FRP Tank Market Trends and Forecast

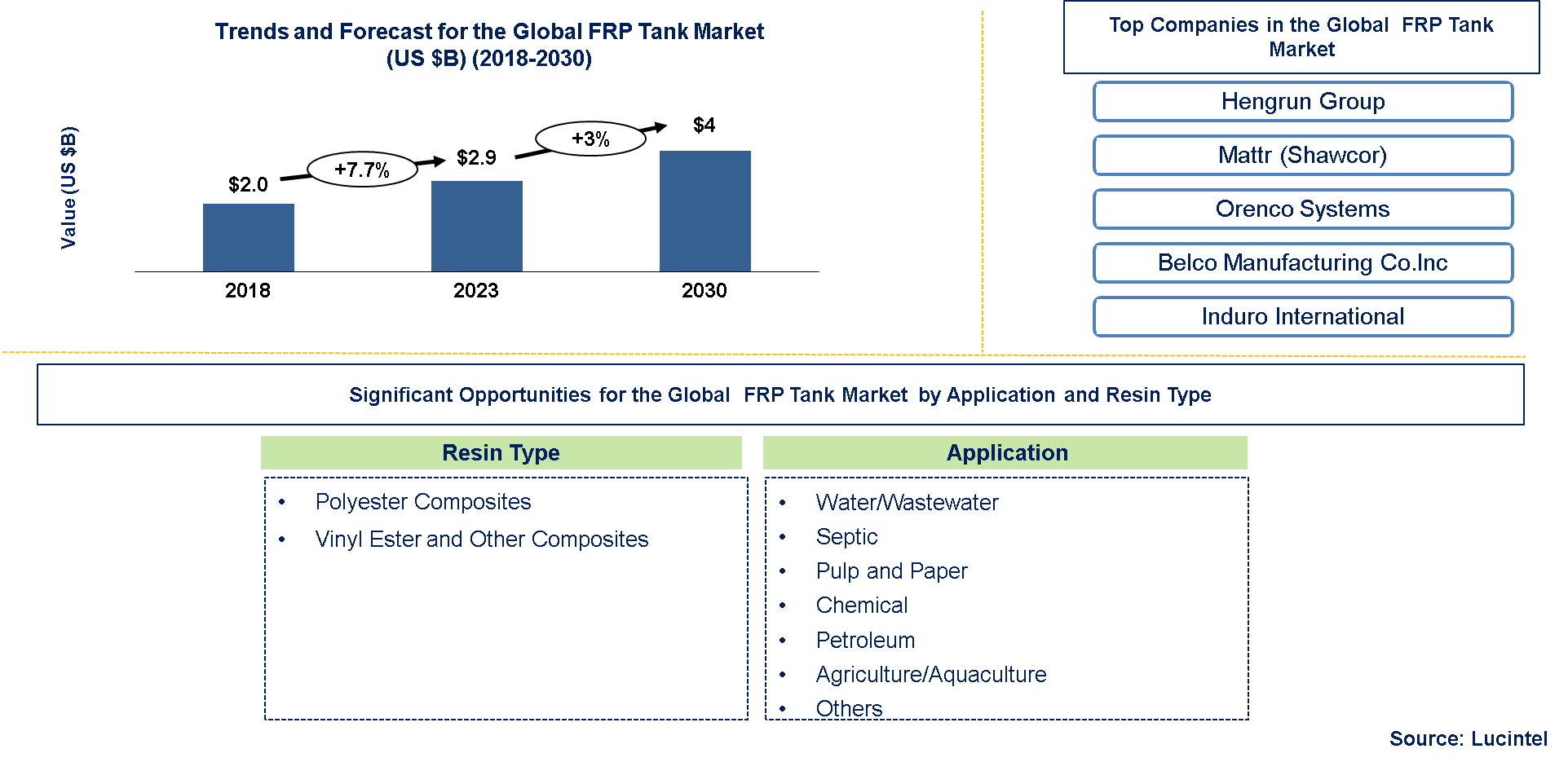

Lucintel finds that the future of composite product of the global FRP tank market looks promising with opportunities in the water/wastewater, septic, pulp and paper, chemical, petroleum, and agriculture/aquaculture applications. The global FRP tank market is expected to reach an estimated $4 billion by 2030 with a CAGR of 3% 2023 to 2030. The major growth drivers for this market are growing demand for oil and gas storage systems, and expansion of chemical plants, rapid urbanization and infrastructure development in developing countries.

Tanks in FRP (Fiber Reinforced Plastic) are made using ingredients like resins, fiberglass, fillers and additives. Fiberglass acting as strong and stiffening agent is bounded together by the matrix which includes resin, usually polyester or vinyl ester or epoxy. Fillers like calcium carbonate decrease costs and improve mechanical properties while additives like flame retardants and UV inhibitors enhance performance and durability. FRP tanks are less expensive than concrete and steel thus allowing for affordable cost due to reduced maintenance, long service life and corrosion resistance. In spite of high initial costs, their lifecycle costs are lower. The pricing varies by design, size and application; this balances between efficiency related to charges incurred during a given period versus effectiveness of the specific product in question.

• Lucintel forecasts that water/wastewater will remain the largest market by value and volume over the forecast period due to infrastructural development.

• Polyester composites FRP tank will remain the largest segment over the forecast period due to its increasing use in various end use industry.

• Asia Pacific is expected to remain the largest region over the forecast period due to increasing energy demand, demand from retail fuel stations, increasing number of desalination plants, looming fresh water shortage, conservation of rainwater, and gaining momentum in replacing old existing tanks. Europe is expected to witness the highest growth over the forecast period.

Tanks in FRP (Fiber Reinforced Plastic) are made using ingredients like resins, fiberglass, fillers and additives. Fiberglass acting as strong and stiffening agent is bounded together by the matrix which includes resin, usually polyester or vinyl ester or epoxy. Fillers like calcium carbonate decrease costs and improve mechanical properties while additives like flame retardants and UV inhibitors enhance performance and durability. FRP tanks are less expensive than concrete and steel thus allowing for affordable cost due to reduced maintenance, long service life and corrosion resistance. In spite of high initial costs, their lifecycle costs are lower. The pricing varies by design, size and application; this balances between efficiency related to charges incurred during a given period versus effectiveness of the specific product in question.

• Lucintel forecasts that water/wastewater will remain the largest market by value and volume over the forecast period due to infrastructural development.

• Polyester composites FRP tank will remain the largest segment over the forecast period due to its increasing use in various end use industry.

• Asia Pacific is expected to remain the largest region over the forecast period due to increasing energy demand, demand from retail fuel stations, increasing number of desalination plants, looming fresh water shortage, conservation of rainwater, and gaining momentum in replacing old existing tanks. Europe is expected to witness the highest growth over the forecast period.

Country wise Outlook for the FRP Tank Market

The FRP Tank market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major FRP Tank producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends in the FRP Tank Market

Emerging trends in the FRP Tank Market shaping its future applications and market dynamics:

• Automation and Manufacturing Techniques: This is by the use of advanced automation and manufacturing techniques such as automated filament winding and robotic assembly, which improves productivity, cuts costs, and uphold steady quality in FRP tanks.

• Smart Tank Technologies: FRP tanks have sensors and IoT (Internet of Things) devices installed that constantly monitor temperature, pressure and fluid levels among other parameters. It allows for preventive maintenance and improved operational efficiency.

• Recycling and Circular Economy Initiatives: Recycling programs for end-of-life FRP tanks encourage a circular economy approach by reducing landfill waste.

• Advanced Composite Materials: Some examples include development of new composites with better fatigue resistance, higher strength-to-weight ratio, and improved chemical resistance amongst others thus leading to long-lasting FRP tanks.

• Improved Corrosion Resistance: Advanced coatings or surface treatments that can provide extra corrosion resistance for even more corrosive environment enables FRP tanks to be used in more aggressive chemical environments.

Emerging trends in the FRP Tank Market shaping its future applications and market dynamics:

• Automation and Manufacturing Techniques: This is by the use of advanced automation and manufacturing techniques such as automated filament winding and robotic assembly, which improves productivity, cuts costs, and uphold steady quality in FRP tanks.

• Smart Tank Technologies: FRP tanks have sensors and IoT (Internet of Things) devices installed that constantly monitor temperature, pressure and fluid levels among other parameters. It allows for preventive maintenance and improved operational efficiency.

• Recycling and Circular Economy Initiatives: Recycling programs for end-of-life FRP tanks encourage a circular economy approach by reducing landfill waste.

• Advanced Composite Materials: Some examples include development of new composites with better fatigue resistance, higher strength-to-weight ratio, and improved chemical resistance amongst others thus leading to long-lasting FRP tanks.

• Improved Corrosion Resistance: Advanced coatings or surface treatments that can provide extra corrosion resistance for even more corrosive environment enables FRP tanks to be used in more aggressive chemical environments.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the FRP Tank Market

Recent developments in FRP Tank Market by various companies highlight ongoing innovations and advancements across different sectors:

• Advanced Materials: FRP tank manufacturers are using more advanced materials like carbon fiber and high-performance resins to increase the strength, toughness and chemical resistance of tanks. This makes such tanks applicable in highly demanding places such as chemical processing, water treatment, and oil and gas.

• Automation and Manufacturing Techniques: In FRP tank production, there is a shift towards automated manufacturing processes. These include advancements made in robotic layup technologies, automated filament winding and improved mold designs that have led to higher rate of production efficiency and product quality consistency.

• Customization And Modular Designs: Companies are increasingly providing more customizable solutions for their customers who need FRP tanks. They come with modular designs which enable them to be transported or installed easily and therefore this enhances easy expansion hence they are suitable for applications in industries such as water management, agriculture, municipal infrastructure among others.

• Focus on Sustainability: The market for FRP tanks has a strong focus on sustainability. They produce lighter tanks that consume less energy during manufacture while maintaining longevity over conventional materials like steel thereby reducing environmental impact thus lowering life-cycle costs.

• Integration of IoT and Monitoring Systems: Some advanced solutions involving FRP tanks incorporate real-time monitoring technologies based on the Internet of Things (IoT) for measuring parameters such as temperature, pressure or chemicals levels within a tank. This helps enhance operational efficiency while also allowing predictive maintenance capabilities hence it improves safety as well.

• Regulatory Compliance and Safety: Manufacturers have directed research efforts towards meeting strict regulatory standards connected to protection of environment in addition to safety concerns. This is done through corrosion resistance testing, fire retardant testing, chemical compatibility tests among others.

• Market Expansion: The growth rate of the FRP tank market is shown by its spread across geographies where traditional materials face challenges such as corrosion due to humidity or corrosive environments. It includes; Growth in the Asia-Pacific region industrial applications driving growth to Asia-Pacific, North America and Europe.

Recent developments in FRP Tank Market by various companies highlight ongoing innovations and advancements across different sectors:

• Advanced Materials: FRP tank manufacturers are using more advanced materials like carbon fiber and high-performance resins to increase the strength, toughness and chemical resistance of tanks. This makes such tanks applicable in highly demanding places such as chemical processing, water treatment, and oil and gas.

• Automation and Manufacturing Techniques: In FRP tank production, there is a shift towards automated manufacturing processes. These include advancements made in robotic layup technologies, automated filament winding and improved mold designs that have led to higher rate of production efficiency and product quality consistency.

• Customization And Modular Designs: Companies are increasingly providing more customizable solutions for their customers who need FRP tanks. They come with modular designs which enable them to be transported or installed easily and therefore this enhances easy expansion hence they are suitable for applications in industries such as water management, agriculture, municipal infrastructure among others.

• Focus on Sustainability: The market for FRP tanks has a strong focus on sustainability. They produce lighter tanks that consume less energy during manufacture while maintaining longevity over conventional materials like steel thereby reducing environmental impact thus lowering life-cycle costs.

• Integration of IoT and Monitoring Systems: Some advanced solutions involving FRP tanks incorporate real-time monitoring technologies based on the Internet of Things (IoT) for measuring parameters such as temperature, pressure or chemicals levels within a tank. This helps enhance operational efficiency while also allowing predictive maintenance capabilities hence it improves safety as well.

• Regulatory Compliance and Safety: Manufacturers have directed research efforts towards meeting strict regulatory standards connected to protection of environment in addition to safety concerns. This is done through corrosion resistance testing, fire retardant testing, chemical compatibility tests among others.

• Market Expansion: The growth rate of the FRP tank market is shown by its spread across geographies where traditional materials face challenges such as corrosion due to humidity or corrosive environments. It includes; Growth in the Asia-Pacific region industrial applications driving growth to Asia-Pacific, North America and Europe.

Strategic Growth Opportunities for Global FRP Tank Market

• Water Supply and Sewage Treatment: The widespread application of FRP tanks in water supply and sewage treatment facilities is due to their resistance to corrosion and long life span. More urbanization, industrialization and environmental controls grow the demand for efficient storage systems that can last long. The expansion of municipal wastewater treatment plants, desalination projects, and industrial wastewater treatment facilities worldwide are some of the opportunities to FRP tanks.

• Petrochemical Industry: Chemical processing industry requires a higher level of chemical resistance from storage solution especially when dealing with corrosive chemicals hence the preference for FRP tanks. These tanks do not react with any acids or bases making it possible to store or process corrosive substances safely. Further global growth in terms of chemical production and manufacturing translates into increase in demand for FRP tanks within this sector.

• Oil and Gas Sector: For petroleum industries, FRP tanks are used as containers for different kinds of liquids such as crude oil, chemicals, wastewater among others. Its lightness as well as ability to withstand corrosion together with harsh weather conditions makes them suitable for use onshore and offshore respectively. Consequently, sustained growth in exploration plus development activities within oil and gas sectors specifically emerging markets will necessitate durable as well as cost friendly types of storage like FRP tanks.

• Agricultural Applications: Agriculture uses FRP tanks for storing water used in irrigation purposes alongside fertilizer and crop protection chemicals among other things. These have advantages such as their resistance to rusting, corroding since they can last longer even though they are exposed to sunlight outdoors within agricultural settings at times need keep up safe rural reliable effective storage solutions thus requiring more FRP tanks due to increased mechanization plus modernization globally.

• Food Processing Industry: One such example is food industry which necessitates keeping beverages according hygiene standard guidelines while providing them with other requirements needed by consumers therefore it is always required hygienic holding materials for that firm. The use of FRP tanks is favored in this sector because they have a smooth inner surface which does not allow bacteria to breed thus making them good for holding drinks, food ingredients and processing fluids. The global demand for processed food and beverages is driving the growth of FRP tanks in this industry.

• Advancement in Technology on Product Innovation: Research and development in materials technology and manufacturing processes continue to drive innovation in FRP tanks. Developments in resin formulation, reinforcement materials as well as production techniques has enhanced the performance, longevity and cost efficiency of FRP tanks. They include modular tank designs, smart monitoring systems and composite materials with enhanced properties that offer new opportunities for growth within the market.

• Sustainable Environment: Increased concerns about environmental sustainability are pushing industries towards greener materials and practices. FRP tanks can be made from recyclable materials and designed for long term durability thereby reducing their environmental impact. Companies emphasizing on green solutions plus sustainability are likely to attract environmentally-conscious consumers thus enhancing their competitiveness within the industry.

FRP Tank Market Drivers and Challenges

The global FRP (Fiber Reinforced Plastic) tank market is pivotal in industries requiring corrosion-resistant storage solutions. Driven by benefits like corrosion resistance, light weight and high strength, and durability and longevity, it faces challenges such as high initial costs, and complex installation and maintenance. This discussion explores key drivers propelling its growth and significant challenges hindering broader market adoption.

The key drivers for the global FRP Tank market include:

1. Corrosion Resistance: Fiber reinforced plastic (FRP) tanks have better corrosion resistance than conventional materials, making them suitable for storing corrosive liquids in industries such as chemicals, water treatment and oil & gas.

2. Light weight and high strength: Compared to traditional materials like steel, FRP tanks are light but strong thus cutting down transportation costs and simplifying installation.

3. Durability and longevity: They also live longer and require little maintenance hence reducing lifecycle costs as well as minimizing downtime for storage-dependent industries.

4. Customization and design flexibility: FRP tanks can be molded into various sizes and shapes thereby enabling their design to meet specific industrial and environmental requirements.

The challenges facing the global FRP Tank Market include:

1. High initial Costs: For certain industries, the upfront costs of using FRP tanks may be higher compared to those of other materials that could discourage first-time investments.

2. Complex Installation and Maintenance: Operating an FRP tank requires specialized skills & equipment which increases operational expenses involved for setting up & maintaining them.

Fiber Reinforced Plastic (FRP) tanks in the world market, have main reasons such as resistance to corrosion that is higher than others, are lighter compared to anything else on the earth and have long life span. These products mainly serve various sectors including chemicals and water treatment. Notwithstanding, high upfront costs and difficult installation processes continue to be a big obstacle for many companies. Continued efforts towards improving design flexibility coupled with regulatory compliance are expected to foster growth in the industry. It is important that these obstacles are addressed so that FRP tanks can be embraced fully by all stakeholders and consequently benefit from their advantages across the globe.

FRP Tank Suppliers and Their Market Shares

In this globally competitive market, several key players such as Hengrun Group, Mattr (Shawcor), Orenco Systems Inc, Belco Manufacturing Co.Inc. and Induro International etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report on “FRP Tank Market Leadership Report".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies FRP tank companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the FRP tank companies profiled in this report includes.

• Hengrun Group Co., Ltd.

• Mattr Infratech (Shawcor)

• Orenco Systems Inc.

• NOV

• L.F. Manufacturing, Inc.

• Hydro Dynamic Engineering Pte Ltd

• Induro International

• Hao Hua Zhongyi GFRP Co. Ltd

• RPS Composites

• Amiantit

• Diamond Fiberglass

These companies have established themselves as leaders in the global FRP Tank Market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the FRP Tank market are evolving, with the entry of new players and the emergence of innovative FRP Tank market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

FRP Tank Market by Segment

The market for FRP (Fiber Reinforced Plastic) tanks is growing in several key areas. In the first place, industrial applications such as chemical processing and water treatment are expanding because of its resistance to corrosion and long life span. Secondly, FRP tanks have been embraced by municipal water and wastewater sectors due to their lightness properties and ability to withstand a wide range of chemicals. Thirdly, the oil and gas industry is increasingly using FRP tanks for storage and transportation of various fluids due to their cost-effectiveness and durability. Moreover, the agricultural sector has also seen growth employing FRP tanks for storing fertilizers and chemicals which are non-corrosive in nature. Lastly, especially with regards to fuel storage, the automotive industry is seeking the use of FRP tanks since they are lightweight yet strong.

Global FRP Tank Market by Application [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Water/wastewater

• Septic

• Pulp and paper

• Chemical

• Petroleum

• Agriculture and aquaculture

• Others

Global FRP Tank Market by Resin Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Polyester Composites

• Vinyl Ester Composites and Others

Global FRP Tank Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of FRP Tank Market

• Market Size Estimates: FRP tank market size estimation in terms of value ($M) and Volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by application, resin and region

• Regional Analysis: FRP tank market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different applications, end use and regions for the FRP tank market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the FRP tank market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model

If you are looking to expand your business in FRP Tank or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the FRP tank market size?

Answer: The global FRP tank market is expected to reach an estimated $4 billion by 2030.

Q2. What is the growth forecast for FRP tank market?

Answer: The FRP tank market is expected to grow at a CAGR of 3% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the FRP tank market?

Answer: The major drivers for this market are corrosion resistance, light weight and high strength, and durability and longevity.

Q4. What are the major applications or end use industries for FRP tank?

Answer: Water/wastewater, septic, pulp and paper, chemical, petroleum, and agriculture/aquaculture are the major applications for FRP tank.

Q5. What are the emerging trends in FRP tank market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include automation and manufacturing techniques, smart tank technologies, recycling and circular economy initiatives, advanced composite materials, and improved corrosion resistance.

Q6. Who are the key FRP tank companies?

Answer: Some of the key FRP tank companies are as follows:

• Hengrun Group Co., Ltd.

• Mattr (Shawcor)

• Containment Solutions

• Orenco Systems Inc.

• Belco Manufacturing Co. Inc.

• L.F. Manufacturing, Inc.

• Zurn Green Turtle

• Hydro Dynamic Engineering Pte Ltd

• Induro International

• Hao Hua Zhongyi GFRP Co. Ltd

• Fabricated Plastic Limited

• Amiantit

• Diamond Fiberglass

Q7.Which FRP tank product segment will be the largest in future?

Answer: Lucintel forecasts that polyester composites in FRP tank will remain the largest segment due to its increasing use in various end use industries.

Q8: In FRP tank market, which region is expected to be the largest in next 6 years?

Answer: Asia Pacific is expected to remain the largest region over next 6 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global FRP tank market by application (water/wastewater, septic, pulp and paper, chemical, petroleum, agriculture, aquaculture, and others), resin type (polyester composites, vinyl ester composites and other) and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?