated $6 billion by 2030.

Q2. What is the growth forecast for lead frame market?

Answer: The global lead frame market is expected to grow with a CAGR of 9% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the lead frame market?

Answer: The major drivers for this market are the strong demand for consumer electronics, increasing use of technology in healthcare, pharmaceutical, and industrial automation, and growing demand for compact and high-performance semiconductor packaging, lead frames are essential components in products like smartphones, automotive sensors, and iot devices.

Q4. What are the major segments for lead frame market?

Answer: The future of the lead frame market looks promising with opportunities in the consumer electronics, industrial & commercial electronics, and automotive markets.

Q5. Who are the key lead frame market companies?

Answer: Some of the key lead frame companies are as follows:

• Stats ChipPAC Pte. Ltd

• Possehl Electronics Deutschland GmbH

• Ningbo Hualong Electronics Co.,Ltd.

• Mitsui High-tec, Inc.

• Dynacraft Industries Sdn. Bhd.

• Ningbo Kangqiang Electronics Co., Ltd.

• Enomoto Co.,Ltd.

Q6. Which lead frame market segment will be the largest in future?

Answer: Lucintel forecasts that dual-layer will remain the largest segment over the forecast period.

Q7. In lead frame market, which region is expected to be the largest in next 7 years?

Answer: APAC will remain the largest region over the forecast period.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% customization without any additional cost.

This report answers following 11 key questions:

Q.1. What are some of the most promising, high-growth opportunities for the lead frame market by product type (single-layer, dual-layer, and multi-layer), manufacturing process (photo etching , stamping, and others), end use (consumer electronics, industrial & commercial electronics , automotive, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which segments will grow at a faster pace and why?

Q.3. Which region will grow at a faster pace and why?

Q.4. What are the key factors affecting market dynamics? What are the key challenges and business risks in this market?

Q.5. What are the business risks and competitive threats in this market?

Q.6. What are the emerging trends in this market and the reasons behind them?

Q.7. What are some of the changing demands of customers in the market?

Q.8. What are the new developments in the market? Which companies are leading these developments?

Q.9. Who are the major players in this market? What strategic initiatives are key players pursuing for business growth?

Q.10. What are some of the competing products in this market and how big of a threat do they pose for loss of market share by material or product substitution?

Q.11. What M&A activity has occurred in the last 7 years and what has its impact been on the industry?

For any questions related to Lead Frame Market Market, Lead Frame Market Market Size, Lead Frame Market Market Growth, Lead Frame Market Market Analysis, Lead Frame Market Market Report, Lead Frame Market Market Share, Lead Frame Market Market Trends, Lead Frame Market Market Forecast, Lead Frame Market Companies, write Lucintel analyst at email: helpdesk@lucintel.com. We will be glad to get back to you soon.