European PVC Compound Market Trends and Forecast

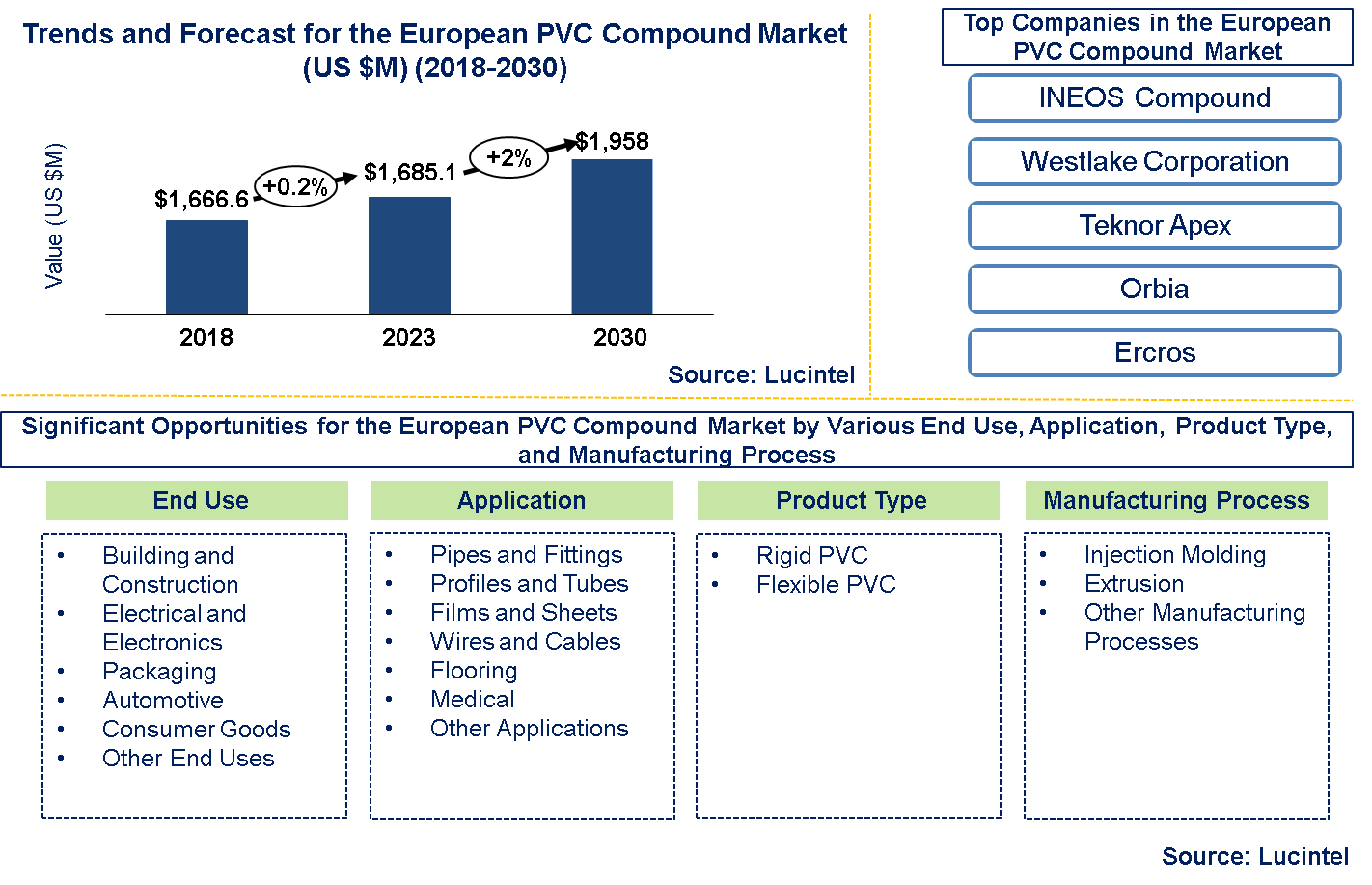

The future of the European PVC compound market looks promising with opportunities in the building & construction, electrical & electronics, packaging, automotive, consumer goods, and other applications. The European PVC compound market is expected to reach an estimated $2 billion by 2030 with a CAGR of 2% 2023 to 2030. The major drivers for this market are increasing construction activities, increased demand for lightweight and corrosion-resistant materials, growing demand for pipe and fitting products, and recyclability.

Mainly, what is used to make PVC compounds are PVC resin that are gotten from VCM (Vinyl chloride monomer). Stabilizers to increase strength and ability to withstand high temperatures, plasticizers for increased flexibility and fillers for added strength and reduced cost form some of the significant raw materials. Besides, pigments as well as impact modifiers are also utilized so as to attain preferred color and performance attributes. The price of PVC compounds is generally competitive vis-à-vis other materials such as polyethylene and polypropylene due to lower cost of production. Though, they might be more pricy when compared to a few low quality polymers since then they include additives and stabilizers which make them perform better and durable. Prices fluctuate along with the costs of inputs as well as by the market forces at play.

• Lucintel forecasts that film and sheets will remain the largest segment over the forecast period due to increasing demand of food packaging in the emerging nations and pipes and fittings is expected to witness the highest growth over the forecast period.

• Building and construction will remain the largest end use and consumer goods segment is expected to witness the highest growth during the forecast period.

Country wise Outlook for the European PVC Compound Market

The European PVC compound market is witnessing substantial growth. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major European PVC Compound producers in key regions: the UK, Germany, and France

Emerging Trends in the European PVC Compound Market

Emerging trends in the European PVC Compound Market shaping its future applications and market dynamics:

• Advanced Formulations: Innovations in PVC compounds for improved mechanical properties, better resistance to UV and weathering, and increased flexibility.

• Green Building Initiatives: Increased need of PVC compounds on green building projects because they are long-lasting, require little attention to remain in shape and save energy.

• Technological Advancements: Deployment of advanced manufacturing technologies and automation to enhance production efficiency and product quality.

• Regulatory Compliance: More emphasis on complying with demanding European Union regulations concerning aspects like the safety and environmental impact of PVCs.

• Market Diversification: The versatility of PVC compounds has led to expansion into new application areas such as automotive, healthcare, and electronics.

A total of 113 figures / charts and 78 tables are provided in this 150-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the European PVC Compound Market

Recent developments in European PVC Compound Market by various companies highlight ongoing innovations and advancements across different sectors:

• Innovation within Eco-friendly Additives: Invention of new eco-friendly additives that can reduce the environmental impact of PVC compounds, consistent with EU sustainability objectives.

• Improved Recycling Technologies: Introduction of improved recycling technologies for post-consumer PVC waste, thereby improving the circularity of PVC products and decreasing dependence on virgin materials.

• Increased Application Areas: More use of special-use PVC compounds such as automotive interiors, medical devices and advanced construction materials which are versatile and have good performance features.

• Compliance with New Regulations: Putting in place tougher compliance measures to meet tighter European Union rules relating to chemicals safety and environment like REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulation.

• Development of Low-Emission PVC Compounds: Production of low-emission polyvinyl chloride compounds to address concerns about volatile organic compounds (VOCs) as well as improve indoor air quality in residential and commercial properties.

Strategic Growth Opportunities for Global European PVC Compound Market

Expansion of Green Building Solutions

• Sustainable Construction: Take advantage of the burgeoning trend toward sustainable, energy-efficient construction by providing PVC compounds that meet green building criteria. Produce compounds with enhanced insulation and low environmental impact to achieve EU sustainability targets.

• Certification and Standards: To target eco-conscious builders and developers, gain certifications for environmentally friendly products such as LEED or BREEAM.

Advancement in Recycling Technologies

• Enhanced Recycling Processes: Improve the effectiveness of recovering and reusing post-consumer PVC through investment in advanced recycling technologies. Develop double loop recycling systems to minimize waste and dependency on primary materials.

• Collaboration with Recycling Facilities: Encourage circular economy by partnering with specialized recyclers to enable new product lines using recycled PVC compounds.

Innovation in High-Performance Compounds

• Customized Formulations: Design special purpose PVC compounds that possess properties such as increased UV resistance, fire retardancy as well as greater impact resistance. These attributes are very vital thus targeting emerging market sectors including aerospace, automotive, high-tech industries among others.

• Advanced Manufacturing Techniques: To create 3D printed form parts whose properties are specific to the end-use application or have other complex shapes employ advanced manufacturing techniques for high-performance PVC compounds.

Expansion into Emerging Markets

• Geographic Diversification: Look out for growth opportunities in emerging European markets where infrastructure development as well as building activities are taking place. Customize products to reflect local regulations and market needs.

• Strategic Partnerships: Establish alliances with local distributors and manufacturers to expand market coverage while streamlining supply chain operations.

Development of Low-Emission and Eco-Friendly Products

• Low-VOC Compounds: Make sure there is a compression molding process for producing a co-molded composite which is then over-molded with an injection molded thermoplastic material consisting of reduced levels of volatile organic chemicals (VOCs). Target these products at indoor applications where air quality is critical.

• Bio-Based Additives: Include bio-based additives in PVC compounds to improve sustainability and attract eco-friendly consumers and regulators.

Technological Advancements and Automation

• Smart Manufacturing: Capitalize industry4.0 technologies for better efficiency, lower costs, and consistent quality in production operations. Employ real-time monitoring with the help of IoT and data analytics to optimize various processes.

• R&D Investments: In order to retain its leadership position in the field of PVC compounds production, NeuPak should enhance its R&D investments aiming at driving innovation and developing advanced technologies ahead of the competitors.

Regulatory Compliance and Adaptation

• Proactive Compliance: Keep up-to-date with changes in regulation by making adapted products that meet the new European Union legislations on chemicals as well as environmental impact. Ensure all products adhere to current safety and performance standards.

• Certifications and Documentation: Having some pertinent certifications coupled with maintaining a reliable paper trail can assist in building confidence among customers while ensuring compliance with industry benchmarks.

Market Segmentation and Targeted Marketing

• Sector-Specific Solutions: Produce customized PVC compounds dedicated to applications within sectors such as automotive, healthcare or telecommunication. Focus on those industries that require unique characteristics from these materials giving their specific needs will be loyal clients.

• Customer Education: Mainly focus on customer education concerning sophisticated PVC compounds so as to build partnerships rather than doing business alone.

.European PVC Compound Market Drivers and Challenges

European PVC compound market is pivotal in industries requiring corrosion-resistant storage solutions. Driven by benefits like trends of sustainability, growth in infrastructure development, and technological advancements, it faces challenges such as regulatory compliance & environmental concerns, and volatility in raw material prices. This discussion explores key drivers propelling its growth and significant challenges hindering broader market adoption.

The key drivers for the European PVC compound market include:

1. Trends of Sustainability: The European sustainable construction movement and green building requirements boost the demand for environmentally friendly PVC compounds. EU-friendly innovations, from recycling to low-emission products that can keep up with the customers’ preferences and also abide by EU rules, attract eco-conscious builders who are looking for materials that will lessen their carbon footprint and meet strict environmental standards.

2. Growth in Infrastructure Development: More infrastructure projects in Europe like highways, bridges and residential buildings create a greater need for durable and cost-effective PVC compounds. These are preferred so much because of how versatile they are; weather resistance is not an issue either especially when used for construction purposes thus they lift up the market.

3. Technological Advancements: Performance improvements as well as broader application range have been gained through technological advancements in PVC compound formulations and manufacturing techniques. Innovations such as improved UV resistance, fire retardancy, and integration of smart manufacturing technologies increase market size through providing high performance solutions to different industries including automotive or aerospace sector.

The challenges in the European PVC Compound Market include:

1. Regulatory Compliance & Environmental Concerns: A stricter regulation by EU on chemical safety as well as environmental implications poses challenges to manufacturers of PVC compounds. Complying with VOCs regulations, hazardous substances disposal or retrieval policies could escalate production costs thereby necessitating significant investments in R&D coupled with process adjustments towards meeting new standards.

2. Volatility in Raw Material Prices: Changes in prices of raw materials like additives and PVC resin will affect production costs leading to reduced profits margin wise. The petrochemical price fluctuations alongside supply chain disruptions can make producers bear higher financial burden which means instability at the market level causing variations against rivals according to profitability level.

The growth of the European PVC compound market is propelled by innovative green and high performing materials as well as growing infrastructural projects. However, there are some challenges like strict compliance to regulations and price fluctuations in raw materials that have to be managed well. It will be important to strike a balance between innovation and dealing with regulation and costs if we are going to stay ahead of competition and maintain stability in the market.

European PVC Compound Suppliers and Their Market Shares

In this competitive market, several key players such as Westlake Corporation, INEOS Compound, and Orbia etc, dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report on “European PVC Compound Market Leadership Report".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies European PVC Compound companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the European PVC Compound companies profiled in this report include.

• Westlake Corporation

• INEOS Compound

• Orbia

• Formosa Plastic Corporation

• Ercros

• Teknor Apex

• ICIG (Benvic Group)

These companies have established themselves as leaders in the European PVC compound Market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the European PVC compound market are evolving, with the entry of new players and the emergence of innovative European PVC compound market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

European PVC Compound Market by Segment

Some of the major emerging applications of PVC compound in Europe include construction, which accounts for pipes, fittings and flooring where it is preferred because of its superior durability and cost effectiveness; automotive that has a high demand for lightweight and high-performance interior components; and medical, where it is used in medical tubing and devices because of its sterilization capabilities as well as safety features. Furthermore, the rise in green building solutions is being propelled by increased need for sustainable materials with energy efficiency qualities.

The study includes trends and forecast for the Europe PVC compound market by application, product type, end use, manufacturing process, and region as follows:

European PVC Compound Market by Applications [Value ($M) and Volume (KT) Analysis for 2018 – 2030]:

• Pipes and Fittings

• Profiles and Tubes

• Film and Sheets

• Wires and Cables

• Flooring

• Medical

• Others

European PVC Compound Market by Product Type [Value ($M) and Volume (KT) Analysis for 2018 – 2030]:

• Rigid PVC

• Flexible PVC

European PVC Compound Market by End Use [Value ($M) and Volume (KT) Analysis for 2018 – 2030]:

• Electrical & Electronics

• Building & Construction

• Packaging

• Automotive

• Consumer Goods

• Others

European PVC Compound Market by Manufacturing Process [Value ($M) and Volume (KT) Analysis for 2018 – 2030]:

• Injection Molding

• Extrusion

• Other Manufacturing Processes

Features of European PVC Compound Market

• Market Size Estimates: PVC Compound market size estimation in terms of value ($M) and Volume (KT)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: PVC Compound market size by various segments, such as application, product type, end use, manufacturing process, and region in terms of value and volume.

• Growth Opportunities: Analysis on growth opportunities in different application, product type, end use, manufacturing process, and region for the European PVC compound market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the European PVC Compound market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in European PVC compound or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the European PVC Compound size?

Answer: The European PVC Compound is expected to reach an estimated to $1,958 million by 2030.

Q2. What is the growth forecast for European PVC Compound market?

Answer: The European PVC compound market is expected to grow at a CAGR of 2% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the European PVC Compound market?

Answer: The major drivers for this market are trends of sustainability, growth in infrastructure development, and technological advancements.

Q4. What are the major end uses European PVC Compound?

Answer: Building and Construction, and Electrical and electronics are the major end uses for PVC compound.

Q5. What are the emerging trends of European PVC Compound market?

Answer: Emerging trend, which has a direct impact on the dynamics of the industry; include advanced formulations, green building initiatives, technological advancements, regulatory compliance, and market diversification.

Q6. Who are the European PVC Compound companies?

Answer: Some of the key European PVC Compound companies are as follows:

• Westlake Corporation

• INEOS Compound

• Orbia

• Formosa Plastic Corporation

• Ercros

• Teknor Apex

• ICIG (Benvic Group)

Q7.Which European PVC Compound application segment will be the largest in future?

Answer: Lucintel forecasts that film and sheets will remain the largest segment over the forecast period due to increasing demand of food packaging in the emerging nations and pipes and fittings is expected to witness the highest growth over the forecast period.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 10 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the European PVC compound market by application (pipes and fittings, profiles and tubes, film and sheets, wires and cables, flooring, medical and other applications), product type (rigid PVC and flexible PVC), end use (building & construction, electrical & electronics, packaging, automotive, consumer goods and other end uses), manufacturing process (injection molding, extrusion, and other manufacturing processes).

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What M & A activities have taken place in the last 5 years in this market?