Global High Performance Nylon for Tribology Market Trends and Forecast

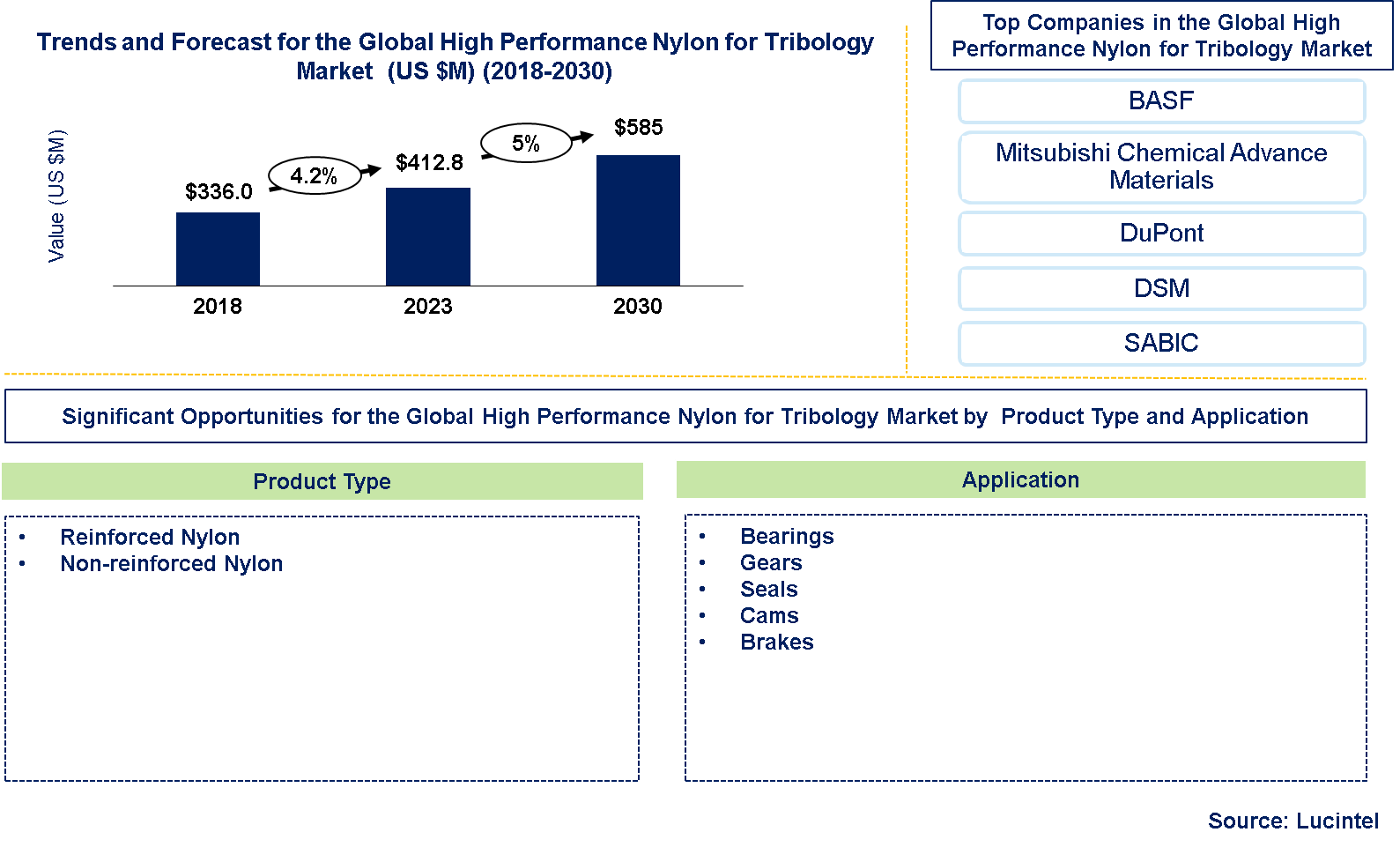

Lucintel finds that the future of the global high performance nylon for tribology market looks promising with opportunities in the bearings, gears, seals, cams, and brakes applications. The global high performance nylon for tribology market is expected to reach $585 million with a CAGR of 5% from 2023 to 2030. The major drivers for this market are growth in vehicle production and replacement of metal with plastics in various industries.

Examples of high-performance nylon for the global tribology market include nylon 6, 66, and specialty nylons such as 46, 11, and 12. These are strengthened with additives like glass, carbon, or aramid fibers to improve their mechanical features. PTFE and molybdenum disulfide are among the lubricants that reduce friction and increase resistance to wear. Despite being costlier than some engineering plastics including POM and PP when compared with standard nylons, it is considered reasonably priced because of its toughness, resistance against wearing out as well as economizing on costs for highly demanding conditions.

• Lucintel forecasts that bearings will remain the largest application and it also expected to witness the highest growth over the forecast period due to increasing demand of nylon bearings in automotive and industrial machinery and growing demand for self lubricating and lightweight bearings.

• Reinforced nylon will remain the largest product type and it is also expected to witness the highest growth over the forecast period, as reinforced nylon provides excellent chemical resistance and high temperature resistance, while enhancing stiffness, strength, and warp resistance.

• Asia Pacific will remain the largest region over the forecast period and it is also expected to witness the highest growth over the over the forecast period due to a increasing focus on reducing vehicle weight for better fuel efficiency and lower emission. Expansion of machinery and motor vehicle production, and strong aftermarket for industrial equipment and automotive spare parts is also driving the market in APAC region.

Country wise Outlook for the Global High Performance Nylon for Tribology Market

The global high performance nylon for tribology market is witnessing substantial growth, driven by increased demand from various industries. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major high performance nylon for tribology market producers in key regions: China, USA, Germany, and India.

Emerging Trends in Global High Performance Nylon for Tribology Market

Emerging trends in Global High Performance Nylon for Tribology Market are shaping its future applications and market dynamics:

1. Development of Nanotechnology: The addition of carbon nanotubes, silica and nanoclays into a matrix of nylon. These types of nanocomposites have improved mechanical strength, thermal stability and wear resistance making them appropriate for tribological applications.

2. Introduction of Self-lubricating Nylons: Advances in self-lubricating nylon grades that reduce the need for external lubricants. These nylons which can be internally lubricated are designed to provide consistent performance and reduce maintenance needs in moving parts.

3. Increasing concern over Bio based and Sustainable Nylons: Increasing concern over eco-friendly nylons made from renewable materials. Biobased high-performance nylons not only decrease the carbon footprint but also have excellent tribological properties, addressing the growing appetite for sustainable resources.

4. Use of 3D Printing and Additive Manufacturing: Use of 3D printing techniques to make customised nylon components with desirable tribological characteristics. This trend enables fast creation of prototypes as well as complicated geometries that cannot be achieved by traditional manufacturing methods.

5. Development of Advanced Surface Treatments: The development of surface treatments and coatings that enhance the tribological performance of nylon components. Techniques like plasma treatment, ion implantation or surface grafting enhance wear resistance while reducing frictional forces.

6. Enhanced Formulations: Development of superior wear and friction properties for high-performance nylon formulations. Such formulations often include additives such as polytetrafluoroethylene (PTFE), graphite, and silicone to improve on tribological performance.

These innovations and trends reflect the industry’s focus on enhancing performance, safety, and user experience while catering to a wide range of applications and preferences.

A total of 89 figures / charts and 76 tables are provided in this 181-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Global High Performance Nylon for Tribology Market

Recent developments in global high performance nylon for tribology market by highlight ongoing innovations and advancements across different sectors

1. Advanced Materials: Recently, improved formulations of high-performance nylons have been developed to improve wear resistance, reduce friction and enhance their overall durability. For example, modifications in nylon composites with strengthened additives are giving a better performance when used under extreme conditions.

2. Emerging Applications: High-performance nylons are increasingly finding applications across various industries including automobile, aviation and machines. Such components as gears, bearings and seals require excellent tribological properties.

3. Sustainability Focus: Nylon materials that are sustainable are being developed by firms. These include bio-based nylons and recycling techniques which helps cut down on the environmental effects caused by the production of nylon.

4. Technological Innovations: Manufacturing technologies like 3D printing or injection molding have progressed to the point where they can manufacture complex geometries and high precision parts from high-performance nylons.

5. Market Expansion: The market for high-performance nylons is growing in developing nations driven by industrialization as well as infrastructure development that requires durable materials.

6. Product Launches: A number of companies are introducing new high-performance nylon products with enhanced properties. For instance, new types of heat and chemical resistant nylons have been unveiled to cater for the ever increasing demands from different sectors.

Strategic Growth Opportunities for Global High Performance Nylon for Tribology Market

1. Demand for Durability and Performance Increase: The demand for materials that boost durability and performance in demanding conditions is on the rise in industries such as automotive, aerospace, and industrial machinery. High-performance nylon is becoming a favored choice for components like bearings, gears, and seals with its low friction abilities and high wear resistance. This offers possibilities of substantial growth especially with increasing applications in these fields.

2. Technology Changes: Recent polymer chemistry improvements coupled with the development of new processing technologies have led to the manufacture of upgraded grades of High Performance Nylons. This includes innovations like enhanced thermal stability; increased mechanical strength and improved chemical resistance opening up new frontiers in application areas. Researching into newer tailored nylons through R&D may help capture the yet unrevealed market dynamics.

3. Trends towards Sustainability: Pushing sustainability responsibility has contributed to changes within the high performance nylon sector. To lessen their effects on environment manufacturers are looking at bio-based nylons as well as recycling technologies. Such businesses can use this to differentiate them from others by demonstrating sustainable practices which meet environmentally minded customers’ criterion.

4. New Markets: Companies could exploit emerging markets including Asia-Pacific or Latin America thus experiencing significant growth prospects in terms of geographical expansion. These regions are witnessing rapid industrialization along with infrastructural development leading to rising need for durable materials across various applications Localizing production and establishing strategic partnerships in these regions can enhance market penetration.

5. Customization and Specialized Solutions: Customization is increasingly being used as a means to address specific tribological requirements. By offering niche specific solutions made from High Performance Nylons, companies can address unique customer needs thereby gaining competitive advantage over rivals. This would entail developing specialized nylons with additives/ composites meant to serve particular industries or situations.

6. Regulatory Compliance and Standards: In regulated industries such as aerospace and automotive it is important that organizations comply with strict regulatory standards and certifications. This will instill confidence to customers hence an assurance for credibility and acceptance into the market on whether High Performance Nylon meets these expectations or not.

High Performance Nylon for Tribology Market Drivers and Challenges

There have been significant advancements in the High Performance Nylon for Tribology Market, as various industries are looking for materials that can work better under high stress and friction conditions. Exceptional wear resistance, low levels of friction and durability are some of the unique features that differentiates these advanced materials mainly used in sectors such as automobile industry, aerospace and industrial machinery. Nevertheless, despite its vast opportunity, it is faced with impediments which influence its growth trajectory. Therefore, stakeholders who wish to successfully navigate this changing terrain must comprehend both the driving factors as well as some of its difficulties.

The key drivers for the high performance nylon for tribology market include:

1. Increased Demand in Automotive and Aerospace Sectors: High performance nylon is increasingly used in automotive and aerospace applications due to its superior wear resistance, low friction, and durability. These sectors demand materials that can withstand high stress and friction, driving market growth.

2. Advancements in Material Technology: Ongoing innovations in high performance nylon formulations and processing technologies enhance their performance characteristics, making them more attractive for applications requiring low friction and high wear resistance.

3. Rising Focus on Energy Efficiency: High performance nylons are used in components that improve energy efficiency, such as bearings and gears. This focus on energy-efficient solutions supports market growth

4. Growth in Industrial Machinery: The expansion of industrial machinery and equipment, which often requires high performance materials for components exposed to heavy wear and friction, boosts demand for high performance nylon.

5. Economic Development and Urbanization: Emerging economies with rapid industrialization and urbanization contribute to increased demand for high performance materials in construction and infrastructure.

The challenges in the high performance nylon for tribology market include:

1. High Cost: The advanced technology and high-quality raw materials used in high-performance nylons result in a higher cost compared to conventional nylons. This can be a barrier for adoption in cost-sensitive applications.

2. Limited Awareness And Adoption: Some industries may have limited awareness of the benefits of high-performance nylons leading to slower adoption rates. Educating end-users about the benefits would be key

3. Competition from Alternative Materials: High-performance nylons face competition from other advanced materials like ceramics or metals that may offer similar or better properties for specific applications.

4. Technical And Processing Challenges: Manufacturing processes involving high-performance nylons are complex as they require precise control for desired results which some manufacturers may not fit.

5. Regulatory And Environmental Concerns: Compliance with environmental regulations or standards related to synthetic material use or disposal can pose challenges. Addressing these issues will deter potential legal or environmental problems by manufacturers.

The market of High Performance Nylon for Tribology is driven by the need of automotive and aerospace sectors, improved material technology and energy saving preferences. These determinants highlight how significant this material can be in terms of enhancing performance and durability on high friction applications. Nonetheless, the market also experiences some challenges such as high production costs, competition from other materials and manufacturing technicalities. In order to achieve optimum advantages for high performance nylon and ensure its continual growth in many demanding application areas, these issues should be addressed while at the same time exploiting the market drivers.

Global High Performance Nylon for Tribology Market Suppliers and Their Market Shares

In this globally competitive market, several key players such as BASF, Mitsubishi Chemical Advance Materials, DuPont, DSM, and SABIC etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. T

High Performance Nylon for Tribology Market by Segment

In the automotive, aerospace and industrial machinery sectors, growth is primarily driven by the High Performance Nylon for Tribology Market. This growth is further supported in automotive applications by growing demand for tough components that can handle friction. In addition to this, the aerospace industry has benefited from such lightweight products with wear resistant properties. The utilization of long-lasting parts with minimum maintenance expenses grows industrial machinery. Furthermore, as a result of these developments in formulation, market expansion occurs through new types of nylon which enhance chemical resistance or thermal stability among others.When it comes to these high-performance nylons all three sectors are focused on efficiency and reduced operational costs

High Performance Nylon for Tribology Market by Application [$M and kilotons shipment analysis for 2018 – 2030]:

• Bearings

• Gears

• Seals

• Cams

• Brakes

High Performance Nylon for Tribology Market by Product Type [$M and kilotons shipment analysis for 2018 – 2030]:

• Reinforced Nylon

o Glass Reinforced

o Carbon Reinforced

o PTFE Reinforced

o Others

• Non-reinforced Nylon

o PA 66

o PA 12

o PA 11

o PA 46

o PEEK

o Others

High Performance Nylon for Tribology Market by Region [$M and kilotons shipment analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of High Performance Nylon for Tribology Market

• Market Size Estimates: High performance nylon for tribology market size estimation in terms of value ($M) and volume (Kilotons)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2023-2030) by various segments and regions.

• Segmentation Analysis: Market size by application and product type.

• Regional Analysis: High performance nylon for tribology market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different application, product type, and regions for the high performance nylon for tribology market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the high performance nylon for tribology market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in composites in the global high performance nylon for tribology market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ_

Q1. What is the high performance nylon for tribology market size?

Answer: The global high performance nylon for tribology market is expected to reach an estimated $585 million by 2030.

Q2. What is the growth forecast for high performance nylon for tribology market?

Answer: The high performance nylon for tribology market is expected to grow at a CAGR of 5% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the high performance nylon for tribology market?

Answer: The major drivers for this market are growth in vehicle production and replacement of metal with plastics in various industries..

Q4. What are the major applications or end use industries for high performance nylon for tribology?

Answer: Bearing and gear are the major end use industries for high performance nylon for tribology.

Q5. What are the emerging trends in high performance nylon for tribology market?

Answer: Emerging trend, which has a direct impact on the dynamics of the industry, includes development of nanotechnology, introduction of self-lubricating nylons, increasing concern over bio based and sustainable nylons, and use of 3D printing and additive manufacturing .

Q6. Who are the key high performance nylon for tribology companies?

Answer: Some of the key high performance nylon for tribology companies are as follows:

• BASF

• DSM

• DuPont

• Mitsubishi Chemical Advance Materials

• Ascend Performance Materials

• Kuraray Co. Ltd.

• Sabic Corporation

• EMS Chemie Holding AG

• Evonik Industries AG

• Radici Group

Q7.Which high performance nylon for tribology product segment will be the largest in future?

Answer: Lucintel forecasts that reinforced nylon will remain the largest product type and it is also expected to witness the highest growth over the forecast period, as reinforced nylon provides excellent chemical resistance and high temperature resistance, while enhancing stiffness, strength, and warp resistance.

Q8: In high performance nylon for tribology market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 7 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global high performance nylon for tribology market by application (bearings, gears, seals, cams, and brakes), product type (reinforced nylons, and non-reinforced nylons), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 7 years in this market?