Global Foam Core Material Market Trends and Forecast

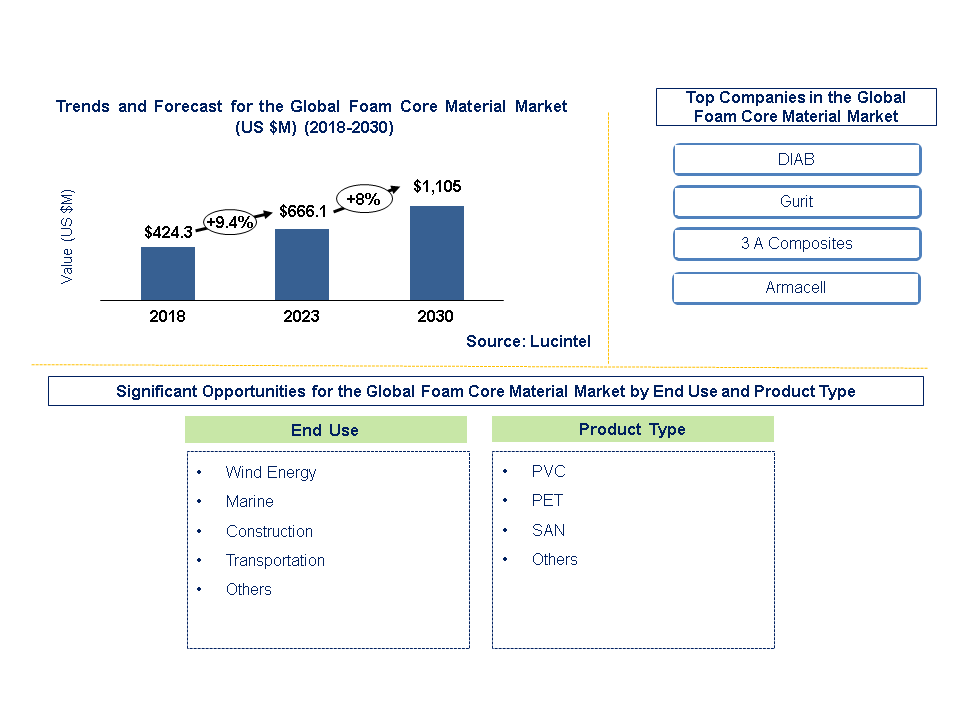

Lucintel finds that the future of the global foam core intermediate material market looks promising with opportunities in wind energy, marine, construction, and transportation end uses. The global foam core material market is expected to reach an estimated $1,105 million by 2030 with a CAGR of 8% from 2023 to 2030. The major driver for foam core material performance benefit and growing demand of foam core material in end uses.

Foam core materials in the market utilize polymers such as polyurethane (PU), polystyrene (PS), or polyvinyl chloride (PVC) that have been foamed to form lightweight cores. These are preferable for their high compressive strength, low density and thermal insulation properties because of the additives they usually contain like blowing agents and stabilizers which improve its mechanical characteristics so that it can be put into use in different sectors of the economy including but not limited to marine applications, aerospace industry, construction as well as motor vehicles. The cost of foam core materials is relatively cheaper compared to alternatives like balsa wood and honeycomb cores. PVC and PET foams among others make foam cores such as these offering a balance of cheapness, production simplicity, and lightweight nature. Despite its higher price and erratic supply, balsa wood has better strength-to-weight ratios than foam cores, making the latter more attractive for low budget projects. Honeycomb cores can however be expensive and difficult to manufacture despite their good strength and stiffness making foam cores in most cases a cheaper alternative. In fact, this kind of pricing makes it the best selection for marine industry, automotive industries as well as wind energy applications amongst other sectors.

• Lucintel forecasts that wind energy will remain the largest end use segment and also expected to witness the highest growth over the forecast period.

• Lucintel forecasts that PET type foam core material will remain the largest product type segment and also expected to witness the highest growth over the forecast period.

• Asia Pacific is expected to remain the largest region and Europe is anticipated to witness the highest growth over the forecast period due to wide acceptance in various end uses owing to their high strength and low weight, which is driving the demand for core materials in various end use

Country wise Outlook for the Foam Core Material Market

Emerging Trends in the Foam Core Material Market

Emerging trends in the foam core material market shaping its future applications and market dynamics:

1. Introduction of Advanced Composites Integration: The aerospace and automotive sectors have seen rising foam core materials integration with advanced composite materials to help in improving structural integrity as well as weight reduction.

2. Adoption of Digital Manufacturing Technologies: To boost precision, customization and production efficiency, adoption of digital design/manufacturing techniques (additive manufacturing, automated foam core production) has been done.

3. Rising Demand in High-Performance Applications: An example of such applications includes the renewable energy infrastructure and electric vehicle battery housings that necessitate high strength-to-weight ratios as well as thermal insulation properties.

4. Innovative Additives and Composites: Keeping up with changing industrial standards and demands for greater product performance, new additives along with composite formulations are being developed to upgrade the properties of foam cores such as resistance against fire, moisture or impacting ability.

These trends indicate a shift towards more sustainable, innovative, and technologically advanced solutions in the foam core material industry to meet evolving consumer and regulatory demands globally.

A total of 82 figures / charts and 25 tables are provided in this 118-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments in the Foam Core Material Market

Recent developments in global foam core material market which highlight ongoing innovations and advancements across different sectors

• Bio-based and Recyclable Foams: Introduction of foam cores that are eco-friendly, made from renewable sources, as well as recyclable materials to address sustainability challenges and minimize environmental damages.

• High-Performance Foams: Development of advanced foam cores with improved mechanical properties, such as high compressive strength, good thermal insulation and resistance to fire for use in difficult conditions in aviation industry, automobile sector and building construction.

• Nanotechnology Integration: The inclusion of nanomaterial into foam cores can reinforce their stiffness, strength and thermal stability thus making it possible to produce lightweight composite structures with enhanced performance.

• 3D Printing and Customization: Recent developments in the field of three dimensional printing have allowed for the manufacture of complex shapes for the core from foam at a design stage hence improving its flexibility while reducing waste during production process.

• Hybrid Core Materials: Development of hybrid foam core materials combining different types of foams or integrating foam with other core materials to optimize performance characteristics for specific applications, such as improved impact resistance and reduced weight.

Strategic Growth Opportunities for Foam Core Material Market

The foam core material market is very dynamic due to its unique properties of being lightweight, strong and thermally stable. Some key strategic growth opportunities for this market include:

Expansion in Renewable Energy Sector:

• Wind Energy Applications: Foam core materials are increasingly used in wind turbine blades due to their lightweight and high-strength properties. As global investment in renewable energy grows, there is significant potential for foam core materials in enhancing the efficiency and durability of wind turbines.

• Solar Panel Structures: Lightweight foam cores can be used in the construction of solar panel supports and frames, reducing overall weight and installation costs while improving structural integrity.

Aerospace and Defense Industry:

• Aircraft Weight Reduction: The aerospace industry continually seeks materials that can reduce aircraft weight to improve fuel efficiency and performance. Foam core materials are ideal for interior panels, floorboards, and other structural components, offering significant growth opportunities.

• Unmanned Aerial Vehicles (UAVs): The increasing use of UAVs in defense and commercial applications drives the demand for lightweight, durable materials like foam cores, which enhance flight performance and battery life.

Automotive Sector Innovations:

• Electric Vehicles (EVs): Foam core materials contribute to weight reduction in electric vehicles, improving battery efficiency and range. The growing EV market presents substantial growth potential for foam core applications in battery enclosures, interior components, and structural elements.

• Noise and Vibration Reduction: Foam cores are used in automotive panels and components to reduce noise and vibration, enhancing passenger comfort and vehicle performance.

Marine Industry Applications:

• Lightweight Boat Construction: Foam core materials are used in the construction of boat hulls, decks, and interiors, providing high strength-to-weight ratios and resistance to water damage. The expanding recreational boating market offers growth opportunities for foam core materials.

• Commercial Shipping: Foam cores are utilized in commercial vessels to improve fuel efficiency and reduce maintenance costs by providing durable, lightweight solutions for structural components.

Building and Construction:

• Energy-Efficient Buildings: Foam core materials are used in the construction of insulated panels and energy-efficient building envelopes, contributing to reduced energy consumption and enhanced thermal performance. The trend towards sustainable construction drives demand for foam cores.

• Prefabricated Construction: Foam cores are increasingly used in prefabricated building components, offering lightweight, strong, and easy-to-install solutions that speed up construction processes and reduce labor costs.

Foam Core Material Market Drivers and Challenges

The foam core material market is propelled by increasing demand in industries seeking lightweight, durable solutions like aerospace and automotive. Key drivers include advancements in manufacturing technologies and the push towards energy efficiency. Challenges such as supply chain complexities, fluctuating raw material costs, and competition from alternative materials require strategic adaptation. Balancing innovation with cost-effectiveness and sustainability will be essential for navigating these dynamics and sustaining market growth.

The factors responsible for driving the foam core material market include:

1. Weight Reduction Requirements: Industries such as aerospace, automotive, and renewable energy demand lightweight materials to enhance fuel efficiency, reduce emissions, and improve overall performance. Foam core materials, known for their high strength-to-weight ratio, are crucial in meeting these requirements.

2. Advancements in Manufacturing Technology: Adoption of advanced manufacturing techniques, including 3D printing and automated layup processes, enhances the efficiency and precision of foam core production. These technologies enable complex geometries and customization, catering to diverse industry needs.

3. Sustainability Focus: There is a growing emphasis on sustainable materials in response to environmental concerns and regulatory pressures. Foam cores made from recycled content or bio-based sources are gaining traction, offering eco-friendly alternatives without compromising performance.

Challenges in the Foam Core Material Market:

1. Supply Chain Complexity: The foam core market relies on a stable supply of raw materials, including petroleum-based chemicals for foam production. Disruptions in supply chains, whether due to geopolitical factors or natural disasters, can impact production and lead to increased costs.

2. Price Volatility: Fluctuations in raw material costs, particularly petroleum-based chemicals, pose challenges for manufacturers in managing operational expenses and pricing strategies. Volatile prices can affect profit margins and competitiveness in the market.

The foam core material market must navigate the dual imperatives of innovation and compliance. Innovations in manufacturing technologies and sustainable materials drive growth, meeting demands for lightweight solutions across industries. However, challenges such as supply chain disruptions and regulatory complexities require continual adaptation. Balancing innovation with operational resilience and regulatory compliance will be key to sustaining competitiveness in this dynamic market.

Foam Core Material Suppliers and Their Market Shares

In this globally competitive market, several key players such as, DIAB, Gurit, 3 A Composites, Armacell, and etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies foam core material companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the foam core material companies profiled in this report include:

• DIAB

• Gurit

• 3A Composites

• Armacell

These companies have established themselves as leaders in the global foam core material industry with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the global foam core material market are evolving, with the entry of new players and the emergence of innovative technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Foam Core Material Market by Segment

Major segments of the foam core material industry experiencing growth include aerospace industry, foam cores have increasingly been utilized in aircraft interiors and structural elements to minimize weight and enhance fuel efficiency. This is also the case with the automotive industry that has adopted foam cores for light weighting purposes pertaining to vehicle interiors and structural panels to improve performance as well as conform to strict emission regulations. Renewable energy applications such as wind turbine blades and solar panel supports are experiencing growth due to their durability, high strength-to-weight ratio and other advantages of foam core materials. Additionally, the construction sector is making use of foam cores in insulated panels and modular building components as a result of growing demand for environmentally friendly construction solutions.

This foam core material market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including end use and product type. The report offers insights into regional dynamics, highlighting the major markets for global foam core material market and their growth potentials. The study includes trends and forecast for the composites in global foam core material market by end use, product type and region as follows:

Foam Core Material Market by End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Wind Energy

• Marine

• Construction

• Transportation

• Others

Foam Core Material Market by Product Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• PVC

• PET

• SAN

• Others

Foam Core Material Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Foam Core Material Market

• Market Size Estimates: Foam core material market size estimation in terms of value ($M) and Volume (M lbs).

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by end use, product type, and region.

• Regional Analysis: Foam core material market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different end use, product type, and regions for the foam core material market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the foam core material market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in composites in the global foam core material market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the foam core material market size?

Answer:The global foam core material market is expected to reach an estimated $1,105 million by 2030.

Q2. What is the growth forecast for foam core material market?

Answer:The foam core material market is expected to grow at a CAGR of 8% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the foam core material market?

Answer: The major driver for foam core material performance benefit and growing demand of foam core material in end uses.

Q4. What are the major end uses for foam core material?

Answer:Wind Energy and marine are the major end uses for foam core material.

Q5. What are the emerging trends in foam core material market?

Answer:Emerging trends, which have a direct impact on the dynamics of the industry, includes introduction of advanced composite integration, adoption of digital manufacturing technologies, rising demand in high-performance applications, and innovative additives and composites.

Q6. Who are the key foam core material companies?

Answer:Some of the key foam core material companies are as follows:

• DIAB

• Gurit

• 3A Composites

• Armacell

Q7.Which foam core material product type segment will be the largest in future?

Answer: Lucintel forecasts that PVC type foam core material will remain the largest product type segment and SAN is expected to witness the highest growth over the forecast period due to majorly used in end use.

Q8: In foam core material market, which region is expected to be the largest in next 7 years?

Answer:Asia Pacific is expected to remain the largest region and Europe will witness the highest growth over next 7 years

Q9. Do we receive customization in this report?

Answer:Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1. What are some of the most promising potential, high growth opportunities for the global foam core material market by end use (wind energy, marine, construction, transportation and others), product type (PVC, PET, SAN and Others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2. Which segments will grow at a faster pace and why?

Q.3. Which regions will grow at a faster pace and why?

Q.4. What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5. What are the business risks and threats to the market?

Q.6. What are the emerging trends in this market and the reasons behind them?

Q.7. What are the changing demands of customers in the market?

Q.8. What are the new developments in the market? Which companies are leading these developments?

Q.9. Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10. What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11. What M & A activities have taken place in the last 5 years in this market?