Core Material Market Trends and Forecast

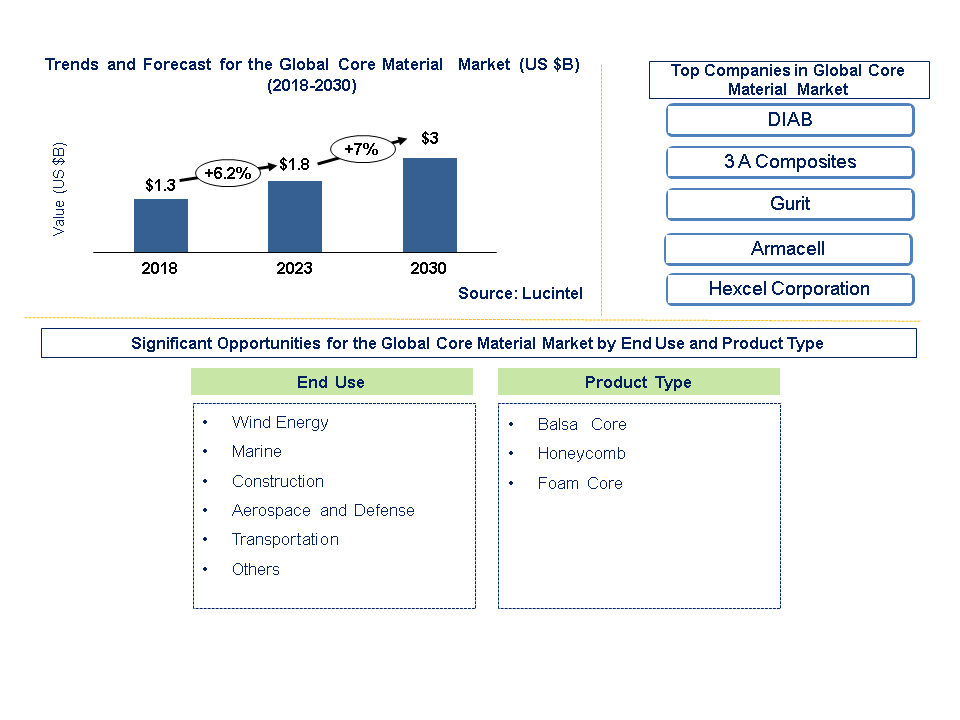

Lucintel finds that the future of the global core intermediate material market looks promising with opportunities in wind energy, marine, construction, aerospace & defense, and transportation end uses. The global core material market is expected to reach an estimated $3 billion by 2030 with a CAGR of 7% from 2023 to 2030. The major drivers for this market are increasing use in production of boats, in transportation, wind turbines blades, and structural composite panels.

Various raw materials are utilized by the core material market to produce lightweight, high-strength cores for composite structures. The main ingredients include balsa wood, which is known for its low density and high strength per unit mass; PVC foam that possesses good mechanical properties and thermal insulation; PET foam that has recyclability and chemical resistance; honeycomb structures made from materials such as aluminum or aramid that have great stiffness and strength. For the construction of strong yet light composite parts, these core materials are needed in industries like aerospace, marine and wind energy applications. the cost of core materials differs greatly from that of traditional alternatives depending on the kind and specific application. In general, core materials such as balsa wood, PVC foam, PET foam and aluminum honeycomb may be more costly than other conventional materials like solid wood or metal due to its advanced features including light weight strength and durability. However, such costlier core materials sometimes have better performance benefits that pay for themselves initially by reducing costs in lightweighting applications that need more strength and improved fuel efficiencies in sectors like aerospace, marine, wind energy.

• Lucintel forecasts that wind energy will remain the largest end use due to increase in the diameter of rotors is driving the demand for core materials in this industry and aerospace & defense is expected to witness the highest growth over the forecast period.

• Honeycomb by product type core material will remain the largest segment and foam core is expected to witness the highest growth over the forecast period.

• Asia Pacific is expected to remain the largest market over the forecast period due to rising demand from electronics and defense industries, growth in the end uses and increasing focus on high performance core material. Europe is expected to witness the highest growth rate over the forecast period.

Country wise Outlook for the Core Material Market

Emerging Trends in the Core Material Market

Emerging trends in the core material market shaping its future applications and market dynamics:

1. Increasing Focus on Sustainability and Eco-Friendly Materials: Severe environmental legislation and increased consumer interest in green products have stimulated the production of more ecologically sustainable core materials, including PET foams made from recycled material and bio-based substitutes.

2. Introduction of Advanced Manufacturing Technologies: Adopting 3D printing and other automated production processes will enhance precision, reduce waste, and decrease unit costs.

3. Rising Demand for Lightweight and High-Performance Materials: The new lightweight core materials with enhanced mechanical properties such as better strength to weight ratios must be developed to match the needs of high-performance applications within aerospace, automotive, wind energy sectors.

4. Multifunctional Core Materials: The innovation into multifunctional type of cores with properties like thermal insulation, acoustic insulation, fireproofing capabilities as well as impact resistance would enable them to be used in a broader variety of applications besides adding value to composite structures

5. Nanotechnology Integration: The efficiency for advanced engineering application is improved through incorporation of nanoscale materials that make the mechanical property enhancement possible also increases the thermal stability as well as overall performance.

These trends indicate a shift towards more sustainable, innovative, and technologically advanced solutions in the core material industry to

meet evolving consumer and regulatory demands globally.

A total of 107 figures / charts and 82 tables are provided in this 212-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments in the Core Material Market

Recent developments in global core material market which highlights ongoing innovations and advancements across different sectors.

• Technological Advancements: The integration of sophisticated manufacturing technologies in advanced materials production processes is transforming the manufacturing of core materials. 3D printing is being tried out to produce complex core geometries that used to be difficult or impossible with conventional methods. Automated production systems are enhancing precision, reducing waste and costs thus making core materials more accessible and useful.

• High-Performance Materials: Recent developments have seen the creation of lightweight core materials with improved mechanical properties. Innovations in material science result in cores with improved strength-to-weight ratios, improved thermal stabilities, and impact resistance. These high-performance materials are particularly important in aerospace, automotive, and wind energy sectors where weight must be decreased while maintaining structural integrity.

• Multifunctional Core Materials: The market trend is towards multifunctional core materials that go beyond just providing structural support for composites. There are now efforts to make core materials that incorporate thermal insulation properties as well as sound proofing capabilities thereby adding more value to such products when they are used in construction, transportation or other industrial applications as an example.

• Nanotechnology Integration: Core materials can have their properties enhanced by nanotechnology. Adding nanomaterials like carbon nanotubes and graphene improves the mechanical strength, thermal conductivity. This development has enabled the emergence of next generation composites possessing substantially advanced performance features.

• Customized Solutions: There is a growing demand for custom made solutions using core products. Manufacturers offer clients customized products according to specific application needs such as unique mass densities, shapes or mechanical propertied among other features. This type of customization results from diverse demands by industries such as shipping marine industry; defense aviation sector; civil engineering infrastructure building works; wind power industry amongst others which look for tailored functionality features only available at specialized suppliers.

• Increased Application in Renewable Energy: These core materials have become crucial in the renewable energy industry, especially for wind turbine blades. As such, lightweight, strong and durable materials are required to enhance the efficiency and performance of wind energy systems through innovative design and production of core materials.

Strategic Growth Opportunities for the Core Material Market

The core material market is very dynamic due to its unique properties of being lightweight, strong and thermally stable. Some key strategic growth opportunities for this market include:

• Renewable Energy Expansion: The growing need for core materials in renewable energy industries, especially wind turbine blades that need lightweight and strong materials to boost their efficiency and functionality. Develop specialized core materials for solar panel applications where thermal stability and long-term durability are paramount.

• Increasing Focus on Sustainability: Invest in development and marketing of eco-friendly and recyclable core materials like recycled PET foams and bio-based cores to meet new environmental regulations and consumer wants. Emphasis should be made on marketing sustainable core materials with emphasis on environment benefits as well as lifecycle advantages so as to attract environmentally conscious clients.

• Advancement in Material Technology: Integrate nanotechnology advances composites to develop high performance core materials that have better mechanical properties, thermal stability, impact resistance among other things. Hybrid material utilization combining traditional cores with advanced nanomaterials to improve performance and meet specific industry requirements.

• Automated and Advanced Manufacturing Processes: Invest in automated manufacturing technologies such as 3D printing or continuous lamination for improved precision reduced waste volumes lower production costs. Implementing advanced quality control measures is important to ensure consistent product quality thereby improving customer satisfaction levels.

• Market Diversification: Look at how we can go beyond traditional sectors by looking at other emerging markets such as electric vehicles drones or advanced robotics among others which are still untapped when it comes to the use of certain types of raw materials in their construction processes such as the manufacture of robotic arms used in industrial plants where they are applied to complete a number of tasks automatically without human intervention. Develop innovative products for medical devices, sports equipment and consumer electronics by utilizing core materials’ unique capabilities.

Core Material Market Drivers and Challenges

Industries such as aerospace, wind energy and marine rely on core materials market which is defined by the need for lightweight high-strength solutions. Material science progressions and the push for sustainability in production has propelled this industry from behind. Yet, this market also faces high production costs and issues with maintaining quality alike.

The factors responsible for driving the core material market include:

1. Light and Strong Properties: Their superior strength-to-weight rations make them favored core materials for aerospace, marine and wind energy applications as exemplified by balsa wood, PVC foam, and honeycomb structures.

2. Rising Technological Advancements: Improvements in manufacturing techniques with the likes of 3D printing among others have improved precision efficiency and cost-effectiveness of core materials.

3. Versatility and Multifunctionality: Other benefits that can be given by core materials like thermal insulation properties or acoustic damping qualities enable them to be used in various industries.

Challenges in the Core Material Market:

1. High Production Costs: The initial cost of advanced core materials and sophisticated manufacturing processes can be a barrier to widespread adoption, especially for cost-sensitive projects.

2. Quality Consistency: Maintaining consistent quality and meeting stringent industry standards and certifications can be challenging, impacting market acceptance and reliability.

3. Material Availability and Supply Chain Issues: Fluctuations in the availability of raw materials, such as balsa wood, and supply chain disruptions can affect production and pricing.

Emerging technologies like nanomaterials and hybrid composites offer new opportunities and challenges, enhancing performance while requiring advanced manufacturing capabilities. The push for customization and tailored solutions further drives innovation, demanding flexibility and technical expertise from manufacturers to meet diverse industry needs.

Core Material Suppliers and Their Market Shares

In this globally competitive market, several key players such as, DIAB, Gurit, 3 A Composites, Armacell, Hexcel Corporation, and etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies core material companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the core material companies profiled in this report includes.

• DIAB

• Gurit

• 3A Composites

• Armacell

• Hexcel Corporation

• The Gill Corporation

• Euro Composites

These companies have established themselves as leaders in the global core material industry with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the global balsa core material market are evolving, with the entry of new players and the emergence of innovative technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Core Material Market by Segment

The demand for light weight and high strength materials to improve fuel efficiency and performance has resulted in a boom in the aerospace sector. Similarly, durable and lightweight cores for turbine blades have resulted in remarkable growth of the wind energy industry. In addition, the marine industry is using core materials because they resist corroding agents and are strong enough for hostile environments. Construction companies also use these materials in projects that require an infrastructure with high weight-bearing capacity but which is lighter than usual. These sectors are spearheading the advancement of core material market as they seek more sophisticated solutions that can improve their performance and be sustainable at the same time.

This core material market report provides a comprehensive analysis of the market's current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, include end use. The report offers insights into regional dynamics, highlighting the major markets for global core material market and their growth potentials. The study includes trends and forecast for the composites in global core material market by end use, product type and region as follows:

Core Material Market by End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Wind Energy

• Marine

• Construction

• Aerospace and Defense

• Transportation

• Others

Core Material Market by Product Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Balsa Core

• Honeycomb

• Foam Core

Core Material Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Core Material Market

• Market Size Estimates: Core material market size estimation in terms of value ($M) and volume (M lbs).

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by end use and product type.

• Regional Analysis: Core material market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different end use, product type, and regions for the core material market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the core material market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in composites in the global core material market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the core material market size?

Answer:The global core material market is expected to reach an estimated $3 billion by 2030.

Q2. What is the growth forecast for core material market?

Answer:The core material market is expected to grow at a CAGR of 7% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the core material market?

Answer: The major drivers for this market are increasing use in production of boats, in transportation, wind turbines blades, and structural composite panels.

Q4. What are the major end uses for core material?

Answer:Wind energy and marine are the major end uses for core material.

Q5. What are the emerging trends in core material market?

Answer:Emerging trends, which have a direct impact on the dynamics of the industry, includes introduction of hybrid system, replacement of conventional metal structures with composites.

Q6. Who are the key core material companies?

Answer:Some of the key core material companies are as follows:

• DIAB

• Gurit

• 3A Composites

• Armacell

• Hexcel

• The Gill Corporation

• Euro Composites

Q7: In core material market, which region is expected to be the largest in next 7 years?

Answer:Asia Pacific is expected to remain the largest region and Europe witness the highest growth over next 7 years

Q8. Do we receive customization in this report?

Answer:Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global core material market by end use (wind energy, marine, construction, aerospace and defense, transportation, and others), product type (balsa core, honeycomb, and foam core) and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?