Global Epoxy Curing Agents Market Trends and Forecast

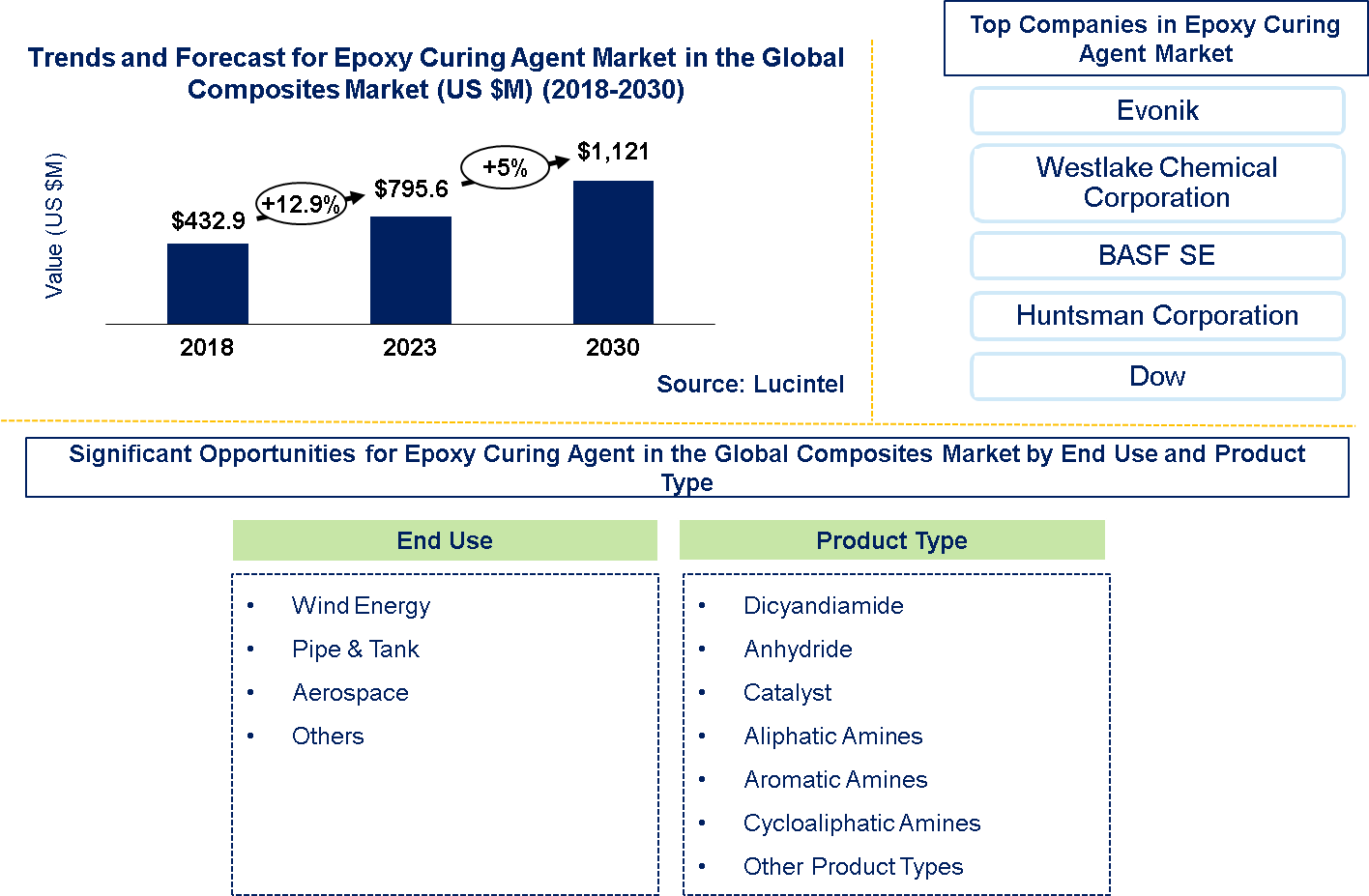

Lucintel finds that the future of the global epoxy curing agent intermediate material market looks promising with opportunities in the wind energy, pipes and tanks, and aerospace end uses. The global epoxy curing agent market is expected to grow with a CAGR of 5% from 2023 to 2030. The major growth drivers for this market are increasing use of high-performance epoxy based composite materials and the growth of end use industries.

Epoxy resin formulations consist mainly of epoxy curing agents composed primarily of aromatic amines, polyamides, cycloaliphatic amines and aliphatic amines. These raw materials play important roles in initiating and speeding up the curing process for epoxy resins thus giving the resulting cured material desired properties such as toughness, chemical resistance and flexibility. Aromatic and aliphatic amines are generally less expensive alternatives than specialty curing agents such as polyamides and cycloaliphatic amines that have specific performance characteristics. Epoxy curing agents’ pricing is sensitive to market competition, availability of raw materials, global economic factors affecting the chemical industry.

-

Aliphatic amines will remain the largest segment and cycloaliphatic amines is expected to witness the highest growth over the forecast period due to its better mechanical properties like; low viscosity, rapid cure at elevated temperature, high thermal resistance, and improved blush resistance.

-

Wind energy will remain the largest segment by value and volume over the forecast period due increasing demand or high performance epoxy based composites materials in wind energy. Aerospace is expected to witness the highest growth over the forecast period.

-

Asia Pacific is expected to remain the largest region due to increasing demand for composites in pipe and tank and wind energy industries. North America is expected to witness the highest growth over the forecast period.

Country wise Outlook for the Global Epoxy Curing Agents Market

The epoxy curing agent market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major epoxy curing agent producers in key regions: the USA, Germany, China, India, and Japan.

Emerging Trends in Global Epoxy Curing Agents Market

Emerging trends in epoxy curing agents in the global composites Market are shaping its future applications and market dynamics:

-

Increasing Use of Epoxy Curing Agent in Specific Applications: A growing trend is developing towards tailored epoxy curing agents for specific industrial requirements leading to customized formulations and specialty applications. Some examples are performance critical coatings, adhesives, electronics and composites.

-

Rising Technological Advancements: The ongoing research-and-development endeavors are dedicated to creating new types of curing agents that can meet evolving industry standards and regulatory requirements. This involves advances in curing agent chemistry and formulation technologies.

-

Growing Demand for High-Performance Formulations: There is a rising demand for epoxy curing agents that offer enhanced performance characteristics such as faster curing times, improved chemical resistance, and superior mechanical properties. For example, this is important in industries like aerospace, automotive or electronics.

-

Market Expansion: Epoxy curing agents in the global composites Market geographical expansion includes the emerging economies and regions with increasing demand for them. This has been driven by infrastructure development, industrial growth and increased use of advanced materials in various applications.

These trends bring out the dynamic nature of the epoxy curing agents in the global composites Market resulting from innovation, sustainability, and across-the-board need for high-performance solution across diverse industrial sectors.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Epoxy Curing Agents

Recent developments in epoxy curing agents in the global composites market by highlight ongoing innovations and advancements across different sectors

-

Growing Demand in Construction and Infrastructure: Epoxy curing agents have witnessed a substantial increase in their usage in the construction and infrastructure sectors. These agents are widely applied in coatings, adhesive, and composites for providing better bonding and durability properties than other conventional materials. This demand is also being supported by ongoing global infrastructure projects particularly in emerging economies.

-

Shift towards Sustainable Solutions: Manufacturers have been focusing on developing eco-friendly epoxy curing agents as environmental concerns heighten and regulations tighten. Bio-based and waterborne curing agents are becoming increasingly popular as they provide sustainable alternatives to traditional solvent-based ones driven both by ecological objectives and regulatory constraints.

-

Technological Advancements: There has been continuous innovation in epoxy resin formulations resulting to improvements of the performance characteristics of these materials. Some of these developments include increased curing efficiency, shortened cure time among other things which makes them more compatible with different surfaces enlarging their application areas.

-

Focus on High-Performance Applications: High quality epoxy curing agents that can meet stringent requirements from industries such as aerospace, automobile and electronics are in higher demand. The epoxy systems used within these industries must possess high strength properties alongside chemical resistance to thermal stability.

-

Regional Market Dynamics: The market dynamics vary significantly across regions. Technological innovations coupled with strict regulatory compliance characterize developed countries including North America and Europe while rapid industrialization and infrastructure development are some of the main drivers propelling growth consumption of epoxy curing agents especially in Asia Pacific region particularly countries like China & India.

Strategic Growth Opportunities for Epoxy Curing Agents Market

The market for epoxy curing agents offers significant strategic growth opportunities driven by different factors and applications. Here are the major growth avenues in bullet points:

Expansion in Construction Industry:

-

Market Demand: The construction industry uses epoxy curing agents for flooring, adhesives, coatings and concrete repair because they have high strength and durability.

-

Opportunities: Rising commercial and residential constructions alongside escalating demand for sustainable and high performance materials push for new generation of epoxy curing agents.

Automotive and Aerospace Applications:

-

Industry Requirements: Automotive parts need epoxy curing agents as composites while aerospace components employ them due to their lightweight properties and mechanical strength.

-

Opportunities: The demand for light weight materials and expanding electric vehicles has pushed for better performing epoxy curing agents that conform to stringent industry standards.

Adhesives and Sealants Market Growth:

-

Application: Epoxy curing agents serve as key components in various industries’ adhesives, sealants, bonding agents etc..

-

Opportunities: Growing use in automotive assembly, electronic manufacturing, and consumer goods creates market openings for fast cure time low VOC bonding agent with excellent adhesion properties made from renewable feedstocks.

Electrical and Electronics Sector:

-

Market Segment: Electrical insulation materials, printed circuit boards (PCBs), semiconductor packaging cannot do without epoxy curing agents.

-

Opportunities: As electronics become more advanced technology-wise with smaller devices requiring faster performance reliability over a wider range of operating temperatures; thermal stability moisture resistance reliable epoxide curatives are being sought after on a larger scale than ever before 5.

Global Epoxy Curing Agents Market Drivers and Challenges

Epoxy curing agents are widely used in many industries including wind energy, pipe and tank, and aerospace because of the ability to improve epoxy resins’ performance and durability. There are many reasons that push the market for epoxy curing agents. Technological advancements have also played a major role in driving innovation in epoxy formulations that have resulted into better properties like faster cures and increased durability. Nevertheless, the market has remained to be full of challenges such as formulating epoxy curing agents that meet various applications requirements yet complying with strict environmental regulations is a daunting task. Nonetheless, there still exists some complications pertaining formulation of these resins since a number of application requirements need to be met while conforming with stringent environmental rules laid down by law makers globally. Expertise in handling and applying technical adhesives cannot be overstated especially as far as concerns over cost-efficiency versus pressure from alternative material sources are concerned.

The key drivers for the epoxy curing agents in the global composites Market include:

-

Growing Demand in Construction and Infrastructure: Globally, there are more construction activities and infrastructure development taking place necessitating the usage of epoxy curing agents in coatings, adhesives, and sealants.

-

Advancements in Technology: The technology for epoxy formulations is progressive as well as curing agents leading to better performance features like rapid curing, long-lasting, highly durable and super bonding characteristics.

-

Expanding Automotive Sector: Higher adoption of lightweight materials and composites in automotive manufacturing has escalated the need for epoxy curing agents in coatings, paints and composite materials.

-

Electronics and Electrical Applications: Increased consumer electronics products as well as telecommunications have resulted into vital electronic encapsulation and insulating materials with epoxy curing agents.

-

Environmental Regulations: The rising demand for eco-friendly curing agents that comply with sustainability initiatives due to increasing regulations promoting low-VOC (volatile organic compound) content and environmentally friendly epoxy formulations.

The key challenges for the epoxy curing agents in the global composites Market include:

-

Environmental Regulations: Increasingly stringent regulations regarding volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) can impact the types of curing agents that can be used, pushing the industry towards more environmentally friendly options.

-

Technical competency: Specialized knowledge of application specific requirements and how to use and process epoxy curing agents is required in formulating and applying them.

-

Cost consciousness: This could cause a slow adoption rate especially in such cost oriented markets such as advanced epoxy formulations which are expensive initially due to the use of highly advanced curing agent.

-

Market rivalry: There is always innovation needed because there is unending competition from other materials or technologies in the coatings, adhesives, and composites sectors.

-

Health safety concerns: Some of the challenges that must be addressed include handling health risks associated with use of epoxy curing agents or contact with them, addressing environmental implications during production processes or afterwards.

The drivers and challenges of the epoxy curing agents in the global composites Market highlight it dynamism and its critical role in various sectors of industry. The need to innovate epoxy curing agents will always be necessary as the global demand for high-performance coatings, adhesives, and composites keeps growing. Struggling with formulation complexity, regulatory compliance, and market competition means that coordinated work on research and development; supply chain cooperation and changes in industry-wide principles is a must. Therefore stakeholders should overcome these difficulties beforehand in order to harness their potentials for growth into profitable ventures while at the same time meeting future demands of advanced epoxy curing solutions sustainably.

Global Epoxy Curing Agents Suppliers and Their Market Shares

In this globally competitive market, several key players such as BASF SE, Evonik, Huntsman Corporation, Westlake Chemical Corporation, Dow Inc. etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each major players

Contact Us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies epoxy curing agents companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the epoxy curing agent companies profiled in this report includes.

These companies have established themselves as leaders in the global epoxy curing agent industry with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the epoxy curing agents in the global composites Market are evolving, with the entry of new players and the emergence of innovative technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Epoxy Curing Agents Market by Segment

There is strong growth in multiple sectors for the market of epoxy curing agents. In this construction field, these are important because of adhesives, coatings and repairs for concrete, infrastructural projects stepping in. Epoxy systems find their application in the automotive industry with respect to coatings as well as composites that increase the performance of vehicles and reduce fuel consumption. Encapsulation and bonding tasks for electronics depend on epoxy cure agents that facilitate the electronic industry expansion. The light weighteness and ultimate properties make epoxy a suitable material for different applications in the aerospace industry such as structural adhesives, composites, and coatings. Furthermore, blade manufacturing and maintenance in wind energy sector utilize epoxy cure agents to showcase their long lasting nature and resistance to weather conditions. These varied uses reveal how widely used these substances are across numerous industries around the globe. The study includes trends and forecast for the epoxy curing agents in the global composites Market by end use, product type, and region as follows:

By End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

By Product Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

-

Aliphatic Amines

-

Aromatic Amines

-

Cycloaliphatic Amines

-

Dicyandiamide

-

Anhydride

-

Catalyst

-

Other Product Types

By Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

-

North America

-

Europe

-

Asia Pacific

-

The Rest of the World

Features of Epoxy Curing Agent Market

-

Market Size Estimates: Epoxy curing agents in the global composites market size estimation in terms of value ($M) and volume (M lbs)

-

Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

-

Segmentation Analysis: Market size by end use, product type, and region

-

Regional Analysis: Epoxy curing agents in the global composites market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

-

Growth Opportunities: Analysis of growth opportunities in different end use industry, product type, and regions for the epoxy curing agents in the global composites market.

-

Strategic Analysis: This includes M&A, new product development, and competitive landscape for the epoxy curing agents in the global composites market.

-

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in composites in the epoxy curing agents in the global composites Market or adjacent markets, then contact us. We have done hundreds of

strategic consulting projects in

market entry,

opportunity screening,

due diligence, supply chain analysis,

M & A, and more.

FAQ_

Q1. What is the epoxy curing agent market size?

Answer: The global epoxy curing agent market is expected to reach an estimated $1,121 million by 2030.

Q2. What is the growth forecast for epoxy curing agent market?

Answer: The epoxy curing agent market is expected to grow at a CAGR of 5% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the epoxy curing agent market?

Answer: The major growth drivers for this market are increasing use of high-performance epoxy based composite materials and the growth of end uses.

Q4. What are the major applications or end use industries for epoxy curing agent?

Answer: Wind energy and pipe and tank are the major end uses for epoxy curing agent.

Q5. What are the emerging trends in epoxy curing agent market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, includes increasing use of epoxy curing agent in specific applications, rising technological advancements, and market expansion.

Q6. Who are the key epoxy curing agent companies?

Answer: Some of the key epoxy curing agent companies are as follows:

• BASF SE

• Evonik

• Huntsman Corporation

• Westlake Chemical Corporation

• Dow Inc.

• Cardolite Corporation

Q7.Which epoxy curing agent product type segment will be the largest in future?

Answer: Lucintel forecasts that aliphatic amines will remain the largest segment and cycloaliphatic amines is expected to witness the highest growth over the forecast period due to its better mechanical properties like; low viscosity, rapid cure at elevated temperature, high thermal resistance, and improved blush resistance.

Q8: In epoxy curing agent market, which region is expected to be the largest in next 7years?

Answer: APAC is expected to remain the largest region and North America witness the highest growth over next 7 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global epoxy curing agent market by end use (wind energy, pipe and tank, aerospace, and others), product type (aliphatic amines, aromatic amines, cycloaliphatic amines, dicyandiamide, anhydride, and catalyst), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?