Indian Composites Market Trends and Forecast

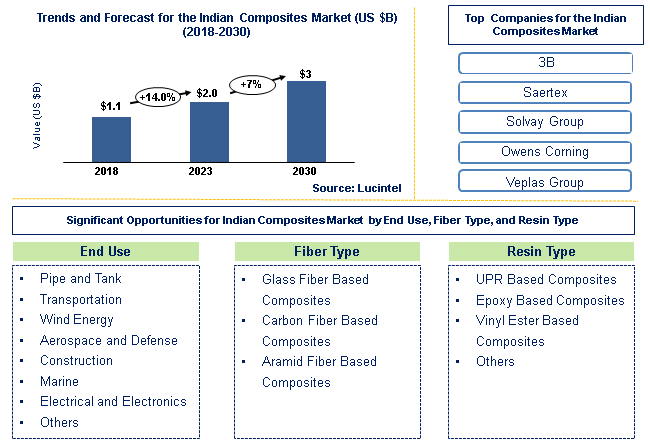

Lucintel finds that the future of the Indian composites market looks promising with opportunities in pipe & tanks, transportation, wind energy, aerospace and defense, construction, marine, and electrical & electronics end uses. The Indian composites market is expected to reach an estimated $3 billion by 2030 with a CAGR of 7% from 2023 to 2030. The major drivers for growth in this market are increasing demand for lightweight materials in the aerospace & defense and automotive industries; corrosion and chemical-resistant materials’ demand in the construction and pipe & tank industries; demand for materials with electrical resistance and high flame retardancy in the electrical and electronics industry.

The Indian composites industry is based on a variety of raw materials such as glass, carbon, aramid and natural fibers for reinforcement; polyester, vinyl ester, epoxy and phenolic resins to bind them together; fillers like calcium carbonate and silica to enhance certain properties. Structure optimization is done using additives and core materials such as foam and honeycomb. India’s cost efficient composite products are an attraction across a wide range of sectors due to their compliance with the global quality standards set. In blending its cost efficiency with quality, India has managed to have a flexible pricing strategy that can be influenced by material type, scale of production, or market dynamics thus enhancing its global competitiveness in composites

• Lucintel forecasts that wind energy will remain the largest end use segment over the forecast period, and it is also expected to witness the highest growth over the forecast period due to the increasing installation of wind turbines and requirement of lightweight and non-corrosive materials in wind energy.

• Glass fiber based composites will remain the largest fiber type segment due to the increasing use of glass fiber based composites, for its better mechanical properties, in construction, transportation, and electrical & electronics end use industries. Carbon fiber based composites segment is expected to witness the highest growth segment over the forecast period.

Country wise Outlook for the Indian Composites Market

The Indian composites market is witnessing substantial growth, driven by increased demand from various industries such as aerospace, transportation, wind energy, and construction. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major Indian composites producers in key regions: India.

Emerging Trends in the Indian Composites Market

Emerging trends in Indian Composites Market are shaping its future applications and market dynamics:

1. Infrastructure Development: Durability, no rust, and unlimited possibilities of designing are the key benefits derived from employing composites in construction.

2. Technological Advancements: The use of automation and 3D printing as technological breakthroughs in advanced manufacturing that support highly efficient composite production.

3. Bio-based Composites: A response to the global demand for sustainable materials involves utilization of green fibers and resins obtained from renewable sources while making composites.

4. Hybrid Composites: These hybrid composites optimize different properties such as glass, carbon, natural fiber thermoset / thermoplastic matrices to suit specific applications.

5. Smart Composites: Real time structural integrity and performance monitoring can be done by incorporating sensors and IoT devices in the structure of composites.

6. Additive Manufacturing: Some waste is reduced by making complicated parts with new design flexibility through additive manufacturing (3D printing) methods applied to composite materials

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Indian Composites Suppliers

Recent developments in Indian composites market by various companies highlight ongoing innovations and advancements across different sectors:

The Automotive Industry: Indian companies have been increasingly resorting to composites for lightweighting vehicles, enhancing fuel economy and meeting stringent emission norms. It is used in body panels, interiors and structural components.

• Renewable Energy: In India composites are being used on wind turbine blades and solar panel structures to maximize performance and durability in support of India’s renewable energy objectives.

• Infrastructure and Construction: Some innovations seek to use composites in bridges; buildings and infrastructure elements by providing such advantages as corrosion resistance, durability and reduced maintenance costs.

• Aerospace and Defense: Composites have been introduced in Indian aircraft parts to decrease weight, increase their fuel efficiency as well as enhance the performances levels of these planes.

• Consumer Goods: Companies are considering composites for consumer electronics, sporting goods, healthcare equipment because they are light weight materials which also provide strength along with aesthetics.

Strategic Growth Opportunities for Indian Composites Market

The Indian composites market is very dynamic due to its unique properties of being lightweight, strong and thermally stable. Some key strategic growth opportunities for this market include:

Diversification in industries:

• Branch out into other sectors like cars and building away from traditional ones as renewable energy, aerospace, and defense that are emerging.

• Take advantage of the fact that composites are lightweight and resistant to rust for them to be able to cope with the changes in the market.

Investment in R&D and Innovation

• Promote collaboration between academia, research institutions as well as industry to foster composite technology innovation.

• Develop advanced composites that have better mechanical properties, fire resistance and sustainability compared to global standards.

Infrastructure Development

• Use composites in infrastructure projects such as bridges, railway systems and urban infrastructures because they last long and require little maintenance.

• Involve composites in urban development projects through government initiatives like Smart Cities Mission.

Sustainability and Eco-Friendly Solutions

• Promote recyclable bio-based composites materials; this would make Indian composite market leader of sustainable solutions based on these materials

• Eco-friendly composites with low carbon footprints should be developed while addressing issues concerning environment regulations

Strategic Partnerships and Collaborations

• International knowledge sharing between technology providers & manufacturers being strategic alliances with international composite companies is important when thinking about further expansion into new markets

• Integrate Indian Composites into Global Supply Chains & Value Networks by collaborating with global OEMs & suppliers.

Government Support and Policies

• Supportive policies and incentives from the government have to be advocated for in order to ensure growth and investment in the composites sector.

• Policy dialogues that will deal with regulatory challenges and streamline approval processes for composite applications should be encouraged.

Indian Composites Market Driver and Challenges

Indian composites market is driven by a growing demand across different sectors such as automobiles, space and infrastructure due to its lightweight, durability and design flexibility. However, it is difficult for the industry to flourish because of some problems like high initial capital investment costs, shortage of skilled labor force and fluctuating prices of raw materials. Major breakthroughs in production methods and actions taken by the government in support of ecological manufacturing are now possible. To influence the trajectory of Indian composite market growth over the next years, one must be able to steer through these changes occurring while industries attempt to economize on resources.

The factors responsible for driving the India composites market include:

1. There is a burgeoning need for stronger and more mobile aluminum in the automotive, aerospace, and construction sectors.

2. The composite use in infrastructure development and defense sector is being encouraged by government.

3. Sustainability materials have gradually become known and accepted as viable material choice during manufacturing operations.

4. Development in the field of composites which has improved performance of products and reduced their cost of making them.

5. This is because different countries now have the capacity to create such advanced products that are required for export.

Challenges in the Indian Composites Market:

1. The first price of infrastructure and technology in composite manufacturing is high.

2. There are not many skilled laborers or specialists in composite design and production.

3. Production costs and profitability are affected by variable prices of raw materials.

4. Market entry, expansion, and growth are hampered by regulatory challenges as well as standards compliance factors.

5. There are attitudes about its durability or long-term performance compared to other conventional materials.

Innovation and strategic initiatives are essential in driving the changing scene of Indian composites market. Although there are continuous challenges in terms of first investment costs and regulatory issues, the growth of this industry relies on continual material and manufacturing innovation. For competitiveness to be enhanced, there is a need to embrace sustainable growth and utilize India’s capabilities for manufacturing thereby ensuring that numerous industries’ increasing demands are met.

Indian Composites Suppliers and Their Market Shares

In this globally competitive market, several key players such as Suzlon, Kineco Limited, CEI Automotive India, Tata AutoComp System, Mobility Solutions dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at helpdesk@lucintel.com. ".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies carbon fiber companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the carbon fiber companies profiled in this report include.

• Suzlon

• Kineco limited

• CEI Automotive India

• Tata AutoComp Systems

• Patil Rail Infrastructure Pvt. Ltd.

• Mobility Solution Ltd.

These companies have established themselves as leaders in the Indian Composites market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the Indian Composites market are evolving, with the entry of new players and the emergence of innovative BRIC composites technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Indian Composites Market by Segment

India is a country that is experiencing robust growth in the various segments of the composites industry. Automotive, which benefits from the increased demand for fuel-efficient and lightweight vehicles, is a significant area of focus. On construction and renewable energy sectors privatization drive, composite materials are being used as they can outlive other materials giving value for money due to their durability and corrosion resistance. Composites are widely used in aerospace and defense industries because of their lightweight and strong properties as well as design variability. Composites are expanding their presence across several fields like sports items, residential commodities such as air conditioners or televisions in India’s markets while showing growth prospects.

Indian Composites Market by End Use [Value ($M) and Volume (M lbs) analysis for 2018 – 2030]:

• Pipe and Tank

• Transportation

• Wind Energy

• Aerospace and Defense

• Construction

• Marine

• Electrical and Electronics

• Others

Indian Composites Market by Fiber Type [Value ($M) and Volume (M lbs) analysis for 2018 – 2030]:

• Glass Fiber Based Composites

• Carbon Fiber Based Composites

• Aramid Fiber Based Composites

Indian Composites Market by Resin Type [Volume (M lbs) analysis for 2018 – 2030]:

• UPR Based Composites

• Epoxy Based Composites

• Vinyl Ester Based Composites

• Others

Features of Indian composites market

• Market Size Estimates: Indian composites market size estimation in terms of value ($M) and volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments.

• Segmentation Analysis: Market size by end use, fiber type, and resin type.

• Growth Opportunities: Analysis of growth opportunities in different end uses, fiber types, and resin types for the Indian composites market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the Indian composites market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in carbon fiber or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the Indian composites market size?

Answer: The Indian composites market is expected to reach an estimated $3 billion by 2030.

Q2. What is the growth forecast for Indian composites market?

Answer: The Indian composites market is expected to grow at a CAGR of 7% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the Indian composites market?

Answer: The major drivers for growth in this market are increasing demand for lightweight materials in the aerospace & defense and automotive industries; corrosion and chemical-resistant materials’ demand in the construction and pipe & tank industries; demand for materials with electrical resistance and high flame retardancy in the electrical and electronics industry.

Q4. What are the major fiber types for Indian composites market?

Answer: Glass fiber based composites and carbon fiber based composites are the major fiber types of Indian composites market.

Q5. What are the emerging trends in Indian composites market?

Answer: Emerging trends, which have a direct impact on the dynamics of the Indian composites market, includes infrastructure development, technological advancement, bio-based composites, smart composites, and hybrid composites.

Q6. Who are the key composites companies in India?

Answer: Some of the key composites companies in India are as follows:

• Suzlon

• Kineco limited

• CEI Automotive India

• Tata AutoComp Systems

• Patil Rail Infrastructure Pvt. Ltd.

• Mobility Solution Ltd.

Q7.Which Indian composites market fiber type segment will be the largest in future?

Answer: Lucintel forecasts that glass fiber based composites will remain the largest fiber type segment due to the increasing use of glass fiber based composites, for its better mechanical properties, in construction, transportation, and electrical & electronics end use industries. Carbon fiber based composites segment is expected to witness the highest growth segment over the forecast period.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 10 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the Indian composites market by end use (pipes & tanks, transportation, wind energy, aerospace and defense, construction, marine, and electrical and electronics, and others), fiber type (glass fiber based composites, carbon fiber based composites, and aramid fiber based composites), and resin type (UPR based composites, epoxy based composites, vinyl ester based composites, and others)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.4 What are the business risks and threats to the market?

Q.5 What are the emerging trends in this market and the reasons behind them?

Q.6 What are the changing demands of customers in the market?

Q.7 What are the new developments in the market? Which companies are leading these developments?

Q.8 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.9 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.10 What M & A activities have taken place in the last 6 years in this market?