HDPE Pipe Market Trends and Forecast

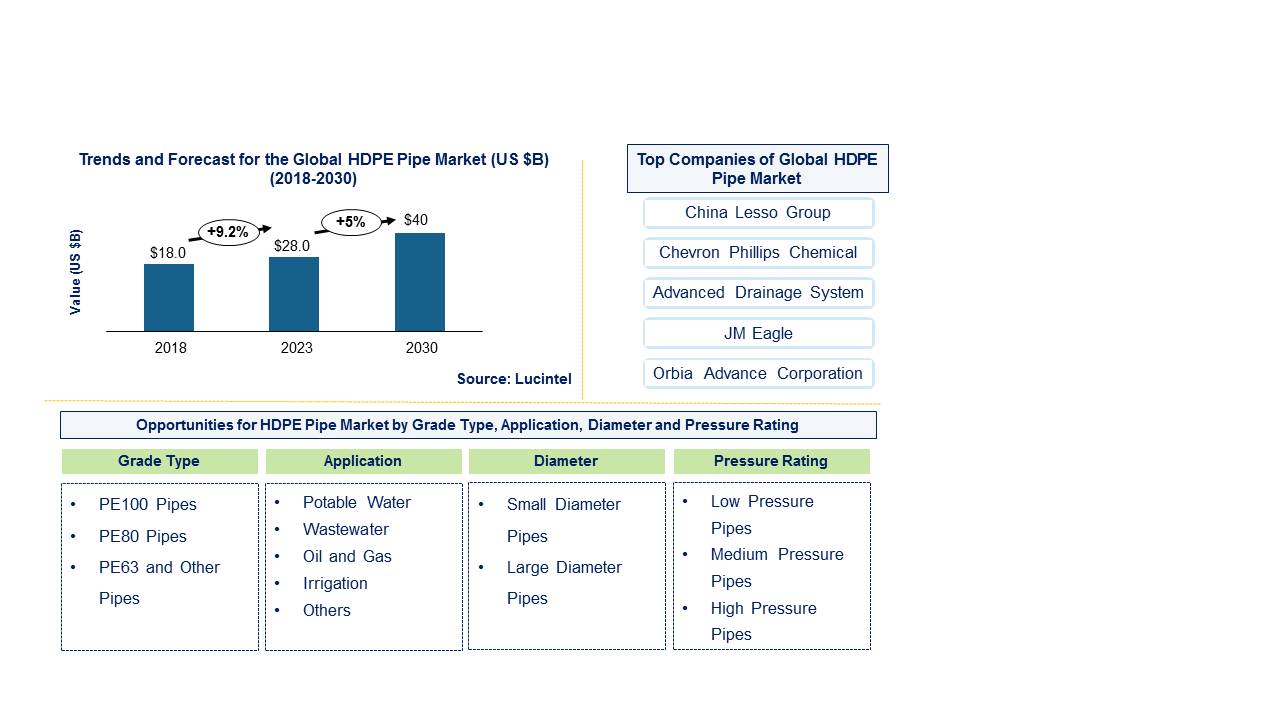

The future of the global HDPE (High Density Poly Ethylene) pipe market looks promising with opportunities in potable water, wastewater, oil and gas, and irrigation sectors. The global HDPE pipe market is expected to reach an estimated $40.4 billion by 2030 with a CAGR of 5% from 2024 to 2030. The major growth drivers for this market are growing residential and non-residential construction activities, replacement of aging pipelines, and increasing awareness of the attractive properties of HDPE pipes.

HDPE pipes are primarily made from high-density polyethylene resin, which is derived from petroleum feedstocks. The raw material undergoes polymerization to form long chains of polyethylene molecules, imparting strength, flexibility, and chemical resistance to the pipes. Additives such as antioxidants, UV stabilizers, and processing aids are incorporated to enhance durability and performance. The quality of raw materials, including the purity of polyethylene resin and the composition of additives, significantly influences the mechanical properties and longevity of HDPE pipes, making them suitable for various applications in water distribution, sewage systems, and industrial pipelines. The price of HDPE pipes tends to be competitive compared to alternatives like PVC (Polyvinyl Chloride) and ductile iron pipes. HDPE pipes offer cost advantages due to their lightweight nature, ease of installation, and long-term durability, which reduces maintenance and replacement costs over their lifespan. In contrast, PVC pipes may be cheaper initially but can require more frequent replacements and maintenance. Ductile iron pipes are heavier and more expensive to install, often requiring specialized equipment. Overall, HDPE pipesÄX%$%X lower life cycle costs and reliability contribute to their strong market position despite fluctuating raw material prices.

• Lucintel forecasts that PE100 pipes are expected to remain the largest segment and witness the highest growth over the forecast period because of their high strength, chemical resistance, low cost, durability, minimal maintenance requirements, and superior energy efficiency.

• Within the global HDPE pipe market, the wastewater segment is expected to witness the highest growth over the forecast period due to increasing spending in municipal infrastructure development.

• APAC is expected to remain the largest market and witness the highest growth rate over the forecast period due to the increasing urbanization, infrastructure development, and the continuous growth of the residential construction and industrial sectors in this region.

Country wise outlook for the HDPE Pipe Market

Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major HDPE pipe producers in key regions: the USA, Germany, China, India, and Saudi Arabia.

Emerging Trends in the HDPE Pipe Market

Emerging trends in the HDPE pipe market include:

• Infrastructure Development: With significant investments in infrastructure projects worldwide, there is a rising demand for HDPE pipes in water supply, sewage systems, and gas distribution. Their durability and corrosion resistance make them ideal for such applications.

• Sustainability and Environmental Concerns: There is a growing focus on the use of sustainable materials, and HDPE pipes are being favored due to their recyclability and lower environmental impact compared to traditional materials like steel and concrete.

• Technological Advancements: Innovations in manufacturing processes, such as advanced extrusion technologies, are enhancing the quality and performance of HDPE pipes. Developments in jointing techniques, like electrofusion and butt welding, are improving installation efficiency and reliability.

• Adoption in Agriculture and Irrigation: The agricultural sector is increasingly adopting HDPE pipes for irrigation systems due to their flexibility, ease of installation, and resistance to chemicals and UV radiation, which contribute to better water management.

• Smart and Connected Systems: The integration of smart technologies, such as sensors and IoT devices, into HDPE pipe networks is emerging. These systems allow for real-time monitoring of pipeline conditions, leak detection, and maintenance, improving overall operational efficiency.

A more than 150 page report to help in your business decisions. Sample figures with some insights are shown below.

Recent Developments by the HDPE Pipe Market

Recent developments in HDPE pipe by various companies highlight ongoing innovations and advancements across different sectors:

• Technological Advancements: Introduction of advanced HDPE pipe formulations with enhanced properties like improved durability, higher pressure ratings, and better resistance to chemicals and abrasion.

• Sustainability Initiatives: Increasing use of recycled HDPE materials in pipe manufacturing to reduce environmental impact and meet sustainability goals.

• Expansion into New Applications: Growing deployment of HDPE pipes in infrastructure projects worldwide, including water supply networks, sewage systems, and gas distribution networks.

• Digital Transformation: Integration of IoT (Internet of Things) technology in HDPE piping systems for real-time monitoring, leak detection, and predictive maintenance.

Strategic Growth Opportunities for HDPE Pipe Market

Some key strategic growth opportunities for this market include:

Infrastructure Development and Urbanization:

• Water and Wastewater Management: Increasing demand for efficient water supply and wastewater management systems in urban and rural areas drives the adoption of HDPE pipes. Growth in infrastructure projects such as water distribution networks, sewage systems, and storm water management presents significant opportunities.

• Gas Distribution: Expansion of natural gas distribution networks, particularly in urbanizing regions, due to the cost-effectiveness, durability, and corrosion resistance of HDPE pipes compared to traditional materials like steel.

Advancements in Manufacturing and Technology:

• Advanced Material Formulations: Development of advanced HDPE pipe formulations with enhanced properties such as improved stress crack resistance, higher pressure ratings, and better chemical resistance. These advancements cater to diverse applications and increase market penetration.

• Innovative Joining Techniques: Adoption of innovative joining methods like electrofusion and butt fusion welding to ensure strong and reliable connections, reducing installation time and maintenance costs.

Expansion into New Applications and Markets:

• Agricultural Irrigation: Growing adoption of HDPE pipes in agricultural irrigation systems due to their flexibility, durability, and resistance to corrosion and chemicals.

• Mining and Industrial Applications: Utilization of HDPE pipes in mining operations for slurry transport, heap leaching, and tailings management, driven by their abrasion resistance and ability to withstand harsh environmental conditions.

• Telecommunication and Cable Protection: Increasing demand for HDPE pipes in telecommunications infrastructure for cable protection, conduit systems, and fiber optic networks.

Sustainability Initiatives and Green Technologies:

• Recycled Materials: Incorporation of recycled HDPE materials in pipe manufacturing to reduce environmental impact and meet sustainability goals. Recycling initiatives help mitigate raw material costs and enhance market competitiveness.

• Environmental Compliance: Adherence to stringent environmental regulations and standards promoting the use of sustainable and eco-friendly materials in construction and infrastructure projects.

Market Expansion in Emerging Economies:

• Asia-Pacific Region: Rapid industrialization, urbanization, and infrastructure development in countries like China, India, and Southeast Asia create opportunities for HDPE pipe applications in construction, water management, and utilities.

• Latin America and Middle East: Increasing investments in oil and gas exploration, industrial development, and infrastructure projects drive demand for HDPE pipes in diverse applications.

By focusing on these strategic growth opportunities, HDPE pipe manufacturers can capitalize on expanding market segments, technological advancements, and sustainability trends to drive long-term growth, profitability, and market leadership.

HDPE Pipe Market Driver and Challenges

HDPE Pipe Market Drivers:

1. Durability and Longevity: HDPE pipes are known for their durability, corrosion resistance, and long service life, making them suitable for various applications in water supply, wastewater management, mining, and industrial sectors.

2. Replacement of Aging Infrastructure: The need to replace aging pipelines made of less durable materials like steel or concrete with HDPE pipes drives market growth due to lower maintenance costs and longer operational lifespan.

3. Lower Installation Costs: HDPE pipes are lightweight, flexible, and easy to transport and install compared to traditional materials such as steel or concrete pipes. This reduces labor costs and installation time, making HDPE pipes a cost-effective solution.

4. Reduced Maintenance: HDPE pipes require minimal maintenance and repair due to their resistance to corrosion, chemical attack, and abrasion, resulting in lower lifecycle costs for end-users.

5. Advanced Material Formulations: Development of high-performance HDPE pipe grades with improved properties such as higher pressure ratings, enhanced flexibility, and superior resistance to chemicals and UV radiation.

6. Innovative Joining Techniques: Adoption of advanced joining methods like electrofusion and butt fusion welding to ensure strong and leak-proof connections, enhancing overall system reliability and performance.

HDPE Pipe Market Challenges:

1. Traditional Materials: Competition from established materials like steel, concrete, and PVC pipes that have a strong market presence and may be preferred in certain applications based on specific performance requirements.

2. Alternative Plastics: Increasing competition from alternative plastic pipes such as PP (Polypropylene) and PVC (Polyvinyl Chloride) pipes that offer similar characteristics and may be perceived as lower-cost alternatives.

3. Regulatory Requirements: Adherence to stringent environmental regulations and standards governing the use of materials in construction and infrastructure projects, including certifications for water quality and safety.

4. Environmental Impact: Challenges related to the disposal and recycling of HDPE pipes at end-of-life stages, particularly ensuring proper recycling and waste management practices to minimize environmental impact.

5. Price Volatility: Fluctuations in the prices of raw materials such as ethylene and propylene, which impact HDPE resin production costs and overall pricing of HDPE pipes.

6. Supply Chain Disruptions: Risks associated with supply chain disruptions, including raw material shortages, transportation delays, and geopolitical factors affecting global resin and pipe production.

Navigating these drivers and challenges requires HDPE pipe manufacturers to focus on innovation, quality assurance, sustainability initiatives, and strategic market positioning to capitalize on growth opportunities and maintain competitiveness in the global market.

HDPE Suppliers and their Market Shares

In this globally competitive market, several key players such as Orbia Advance Corporation, China Lesso Group, Sekisui Chemical, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies HDPE pipe companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the HDPE pipe companies profiled in this report include.

• Orbia Advance Corporation

• China Lesso Group

• Advanced Drainage Systems

• Sekisui Chemical

• Formosa Plastics Group

• Supreme Industries

• Jain Irrigation

• Astral Pipes

These companies have established themselves as leaders in the HDPE pipe industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the HDPE pipe are evolving, with the entry of new players and the emergence of innovative HDPE pipe technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

HDPE Pipe Market by Segments

The major segment of HDPE pipes experiencing significant growth is in infrastructure development, particularly in water supply and wastewater management projects. HDPE pipes are increasingly preferred for their durability, corrosion resistance, and cost-effectiveness compared to traditional materials like concrete and metal. Rapid urbanization, coupled with investments in infrastructure upgrades and expansion projects globally, has driven the demand for HDPE pipes in applications such as potable water distribution, sewage and drainage systems, and industrial pipelines. Additionally, the agricultural sector is adopting HDPE pipes for irrigation due to their flexibility, longevity, and ability to withstand harsh environmental conditions. These factors collectively contribute to the robust growth of HDPE pipes in the infrastructure and agricultural sectors.

This HDPE pipe market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including application, grade type, diameter type, and pressure rating. The report offers insights into regional dynamics, highlighting the major markets for HDPE pipe and their growth potentials. The study includes trends and forecast for the global HDPE pipe market by application, grade type, diameter type, pressure rating, and region as follows:

HDPE Pipe Market by Application [Value ($ Million) from 2018 to 2030]:

• Potable Water

• Wastewater

• Oil and Gas

• Irrigation

• Others

HDPE Pipe Market by Grade Type [Value ($ Million) from 2018 to 2030]:

• PE100 Pipes

• PE80 Pipes

• PE63 and Other Pipes

HDPE Pipe Market by Diameter Type [Value ($ Million) from 2018 to 2030]:

• Large Diameter Pipes

• Small Diameter Pipes

HDPE Pipe Market by Pressure Rating [Value ($ Million) from 2018 to 2030]:

• High Pressure Pipes

• Medium Pressure Pipes

• Low Pressure Pipes

HDPE Pipe Market by Region [Value ($ Million) and Volume (Thousand Tons) from 2018 to 2030]:

• North America

o United States

o Canada

o Mexico

• Europe

o Germany

o United Kingdom

• APAC

o China

o India

o Japan

• ROW

o Middle East

o Brazil

Features of the HDPE Pipe Market

• Market Size Estimates: HDPE pipe market size estimation in terms of value ($M).

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: HDPE pipe market size by various segments, such as grade type, application, diameter, and pressure rating.

• Regional Analysis: HDPE pipe market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis on growth opportunities in different grade type, application, diameter, and pressure rating, and regions for HDPE pipe market.

• Strategic Analysis: This includes M&A and competitive landscape for the HDPE pipe.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in HDPE Pipe or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the HDPE pipe market size?

Answer: The global HDPE pipe market is expected to reach an estimated $40 billion by 2030.

Q2. What is the growth forecast for HDPE pipe market?

Answer: The HDPE pipe market is expected to grow at a CAGR of 5% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the HDPE pipe market?

Answer: The major growth drivers for this market are growing residential and non-residential construction activities, replacement of aging pipelines, and increasing awareness of the attractive properties of HDPE pipes.

Q4. What are the major applications or end use industries for HDPE pipe?

Answer: Potable water, wastewater, oil & gas, and irrigation are the major end use for HDPE pipe

Q5. What are the emerging trends in HDPE pipe market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include with significant investments in infrastructure projects worldwide, there is a rising demand for HDPE pipes in water supply, sewage systems, and gas distribution. Their durability and corrosion resistance make them ideal for such applications.

Q6. Who are the key HDPE pipe companies?

Answer: Some of the key HDPE pipe companies are as follows:

• Orbia Advance Corporation

• China Lesso Group

• Advanced Drainage Systems

• Sekisui Chemical

• Formosa Plastics Group

• Supreme Industries

• Jain Irrigation

• Astral Pipes

Q7. Which HDPE pipe product segment will be the largest in future?

Answer: Lucintel forecasts that PE100 pipes are expected to remain the largest segment and witness the highest growth over the forecast period because of their high strength, chemical resistance, low cost, durability, minimal maintenance requirements, and superior energy efficiency.

Q8: In HDPE pipe market, which region is expected to be the largest in next 5 years?

Answer: North America will remain the largest region and is expected to witness the highest growth over next 5 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the HDPE pipe market by application (potable water, wastewater, oil and gas, irrigation, and others), grade type (PE100, PE80, PE63 and others), diameter (small diameter pipes (up to 15 inches) and large diameter pipes (15 inches and above), pressure rating (high, medium, and low pressure), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the HDPE pipe market?

Q.5 What are the business risks and threats to the HDPE pipe market?

Q.6 What are emerging trends in this HDPE pipe market and the reasons behind them?

Q.7 What are some changing demands of customers in the HDPE pipe market?

Q.8 What are the new developments in the HDPE pipe market? Which companies are leading these developments?

Q.9 Who are the major players in the HDPE pipe market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in the HDPE pipe market, and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M&A activities did take place in the last five years in the HDPE pipe market?

For any questions related to HDPE pipe market or related HDPE pipe , HDPE pipe sales, HDPE pipe companies, , top HDPE pipe companies, HDPE pipe manufacturers, largest HDPE pipe companies, HDPE pipe manufacturer, HDPE pipe company, HDPE pipe manufacturing, HDPE pipe industry, ans HDPE pipe consumables, write Lucintel analyst at email: helpdesk@lucintel.com we will be glad to get back to you soon.