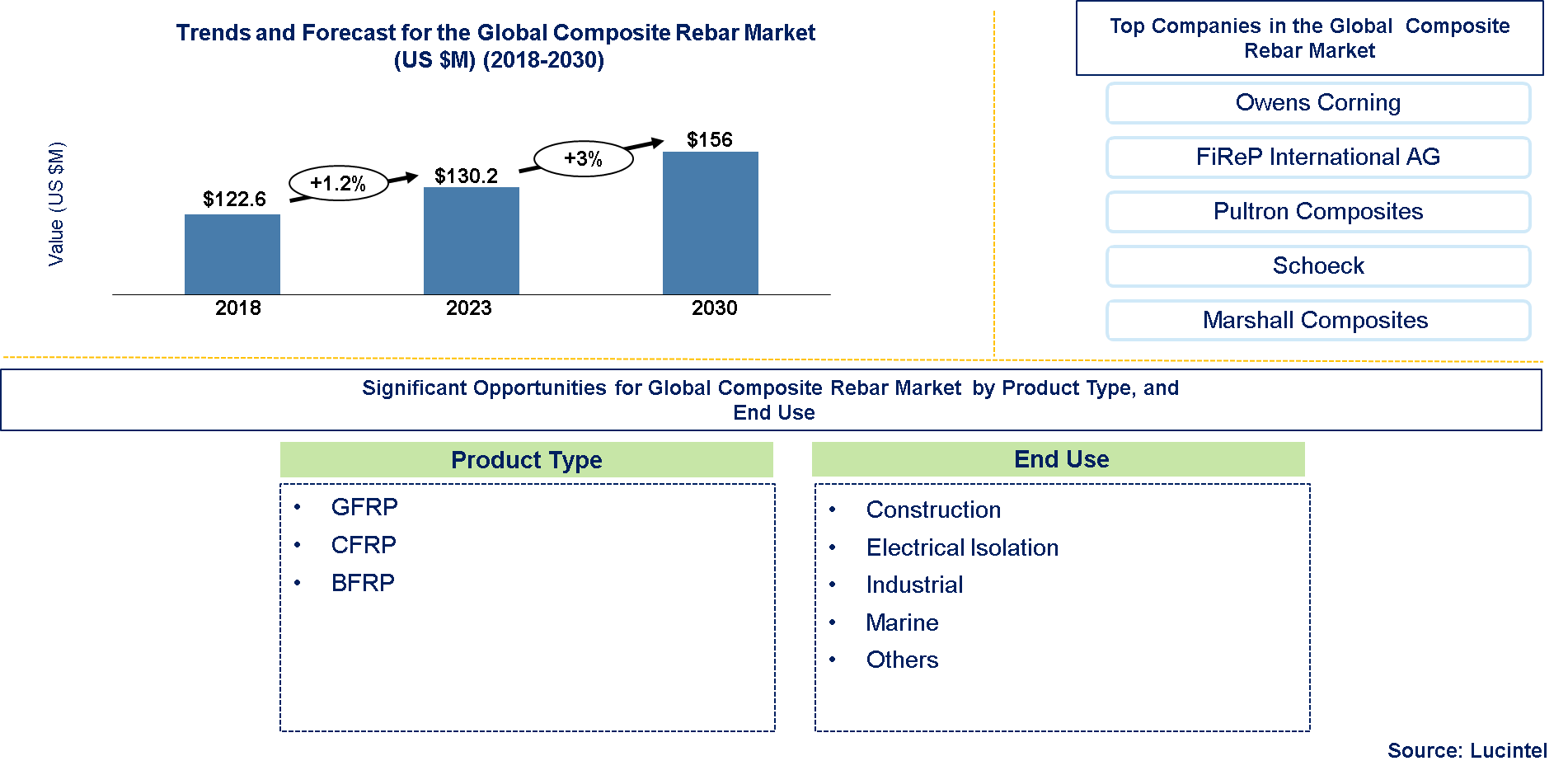

Composite Rebar Market Trends and Forecast

The future of the composite rebar market looks promising with opportunities in the exterior, interior, power train system, chassis system, under body system, and pressure vessel market. The composite rebar market is expected to reach an estimated $156 million by 2030 with a CAGR of 3% 2023 to 2030. The major drivers of growth for this market are increasing automotive production and increasing demand for lightweight materials in electric and hybrid vehicles, to achieve higher fuel efficiency and reduce greenhouse gas emissions.

Composite rebar, commonly called fiber-reinforced polymer (FRP) rebar, is derived from materials like fiberglass, carbon fibers or basalt fibers combined with a matrix of polymer resin. These ones provide more tensile strength, resistance to corrosion and lightness as compared to normal steel rebar. The manufacture encompasses the use of pultrusion and winding methods where durable and long lasting reinforcing products are produced for building applications. Composite rebar is typically more costly than conventional steel rebar, going for around $1.50 to $4.00 a foot in comparison to the $.50 to $2.50 a foot range of steel rebar. The increased cost signifies that composite rebar has better corrosion resistance, lighter and durable hence it’s widely used in adverse conditions like sustainable construction projects or difficult locations.

• Lucintel forecasts that construction will remain the largest end use segment and is also expected to witness the highest growth over the forecast period due to because of investments in infrastructure, including bridges, buildings, highways, water distribution systems, and other facilities.

• Glass fiber reinforced plastic (GFRP) composite rebar will remain the largest segment over the forecast period due to demand in roads, bridges, tunnels, MRI rooms, marine structures, and water fronts.

• North America is expected to remain the largest region and APAC the highest growth over the forecast period because of growth in the replacement of existing and development of new infrastructures.

Composite rebar, commonly called fiber-reinforced polymer (FRP) rebar, is derived from materials like fiberglass, carbon fibers or basalt fibers combined with a matrix of polymer resin. These ones provide more tensile strength, resistance to corrosion and lightness as compared to normal steel rebar. The manufacture encompasses the use of pultrusion and winding methods where durable and long lasting reinforcing products are produced for building applications. Composite rebar is typically more costly than conventional steel rebar, going for around $1.50 to $4.00 a foot in comparison to the $.50 to $2.50 a foot range of steel rebar. The increased cost signifies that composite rebar has better corrosion resistance, lighter and durable hence it’s widely used in adverse conditions like sustainable construction projects or difficult locations.

• Lucintel forecasts that construction will remain the largest end use segment and is also expected to witness the highest growth over the forecast period due to because of investments in infrastructure, including bridges, buildings, highways, water distribution systems, and other facilities.

• Glass fiber reinforced plastic (GFRP) composite rebar will remain the largest segment over the forecast period due to demand in roads, bridges, tunnels, MRI rooms, marine structures, and water fronts.

• North America is expected to remain the largest region and APAC the highest growth over the forecast period because of growth in the replacement of existing and development of new infrastructures.

Country wise Outlook for the Composite Rebar Market

The composite rebar market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major Composite Rebar producers in key regions: the USA, Canada, Russia and China

Emerging Trends in the Composite Rebar Market

Emerging trends in the composite rebar market shaping its future applications and market dynamics:

• Advancements in Material Technology: The use of other fiber types such as basalt, glass and carbon exist in the market today. The strength of these materials is modernized by using resins matrixes leading to their durability and cheapness.

• Expansion in Infrastructure Projects: This light weight characteristic has allowed for its use in bridges, tunnels, ocean structures or any other structure that is built on water since it does not corrode under such conditions.

• Sustainable Construction Practices: The adoption of composite rebar is getting higher because it doesn’t corrode and lasts for a long time, hence promoting development of sustainable infrastructure.

• Regulatory Support: Non-corrosive materials have been promoted by governments to be used during construction hence composite rebar’s demand as an alternative to conventional steel.

Emerging trends in the composite rebar market shaping its future applications and market dynamics:

• Advancements in Material Technology: The use of other fiber types such as basalt, glass and carbon exist in the market today. The strength of these materials is modernized by using resins matrixes leading to their durability and cheapness.

• Expansion in Infrastructure Projects: This light weight characteristic has allowed for its use in bridges, tunnels, ocean structures or any other structure that is built on water since it does not corrode under such conditions.

• Sustainable Construction Practices: The adoption of composite rebar is getting higher because it doesn’t corrode and lasts for a long time, hence promoting development of sustainable infrastructure.

• Regulatory Support: Non-corrosive materials have been promoted by governments to be used during construction hence composite rebar’s demand as an alternative to conventional steel.

A total of 66 figures / charts and 65 tables are provided in this 131-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Composite Rebar Market

Recent developments in composite rebar market by various companies highlight ongoing innovations and advancements across different sectors:

• Technological Innovations: Technological advancements that would increase the efficiency or longevity of the composite rebar, for example, advanced resin formulations and automation of production.

• Market Expansion: Widespread adoption in global construction projects with emphasis on regions vulnerable to corrosion or earthquakes which underscored advantages of composites against traditional steel.

• Product Diversification: Introduction of new types of fire resistant composites rebars as well as those that can be customized to suit different structures.

• Industry Collaborations: Integration of creative solutions into major infrastructure projects following partnerships between manufacturers of this material and construction companies proving its acceptance and growth in the market.

Recent developments in composite rebar market by various companies highlight ongoing innovations and advancements across different sectors:

• Technological Innovations: Technological advancements that would increase the efficiency or longevity of the composite rebar, for example, advanced resin formulations and automation of production.

• Market Expansion: Widespread adoption in global construction projects with emphasis on regions vulnerable to corrosion or earthquakes which underscored advantages of composites against traditional steel.

• Product Diversification: Introduction of new types of fire resistant composites rebars as well as those that can be customized to suit different structures.

• Industry Collaborations: Integration of creative solutions into major infrastructure projects following partnerships between manufacturers of this material and construction companies proving its acceptance and growth in the market.

Strategic Growth Opportunities for Global Composite Rebar Market

Electric Vehicles (EVs) and Hybrid Cars

• Reducing Weight for More Range: Carbon fiber’s light weight provides a significant increase in the range EVs, thereby addressing one of the major consumer concerns – battery life.

• Structural Components: This increases safety and performance when used in electric vehicle battery enclosures and chassis.

• Sustainability and Efficiency: Encouragement of carbon fibers use to reduce total vehicle emissions corresponds with worldwide sustainability targets.

Advanced Manufacturing Methods

• Automated Fiber Placement (AFP): AFP investment can cut production costs and time making carbon fiber more competitive with traditional materials.

• 3D Printing: Additive manufacturing techniques adoption for quick efficient creation of intricate carbon fiber components.

• Resin Transfer Molding (RTM): Enhancements in RTM processes could make production quicker while enhancing quality of carbon fibers parts.

?

Recycling and Sustainability Initiatives

• Recyclable Carbon Fiber: Developing & promoting recyclable automotive components made from CFRP materials to enhance their sustainability profile.

• Eco-Friendly Production Methods: Use renewable energy sources as well as waste minimization to reduce the carbon footprint of carbon fiber production.

• Circular Economy Models: Embracing circular economy principles by reclaiming end-of-life CFRP parts for use in new applications.

Collaborations and Partnerships

• Strategic Alliances with Automakers: Partnering with leading automobile manufacturers to form alliances aimed at developing customized car models using CFRPs.

• Joint Ventures with Technology Firms: Collaborating with tech companies to integrate smart technologies into CF composites for advanced vehicle functionalities.

• Government and Research Institutions: Participating in research initiatives, public-private partnerships to drive innovation, share costs etc,

Market Diversification

• Expansion into Luxury and Sports Cars: Leveraging on high-performance attributes of CF to target luxury car segment or sports car sector respectively.

• Commercial and Heavy Vehicles : Commercialization of CFRP composites for improved fuel efficiency or carrying capacity in commercial vehicles – trucks inclusive.

• Aftermarket Components: Developing high-quality aftermarket carbon fiber parts for vehicle customization and performance upgrades.

?

Technological Advancements

• Enhanced Material Properties: Continuous research should focus on enhancing the strength, stiffness as well as thermal properties of carbon fiber.

• Hybrid Composites: Combining CF with other materials such as Kevlar or aluminum to achieve some specific performance features.

• Smart Materials Integration: Real-time monitoring and diagnostic tools are embedded in carbon fiber components using integrated sensors/ electronics.

Regulatory and Policy Support

• Compliance with Emission Standards: Use of carbon fiber to assist automobile manufacturers achieve stringent global fuel economy standards, emission guidelines etc.

• Incentives for Lightweight Materials: Promoting government incentives and subsidies that encourage use of lightweight materials in the auto industry.

• Safety Regulations: Using CFRP in critical structural components enables them to meet/exceed safety regulations.

Cost Reduction Strategies

• Economies of Scale: Aiming at lowering per unit prices by leveraging cost efficiencies through increased production volumes.

• Supply Chain Optimization: Streamlining the supply chain so as to reduce costs and improve accessibility of carbon fiber (CF).

• Alternative Raw Materials: Cost effective alternative feedstock options for traditional precursors to CFs.

Electric Vehicles (EVs) and Hybrid Cars

• Reducing Weight for More Range: Carbon fiber’s light weight provides a significant increase in the range EVs, thereby addressing one of the major consumer concerns – battery life.

• Structural Components: This increases safety and performance when used in electric vehicle battery enclosures and chassis.

• Sustainability and Efficiency: Encouragement of carbon fibers use to reduce total vehicle emissions corresponds with worldwide sustainability targets.

Advanced Manufacturing Methods

• Automated Fiber Placement (AFP): AFP investment can cut production costs and time making carbon fiber more competitive with traditional materials.

• 3D Printing: Additive manufacturing techniques adoption for quick efficient creation of intricate carbon fiber components.

• Resin Transfer Molding (RTM): Enhancements in RTM processes could make production quicker while enhancing quality of carbon fibers parts.

?

Recycling and Sustainability Initiatives

• Recyclable Carbon Fiber: Developing & promoting recyclable automotive components made from CFRP materials to enhance their sustainability profile.

• Eco-Friendly Production Methods: Use renewable energy sources as well as waste minimization to reduce the carbon footprint of carbon fiber production.

• Circular Economy Models: Embracing circular economy principles by reclaiming end-of-life CFRP parts for use in new applications.

Collaborations and Partnerships

• Strategic Alliances with Automakers: Partnering with leading automobile manufacturers to form alliances aimed at developing customized car models using CFRPs.

• Joint Ventures with Technology Firms: Collaborating with tech companies to integrate smart technologies into CF composites for advanced vehicle functionalities.

• Government and Research Institutions: Participating in research initiatives, public-private partnerships to drive innovation, share costs etc,

Market Diversification

• Expansion into Luxury and Sports Cars: Leveraging on high-performance attributes of CF to target luxury car segment or sports car sector respectively.

• Commercial and Heavy Vehicles : Commercialization of CFRP composites for improved fuel efficiency or carrying capacity in commercial vehicles – trucks inclusive.

• Aftermarket Components: Developing high-quality aftermarket carbon fiber parts for vehicle customization and performance upgrades.

?

Technological Advancements

• Enhanced Material Properties: Continuous research should focus on enhancing the strength, stiffness as well as thermal properties of carbon fiber.

• Hybrid Composites: Combining CF with other materials such as Kevlar or aluminum to achieve some specific performance features.

• Smart Materials Integration: Real-time monitoring and diagnostic tools are embedded in carbon fiber components using integrated sensors/ electronics.

Regulatory and Policy Support

• Compliance with Emission Standards: Use of carbon fiber to assist automobile manufacturers achieve stringent global fuel economy standards, emission guidelines etc.

• Incentives for Lightweight Materials: Promoting government incentives and subsidies that encourage use of lightweight materials in the auto industry.

• Safety Regulations: Using CFRP in critical structural components enables them to meet/exceed safety regulations.

Cost Reduction Strategies

• Economies of Scale: Aiming at lowering per unit prices by leveraging cost efficiencies through increased production volumes.

• Supply Chain Optimization: Streamlining the supply chain so as to reduce costs and improve accessibility of carbon fiber (CF).

• Alternative Raw Materials: Cost effective alternative feedstock options for traditional precursors to CFs.

Composite Rebar Market Drivers and Challenges

Carbon fiber in the global automotive composite tank market is pivotal in industries requiring corrosion-resistant storage solutions. Driven by benefits like durability and design flexibility, it faces challenges such as high initial costs and logistical complexities. This discussion explores key drivers propelling its growth and significant challenges hindering broader market adoption.

The key drivers for the composite rebar market include:

1. Weight and Fuel Efficiency: Carbon fiber’s high strength-to-weight ratio resultantly lowers the weight of vehicles, enhancing fuel efficiency as well as minimizing emissions. It is a very important characteristic given that automakers have to grapple with demanding environmental regulations and the market for green cars.

2. Increasing Adoption in Electric Vehicles (EVs): Battery efficiency and vehicle range require lightweight materials in the era of electric vehicles. Weight reduction without compromising structural integrity makes carbon fiber suitable for EV makers seeking both quality performance and sustainability.

3. Technological Advancements in Manufacturing: Over this years, there have been major innovations in manufacturing processes like automated fiber placement (AFP) and 3D printing which have led to lower production costs and increased scalability of carbon fiber components. This has made carbon fiber more readily available thereby putting it at par with the other traditional materials used in the automotive industry.

The challenges in the composite rebar market include:

1. High Production Costs: Despite technological advancements, carbon fiber production is still expensive compared to traditional materials such as aluminum or steel. The price of raw materials is too high while manufacturing consumes lots of energy thereby making these barriers insurmountable especially among price conscious customers.

2. Recycling and End-of-Life Management: Recycling practices are not common with regard to carbon composites due to complexity associated therewith; thus posing environmental problems. In order for these issues on sustainability to be addressed alongside meeting certain legal requirements that are hindering growth as well as acceptance by industry players, recycling methods need to be developed that are efficient but inexpensive.

.

The potential of carbon fiber in improving fuel economy and supporting the electric vehicle revolution, driven by technological advancements, drives the global market for automotive composite. Nevertheless, its widespread application is impeded by high costs of production and difficulties in recycling. In this backdrop however, the industry remains focused on achieving cost efficient and sustainable innovation.

Composite Rebar Suppliers and Their Market Shares

In this globally competitive market, several key players such as FireP International AG, Pultron Composites, and Owens Coring etc, dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report on “Composite Rebar Market Leadership Report".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies composite rebar companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the composite rebar companies profiled in this report include.

• FireP International AG

• Pultron Composites

• Owens Corning

• Schoeck

• Marshall Composite Technology LLC

These companies have established themselves as leaders in the composite rebar market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within composite rebar market are evolving, with the entry of new players and the emergence of innovative composite rebar market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

In this globally competitive market, several key players such as FireP International AG, Pultron Composites, and Owens Coring etc, dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report on “Composite Rebar Market Leadership Report".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies composite rebar companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the composite rebar companies profiled in this report include.

• FireP International AG

• Pultron Composites

• Owens Corning

• Schoeck

• Marshall Composite Technology LLC

These companies have established themselves as leaders in the composite rebar market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within composite rebar market are evolving, with the entry of new players and the emergence of innovative composite rebar market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Composite Rebar Market by Segment

The largest developed markets for these materials are in infrastructure construction, notably bridge works, road construction and water supply work because of their ability to withstand corrosion and longevity. Other niche areas include marine constructions owing to their ability to resist saltwater corrosion as well as industrial sectors where light weight and high strength are required or could be beneficial to certain applications. In addition, demand is growing in the renewable energy industry, particularly wind turbine foundations.

The study includes a forecast for the global composite rebar market by end use, product type, and region as follows:

The largest developed markets for these materials are in infrastructure construction, notably bridge works, road construction and water supply work because of their ability to withstand corrosion and longevity. Other niche areas include marine constructions owing to their ability to resist saltwater corrosion as well as industrial sectors where light weight and high strength are required or could be beneficial to certain applications. In addition, demand is growing in the renewable energy industry, particularly wind turbine foundations.

The study includes a forecast for the global composite rebar market by end use, product type, and region as follows:

By End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]

• Construction

• Electrical Isolation

• Industrial

• Marine

• Others

By Product Type [Value ($M) and Volume (M lbs) Analysis for 2017 – 2028]

• Glass Fiber Reinforced Polymer Rebar (GFRP Rebar)

• Carbon Fiber Reinforced Polymer Rebar (CFRP Rebar)

• Basalt Fiber Reinforced Polymer Rebar (BFRP Rebar

• Glass Fiber Reinforced Polymer Rebar (GFRP Rebar)

• Carbon Fiber Reinforced Polymer Rebar (CFRP Rebar)

• Basalt Fiber Reinforced Polymer Rebar (BFRP Rebar

By Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]

• North America

• Europe

• Asia Pacific

• Rest of the World

• North America

• Europe

• Asia Pacific

• Rest of the World

Features of Composite Rebar Market

• Market Size Estimates: Composite rebar market size estimation in terms of value ($M) and volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by product type, end use, and region

• Regional Analysis: Composite rebar market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different end use, product type, and regions for the composite rebar market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the composite rebar market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in Composite Rebar or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

• Market Size Estimates: Composite rebar market size estimation in terms of value ($M) and volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by product type, end use, and region

• Regional Analysis: Composite rebar market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different end use, product type, and regions for the composite rebar market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the composite rebar market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in Composite Rebar or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the composite rebar market size?

Answer: The global composite rebar market is expected to reach an estimated $156 million by 2030.

Q2. What is the growth forecast for composite rebar market?

Answer: The composite rebar market is expected to grow at a CAGR of 3% 2023 to 2030.

Q3. What are the major drivers influencing the growth of the composite rebar market?

Answer: The major drivers for this market are increase in new transportation construction and growth in commercial and residential construction. Growing acceptance of fiber reinforced plastic (FRP) rebars and initiatives for research and development for FRP rebars are other key drivers for this market.

Q4. What are the major applications or end uses for composite rebar?

Answer: Construction and marine are the major end uses industries for composite rebar.

Q5. What are the emerging trends in composite rebar market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include introduction of nano-sized filler used in the manufacturing of FRP rebars.

Q6. Who are the key composite rebar companies?

Answer: Some of the key composite rebar companies are as follows:

• FireP International AG

• Pultron Composites

• Owens Corning

• Schoeck

• Marshall Composite Technology LLC

Q7. Which composite rebar product segment will be the largest in future?

Answer: Lucintel forecasts that glass fiber reinforced plastic (GFRP) composite rebar will remain the largest segment over the forecast period due to demand in roads, bridges, tunnels, MRI rooms, marine structures, and water fronts.

Q8. In composite rebar market, which region is expected to be the largest in next 5 years?

Answer: North America is expected to remain the largest region and witness the highest growth over next 5 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

Q1. What is the composite rebar market size?

Answer: The global composite rebar market is expected to reach an estimated $156 million by 2030.

Q2. What is the growth forecast for composite rebar market?

Answer: The composite rebar market is expected to grow at a CAGR of 3% 2023 to 2030.

Q3. What are the major drivers influencing the growth of the composite rebar market?

Answer: The major drivers for this market are increase in new transportation construction and growth in commercial and residential construction. Growing acceptance of fiber reinforced plastic (FRP) rebars and initiatives for research and development for FRP rebars are other key drivers for this market.

Q4. What are the major applications or end uses for composite rebar?

Answer: Construction and marine are the major end uses industries for composite rebar.

Q5. What are the emerging trends in composite rebar market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include introduction of nano-sized filler used in the manufacturing of FRP rebars.

Q6. Who are the key composite rebar companies?

Answer: Some of the key composite rebar companies are as follows:

• FireP International AG

• Pultron Composites

• Owens Corning

• Schoeck

• Marshall Composite Technology LLC

Q7. Which composite rebar product segment will be the largest in future?

Answer: Lucintel forecasts that glass fiber reinforced plastic (GFRP) composite rebar will remain the largest segment over the forecast period due to demand in roads, bridges, tunnels, MRI rooms, marine structures, and water fronts.

Q8. In composite rebar market, which region is expected to be the largest in next 5 years?

Answer: North America is expected to remain the largest region and witness the highest growth over next 5 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global composite rebar market by end use (construction, electrical isolation, industrial, marine, and others), product type (glass fiber, carbon fiber, basalt fiber), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?

Q.1 What are some of the most promising potential, high growth opportunities for the global composite rebar market by end use (construction, electrical isolation, industrial, marine, and others), product type (glass fiber, carbon fiber, basalt fiber), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?