FRP Panel Market Trends and Forecast

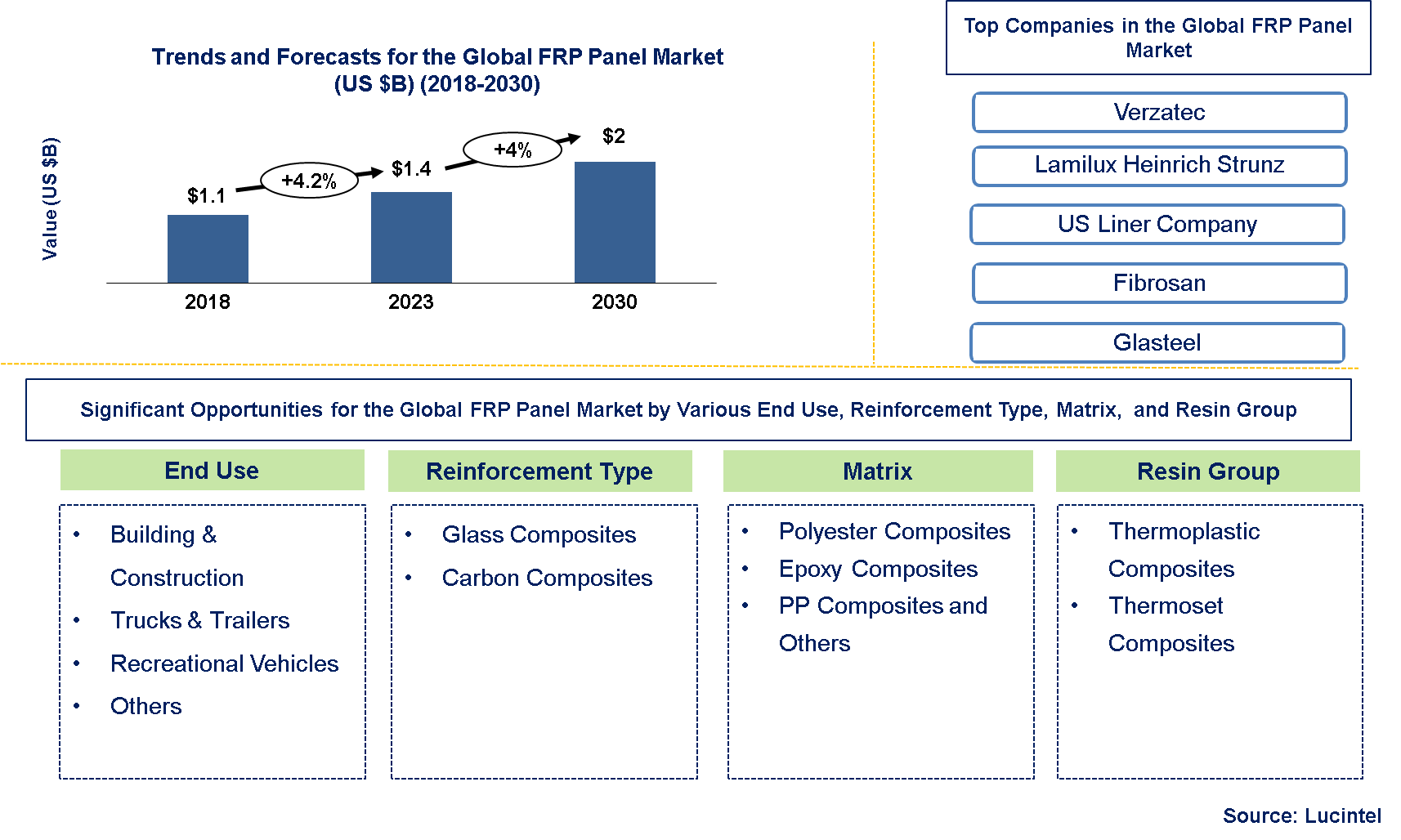

Lucintel finds that the future of the composite product of the global FRP panel market looks promising with opportunities in building and construction, trucks and trailers, recreational vehicles, and others. The global FRP panel market is expected to reach an estimated $1.8 billion by 2030 with a CAGR of 4% 2023 to 2030. The major drivers for this market are the increasing residential and commercial construction activities and rising demand for durable, corrosion resistant, lightweight products in the construction and truck and trailer industries.

The global FRP panel market relies on resins such as polyester, vinyl ester, and epoxy to bind fibers for structural strength, with E-glass and S-glass fibers providing high strength and corrosion resistance. Fillers like calcium carbonate and talc enhance mechanical properties and fire resistance, while gel coat layers protect against UV damage and enhance aesthetics. Catalysts and accelerators control resin curing. FRP panels vary in price based on dimensions, thickness, materials, and manufacturing processes, yet generally offer competitive pricing compared to steel, aluminum, and wood. They provide long-term savings through durability, low maintenance needs, and resistance to corrosion and weathering, enhancing market competitiveness globally.

• Lucintel forecasts that building and construction will remain the largest end use segment and trucks and trailers segment is expected to witness highest growth over the forecast period.

• Polyester composites will remain the largest segment over the forecast period due to its low cost and mostly used in applications, such as side wall panels, roof, and floors. Epoxy composites is expected to witness highest growth over the forecast period.

• North America is expected to remain the largest market and due to the growing residential and commercial construction industry and increasing production of recreational vehicles and trucks & trailers. APAC is also expected to witness the highest growth over the forecast period.

Country wise Outlook for the FRP Panel Market

The FRP Panel market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major FRP Panel producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends in the FRP Panel Market

Emerging trends in the FRP Panel Market shaping its future applications and market dynamics:

1. Nanostructured FRP Panels: This is the development of nano-enhanced FRP panels with better mechanical properties like strength, stiffness and impact resistance which are suitable for high-performing applications.

2. Smart FRP Panels: These are sensors integrated into and smart technologies employed on FRP panels to monitor structural health condition in real-time temperature and environmental conditions in buildings, infrastructure.

3. Biodegradable Resins: This involves studying biodegradable and bio-based resins for FRP panels so as to increase sustainability throughout the product’s lifecycle by reducing its environmental impact.

4. Advanced Surface Treatments: This implies that advanced surface coatings and treatments are put into practice on FRP panels to improve their weather resistance, UV stability, and aesthetic appeal.

5. Prefabricated Solutions: In order to facilitate rapid construction timeframes and modular building systems’ development, there has been a need for prefabricated systems made of FRP panels which offer flexibility, cost-effectiveness, reduced on-site labor requirements.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the FRP Panel Market

Recent developments in FRP Panel Market by various companies highlight ongoing innovations and advancements across different sectors:

1. Construction: Advancement in FRP lightness and durability panels for building facades, roofing, and modular construction, which are cost effective and pliable in design.

2. Transportation: Integration of FRP panels into transportation vehicles such as buses, trains, and trucks to cut down on weight, improve fuel mileage and prevent corrosion.

3. Infrastructure: Increasing use of FRP panels in infrastructure projects including bridges, tunnels, wastewater treatment plants because of their high strength to weight ratio and resistance to environmental factors.

4. Renewable Energy: The use of FRP panels on wind turbine blades and solar panel structures enhances durability and performance of renewable energy installations.

5. Industrial Applications: Application of FRP Panels for chemical resistant fire protection thermal insulation used for safety support at an industrial facility

Strategic Growth Opportunities for FRP Panel Market

The balsa core material market is very dynamic due to its unique properties of being lightweight, strong and thermally stable. Some key strategic growth opportunities for this market include:

Expansion in the Construction Industry

• Architectural Uses: Growing application of FRP panels in building façade, interior elements and decoration due to their adaptability, beauty, and simplicity of adaptation or design.

• Infrastructure Projects: Demand for FRP panels in infrastructure projects like bridges, walkways, and railway platforms because of their high strength-to-weight ratio, longevity as well as resistance to harsh environments.

Transportation Sector:

• Automotive: Increasing installation of FRP panels in motor vehicle manufacturing for light body parts or panels (weight saving benefit), indoor components (comfortable driving environment) and mainframe sections (CO2 emission reduction).

• Aerospace: They are used on aerospace applications including airplane interiors, cabin componentry as well as outer skin for their performance attributes such as stiffness, strength and resistance to fire.

Energy Sector Applications

• Renewable Energy: The integration of these materials into wind turbine blades and nacelles ensures better productivity levels over time while also ensuring durability within these areas thus reducing maintenance costs.

• Oil and Gas: Used on offshore platforms; tanks; and pipelines due to its corrosion resistance property while remaining structurally sound even under extreme environmental conditions.

Marine and Shipbuilding

• Boat Building: The increasing use of advanced composites in ship hulls, decks and superstructures means that they can be made lighter than ever before withstanding salt water attacks besides allowing for easy design changes even after the boat’s completion stage.

• Offshore Structures: They are employed in offshore platforms; pontoons; marine infrastructures due to their ability resist marine organisms’ impacts or degradation from the environment.

Environmental & Regulatory Trends

• Green Building Initiatives: Compliance with sustainable building standards & certifications drives demand for eco-friendly construction materials such as FRP panels.

• Regulatory Compliance: Strict environmental regulations & safety standards must be met by various industries resulting into more acceptance from market & growth opportunities available through production improvements intended at recycling technologies aimed at eliminating pollutants from waste products.

Technological Advances

• Advanced Manufacturing Techniques: Efficient automated production methods and advanced molding techniques can be implemented in complexly shaped FRP panels produced for large volume.

• Material Innovations: Development and research are actively going on to enhance material properties which include fire resistance, insulation as well as acoustic performance to widen the applications.

FRP Panel Market Drivers and Challenges

The growing demand for this material in various industries is the main driving force behind the FRP panel market. FRP panels are an excellent choice for construction, transportation, and industrial purposes due to their being lightweight, durable and resistant to corrosion. This has also been enhanced by the fact that they have a wide range of design options which enable them to be used even in harsh conditions. The market’s expansion is being driven by innovations in composites technology that offer better strength-to-weight ratios and cost savings. FRP panels will significantly influence the direction modern infrastructure and manufacturing landscape take in terms of sustainability and performance globally as we move forward.

The factors responsible for driving the FRP Panel market include:

1. FRP panels being lightweight make them easier to handle and install.

2. This increases their lifespan and reduces repairs and maintenance costs due to the fact that they are highly durable and resistant to corrosion.

3. Customizations can be made according to specific project needs as they have a wide range of design options.

4. Heedlessly, this is making them find more use in construction, transportation and industrial sectors since it offers better performance than previous materials.

5. The efficiency and performance of these substances have been further enhanced due to improvements in composites which increase the strength-to-weight ratios.

6. Public demand for green materials such as fiberglass reinforced plastics (FRPs) is driven by environmental sustainability concerns.

Challenges in the FRP Panel Market:

1. Variation in inputs costs has significant effects on the prices of goods and services, thus reducing profitability.

2. Regulatory complexities and compliance requirements are diverse across territories thus affecting market entry.

3. Misconceptions concerning durability as opposed to other usual materials.

4. Its installation and maintenance need expert knowledge, which might limit its spread.

5. With other similar or supposedly better properties perhaps alternative materials compete for market share.

6. Economic uncertainties along with market volatility influence investment decisions, project timelines among others

The FRP panel industry is well positioned to benefit from advancements in composite technology and rising demand for lightweight, tough, eco-friendly products. Nevertheless, managing changing prices of raw materials, regulatory environments as well as competition will be a key determinant. Future market orientation will be greatly influenced by innovations that improve the performance of panels, enhance sustainability and guide consumer tastes and preferences by establishing new standards in these areas.

FRP Panel Suppliers and Their Market Shares

In this globally competitive market, several key players such as Verzatec, Lamilux Heinrich Strunz, US Liner Company, Fibrosan, and Glasteel. etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at helpdesk@lucintel.com. ".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies FRP panel cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the FRP Panel companies profiled in this report include.

• Verzatec

• Lamilux Heinrich Strunz

• US Liner Company

• Fibrosan

• Glasteel

These companies have established themselves as leaders in the global FRP Panel Market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the FRP Panel market are evolving, with the entry of new players and the emergence of innovative FRP Panel market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

FRP Panel Market by Segment

FRP (Fiber Reinforced Plastic) panel market is growing globally across diverse segments. The demand for lightweight, corrosion-resistant panels in commercial and residential buildings is increasing in the construction industry. FRP panels are extensively used in vehicle interiors, exteriors, and freight containers due to their high strength and design adaptability, making FRP panels grow within the transport sector. The use of FRP panels as chemical resistance walls, ceilings and structural components continues to raise thus expanding industrial applications. Durability of FRP panels remains a significant advantage in infrastructure projects involving bridges, platforms or utility structures. In addition to that, renewable energy sector further expands the market by employing solar mounting structures and wind turbine blades from FRP panels amongst others.

Global FRP Panel Market By End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Building and Construction

• Trucks and Trailers

• Recreational Vehicles

• Others

Global FRP Panel Market By Reinforcement Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Glass Composites

• Carbon Composites

Global FRP Panel Market By Matrix [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Polyester Composites

• Epoxy Composites

• PP Composites and Others

Global FRP Panel Market By Resin Group [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Thermoset composites

• Thermoplastic Composites

Global FRP Panel Market By Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

o US

o Canada

o Mexico

• Europe

o Germany

o The United Kingdom

o France

o Russia

o Other European Countries

• Asia Pacific

o China

o Japan

o India

o South Korea

o Other APAC Countries

• The Rest of the World

o Brazil

o Argentina

o Other ROW Countries

Features of FRP Panel Market

• Market Size Estimates:FRP panel market size estimation in terms of value ($M) and volume (M. lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis[Market size by end use, reinforcement, matrix type, resin group, and region.

• Regional Analysis:FRP panel market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different end use industry, by reinforcement, by matrix, by resin group and regions for the FRP panel market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the FRP panel market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in FRP panel or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the FRP panel market size?

Answer: The global FRP panel market is expected to reach an estimated $1.8 billion by 2030.

Q2. What is the growth forecast for FRP panel market?

Answer: The FRP panel market is expected to grow at a CAGR of 4.0% from 2022 to 2028.

Q3. What are the major drivers influencing the growth of the FRP panel market?

Answer: The major drivers for this market are the increasing residential and commercial construction activities and rising demand for durable, corrosion resistant, lightweight products in the construction and truck and trailer industries.

Q4. What are the major applications or end use industries for FRP panel?

Answer: Building and construction, truck and trailer, and recreational vehicles are the major end use industries for FRP panel.

Q5. What are the emerging trends in FRP panel market?

Answer: Emerging trends, which have a direct impact on the dynamics of the FRP panel industry includes, nanostructured FRP panels, smart FRP panels, biodegradable resins, advanced surface treatments, and prefabricated solutions.

Q6. Who are the key FRP panel companies?

Answer: Some of the key FRP panel companies are as follows:

• Verzatec S.A de C.V (Crane Composites Inc.)

• Lamilux Heinrich Strunz Holding GmbH & Co. KG

• US Liner Company, Glasteel Inc.

• Fibrosan, Wabash National

• Kalwall Corporation

• Panolam Industries International INC.

• Fiber-Tech Indsutries Enaris S.A.

• Dongguan MIYABI- FRP Ltd.

Q7. Which FRP panel reinforcement segment will be the largest in future?

Answer: Lucintel forecasts that polyester based composites will remain the largest segment, and it is also expected to witness the highest growth over the forecast period due to its low cost and mostly used in applications, such as side wall panels, roof, and floors.

Q8. In FRP panel market, which region is expected to be the largest in next 7 years?

Answer: North America is expected to remain the largest region over next 7 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global FRP panel market by end use (building and construction, truck and trailer, recreational vehicles and others), reinforcement (glass composites and carbon composites), matrix type (polyester composites, epoxy composites and PP composites and others), resin group (thermoset composites and thermoplastic composites), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 6 years in this market?