Composite Surface Film Market Trends and Forecast

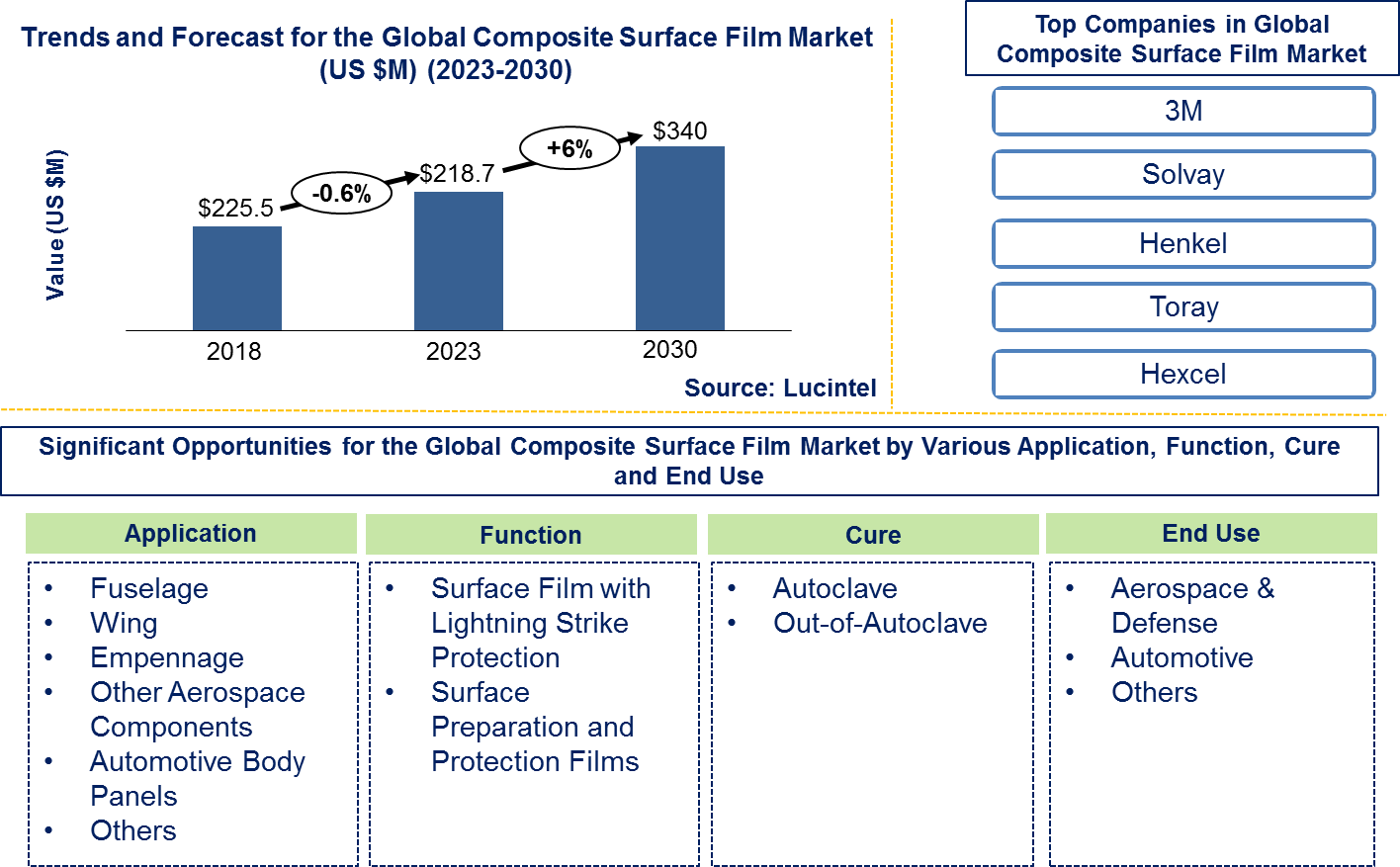

Lucintel finds that the future of the global composite surface film intermediate material market looks promising with opportunities in the aerospace & defense and automotive end uses. The global surface film market is expected to reach an estimated $340 million by 2030 with a CAGR of 6% 2023 to 2030. The major drivers for this market are increasing penetration of composites in the key aircraft programs, rising demand for the high quality surface finish and aerodynamic surface with reduced paint preparation activities and increasing use of composites in automotive.

To make composite surface films, some resins like epoxy, polyester and vinyl ester reinforced with things such as carbon fibers or aramid fibers are used in order to increase their durability. Other additives such as UV stabilizers, dyes for coloring and flame retardants also improve performance of these films. Fillers on the other hand such as calcium carbonate or clay reduce costs while giving them better mechanical properties. Apart from that they are useful for manufacturing purposes by enabling smooth surfaces through the use of solvents and release agents. Consequently, when compared to traditional coatings, composite surface films have generally high initial expenses due to their superior characteristics they possess though; lowering maintenance costs thus leading long life spans which result into long term savings. In fact, developments in technology and improved production efficiencies have made them cheaper than ever before.

• Lucintel forecasts that wings will remain the largest application segment over the forecast period due to increasing penetration of composites in the segment and higher penetration of composites in new airplane programs for light weight and fuel efficiency.

• Surface preparation and protection film will remain the largest segment over the forecast period due to its property of reduction in the post molding finishing processes, like pit filling and sanding, resulting in ease of painting procedures.

• North America is expected to remain the largest region over the forecast period due to aircraft delivery and increasing penetration of composites in the structural components of aircraft.

Country wise Outlook for the Composite Surface Film Market

The composite surface film market is witnessing substantial growth globally, driven by increased demand from various industries such as packaging, transportation, electrical and electronics, and construction. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major surface film producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends in the Composite Surface Film Market

Emerging trends in the composite surface film market shaping its future applications and market dynamics:

• Nanotechnology Integration: The inclusion of nanotechnology in composite surface films is transforming their properties. Nanomaterials such as graphene and carbon nanotubes aid to improve strength, conductivity and thermal performance.

• Automated Manufacturing Processes: Comprised of robotics or/and 3D printing, advanced automated manufacturing processes create ability for more efficient and precise production of composite surface films leading to reduced the costs of production and improved quality goods.

• Recyclable Composite Surface Films: Recyclable composite surface films are being researched and developed to address the end-of-life disposal issues connected with composites materials. Such innovations follow circular economy principles.

• Multifunctional Surface Films: Development of multifunctional composites surfaces films that offer extra functions like self-healing properties; anti-fouling properties etc. This kind innovation comes in handy in a harsh environment conditions and critical applications.

• Advanced Resin Systems: In resin systems current developments are resulting in composite surface films that have advanced mechanical properties, thermal stability and chemical resistance. Epoxy, polyurethane, phenolic resins are some major areas of focus.

• Smart Composite Films: These smart composite surface films have been developed with sensors embedded within them that can monitor structural health by providing real-time data on performance. By being able to detect damage and wear these film also improve maintenance activities thereby enhancing safety.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Composite Surface Film Market

Recent developments in composite surface film market by various companies highlight ongoing innovations and advancements across different sectors:

• Marine Sector: On one hand, to protect hulls and other structures against fouling, water damage and abrasion, there have been developments of composite surface films for marine applications. Thus, through the application of such films on marine vessels, their lifetime can be prolonged due to their high resistance towards saltwater corrosion as well degradation by UV light.

• Wind Energy: An important element of wind turbine blades is that they require composite surface films to protect them from extreme weather like erosion or harsh climatic conditions. This has led to the development of film materials, which improve aerodynamic efficiency and reduce maintenance costs over a blade’s life span.

• Construction & Infrastructure: During construction, more and more building materials are using composite surface films like architectural elements in order to enhance their aesthetic charm and durability. Innovations include buildings that have self-cleaning, anti-graffiti or energy efficient film materials installed.

• Sports & Leisure Sector: When you apply composite surface films on products such as sporting goods and recreational commodities, some of the benefits realized are enhanced tensile strength, greater impact resistance, more flexibility etc. Improvement is evidenced through lighter films with long-lasting purposes that better overall product performances.

Strategic Growth Opportunities for Composite Surface Film Market

• Aerospace and Defense: The aviation sector and military industry have been one of the main driving forces in the growth of composites surface films market. This is important for long viewing life on aircrafts making them to be durable, perform better while ensuring that they last long as defense materials. Also, there has been an upsurge in demand for lightweight materials that will help reduce on fuel consumption as well as prevent emissions which may lead to environmental degradation like moisture ingress and abrasion making surface films against these effects necessary. In the same vein, military technologies have advanced over time due to need for stealth capabilities hence more emphasis is on specialized surface films with radar-absorbing properties and reduced infrared signatures.

• Automotive Industry: There is an increasing trend in the automotive field where cars are designed with lightweight materials to improve their efficiency and performance, especially considering the rise in electric vehicles (EVS). Composite surface films are used to reduce component weight while providing extra protection against wear, abrasion or sunburn. As car manufacturers increasingly opt for composite materials in their exterior panels, interior and structural components, it can be concluded that there will be a high need for well-finished surface films able to provide beauty, durability plus weathering resistance.

• Renewable Energy: Another tactical opportunity in the renewable energy industry is composite surface films, particularly for wind turbines. They must be able to weather adverse conditions and remain aerodynamically efficient always. And so, films keep away winds and water which can erode composites of blades thereby ensuring that they last longer while reducing the maintenance cost at all levels of the wind farms. Energy investments into wind power generation have underscored one thing that will never change; a constant requirement of dependable materials like those mentioned before.

• Construction and Infrastructure: Construction and infrastructure sectors also have been increasingly using composites surface films. Alternatively they are known as FRP products, which offer more corrosion resistance to chemicals or weathering than steel or concrete. In other words, the use of surface films makes composites used in bridges buildings and other infrastructural projects last longer and look better. Therefore, global urbanization and infrastructure development will lead to demand for sustainable materials in construction that will necessitate composites and their related surface films.

• Consumer Goods and Electronics: Consumer goods and electronics industries use plastics because of their lightness as well as their adaptability. In sports equipment, boats, televisions, and so forth; composite materials come in here thus they require care in terms of surface films that can protect them from any scratches or impacts coming from the outside. Otherwise called FRP (Fiberglass Reinforced Plastics) these have a better resistance to corrosion, chemicals or weathering than conventional ones such as steel or concrete. Durable beauty is what consumers are going after therefore this implies that there is a huge market for composites surface films in this field.

Composite Surface Film Market Drivers and Challenges

The global market for surface film composites is growing due to the uncontrolled demand in aerospace, advancements in composite manufacturing and growing use in wind energy. High cost of production, complexity during application process and compatibility issues are some of the challenges faced by these films in enhancing performance and durability of composites. To effectively exploit market opportunities, it is essential to understand these dynamics.

The key drivers for the global composite surface film market include:

1. Uncontrolled Demand in Aerospace and Automotive Sectors: In the aerospace and automotive industries, lightweight and durable features of composite surface films make them significant consumers.

2. Growing Use in Wind Energy: Composites have become more popular especially in the production of wind turbine blades which in turn has increased the need for surface coatings that will enhance durability and performance.

3. Advancements in Composite Manufacturing: Composite materials manufacturing has significantly grown through the introduction of cosmetic finish films that are not only visually appealing but also have a high strength and ability to withstand harsh environmental conditions.

4. Maintenance and Repair Applications: The essentiality of surface films (as a result of strict automotive fuel consumption rules and aircraft smoke) prompts the use of lightweight materials such as composites.

The challenges in the global composite surface film market include:

1. High Cost of Production: The addition of surface films to composite materials may result in higher costs, which could reduce their popularity particularly among markets that are cost-conscious.

2. Complexity during Application Process: This, though, is difficult to do because it depends on specialized skills as well as application equipment’s that make a proper surface film application during manufacturing and preserving operations a daunting task.

Global composite surface films market is expected to grow driven by increasing demand from aerospace, automotive and wind power sectors. They are required to enhance composites’ durability, aesthetics and performance in order to meet strict regulations and improve operational effectiveness. Nevertheless, such problems include cost issues, application intricacy, compatibility conflicts, eco worries as well as quality control criteria that must be considered cautiously. Overcoming these obstacles with creative ideas, strategic partnerships and advancements in production methods is critical for sustaining business growth and responding to the evolving dynamics in the composites surface film sector.

Surface Film Suppliers and Their Market Shares

In this globally competitive market, several key players such as 3M, Solvay, Henkel, Sinopec, Hexcel, and Toray etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies surface film caters increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the surface film companies profiled in this report include.

• 3M

• Solvay

• Henkel

• Toray

• Hexcel

These companies have established themselves as leaders in the global composite surface film market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations. The market share dynamics within the composite surface film market are evolving, with the entry of new players and the emergence of innovative composite surface film market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Composite Surface Film Market by Segment

There has been a robust growth in the composites surface film market across major segments. This is necessitated by the fact that aeronautics and aerospace require lightweight materials for their improved performance and durability via surface protection. The use of these materials is growing in the automotive sector, specifically exterior parts which are desired to be lighter in weight but enhanced with aesthetic appeal. The significant expansion of wind energy segment is as a result of increased installation of wind turbines which need weather-resistant and tough surface films. They have also been increasing in marine applications such as boat building and marine infrastructure because they are highly resistant to corrosion and last long. Surface films have also found application in construction where they are used in architectural panels and infrastructure for weatherproofing and structural enhancement thereby further fueling market expansion.

Composite Surface Film Market by End Use [Value ($M) and Volume (Thousand Sq. Meters) Analysis for 2018 – 2030]:

• Aerospace

• Automotive

• Others

Composite Surface Film Market by Application [Value ($M) and Volume (Thousand Sq. Meters) Analysis for 2018 – 2030]:

• Fuselage

• Wings

• Empennage

• Automotive Body Panels

• Other Aerospace Parts

• Others

Composite Surface Film Market by Function [Value ($M) and Volume (M Sq. Meters) Analysis for 2018 – 2030]:

• Surface Film with Lightning Strike Protection

• Surface Preparation and Protection Films

Composite Surface Film Market by Cure [Value ($M) and Volume (Thousand Sq. Meters) Analysis for 2018 – 2030]:

• Autoclave

• Out of Autoclave

Composite Surface Film Market by Region [Value ($M) and Volume (Thousand Sq. Meters) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Composites Surface Film Market

• Market Size Estimates: Composite surface film market size estimation in terms of value ($M) and volume (M Sq. Meters)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by end use, application, function, cure, and region

• Regional Analysis: Composite surface film market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different end use industry, product type and regions for the composite surface film market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the composite surface film market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in surface film or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the composite surface film market size?

Answer: The global composite surface film market is expected to reach an estimated $340 million by 2030.

Q2. What is the growth forecast for composite surface film market?

Answer: The composite surface film market is expected to grow at a CAGR of 6% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the composite surface film market?

Answer: The major drivers for this market are uncontrolled demand in aerospace, advancements in composite manufacturing and growing use in wind energy.

Q4. What are the major applications or end use industries for composite surface film?

Answer: Aerospace and automotive are the major end use for composite surface film.

Q5. What are the emerging trends in composite surface film market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include nanotechnology integration, automated manufacturing processes, recyclable composite surface films, multifunctional surface films, and advanced resin systems.

Q6. Who are the key composite surface film companies?

Answer: Some of the key composite surface film companies are as follows:

• Solvay S.A.

• 3M

• Henkel

• Hexcel

• Axiom Materials

• Park Electrochemical Corporation

• Gurit

• Toray Industries Inc

Q7.Which composite surface film product segment will be the largest in future?

Answer: Lucintel forecasts that wings composite surface film will remain the largest segment over the forecast period due to increasing penetration of composites in the segment and higher penetration of composites in new airplane programs for light weight and fuel efficiency.

Q8: In composite surface film market, which region is expected to be the largest in next 7 years?

Answer: North America is expected to remain the largest region over next 7 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global composite surface film market by end use (aerospace & defense, automotive, others) application (fuselage, wings, empennage, other aerospace components, automotive body panels, and others), function type (surface preparation and protection films, and surface films with LSP), cure (autoclave and out of autoclave), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?