Composites Materials in the Global Boating Market Trends and Forecast

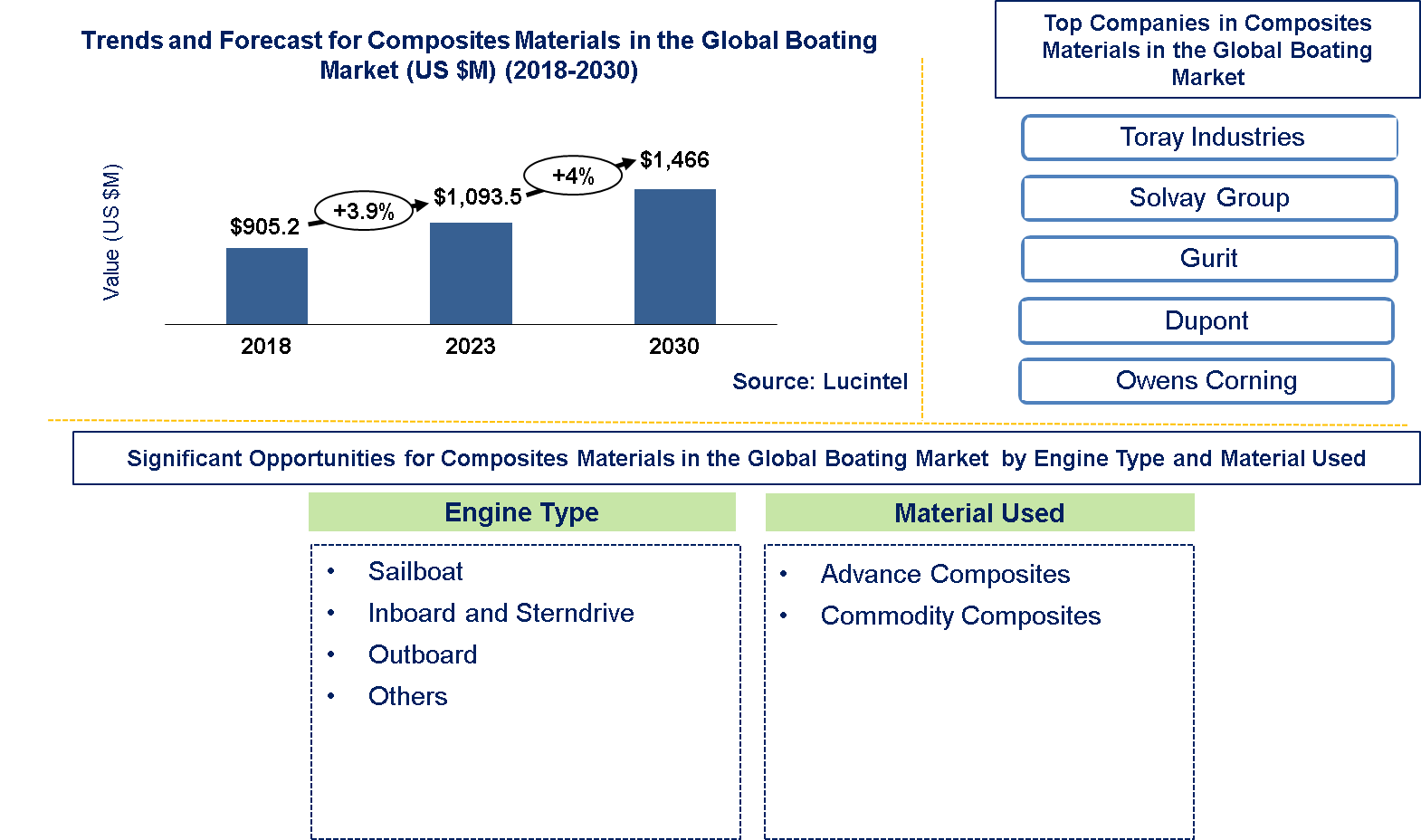

Lucintel finds that the future of the composites materials in the global boating market looks promising with opportunities in sailboard, inboard and strerndrive, outboard and others shoes. The composites materials in the global boating market is expected to reach an estimated $1,466 million by 2030 with a CAGR of 4% from 2023 to 2030. The major growth driver in this market is penetration of composites in the new applications in marine due to its better mechanical properties like corrosion resistance and chemical resistance.

The raw materials needed in the global composites sector are reinforcing fibers like glass, carbon, aramid or natural fibers among others and resin matrices such as epoxy, polyester, vinyl ester, or phenolic to bind them and carry loads. Core materials such as foam or honeycomb structures can also be used as fillers and additives to enhance properties and strength in sandwich composites. Furthermore, release agents play a role in manufacturing efficiency. Composites that withstand corrosion and fatigue while having high strength-to-weight ratio are usually preferred by boating industry because they are lightweight. Even though composite has higher initial costs than fiberglass or aluminum; it is cheaper in terms of long-term maintenance reduced fuel consumption making it favorable for boat manufacturers who value durability and performance above all else.

• Lucintel forecasts that, inboard and sterndrive is expected to be the largest engine type by value and volume and sailboat is expected to witness the highest growth over the forecast period.

• North America is expected to remain the largest region by value and volume and over the forecast period due to increasing retail sale units of the boats in this region. Europe is expected to witness the highest growth over the forecast period.

Country wise Outlook for the Composites Materials in the Global Boating Market

The composites materials in the global boating market are witnessing substantial growth globally. Below image highlights recent developments by major composites materials in the global boating market producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends in the Composites Materials in the Global Boating Market

Emerging trends in the composites materials in the global boating market shaping its future applications and market dynamics:

1. Nano-composites: Nanoparticles included for increased mechanical properties like toughness, and impact resistance but still lightweight.

2. High-Performance Resin Systems: New resin formulations that improve durability, water resistance, and processing ease tailored for marine environments

3. Recycled and Bio-Based Composites: Sustainable boat components made from recycled fiber and bio-based resins with no effect on performance

4. Hybrid Composites: Optimum balance of strength, weight, and cost by combining carbon fiber, glass fiber plus other elements.

5. Smart Composites: Real-time monitoring of structural health and performance in composites using built-in sensors and smart technologies.

6. Enhanced Durability: Superior corrosion resistance; UV radiation resistant as well as marine environment-friendly composite materials to increase vessel lifespan.

7. 3D Printing and Automation: Use of 3D printing integrated with automation to enable manufacturing of complex composite components at higher accuracy with reduced costs.

8. Customization and Design Flexibility: Utilizing advanced composites to offer variety in boat designs to meet different customer tastes/preferences.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Composites Materials in the Global Boating Market

Recent developments in composites materials in the global boating market by various companies highlight ongoing innovations and advancements across different sectors:

• Advanced composites: More use of sophisticated carbon and aramid fibers to increase strength and decrease weight in boat hulls and components.•

• Resin Innovations: Developing stronger and better UV resistant resin systems for longer lasting boats with more aesthetically pleasing finishes.

• Eco-friendly materials: Introduction of bio-based and recyclable composite materials to meet emerging green laws and address consumer preferences for eco-products.

• Improved Manufacturing Techniques: The employment of automated, precise manufacturing processes like resin infusion, prepreg layup among others that boost productivity, improve quality of components.

• Smart Composites: Real-time monitoring of boat performance as well as structural health through the integration sensors together with smart technologies in composites.

Strategic Growth Opportunities for Composites Materials in the Global Boating Market

Construction using Lightweight Materials

• Market Demand: Consumers’ increasing predilection for light weight boats to enhance fuel consumption and performance.

• Opportunity: Composite materials like carbon fiber and fiberglass, unlike wood or metal traditional materials, have a lot of weight savings that increase speed, maneuverability and range.

Durability and Longevity

• Industry Need: Boats require materials that withstand marine environments, including saltwater corrosion and UV exposure.

• Opportunity: Composites offer better durability, impact resistance and therefore extended lifespan of the vessel hence reduces maintenance cost, as an advantage to both recreational boaters as well as commercial boaters.

Design Flexibility and Customization

• Consumer Trend: There is a growing demand for customized boats with unique designs and features.

• Opportunity: Composite materials allow for complex shapes, seamless integration of components, and innovative design options that meet diverse customer preferences thereby boosting market competitiveness.

Innovative Applications and Market Expansion

Emerging Markets: Growth opportunities in developing regions with expanding marine leisure and commercial industries

Opportunity: Penetration into new markets through creation of innovative composite solutions tailored to regional needs and preferences, taking advantage of global distribution networks as well as strategic alliances between the market players.

Composites Materials in the Global Boating Market Drivers and Challenges

Unprecedented performance attributes such as being light, resistant to wear and tear and easy to shape coupled with high versatility are the key factors for composite use in the global sports goods industry. These materials allow makers to create fine sport instruments like tennis rackets, golf clubs and bicycles that help athletes improve their performance. But high cost of materials, complicated manufacturing processes and rigorous quality standards make it difficult. To overcome these hurdles, one must continuously innovate composites through sustainable production methods as well as form strategic alliances aimed at satisfying customer’s changing demands based on market competition and legal obligations.

The key drivers for the composites materials in the global boating market include:

1. Weight Reduction: Compared to traditional materials like steel and aluminum, composite materials such as fiberglass and carbon fiber provide a significant weight reduction. As a result, boats have better fuel economy and enhanced performance.

2. Corrosion Resistance: Composite materials have high resistance to corrosion, which is very important in marine environment. This makes boats last longer and reduces the cost of their maintaining.

3. Design Flexibility: Composites offer extra design flexibility enabling manufacturers to make advanced product forms that are difficult to achieve with other conventional materials.

4. Durability and Strength: The high strength-to-weight ratios of composite materials provide them endurance and the capacity to survive challenging maritime environments.

5. Technological Advancements: Improved resin systems, manufacturing processes among others continue to push the adoption of composites in the boating industry.

6. Environmental Benefits: By reducing consumption of fuel while sailing, composite material helps create an eco-friendly boat. Additionally, there are some composites that are recyclable or made from renewable sources.

7. Cost Efficiency: Composite materials may be expensive initially but can prove cost-effective over time due to lower maintenance costs, improved fuel efficiency and longevity.

The challenges in the composites materials in the global boating Market include:

1. High Initial Cost: The initial cost of composite materials used for their production can be higher than for conventional ones thus acting as a stumbling block for some boat makers/buyers.

2. Complex Manufacturing Process: Manufacturing composite products often involves specialized equipment and labor thereby complicating it and making it more costly too.

3. Repair and Maintenance: Repairs on damage sustained by composites will tend to be harder hence more expensive compared with traditional material repairs since they usually need special techniques together with certain types of material inputs.

4. Environmental Concerns: Disposal of non-recyclable composites has environmental implications. Besides, some of the composites are manufactured using hazardous chemicals.

5. Limited Recycling Options: Recycling composite materials poses a challenge and there are few recycling options available that has raised concerns about their environmental impact when their lifecycle ends.

6. Regulatory and Standards Compliance: Navigating regulatory frameworks and adhering to diverse standards for marine applications can be difficult and time-consuming in relation to composite materials.

7. Market Acceptance: Consumer and industry stakeholders need more awareness about the benefits of composite materials as well as an increased market acceptance despite their advantages.

8. Raw Material Availability: Carbon fiber, specialty resins and other raw materials used for producing composites can become rare or expensive thus affecting total cost and supply chain stability.

Innovation in vessel design and performance is driven by the lightness and resilience of composites, which benefit the global boating market. For instance, material costs and recycling concerns pose a challenge to sustainability and advancements in manufacturing. It is important for these factors to be balanced so as to leverage on the potential impact of composites that can guarantee continued growth and competitiveness in today’s marine industry..

Composites Materials in the Global Boating Suppliers and Their Market Shares

In this globally competitive market, several key players such as Toray Industries, Solvay Group, Gurit, Dupont, and Owens Corning, etc. dominates the market and contributes to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report on “Composites Materials in the Global Boating Market Leadership Report".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies global boating market companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the composites materials in the global boating market companies profiled in this report include.

• Toray Industries Inc.

• Solvay

• Gurit

• Dupont

• Owens Corning

These companies have established themselves as leaders in the global composites materials in the global boating market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations. The market share dynamics within the composites materials in the global boating market are evolving, with the entry of new players and the emergence of innovative composites materials in the global boating market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Composites Materials in the Global Boating Market by Segment

The main parts of composite materials which are growing in the global boating market are high-performance marine vessels especially carbon fiber composites for racing yachts and speed boats that are light and strong. Glass fiber composites have become common in recreational boats like jet skis, sail boats and motor boats due to their durability and low maintenance. While advanced composites are used by commercial and military ships for better performance, fuel efficiency and corrosion resistance. There is a growing demand for eco-friendly boats using bio-based and recyclable composites to comply with environmental regulations as well as buyer preferences. In addition, composites find extensive use in structural components such as hulls, decks, interiors across all boat types to reduce mass and enhance performance.

Global Composites Materials in the Global Boating Market by Engine Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Sailboat

• Inboard and Sterndrive

• Outboard

• Others

Global Composites Materials in the Global Boating Market by Material Used [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Advance Composites

• Commodity Composites

Global Composites Materials in the Global Boating Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Composites Materials in the Global Boating Market

• Market Size Estimates: Composite Materials in the Global Boating market size estimation in terms of value ($M) and volume (M lbs).

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by engine type, material used, and region

• Regional Analysis: Composite materials in the global boating market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different engine type, material used, and regions for the composite materials in the global boating market.

• Strategic Analysis: This includes M&A, and capacity expansion, for the composite material in the global boating market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in boating market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the composite materials in the global boating market size?

Answer: The composite materials in the global boating market is expected to reach an estimated $1,466 million by 2030.

Q2. What is the growth forecast for composite materials in the global boating market?

Answer: The composite materials in the global boating market is expected to grow at a CAGR of 4% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the Composite Materials in the Global Boating Market?

Answer: The major growth driver in this market is penetration of composites in the new applications in marine due to its better mechanical properties like corrosion resistance and chemical resistance.

Q4. What are the major engine type industries for Composite Materials in the Global Boating Market?

Answer:inboard and sterndrive and outboard are the major engine type composite materials in the global boating market.

Q5. What are the emerging trends in Composite Materials in the Global Boating Market?

Answer: Emerging trends, which have a direct impact on the dynamics of the composite materials in the global boating market, include the nano composites, high performance resin system, recycled and bio-based composites, hybrid composites, and smart composites.

Q6. Who are the key Composite Materials in the Global Boating Market companies?

Answer: Some of the key composite materials in the global boating market companies are as follows:

• Toray Industries Inc.

• Solvay

• Gurit

• DuPont

• Hexion

• Owens Corning

Q7.Which composite materials in the global boating market engine type segment will be the largest in future?

Answer: Lucintel forecasts that, inboard and sterndrive is expected to be the largest engine type by value and volume due to the increase in consumers disposable income and maintaining lifestyle of the consumers.

Q8: In composite materials in the global boating market, which region is expected to be the largest in next 7 years?

Answer: North America is expected to remain the largest region over next 7 years.

Q9. Do we receive customization in this report?

Answer:Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the composite material in the global boating market by engine type (sailboat, inboard and sterndrive, and others), material used (advance composites and commodity composites), and region (North America, Europe, Asia Pacific, and Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?