Epoxy Resin in the Global Composites Industry Trends and Forecast

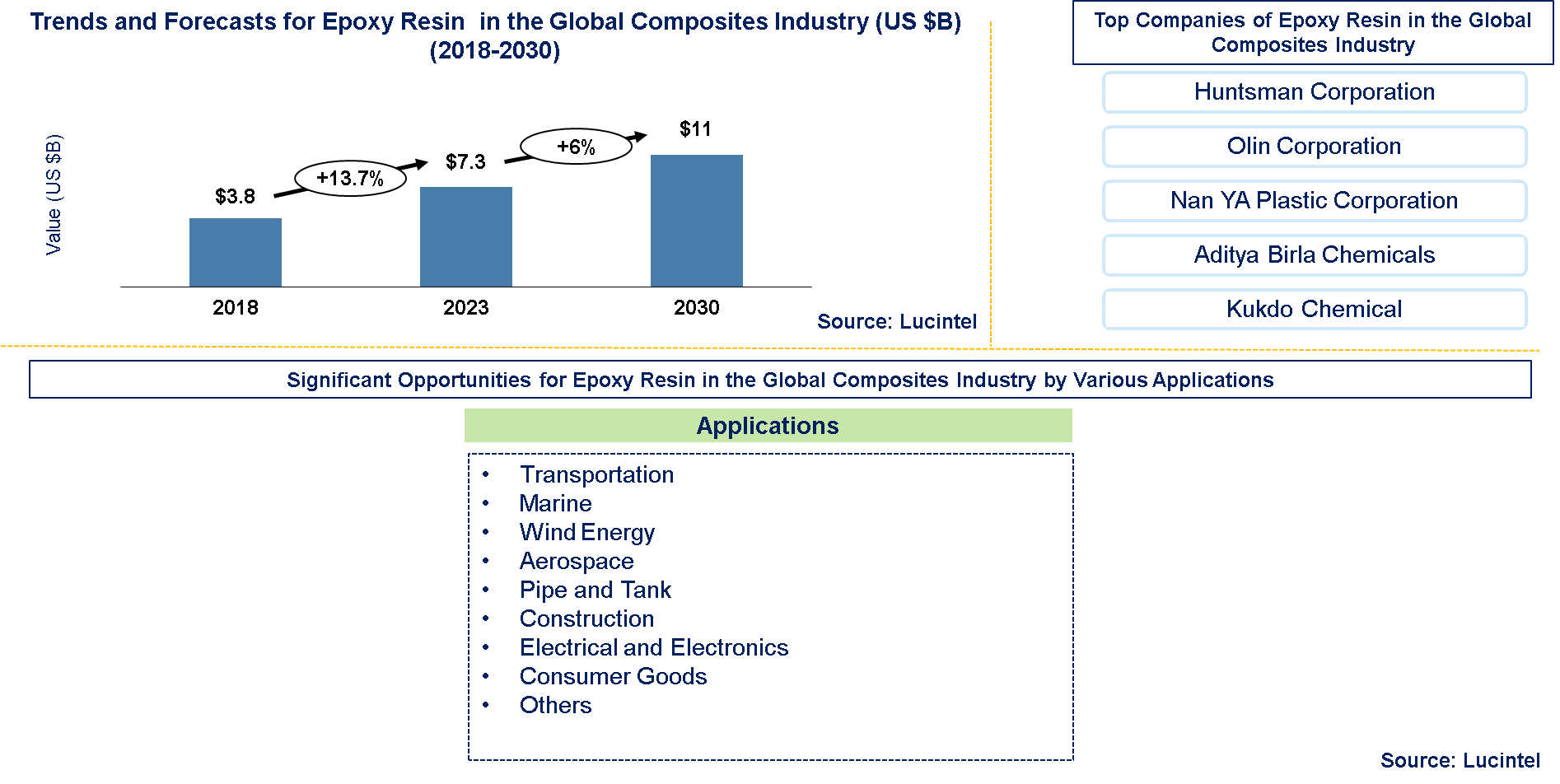

Future of epoxy resin in the global composites industry looks promising with opportunities in transportation, marine, wind energy, aerospace, pipe & tank, construction, electrical and electronics, and consumer goods applications. The epoxy resin in the global composites industry is expected to reach an estimated $11 billion by 2030 with a CAGR of 6% from 2023 to 2030. The major drivers of growth for this industry are increasing use of epoxy resin in the global composites industry in aerospace, electrical and electronic, wind energy, and pipe & tank applications. Epoxy provides superior properties over other thermoset such as polyester, vinyl ester, etc. in the areas of improved adhesion, chemical, and heat resistance along with enhanced mechanical performance.

The main constituents of epoxy resins are epichlorohydrin and bisphenol-A (BPA). Epichlorohydrin is a chlorinated compound of propylene whereas BPA is produced from phenol and acetone. Raw materials such as aliphatic glycols, polyols, carboxylic acids are also used in the production of special epoxy resins. Fillers, hardeners, and additives are added to improve the properties and processability. These materials undergo polymerisation reactions to yield final epoxy resin product. Generally, prices for epoxy resin are higher than any other resins such as polyester and vinyl ester due to their better performance attributes of mechanical strength and chemical resistance. Though polyester resins are cheaper and commonly used, the high costs associated with epoxy resins in terms of applications requiring durability and reliability make it a justifiable expense. However, the price of this product fluctuate based on market demand and cost of ingredients.

• Lucintel forecasts that wind energy will remain the largest application segment over the forecast period due to the increased use of epoxy resin due to its mechanical properties in this segment.

• Asia Pacific is expected to remain the largest region over the forecast period due to due to the increasing demand for tablets, computers, and cell phones in APAC spurred growth for epoxy resin in the global composites industry in the electrical and electronics segment.

Country wise Outlook for the Epoxy Resin in the Global Composites Industry

Epoxy resin in the global composites industry is witnessing substantial growth globally. Major players in the industry are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major epoxy resin in the global composites producers in key regions: the USA, Germany, China, and Japan.

Emerging Trends in the Epoxy Resin in the Global Composites Industry

Emerging trends in epoxy resin in the global composites industry shaping its future applications and market dynamics:

• Increasing Sustainable Epoxy Resin Demand: Development of environmentally friendly, plant-based and up cycled epoxy resins.

• Light weighting: They are being highly used in automotive and aerospace industries, for weight reduction and better fuel efficiency.

• Advanced Manufacturing: It is the adoption of 3D printing and automated fiber placement among other advanced manufacturing techniques.

• Smart Materials: Nano-materials have been integrated to improve properties such as strength, thermal stability and electrical conductivity.

• Increasing Demand in Electronics and Wind Energy: This is due to their superior performance characteristics with regard to turbine blades in electronics for encapsulation, and in wind energy.

A total of 80 figures / charts and 72 tables are provided in this 152-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Epoxy Resin in the Global Composites Industry

Recent developments in epoxy resin in the global composites industry by various companies highlight ongoing innovations and advancements across different sectors:

• Technology Developments: Addition of nanomaterials to epoxy resins for improved mechanical properties, thermal stability and electrical characteristics. This involves the creation of advanced applications through self-healing and shape-memory abilities in smart epoxy resins.

• Applications for Specific Industries: Increased fuel efficiency and performance gains, lightweight epoxy composites are being increasingly used within the automotive sector and aerospace sectors respectively. This enhanced wind turbine blades’ epoxy resins guarantees optimal performance, even under harsh conditions.

• Production Innovations: Development of technologies for 3D printing using epoxy resins for manufacturing composite structures which are difficult to produce by other methods. Automated fiber placement methods enable high-precision and shorter production times in composite manufacturing processes.

• Market Expansion: Construction of additional plants producing epoxy resin is being undertaken by companies that seek to meet increasing demand from emerging markets they operate in today. Strategic partnerships have been formed with other firms or companies so as to increase product offerings through collaboration efforts on ideas or improvements with regard to those products, which would be beneficial for consumers and producers alike.

• Regulatory Compliance: Low-VOC (volatile organic compounds) epoxy resins that comply with stringent environmental regulations. In this aspect, we find a renewed interest in enhancing the adherence to international safety standards required for epoxy resin-based composites that are used in critical applications.

• Customer Focused Solutions: Epoxy resin formulations tailored to specific customer needs are being formulated for different industries including electronics and construction. This involves offering extensive technical support and training towards ensuring maximum productivity of customers through appropriate use of epoxy resin products.

Strategic Growth Opportunities for Global Epoxy Resin in the Global Composites Industry

Expansion into Emerging Markets

• Asia-Pacific Region: This creates significant opportunities for the epoxy resin market in construction, automotive and electronics industries due to the rapid growth of industrialization and urbanization in countries like China and India.

• Latin America and Africa: There is huge potential for market expansion due to increasing demand for high-performance materials and growing infrastructure projects.

Focus on Renewable and Bio-Based Epoxy Resins

• Sustainability Initiatives: Development of bio-based epoxy resins as a greener alternative to conventional petroleum-based resins has been driven by increasing consumer awareness about environmental issues and stricter regulations regarding emerging trends in consumer behavior.

• R&D Investments: Through research and development investments, manufactures are able to develop a number of properties that will attract eco-conscious consumers.

Innovation in High-Performance Applications

• Aerospace and Defense: Advanced epoxy resins with superior mechanical thermal properties can be developed for use in aerospace applications, thus opening up new revenue streams.

• Automotive Lightweighting: Manufacturers can make use of epoxy composites for vehicle light weighting purposes so as to meet strict emission standards while also improving fuel efficiency rates.

Expansion of Product Portfolio

• Specialized Epoxy Resins: Custom-made or tailored-for-industry types of specialized epoxy resins, an example being those used by industries such as electronics, construction or marine would not only promote but also address niche markets.

• Epoxy Resin Blends: Attracting wide range customers can be achieved through making blends such as UV resistance, impact resistance among others hence having enhanced characteristics.

Strategic Partnerships and Collaborations

• Joint Ventures: Joint ventures with companies in the complementary sectors can be beneficial to the aforementioned as it eases technology transfer, market access and innovation.

• Research Collaborations: By partnering with research institutions and universities, manufacturers may develop cutting-edge epoxy resin technologies.

Sustainability and Circular Economy Initiatives

• Recyclable Epoxy Composites: Besides, end-of-life disposal challenges can be overcome while still maintaining the principles of circular economy by encouraging development of recyclable epoxy composites.

• Waste Reduction: Operational costs can be reduced by adopting waste reduction strategies during production process which will enhance environmental sustainability.

Enhancing Customer Support and Services

• Technical Support and Training: Comprehensive technical support services and training programs are often provided for customers so that they can effectively adopt products thereby increasing their satisfaction levels.

• Customized Solutions: To create competitive advantages, epoxy resins can be supplied to customers in various forms such as formulated solutions, blends or even custom-made formulations.

Regulatory Compliance and Standards

• Meeting Global Standards: Market credibility and acceptance is enhanced when companies comply with international safety as well as environmental standards for instance ISO 9001and 14001 respectively.

• Proactive Adaptation: Additionally, proactive adaptation to new regulations minimizes risks involved with changing legal requirements hence helping capitalize on emerging opportunities before competitors strike back.

Marketing and Branding Strategies

• Building Brand Awareness: The campaign should aim at building brand awareness among potential customers who may not have heard about epoxy resins before or those who do but don’t understand much about them yet.

• Digital Marketing: An organization should embrace digital marketing channels in addition to interacting via various online platforms thus reaching a wider audience than ever before.

Epoxy Resin in the Global Composites Industry Drivers and Challenges

Epoxy resin in the global composites industry is pivotal in industries requiring corrosion-resistant storage solutions. Driven by benefits like increasing demand in construction and infrastructure, emerging automotive and aerospace applications, and electronics & electrical developments, it faces challenges such as volatility of raw material prices, and environmental concerns and health concerns. This discussion explores key drivers propelling its growth and significant challenges hindering broader market adoption.

The key drivers for epoxy resin in the global composites industry include:

1. Increasing Demand in Construction and Infrastructure: The escalating construction activities across the globe, especially in emerging markets, boost the demand for epoxy resins which ideally tailor them to coatings, adhesives and composites used in construction such as bridges, buildings, and roads due to their exceptional features like high mechanical strength, chemical resistance and durability.

2. Emerging Automotive and Aerospace Applications: There has been a rise in demand of epoxy resins due to lightweight cars and airplanes that consume less fuel. For aerospace application purposes there has been corrosion resistance as well as increased strength while for vehicles they have reduced weight leading to more efficiency with regards to fuel consumption.

3. Electronics & Electrical Developments: Technological improvements it came along with consumer’s needs are driving electronics growth rapidly hence giving impetus to the epoxy resin market. These resins become indispensable when it comes to encapsulating electronic components and insulating them against moisture, dust or other environmental agents thus ensuring longevity and dependability.

The challenges in epoxy resin in the global composites Industry include:

1. Volatility of Raw Material Prices: Volatility of raw material prices particularly bisphenol-A (BPA) and epichlorohydrin derived from petroleum-based feedstock pose challenges to the epoxy resin market. Fluctuating crude oil costs coupled with chain disruptions can greatly affect production costs as well as company profits.

2. Environmental Concerns and Health Concerns: Increasing environmental scrutiny over use of BPA because of its implications on human health is also a problem for epoxy resins. Regulations aimed at curbing volatile organic compounds (VOCs) and developing greener alternatives require significant R&D expenditure that could increase costs for manufacturers while making compliance complex.

.

The epoxy resin market growth hinges on sustainable innovations and developments in bio-based resins and advanced composites, which are environmentally friendly. The main obstacles include eco-friendly alternatives and environmental regulations that need to be put in place. Balance between innovation and meeting the regulatory compliance will be a key thing for manufacturers to consider when looking to sustain growth while at the same time meeting their market obligations as well as environmental concerns.

Epoxy Resin in the Global Composites Suppliers and Their Market Shares

In this globally competitive market, several key players such as Huntsman Corporation, Olin Corporation, and Nan Ya Plastic etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report on “Epoxy Resin in the Global Composites Industry Leadership Report".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies epoxy resin in the global composites industry companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the epoxy resin in the global composites industry companies profiled in this report includes.

• Huntsman Corporation

• Olin Corporation

• Nan Ya Plastics Corporation

• Aditya Birla Chemicals Limited (Thai Epoxy)

• Kukdo Chemical Co., Ltd.

• Westlake

These companies have established themselves as leaders in epoxy resin in the global composites industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the epoxy resin in the global composites industry are evolving, with the entry of new players and the emergence of innovative epoxy resin in the global composites industry technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Epoxy Resin in the Global Composites Industry by Segment

The demand for lightweight and fuel-efficient automotive composites is one of the major growing segments in the epoxy resin market. Durability of materials with high strength is what aerospace applications require. Epoxy resins are very important for insulation and protection in electronics. Moreover, construction sector is growing due to more use of epoxy based coatings and adhesives on infrastructure projects.

The study includes a forecast for epoxy resin in the global composites industry by application, and region as follows:

By Application [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Transportation

• Marine

• Wind Energy

• Aerospace

• Pipe and Tank

• Construction

• Electrical and Electronics

• Consumer Goods

• Others

By Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Epoxy Resin in the Global Composites Industry

• Market Size Estimates: Epoxy resin industry size estimation in terms of value ($M) and Volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by application and region

• Regional Analysis: Epoxy resin in the global composites industry breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different application and regions for the epoxy resin in the global composites industry.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the epoxy resin in the global composites industry.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model..

If you are looking to expand your business in epoxy resin in the global composites or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the epoxy resin in the global composites industry size?

Answer: The epoxy resin in the global composites industry is expected to reach an estimated $11 billion by 2030.

Q2. What is the growth forecast for epoxy resin in the global composites industry?

Answer: The epoxy resin in the global composites industry is expected to grow at a CAGR of 6% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the epoxy resin in the global composites industry?

Answer: The major drivers of growth for this industry are increasing demand in construction and infrastructure, emerging automotive and aerospace applications, and electronics & electrical developments.

Q4. What are the major applications or end use industries for epoxy resin in the global composites industry?

Answer: Transportation, marine, wind energy, aerospace, pipe & tank, construction, electrical and electronics, and consumer goods use are the major applications for epoxy resin in the global composites industry.

Q5. What are the emerging trends in epoxy resin in the global composites industry?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include increasing sustainable epoxy resin demand, light weighting, advanced manufacturing, smart materials, and increasing demand in electronics and wind energy.

Q6. Who are the key epoxy resin in the global composites industry companies?

Answer: Some of the key epoxy resin in the global composites industry companies are as follows:

• Huntsman Corporation

• Olin Corporation

• Nan Ya Plastics Corporation

• Aditya Birla Chemicals Limited (Thai Epoxy)

• Kukdo Chemical Co., Ltd.

• Westlake

Q7. In epoxy resin in the global composites industry, which region is expected to be the largest in next 7 years?

Answer: APAC is expected to remain the largest region and it is also witness the highest growth over next 7 years.

Q8 . What is the Price of Epoxy Resin?

Answer: Average epoxy resin prices can vary between $ 2.5 to $3.5 per pound. Epoxy resin used for general industrial applications are typically lower in price. High purity grades are used in applications such as electronics or aerospace, come in higher prices.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the epoxy resin in the global composites industry by applications (transportation, marine, wind energy, aerospace, pipe and tank, construction, electrical and electronics, consumer goods, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?