Invar Tooling Market Trends and Forecast

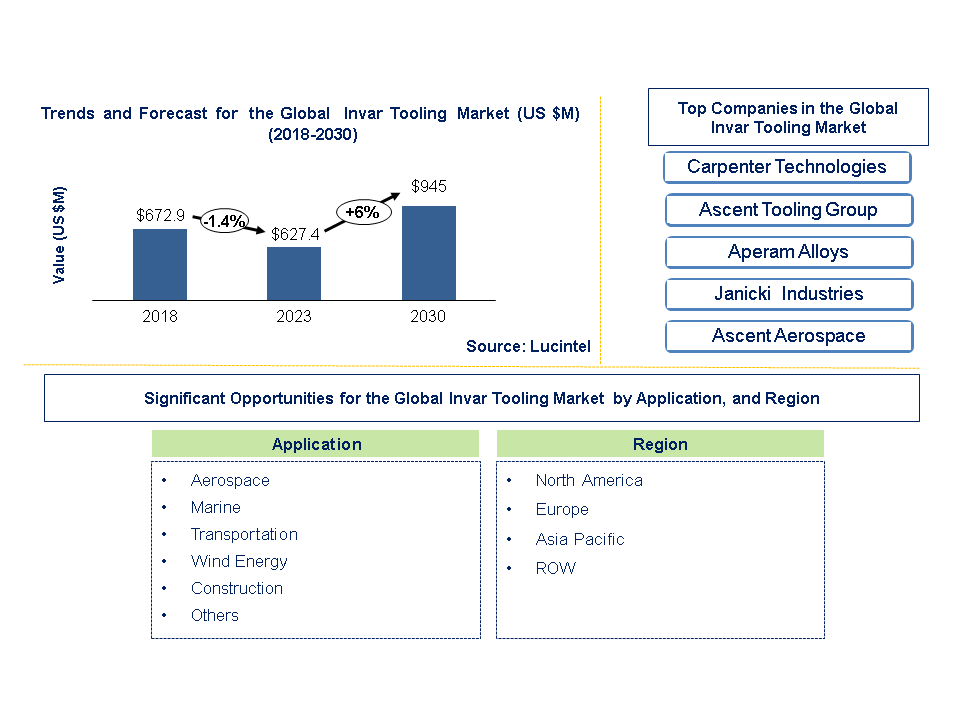

Lucintel finds that the future of the invar tooling market looks promising with opportunities in aerospace, transportation, marine, construction, and wind energy applications. The global invar tooling market is expected to reach an estimated $945 million by 2030 with a CAGR of 6% from 2023 to 2030. The major drivers for this market are increasing penetration of composite materials in the aerospace industry. Emergence of high temperature molding processes like autoclave is expected to further boost the market.

Invar tooling is famous for its low thermal expansion capability and is largely composed of Invar alloy made up of 36% nickel and 64% iron. The production process also incorporates small amounts of other substances such as carbon, manganese or silicon that are used to enhance some specific properties. Raw materials needed include pure iron, high-purity nickel and other different metal mixtures. Precision melting and alloying methods are critical in achieving the targeted low thermal expansion features. This kind of tooling is extensively used in industries where dimensional stability under temperature variation is required like aerospace and automotive industries.

• Lucintel forecasts that aerospace will remain the largest end use segment and it is also expected to witness the highest growth over the forecast period.

• North America is expected to remain the largest region over the forecast period due to growth in end use applications and due to a wider acceptance of invar tooling in product manufacturing and mass customization. APAC is expected to witness the highest growth over the forecast period.

Country wise Outlook for the Composites in the Global Invar Tooling Market

Emerging Trends in the Composites in the Global Invar Tooling Market

1. Increasing Use for Aerospace And Defense: The rise in demand for light weight and high strength materials in the aerospace and defense industry is causing the increased adoption of Invar tooling for manufacturing precision components.

2. Rising Advancements in Manufacturing Technologies: Advances in additive manufacturing and 3D printing technologies have allowed more efficient and intricate Invar tooling designs to be made, hence shortening production time as well as costs.

3. Increasing Sustainability and Recycling: Increasing focus on sustainability has prompted more recycling and Invar material re-use thereby reducing environmental impacts as well as material costs.

4. Enhanced Thermal Management Solutions: Innovations in thermal management are increasing the functionality of Invar tooling in high-precision applications; this makes it more attractive to industries with strict thermal requirements

5. Expansion into Automotive Sector: The shift of the automotive industry towards electric vehicles and advanced manufacturing techniques will raise the usage of Invar tooling used to make high precision components.

These trends indicate a shift towards more sustainable, innovative, and technologically advanced solutions in the invar tooling industry to meet evolving consumer and regulatory demands globally.

A total of 55 figures / charts and 42 tables are provided in this 100-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Invar Tooling

Recent developments in global invar tooling by various companies highlight ongoing innovations and advancements across different sectors

• Advanced Composite Integration: Integrating Invar tooling with advanced composite materials is being developed to reduce weight and improve performance in aerospace and automotive applications.

• Improved Manufacturing Processes: Using better ways of carrying out additive manufacturing and CNC machining are enabling cost savings and faster turnaround times by having more accuracy in the production of Invar tools.

• Sustainable Practices: Recycling and reusing Invar materials is becoming more popular mainly due to the exigencies of sustainability as well as cost efficiency.

• High-Performance Coatings: Surface coatings for Invar tools have been innovated so that they last longer, especially under severe environments.

• Thermal Management Solutions: These technological advancements have optimized Invar tooling’s performance in application areas that require very tight thermal tolerance such as aerospace industry.

Strategic Growth Opportunities for Invar Tooling Material Market

Invar tooling market is known for its precision and minimal thermal expansion, this means it has got some strategic growth prospects. Here are the key opportunities to explore:

Market Diversification

• Aerospace Industry: The use of Invar tooling in aerospace sector can be expanded to manufacture accurate molds for composite parts that require high dimensional stability.

• Automotive Sector: The use Invar’s properties in making tools for lightweight composite parts which will enhance fuel efficiency and performance in automotive applications.

• Renewable Energy: This will involve production of wind turbines components like blades and solar panels using Invar tooling which are stable and durable.

Technological Advancements

• Advanced Manufacturing Techniques: Invest in cutting-edge manufacturing processes such as additive manufacturing, and precision machining approaches to increase the production scale and efficiency of Invar tooling.

• Material Innovations: Research new alloy compositions and treatments that can improve the performance characteristics of Invar so it would work even better with high-precision applications.

• Digitalization: Equip factories with Industry 4.0 technologies including IoT and AI, thus enabling real-time monitoring, predictive maintenance, and better quality control in the process of producing Invar tooling.

Global Market Expansion

• Emerging Markets: These include growing aerospace, automotive and renewable energy markets found within Asia-Pacific or Latin American states that should be targeted by businesses expanding internationally.

• Localized Production: Place manufacturing units at strategic locations to reduce logistics costs, enhance supply chain efficiency and accommodate regional market requirements.

Invar Tooling Material Market Drivers and Challenges

The requirement for high precision coupled with low thermal expansion, especially in segments like aerospace and automotive, keeps the Invar tooling market growing. These trends are driven by technological advancements and increasing demand for performance-driven materials. However, such developments are not without challenges such as high production costs, supply chain constraints and competitive pressures that necessitate continuous innovation and strategic investments.

1. Precision Requirements: For instance, the ability of Invar to have minimal thermal expansion makes it suitable for precise tooling requirements of sectors including aerospace and automotive characterized by dimensional stability.

2. Rising Demand in Aerospace Industry: The demand for advanced aerospace components such as composite molds and tooling increases due to their reliability and accuracy thus contributing to the growth of Invar tooling market.

3. Automotive Sector Advancements: Precise tool solutions are needed due to the change in automobile industry materials which now prefer light and strong metals thus improving fuel efficiency as well as performance – this quality exists with Invar.

4. Increasing demand for Renewable Energy: Moreover, renewable energy sectors like wind power generations need more robust tools in manufacturing areas such as turbine blades or solar panels which require Invar tooling technology.

Challenges in the Invar Tooling Market

1. High Costs of Production: The high cost of production of Invar tooling is due to the costly raw-materials and specialized manufacturing processes that can hinder the market growth.

2. Supply Chain Constraints: Relying on high-quality suppliers for raw materials may lead to supply chain disruptions and price volatility, which could compromise consistency and availability of Invar tooling.

For the invar tooling market to move into the future, it must find a balance between cost effectiveness and technological advancements. The development of hybrid materials or exploring new fields such as predictive maintenance using digital twins is some such avenues for growth. Nonetheless, there are challenges related to financial resources required for integration as well as skilled labor availability indicating the need for investment planning and workforce preparation initiatives.

Global Invar Tooling Suppliers and Their Market Shares

In this globally competitive market, several key players such as , Ascent Tooling Group, Janicki Industries, Kaman Corporation, Aperam Alloys Imphy Alloys, Carpenter Technologies etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies invar tooling companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the invar tooling companies profiled in this report includes.

• Ascent Tooling Group

• Janicki Industries

• Kaman Corporation

• Aperam Alloys Imphy Alloys

• Carpenter Technologies

• Loiretech

• Waukesha Foundry Inc.

These companies have established themselves as leaders in the global invar tooling market with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the global invar tooling market are evolving, with the entry of new players and the emergence of innovative technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Invar Tooling Market by Segment

Major segments of the invar tooling experiencing growth include aerospace and defense sectors experiencing an increasing demand for Invar tools as they are accurate and have dimensional stability even under varying temperatures. The automotive industry has increased its application of Invar tooling to develop lightweight precision components, especially for electric cars. Electronics form a fast-growing segment requiring moulds and tools that ensure high accuracy in the production of devices.

This invar tooling market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including application. The report offers insights into regional dynamics, highlighting the major markets for invar tooling and their growth potentials. The study includes trends and forecast for the global invar tooling market by application, and region as follows:

Invar Tooling Market by Application [Value ($M) and Volume (M lbs) Shipment Analysis for 2018 – 2030]:

• Transportation

• Marine

• Wind Energy

• Aerospace

• Construction

• Others

Invar Tooling Market by Region [Value ($M) and Volume (M lbs) Shipment Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• Rest of the World

Features of Invar Tooling Market

• Market Size Estimates: Invar tooling market size estimation in terms of value ($M) and Volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various applications and regions.

• Segmentation Analysis: Market size by application and region

• Regional Analysis: Invar tooling market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different applications and regions for the invar tooling market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the invar tooling market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in composites in the global invar tooling market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the invar tooling market size?

Answer:The global invar tooling market is expected to reach an estimated $945 million by 2030.

Q2. What is the growth forecast for invar tooling market?

Answer:The invar tooling market is expected to grow at a CAGR of 6% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the invar tooling market?

Answer: The major drivers for this market are increasing penetration of composite materials in the aerospace industry. Emergence of high temperature molding processes like autoclave is expected to further boost the market.

Q4. What are the major applications or end use industries for invar tooling?

Answer:Aerospace and transportation are the major applications for invar tooling.

Q5. What are the emerging trends in invar tooling market?

Answer:Emerging trends, which have a direct impact on the dynamics of the industry, include increased usage of technical industrialization and serial production, increased use of invar/composite combination materials for tooling for weight reduction, and investment in multi-model tools and production lines.

Q6. Who are the key invar tooling companies?

Answer:Some of the key invar tooling companies are as follows:

• Ascent Tooling Group

• Janicki Industries

• Kaman Corporation

• Aperam Alloys Imphy Alloys

• Carpenter Technologies

• Loiretech

• Waukesha Foundry Inc.

Q7: In invar tooling market, which region is expected to be the largest in next 7 years?

Answer:North America is expected to remain the largest region over next 7 years

Q8. Do we receive customization in this report?

Answer:Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global invar tooling market by application (transportation, marine, wind energy, aerospace, construction and others) and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?