HDI PCB Market Trends and Forecast

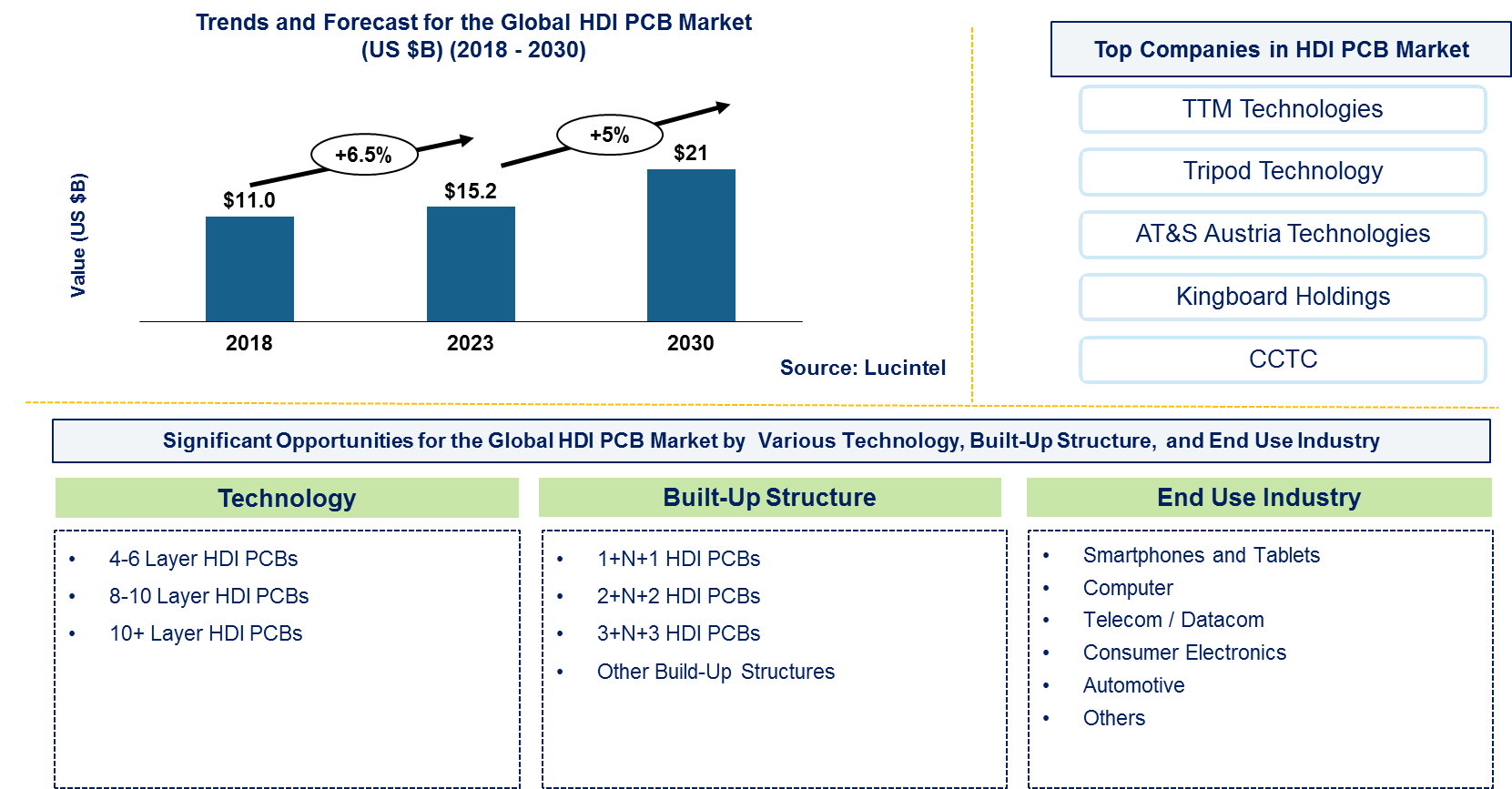

Lucintel finds that the future of the global high-density interconnect (HDI) PCB market looks promising with opportunities in the smartphone, computer, telecom and datacom, consumer electronics, and automotive industries. The global HDI PCB market is expected to reach an estimated $21 billion by 2030 with a CAGR of 5% from 2023 to 2030. The major drivers for this market are increasing demand for miniaturization of electronic devices, growing technological advancement, and rising demand from 5G and IoT.

High-Density Interconnect (HDI) PCBs are advanced printed circuit boards characterized by a high wiring density, smaller size, and the use of microvias, which allow for greater routing efficiency and compact design. HDI PCBs typically feature multiple layers of interconnected circuitry, enabling complex designs in a limited footprint, making them ideal for modern electronics like smartphones, tablets, and advanced medical devices. Key components of HDI PCBs include microvias, which are small holes that connect layers; blind and buried vias that help reduce signal paths; and high-performance materials that enhance electrical performance. Additionally, HDI designs often incorporate thicker copper layers and surface mount technology (SMT) components, contributing to better thermal management and reliability.

• Lucintel forecasts that 4-6 layers will remain the largest segment due to increasing demand in smartphones and telecommunication equipment. The 10+ layer HDI PCB market is expected to witness the highest growth during the forecast period due to the growing demand for smart wearables and connected devices.

• Smartphones will remain the largest end use industry due to the increasing demand for high performance PCB and growing demand for more space in smartphones for larger batteries. Automotive is expected to witness the highest growth over the forecast period due to advancement in automotive electronics.

• Asia Pacific will remain the largest market, and it is also expected to witness the highest growth over the forecast period due to the increasing electronic content in automotive and growth in consumer electronic devices & telecommunication products.

Country wise Outlook for the HDI PCB Market

The HDI PCB market is witnessing substantial growth globally, driven by increased demand from various industries such as smartphone, computer, telecom and datacom, consumer electronics, and automotive industries. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major HDI PCB producers in key regions: the USA, Germany, China, Japan, Taiwan, and Brazil.

Emerging Trends in the HDI PCB Market

The HDI PCB marketÄX%$%Xs size has been expanding rapidly, driven by the increasing adoption of HDI PCB in various industries. The HDI PCB’s market is influenced by factors such as higher layer counts in HDI PCBs to accommodate complex designs and functionalities, integration of passive and active components within the PCB structure, and emphasis on flexible HDI PCBs for bendable and wearable electronics. The market size is estimated to continue its upward trajectory as industries across the globe seek to improve performance, efficiency, and sustainability.

Emerging trends in HDI PCB are shaping its future applications and market dynamics:

1. Miniaturization: The need for smaller, light-weight, reduced size electronic gadgets pushes the development of finer line widths and gaps that facilitate increased component densities on PCBS.

2. Higher Layer Counts in HDI PCBs: There is a trend towards higher layer counts in HDI PCBs to allow for complex designs and functionalities like; more build-up layers and stacked microvias.

3. Advanced Materials: Advanced materials such as high-frequency laminates and low-loss materials have been adopted as substrate materials which support fast signal transmission and thermal management.

4. Embedded Components: Embedding passive and active components within the structure of the PCB with resultant lower footprints and improved signal integrity by minimizing parasitic effects.

5. High-Frequency Applications: This results from increase in demand for HDI PCBs used in high frequency applications such as 5G telecommunications, radar systems or automotive radar where signal integrity has to be stringent together with low loss characteristics.

6. Flexibility and Reliability: Focus on flexible HDI-PCBs for bendable and wearable electronics making use of flexible substrates as well as advanced assembly techniques to ensure reliability under mechanical stress

These trends reflect the industryÄX%$%Xs focus on enhancing performance, functionality, and reliability of HDI PCBs to meet the evolving requirements of modern electronic devices and applications.

A total of 99 figures / charts and 76 tables are provided in this 199-page report to help in your business decisions. Sample figures with insights are shown below.

Recent Developments in the HDI PCB Market

Recent developments in HDI PCB market which highlights ongoing innovations and advancements across different sectors:

• Miniaturization and Integration: The demand for smaller and lighter electronic devices with enhanced functionality is on the rise, which has led to miniaturization and integration. This trend is driven by HDI PCBs that allow for finer trace routing and greater component density in order to increase the functionality in reduced space.

• Increased Layer Count: HDI PCBs have more layers compared to other types of printed circuit boards and possess complex routing abilities. In recent days, there has been progress made regarding layer stacking technologies which now make it possible to increase the number of layers further while ensuring signal integrity as well as minimizing interference.

• Advanced Materials: To achieve excellent electrical performance, thermal management, and reliability during manufacture of HDI PCBs, advanced materials must be used. The latest improvements have been focusing on materials with better dielectric properties, better resistance to environmental factors such as moisture or corrosion and higher thermal conductivity.

• Advanced Manufacturing Techniques: Innovations like laser drilling, sequential build-up (SBU) and via filling technologies have facilitated production of finer vias and microvias in HDI PCBs. These improvements are aimed at enabling higher interconnect densities together with improved signal integrity.

• Flexibility and Durability: The HDI PCBs enclose flexibility and durability especially when used in wearable devices, automotive electronics as well as aerospace systems. Recent developments include flexible HDIs that can bend without breaking while still retaining their electrically conductive characteristics.

• Integration with Advanced Technologies: Advanced technologies such as 5G Communication Systems, Artificial Intelligence (AI), Internet of Things (IoT) etc., are increasingly being integrated into HDI PCBs themselves. Consequently, manufacturers have focused on high-speed data transmission; low latency together with reliability through designing specific products that are tailored towards these applications.

• Environmental Considerations: The development of environmentally friendly HDIs meet up strict environmental regulations including sustainability criteria. Such initiatives include use of green materials, processes that minimize waste generation, and components recyclability at the end of their lifespan.

Strategic Growth Opportunities for HDI PCB Market

The HDI PCB market is well positioned for strong growth due to technology advancement, demand for miniaturization and industry diversification. The following presents the strategic growth opportunities in the market of HDI PCB:

• Rapid Technological Advancements: In the electronics industry, HDI PCBs are leading innovations in technology. For example, there is a continuous demand for more efficient, lighter and smaller electronic devices like smartphones, tablets, wearables and IoT devices hence need for HDI PCBs. These boards make it possible to pack components at high density thereby improving signal integrity and minimizes electromagnetic interference (EMI) which form important aspects regulating performance of modern-day electronic commodities.

• Miniaturization and Performance Requirements: HDI PCBs are driven by miniaturization as an essential factor while these devices become compact with increased functionality and performance demands. Fine lines & spaces, micro vias as well as multiple layers among others enabled by HDI technology enable higher circuit density and complexity desired by designers. This enables some space saving solutions that are necessary in meeting size/weight requirements found in consumer electronics or automotive applications.

• Emerging Applications in Automotive and Aerospace: For advanced driver assistance systems (ADAS), in-vehicle infotainment (IVI), navigation systems or even avionics; the automotive or aerospace industries have started adopting HDI PCBs at increased rates. High-speed data transmission & signal integrity withstanding harsh environments temperature variations mechanical stresses characterizes these applications necessitating dependable PCBs.

• 5G and IoT Connectivity: This has led to an increasing uptake of HDI PCBs capable of supporting low power consumption as well as high-speed data transmission high frequency signals in support of 5G network deployments along with proliferation of IoT devices. Also, RF components can be integrated into small-sized printed circuit board designs through HDIs so that RF antennas and sensors can be incorporated into mobile phones thereby making them smart communicators.

• Market Expansion in Asia-Pacific: China, Japan, South Korea & Taiwan are the countries where electronics majors are based in who dominate the HDI PCB market in Asia-Pacific. PCB manufacturing has shown a strong infrastructure coupled with skilled workforce and supportive governmental policies promoting technology as well as industry growth. The suppliers can fulfill global demand and maintain competitiveness through expanding manufacturing capacities and capabilities within Asia-Pacific.

• Focus on Sustainability and Material Innovations: The emphasis on sustainable operations in the electronics sector is driving development of eco-friendly materials and processes for HDI PCB production. For example, recyclable substrates & lead free finishes enhance product reliability & performance while supporting environmental goals. Furthermore, these companies can invest into sustainable practices that would make them stand out from others targeting environmentally friendly customers.

• Strategic Partnerships and Investments: Innovation and market expansion are driven by collaboration between manufacturers of PCBs, users of those products and technology providers. On the other hand, strategic partnerships grant access to additional markets or R&D expertise or complementary technologies. Advanced manufacturing equipment together with digitalization aids in reducing lead times enhancing overall product quality plus reliability while improving productivity through automation investments.

The HDI PCB marketÄX%$%Xs strategic growth opportunities lie in leveraging technological advancements, meeting miniaturization demands, expanding into emerging applications and regions, embracing connectivity trends like 5G and IoT, focusing on sustainability, and fostering strategic collaborations. Companies that innovate and adapt to these opportunities are well-positioned to capitalize on the growing demand for high-performance electronic solutions in various industries worldwide.

HDI PCB Market Driver and Challenges

HDI PCB has a very important role in many applications including smartphones and tablets, computer, telecom/datacom industries The changing market dynamics are being driven by the increasing demand for miniaturization of electronic devices, growing technological advancement, and rising demand from 5G and IoT. However, challenges like complexity in design and manufacturing and cost and pricing pressure to sustain growth and innovation in the HDI PCB market. The factors responsible for driving the HDI PCB market include:

• Miniaturization Requirements: Consumer’s preference for smaller and lighter electronic gadgets such as mobile phones, tablets, wearable techs and Internet of Things (IoT) devices is the force behind increased demand for HDI PCBs. In a way that they can take up more elements in less space, this allows for higher complexity and circuit density.

• High Performance Requirements: The ability of HDI PCBs to support high-speed data transmission, low signal loss and improved reliability has been crucial in supporting advanced technologies. This is because HDI technology provides better signal integrity and reduced electromagnetic interference (EMI) which has numerous applications in sectors like automotive industry (ADAS, IVI), telecommunications, aerospace (avionics).

• Technological Advances: Continuous improvements in processes used to manufacture PCB materials design tools create finer lines and spaces between pads and microvias resulting into multiple layers of HDI PCB production. All these developments affect the effectiveness of most electronic equipment.

• Demand from 5G and IoT: The emergence of 5G networks complemented by an increasing number of Internet-of-things (IoTs) encourages the need for HDI-PCBs capable of supporting high-frequency signals, fast transmission rates with low power consumption. By adopting RF components, antennas as well as sensors into small-sized printed circuit boards; it helps simplify many things.

• Market Growth in Asia-Pacific: e China, Japan South Korea Taiwan are countries where APAC gets a lot of its electronics products manufactured. Through its robust infrastructure, skilled manpower base as well as encouragement towards innovation through policy regulations; this promotes fostering growth within this market segment thereby enhancing APAC’s position as one among the biggest hubs for electronic manufacturing industry globally.

Challenges facing the HDI PCB market are:

Complexity in Design and Manufacturing: Design and manufacture of HDI PCBs are complex processes as they involve finer pitches, multiple layers, and higher quality demands. These complexities can only be effectively managed by specialists who were trained on machines to use.

Financial Constraint and Pricing Pressure: The manufacturing cost of HDI PCBs is generally higher than that of traditional PCBs because of better materials, complex operations, and tighter tolerances. Achieving cost efficiency without compromising on performance remains a challenge in low-cost segments.

Reliability and Durability Issues: Durable and reliable electronics are necessary especially for automobiles, airplanes, or medical devices where the printed circuit board failure would have serious implications. Thermal management, mechanical stress or material compatibility are examples other things that must be considered and tested upon.

Supply Chain and Component Availability: The supply chain for HDI PCBs relies on a complicated network of raw materials, components, tools etc. This could hamper production schedules as well as lead times through shortages in critical materials or components causing disruptions within the supply chain.

Environmental Requirements And Regulatory Compliances: Environmental directives such as RoHS (Restriction of Hazardous Substances Directive) complicate the manufacture of HDI PCBs while industry standards are also difficult to meet. Continuous challenges include environmentally friendly practices and control over dangerous substances during manufacturing processes .

To navigate these drivers and challenges requires continuous innovation , investment in technology and talent, strategic partnerships, proactive market and regulatory responses . Companies which can master these elements will exploit opportunities for growth arising from an increasing market for HDI PCBs worldwide across different applications.

HDI PCB Suppliers and their Market Shares

In this globally competitive market, several key players such as TTM, Tripod, AT&S, Kingboard, CCTC, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at helpdesk@lucintel.com. Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies HDI PCB companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the HDI PCB companies profiled in this report includes.

• TTM Technologies, Inc.

• Tripod Technology Corporation

• AT&S

• Kingboard Holdings Ltd.

• CCTC

• DG Shengyi Electronics

• Dynamic Electronics Co. Ltd.

• Gold Circuit Electronics

• Olympic

• DAP

• Unimicron Technology Corp.

• Compeq Manufacturing Co., Ltd.

• Ibiden Co., Ltd.

• Zhen Ding Technology Holding Limited

• Unitech

• Samsung Electro-Mechanics

• Meiko Electronics Co. Ltd

These companies have established themselves as leaders in the HDI PCB industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the HDI PCB market are evolving, with the entry of new players and the emergence of innovative HDI PCB technologies. Additionally, collaborations between component suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

HDI PCB Market by Segment

Major segments of HDI PCB that are experiencing growth include smartphone, computer, telecom/Datacom, consumer electronics, and automotive industries.. HDI PCBs are crucial components in smartphones, tablets, and wearable devices due to their compact size, high interconnect density, and ability to support advanced functionalities like 5G connectivity and AI applications. HDI PCBs are integral to automotive electronics, supporting features such as infotainment systems, driver assistance systems, and electric vehicle (EV) powertrains. The automotive sectorÄX%$%Xs shift towards electric and autonomous vehicles further boosts demand for HDI PCBs with higher reliability and performance.

This HDI PCB market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including end use industry, technology, and build-up structure. The report offers insights into regional dynamics, highlighting the major markets for HDI PCB and their growth potentials. The study includes trends and forecast for the global HDI PCB market by end use industry, technology, build-up structure and region as follows:

By End Use Industry [$M and Thousand Sqm shipment analysis for 2018 – 2030]:

• Smartphones and Tablets

• Computers

• Telecom/Datacom

• Consumer Electronics

• Automotive

• Others

By Technology [$M and Thousand Sqm shipment analysis for 2018 – 2030]::

• 4-6 Layer

• 8-10 Layer

• 10+ Layer

By Build-Up Structure [$M and Thousand Sqm shipment analysis for 2018 – 2030]:

• 1+n+1

• 2+n+2

• 3+n+3

• Others

By Region [$M and Thousand Sqm shipment analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of HDI PCB Market

Market Size Estimates: High Density Interconnect (HDI) PCB market size estimation in terms of value ($M) and Volume (Thousand Sqm)

Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

Segmentation Analysis: High Density Interconnect (HDI) PCB market size by various segments, such as end use industry, technology, and built-up structure, in terms of value and volume.

Regional Analysis: High Density Interconnect (HDI) PCB market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis on growth opportunities in various end use industries, technologies, built-up structures, and regions for the high density interconnect (HDI) PCB market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for the high density interconnects (HDI) PCB market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

FAQ

Q1. What is the HDI PCB market size?

Answer: The global HDI PCB market is expected to reach an estimated $21 billion by 2030.

Q2. What is the growth forecast for HDI PCB market?

Answer: The HDI PCB market is expected to grow at a CAGR of 5% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the HDI PCB market?

Answer: The major drivers for this market are increasing demand for miniaturization of electronic devices, growing technological advancement, and rising demand from 5G and IoT.

Q4. What are the major applications or end use industries for HDI PCB?

Answer: Smart phones and tablets and computers are the major end use industries for HDI PCB market.

Q5. What are the emerging trends in HDI PCB market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include higher layer counts in HDI PCBs to accommodate complex designs and functionalities, integration of passive and active components within the PCB structure, and emphasis on flexible HDI PCBs for bendable and wearable electronics.

Q6. Who are the key HDI PCB companies?

Answer: Some of the key HDI PCB companies are as follows:

• TTM Technologies, Inc.

• Tripod Technology Corporation

• AT&S

• Kingboard Holdings Ltd.

• CCTC

• DG Shengyi Electronics

• Dynamic Electronics Co. Ltd.

• Gold Circuit Electronics

• Olympic

• DAP

• Unimicron Technology Corp.

• Compeq Manufacturing Co., Ltd.

• Ibiden Co., Ltd.

• Zhen Ding Technology Holding Limited

• Unitech

• Samsung Electro-Mechanics

• Meiko Electronics Co. Ltd

Q7.Which HDI PCB technology segment will be the largest in future?

Answer: Lucintel forecasts that 4-6 layers will remain the largest segment due to increasing demand in smartphone and telecom and datacom. The 10+ layer HDI PCB market is expected to witness the highest growth during the forecast period due to the growing demand for smart wearables and connected devices.

Q8: In HDI PCB market, which region is expected to be the largest in next 5 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 5 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the global high density interconnect (HDI) PCB market by end use industry (smartphones and tablets, computers, telecom/datacom, consumer electronics, automotive and others), technology (4-6 layer, 8-10 layer, 10+ layer), build-up layer count (1+n+1, 2+n+2, 3+n+3, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the High Density Interconnect (HDI) PCB market?

Q.5 What are the business risks and threats to the high density interconnect (HDI) PCB market?

Q.6 What are the emerging trends in the high density interconnect (HDI) PCB market and the reasons behind them?

Q.7 What are some changing demands of customers in the high density interconnect (HDI) PCB market?

Q.8 What are the new developments in the high density interconnect (HDI) PCB market? Which companies are leading these developments?

Q.9 Who are the major players in the high density interconnect (HDI) PCB market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in the high density interconnect (HDI) PCB market, and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M&A activities did take place in the last five years in the high density interconnect (HDI) PCB market?

For any questions related to High Density Interconnect (HDI) PCB market or related to High Density Interconnect (HDI) PCB market share, High Density Interconnect (HDI) PCB market analysis, and High Density Interconnect (HDI) PCB market size, write to Lucintel analysts at helpdesk@lucintel.com. We will be glad to get back to you soon.