FRP Tanks in Water and Wastewater Market Trends and Forecast

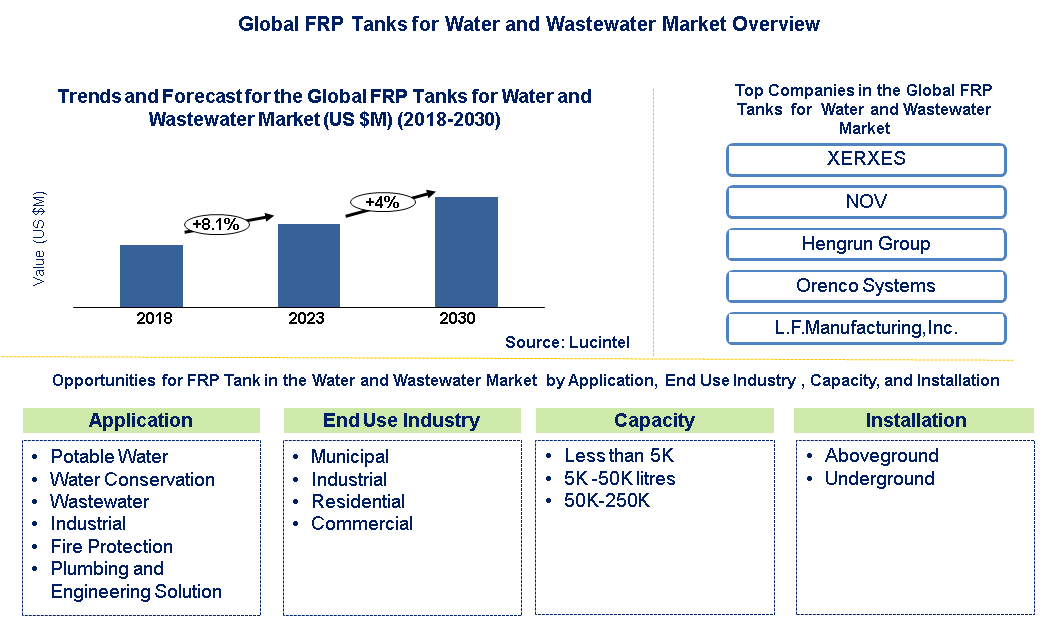

Lucintel finds that the future of composite product of the FRP tanks in the global water and wastewater market looks promising with opportunities in the municipal, industrial, residential, and commercial industry. The global FRP tanks in the global water and wastewater market is expected to grow with a CAGR of 4% from 2023 to 2030. The major drivers for this market are growing construction activities, increasing concerns towards water conservation and fire protection, and aging water infrastructure.

FRP tanks are constructed in the water and wastewater market by mixing polyester resins with glass fibers to improve their durability through corrosion resistance. To increase UV resistance, additives such as fillers and pigments as well as resin curing catalysts are used in the manufacture of these tanks. Wear resistant gel coats can also be added. Installation, maintenance and handling costs for FRP tanks are considerably lower than for steel or concrete; they offer competitive prices in comparison to those of steel or concrete due to reduced installation, maintenance and handling costs. A lightweight design also reduces expenses and logistical challenges. The materials resist corrosion thereby prompting low repair and replacement expenses with passage of time. All this makes FRP tanks an affordable option that offers good value for money when considering whole life cycle economics versus more conventional approaches of water supply and waste water treatment.

-

Lucintel forecasts that residential use will remain the largest end use industry segment and is also expected to witness the highest growth over the forecast period due to growth in water infrastructure activities in the emerging economies such as China and India.

-

Wastewater application will remain the largest application and it is expected to witness highest growth over the forecast period due to increasing government spending on recycling and reuse of wastewater.

-

Europe is expected to remain the largest region and APAC is expected to witness the highest growth over the forecast period due to rapid industrialization, urbanization and high government investment for infrastructure development, and water/waste water management programs

Country wise Outlook for the FRP Tanks in Water and Wastewater Market

The FRP tanks in water and wastewater market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major FRP tank producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends in the FRP Tanks in Water and Wastewater Market

Emerging trends in the FRP tanks in water and wastewater market shaping its future applications and market dynamics:

-

UV Resistance and Weatherability: Development of enhanced FRP tanks that protects against harmful sun effects while being exposed to the environment for a long time.

-

Smart Tanks Technologies: Incorporation of internet of things (IoT), sensors, and automation in FRP tanks for monitoring water levels, pressure, temperature, chemical concentrations etc. This enables predictive maintenance, early fault detection and optimized operational efficiency.

-

Bio-Based Resins and Sustainable Materials: Decrease in use of petroleum based materials by making use of bio-based resins sourced from natural resources in FRP tank fabrication processes. Moreover, recyclable and environmental-friendly materials are introduced to support the concept of circular economy.

-

Advanced Composite Materials: Ongoing research on newer types of composites with improved properties like stronger strength, better fatigue resistance as well as improved chemical stability. These additional features make these composites suitable for harsh wastewater or water environments hence more durable and reliable FRP tanks.

-

Modular and Customizable Designs: A modular system for FRP tank development which can be easily installed scaled up or modified to suit particular applications. Additionally, quick deployment is facilitated as well as flexibility in case storage volumes change or space limitations occur within plants.

-

Enhanced Corrosion Protection: Technological developments that have been made on corrosion resistant coatings & linings for FRP Tanks which have increased their service life under severe water/wastewater treatment conditions. Furthermore these coatings provide extra protection from abrasion and degradation caused by chemicals.

-

Energy Efficiency: Other design innovations to make fiberglass reinforced plastic (FRP) storage tank energy efficient such as optimizing insulation attributes for heat loss prevention during heated water storage applications or incorporating energy recovery systems into waste water treatment operations.

-

Safety Features and Compliance With Standards and Regulations: Integration of safety measures in addition to complying with water and waste water management by laws; which may include design considerations for seismic resistance, leak detection systems, fire protection.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the FRP Tanks in Water and Wastewater Market

Recent developments in FRP tanks in water and wastewater market by various companies highlight ongoing innovations and advancements across different sectors:

-

Corrosion Resistance: In water and wastewater applications, FRP tanks have increasingly become the favorite due to their better corrosion resistance compared to conventional materials such as steel. Presently, it is paramount for further improvement of this characteristic to be able to handle hard chemicals and different degrees of acidity in waste water treatment.

-

Lightweight and Durability: Manufacturers are making strides in designing FRP tanks that attain a delicate balance between lightweight construction and durability. This makes transportation, installation and maintenance across the life of the tank much simpler.

-

Modular and Scalable Designs: Currently there is a growing shift towards modular FRP tank designs which accommodate changes in scale depending on water treatment plants requirements. This implies that an extension or change in capacity can be easily done without any significant disruption to ongoing operations.

-

Integration of Filtration and Purification Technologies: Advanced filtration and purification technologies are being incorporated into FRP tanks so as to improve water quality standards. These include membranes, UV disinfection systems among other treatment measures being built within the tank structure itself.

-

Environmental Sustainability: Innovations in FRP tank manufacturing focused on sustainability include using ecofriendly resins and materials that minimize environmental impacts during production as well as during use. It is also consistent with global trends toward green infrastructure which encourages sustainable water management practices.

-

Smart Monitoring and IoT Integration: Some solutions for FRP tanks have taken up IoT technology for real-time monitoring of water quality aspects, tank conditions, as well as operational efficiency. As such predictive maintenance becomes possible while improving process control in order to ensure compliance with regulations.

-

Compliance with Regulatory Standards: On-going research activities aim at meeting strict regulatory requirements on drinking water safety. Such testing should include chemical resistivity, structural integrity test as well as compatibility of disinfectant processes.

-

Cost-Effectiveness and Longevity: Advances in manufacturing processes and material science aim at enhancing cost-effectiveness and lifetime of FRP tanks for water and wastewater applications. These include improving production efficiencies and extending the service life by design changes as well as maintenance strategies.

Strategic Growth Opportunities for FRP Tanks in Water and Wastewater Market

The FRP tanks in water and wastewater market is very dynamic due to its unique properties of being lightweight, strong and thermally stable. Some key strategic growth opportunities for this market include:

Durability and Corrosion Resistance.

-

Benefit: FRP tanks are naturally resistant to chemical corrosion encountered in water and wastewater treatment processes.

-

Opportunity: The growing investment into infrastructure across the world necessitates durable storage solutions that lower maintenance costs and downtime.

Flexibility in Designing and Customization

-

Benefit: FRP containers can be customized to meet specific project requirements such as scale, design, and internal configurations

-

Opportunity: The push for personal solutions in water treatment plants and industrial establishments enhances market penetration.

Environmental Compliance and Regulatory

-

Benefit: FRP tanks are designed to meet the strict environmental standards for hazardous chemicals storage as well as wastewater.

-

Opportunity: Safety-based markets rooted in compliance expansion with environment protection as a priority will enhance market growth.

The Efficiency of Lifecycle Costs

-

Benefit: Reduced corrosion leads to low costs of maintenance when compared to traditional materials; concrete or steel being examples with longer lifespans they have.

-

Opportunity: Municipal water treatment systems and industrial wastewater management being cost sensitive industries demand affordable storage options.

Advancement in Technology

-

Benefit: Innovations in resin formulations improve the durability, strength, and ease of installation of FRP tanks increasing their efficiency of use.

-

Opportunity: Advancements in composite based materials coupled with automated manufacturing increase product performance while supporting scalability

Desalination Projects on the Rise

-

Benefit: They can withstand saline environments making them suitable for desalination plants hence their ease of maintenance.

-

Opportunity: Increasing need for freshwater resources within semi-arid regions has led to rapid deployment of desalination schemes that require abundant supply capacity.

Sustainability Focus

-

Benefits: Recyclability is possible with FRP tanks reducing its carbon footprint besides other environmental effects associated with concrete or metal constituents.

-

Opportunities: Widespread adoption of sustainable practices across water utility sectors is promoting utilization of eco-friendly storage alternatives.

Expansion into New Economies

-

Advantageous: FRP tanks are a new market that can be exploited through infrastructure developments and industrialization in Asia-Pacific and Latin America.

-

Opportunity: strategic alliances, local manufacturing set-ups – which enable the companies to exploit the growing, demand for modern water and wastewater infrastructure.

FRP Tanks in Water and Wastewater Market Drivers and Challenges

The FRP tanks market for water and wastewater applications is driven by its inherent advantages such as corrosion resistance, durability and customization capabilities, thereby meeting critical storage needs in harsh industrial environments. Nevertheless, it faces challenges that include; high initial costs, strict regulatory requirements as well as competition from conventional materials like concrete and steel. How to navigate these factors will be crucial in leveraging the strengths of FRP tanks to improve operational efficiency, minimize maintenance expenses and guarantee compliance with environmental norms. Overcoming these hurdles will be very critical in sustaining growth rates and meeting the changing needs of the world’s water and wastewater treatment sector.

The factors responsible for driving the FRP tank in water and wastewater market include:

-

Corrosion Resistance: FRP tanks are impervious to chemical corrosion and wastewater, guaranteeing a long life with less maintenance.

-

Durability and Longevity: As compared to traditional materials such as steel or concrete, they have an extended lifespan that diminishes the lifecycle costs.

-

Customization: FRP tanks can be adjusted so as to suit specific project requirements which include sizes, shapes and internal configurations hence becoming design flexible.

-

Regulatory Compliance: Enhancing market acceptance by meeting stringent environmental regulations for storing hazardous chemicals and wastewater.

-

Technological Advancements: Resin formulations and manufacturing techniques are characterized by improvements in performance as well as installation efficiency.

Challenges in the FRP tank in water and wastewater market:

-

High Initial Costs: Instead of conventional materials, FRP tanks may cost more initially. Therefore, cost-benefit analysis may be necessary here.

-

Perception and Education: There is need for getting rid of doubts concerning the reliability together with performance vis-à-vis the conventional materials that are used mainly such as concrete or steel.

-

Competitive Landscape: This arises from competition posed by alternative materials besides existing infrastructure made up of traditional tank materials.

-

Complex Installation & Maintenance: Specialized installation skills are required for complex installations while regular inspections should be carried out to ensure its optimal operation

-

Material Selection & Design Complexity: It is difficult to select appropriate resin systems plus reinforcements for specific applications hence it affects its performance and longevity.

Improvements in FRP tank technology for water and sewage treatment are being driven by innovation, thus increasing efficiency and sustainability. Nonetheless, high initial expenses and choice of material challenges show the importance of continuous improvement and industry partnership. The effective handling of these complexities compliments the role of FRP tanks in meeting stringent regulatory requirements as well as adaptive market calls for strong, eco-friendly storage solutions in industrial applications.

FRP Tanks in Water and Wastewater Suppliers and Their Market Shares

In this globally competitive market, several key players such as XERXES, NOV, Hengrun Group, and Orenco Systems dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at

helpdesk@lucintel.com.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies FRP Tanks in water and wastewater cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the FRP Tanks in water and wastewater companies profiled in this report include.

These companies have established themselves as leaders in the global FRP tanks in water and wastewater market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations. The market share dynamics within the FRP Tanks in the water and wastewater market are evolving, with the entry of new players and the emergence of innovative FRP Tanks in water and wastewater market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

FRP Tanks in Water and Wastewater Market by Segment

There are several segments of FRP tanks experiencing growth in the water and wastewater market. Firstly, municipal water treatment facilities are increasingly taking up FRP tanks due to their resistance to corrosion and chemicals. Secondly, industrial applications such as chemical processing and oil refineries have increased the use of FRP tanks for storage and processing needs. Thirdly, agricultural sectors have resorted to using FRP tanks for safe storing fertilizers and chemicals. Also, there is an increase in the wastewater treatment sector because FRP tanks offer long lasting solutions for sewage treatment and effluent storage. Finally, the expansion of desalination plants has necessitated need for efficient handling of brine as well as seawater storage requiring much demand for FRP tanks. The study includes trends and forecast for the global FRP tanks in water and wastewater by end use industry, installation, application, capacity, and region as follows:

By End Use Industry [Value ($M) Analysis for 2018 – 2030]:

-

Municipal

-

Industrial

-

Residential

-

Commercial

By Application [Value ($M) Analysis for 2018 – 2030]:

-

Wastewater

-

Industrial Wastewater

-

Plumbing Engineered Solutions

-

Water Conservation

-

Potable Water

-

Fire Protection

By Installation [Value ($M) Analysis for 2018 – 2030]:

By Capacity [Value ($M) Analysis for 2018 – 2030]:

-

Less Than 5k Liters

-

5k-50k Liters

-

50k-25k Liters

By Region [Value ($M) Analysis for 2018 – 2030]:

Features of FRP Tanks in Water and Wastewater Market

-

Market Size Estimates:FRP tank in the global water and wastewater market size estimation in terms of value ($M)

-

Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

-

Segmentation Analysis: Market size by end use industry, application, installation, capacity, and region

-

Regional Analysis: FRP tank in the global water and wastewater market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

-

Growth Opportunities: Analysis of growth opportunities in different end use industry, application, installation, capacity, and regions for the FRP tank in the global water and wastewater market.

-

Strategic Analysis: This includes M&A, new product development, and competitive landscape for the recycled carbon fiber market.

-

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in FRP Tanks in water and wastewater or adjacent markets, then contact us. We have done hundreds of

strategic consulting projects in

market entry,

opportunity screening,

due diligence, supply chain analysis,

M & A, and more.

FAQ

Q1. What is the growth forecast for FRP tank in the global water and wastewater market?

Answer: The FRP tank in the global water and wastewater market is expected to grow at a CAGR of 4% from 2024 to 2030.

Q2. What are the major drivers influencing the growth of the FRP tank in the global water and wastewater market?

Answer: The major drivers for this market are growing construction activities, increasing concerns towards water conservation and fire protection, and aging water infrastructure.

Q3. What are the major applications or end use industry industries for FRP tank in the global water and wastewater?

Answer: Municipal and industrial, use are the major end use industry industries for FRP tank in the global water and wastewater.

Q4. What are the emerging trends in FRP tank in the global water and wastewater market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include UV resistance and weatherability, smart tank technologies, bio-based resins and sustainable materials, advance composite materials, and modular and customizable design.

Q5. Who are the key FRP tank in the global water and wastewater companies?

Answer: Some of the key FRP tank in the global water and wastewater companies are NOV, ZCL Composites Inc., Orenco Systems Inc., Hengrun Group Co. Ltd, L.F. Manufacturing, Inc., and Zurn Green Turtle

Q6. Which FRP tank in the global water and wastewater application segment will be the largest in future?

Answer: Lucintel forecasts that wastewater application will remain the largest application and it is expected to witness highest growth over the forecast period due to increasing government spending on recycling and reuse of wastewater.

Q7. In FRP tank in the global water and wastewater market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region over next 7 years.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global FRP tank in the global water and wastewater market by application (wastewater, industrial wastewater, plumbing engineered solutions, water conservation, potable water, fire protection), installation (underground and aboveground), capacity (less than 5k, 5k-50k, and 50k-250k), end use industry (municipal, industrial, residential and commercial), and region (North America, Europe APAC, and the Rest of the World?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 6 years in this market?