The Impact of COVID-19 is included in Composite Cylinder Market. Buy it today to get an advantage.

Request the impact of COVID-19 on your product or industry

Composite Cylinder Market Trends and Forecast

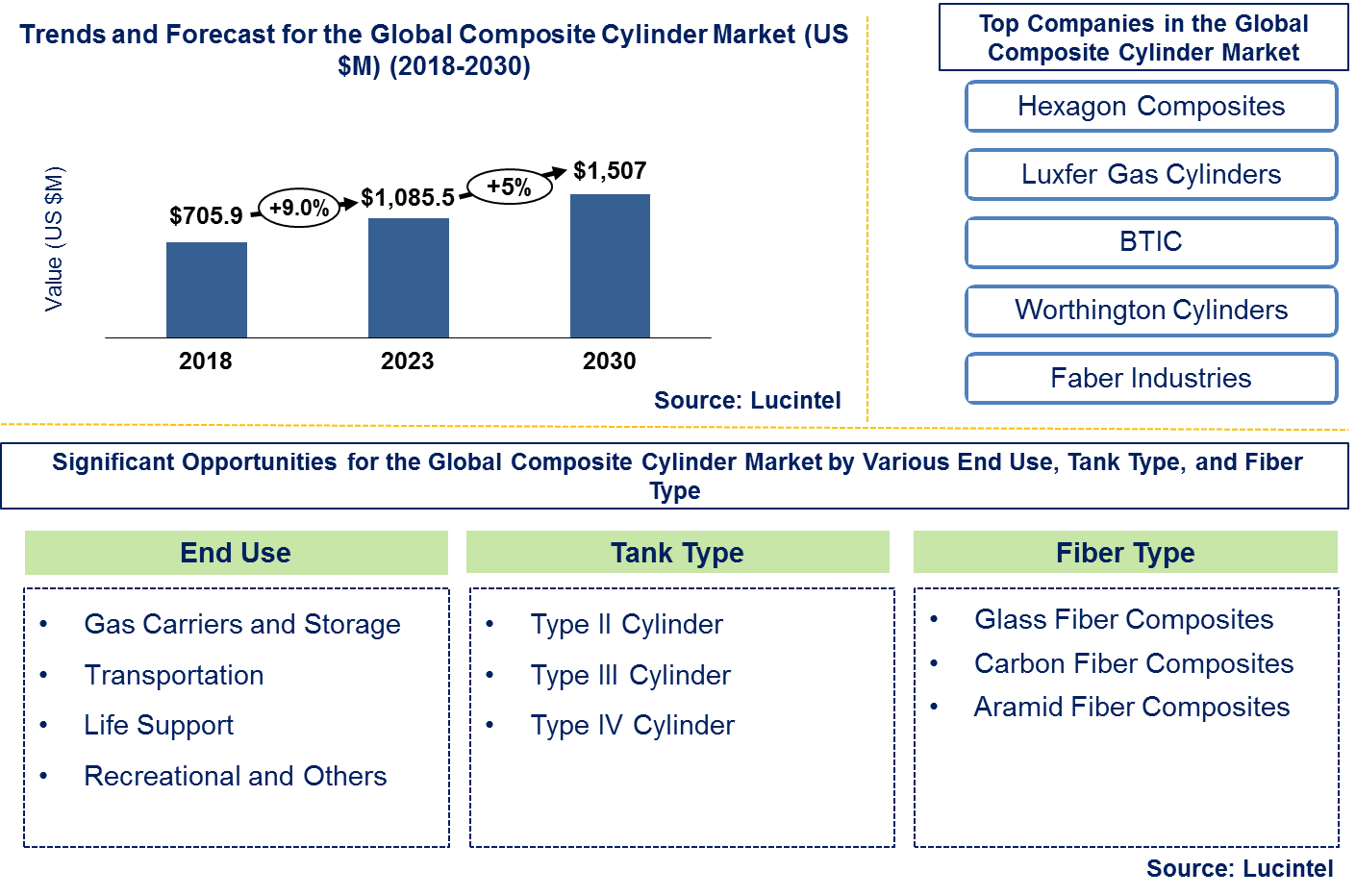

Lucintel finds that the future of global composites product such as type II, type III and type IV cylinder market looks promising with opportunities in gas carriers & storage, transportation, life support, and recreation industries. The global composites cylinder market is expected to reach an estimated $1,507 million by 2030 with a CAGR of 5% from 2023 to 2030. The major drivers for market growth are increasing number of natural gas vehicles (NGVs) and growing demand for lightweight cylinders with higher pressure requirement and greater gas carrying capacity per cylinder. Emerging trends which have a direct impact on the dynamics of the industry include the increase in green fleet and development of type V tanks.

Carbon, glass, and aramid fibers are combined with epoxy, polyester or vinyl ester resins to make composite cylinders which are lightweight and have high strength. These materials have been engineered to improve the mechanical properties of such a flame retardant or gloss improver. Composite cylinders outperform steel ones in terms of weight reduction, better corrosion resistance and increased safety despite their costliness. Over time, these initial costs can be offset by savings in transportation, handling and maintenance allowing them to compete where performance and durability count. The market for this product is changing as it moves towards advanced materials and processes that emphasize safety above all else in various applications ranging from aerospace to automotive and industrial sectors.

-

Lucintel forecasts that the gas carriers & storage is expected to remain the largest market by value and also expected to grow with the highest CAGR during the forecast period.

-

Within the global composite cylinder market, the carbon fiber composites segment is expected to remain the largest market by value.

-

Europe is expected to remain the largest market for composite cylinder due to the higher acceptance level and increasing use of lightweight cylinders.

Country wise Outlook for the Composite Cylinder Market

The composite cylinder market is witnessing substantial growth globally, driven by increased demand from various industries such as gas carriers and storage, transportation, life support, and recreational. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major composite cylinders producers in key regions: the USA, Germany, China, India, and Brazil.

Emerging Trends in the Composite Cylinder Market

Emerging trends in the composite cylinder market shaping its future applications and market dynamics:

-

Nano-Enhanced Composites: Combining of nanomaterials such as carbon nanotubes and graphene to improve mechanical and barrier properties, resulting in stronger materials with less gas permeability.

-

Intelligent Composite Cylinders: incorporation of sensors for real time pressure, temperature, structural integrity monitoring which help in improving safety as well as maintenance efficacy.

-

Additive Manufacturing (3D Printing): Innovations in the method of adding material to a forming structure so as to produce complex shapes and custom composites reducing time required and materials wasted.

-

Advanced Resin Systems: innovation of fresh resin formulations with better characteristics like increased strength, toughness and resistance to environmental factors.

-

Hybrid Composites: Mixing different kinds of fibers (e.g. glass and carbon) to get the desired features like cost effectiveness and optimal strength-to-weight ratio which require different types of fibers

-

LP Gas Composite Cylinders: Substituting traditional metallic cylinders with light weight composite ones for Liquefied Petroleum Gas (LPG) storage that are safer, last longer, can be handled easily.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Composite Cylinder Market

Recent developments in composite cylinder market by various companies highlight ongoing innovations and advancements across different sectors:

-

Increased Adoption in Automotive: Owing to the requirements for weight reduction and stringent regulations of emissions, the use of composite cylinders in automobiles for CNG compressed natural gas and the hydrogen fuel storage is accelerating.

-

Advancements in Material Science: Strength, resistance to corrosion, and durability can be improved by research and development on new resin formulations as well as fiber reinforcements.

-

Safety Standards and Certifications: In order to comply with industry regulations, such as ensuring reliability of composites cylinders, there has been development of very strict safety standards and certifications.

-

Expansion in Renewable Energy: Support for sustainable energy solutions through an increased demand for composite cylinders used in hydrogen storage fuel cells and biogas storage.

Strategic Growth Opportunities for Composite Cylinder Market

The composite cylinder market is very dynamic due to its unique properties of being lightweight, strong and thermally stable. Some key strategic growth opportunities for this market include:

Increased Uptake in Automotive Field

-

Market Demand: The increasing demand for fuel storage solutions that are lightweight and strong.

-

Opportunity: Lightweight cylinders, which also offer safety enhancements, work with alternative fuels such as natural gas and hydrogen.

Expanding into Aerospace Applications

-

Critical Requirements: Composite cylinders are used for aircraft oxygen storage and auxiliary power units (APUs).

-

Opportunity: Increasing air traffic requires the use of light weight corrosion resistant cylinders that improve fuel efficiency and operational safety.

Entry into Industrial Gas Storage:

-

Market Segment: The composite cylinder deals with industrial gases storage and transportation.

-

Opportunity: As a result of being corrosion resistance with high pressure capabilities, they are increasingly being used in manufacturing, healthcare, and specialty gases.

Use in Medical Applications:

Industry Trends: Composite cylinders are essential for medical oxygen and portable oxygen concentrators.

-

Opportunity: Expansion of healthcare infrastructure necessitates lightweight portable cylinders to enhance patient mobility and safety.

Emerging Market in Energy Storage:

-

Integration of Renewable Energy Sources: Compressed Natural Gas (CNG) & Hydrogen by composite Cylinders as an Energy Storage Solution

-

Opportunity: For the purpose of sustainable energy storage and distribution; there is therefore a need for efficient lightweight cylinder expansion driven by renewable energy sources shift.

Composite Cylinder Market Driver and Challenges

The growth of the market for composite cylinders is driven by the need for lighter and stronger alternatives to conventional metal cylinders in different industries. As a motivator, corrosion resistant improved safety and compatibility with various types of gases and liquids are some benefits that composite cylinders offer. Nevertheless, there are setbacks such as high costs of materials used in making composites, very strict regulations on safety and performance standard and customer perceptions about its durability and reliability in a long run. To counter these obstacles, innovative materials, manufacturing techniques as well as full compliance with strict industrial norms have to be employed so that changing client needs can be met leading to a prevalence of composite cylinders throughout the world.

The factors responsible for driving the composite cylinder market include:

1. Weight Reduction Demands: Composite gas cylinder offers notable difference in weight as compared to common metal cylinders hence they are suitable for use in vehicles, aircrafts and portable gases.

2. Corrosion Resistance: More excellent protection from decay by the composites increases the life of the cylinder, lowers maintenance prices, and ensures safety of industrial and medical distributions of gases.

3. Safety and Durability Requirements: Composites make it possible for the cylinders to conform to strict safety standards thus ensuring high reliability at elevated pressure required in fire fighting, medical oxygen and industrial gases.

4. Compatibility with Alternative Fuels: The rising popularity of alternative fuels such as CNG and hydrogen has contributed towards a heightened demand for lightweight and durable composite cylinders within the transportation industry.

Challenges in the Composite Cylinder Market:

1. High Initial Costs: Putting money into the manufacture of composite materials and manufacturing processes may sometimes be more expensive as compared to traditional cylinders, thus lowering their acceptance especially in cost-focused markets.

2. Regulatory Compliance: Satisfying strict regulatory demands for security, performance capability and material accreditation poses challenges in international markets that affect entry into the market and growth thereof.

3. Consumer Perception and Acceptance: Doubts about longevity, predictability, and public opinion regarding composites versus traditional metals can impede adoption across some applications.

4. Manufacturing Complexity: Elaborate procedures involved in making composite cylinders along with quality control benchmarks necessitate specific skill set and facilities that impact production scalability and costs.

To conquer difficulties and use the whole possible potential of composite cylinders, innovation is vital. Market acceptance will be driven by advances in material science, manufacturing practices and regulatory compliance thus expanding application horizons. Addressing consumer perceptions through education on composite cylinders and showing long term benefits will be vital for industry growth as well as ensuring sustained adoption in diverse sectors globally.

Composite Cylinder Suppliers and Their Market Shares

In this globally competitive market, several key players such as Hexagon Composites, Luxfer Gas Cylinders, BTIC, Worthington Cylinders, and Faber Industries. etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at helpdesk@lucintel.com. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report on “Composite Cylinder Market Leadership Report".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies composite cylinder companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the composite cylinders companies profiled in this report include.

These companies have established themselves as leaders in the global composite cylinder market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the composite cylinder market are evolving, with the entry of new players and the emergence of innovative composite cylinder market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities

Composite Cylinder Market by Segment

In the global market, industries like automotive (related to lightweight cylinders for fuel efficiency and EV applications) are key growth areas. Other sectors include renewable energy (such as hydrogen storage for fuel cells and renewables), which is leaned on lightness and high pressure capabilities. Composite cylinders are more preferred by industrial gases because of their resistance to corrosion. In medical fields we need cylinders for clean portable gas storage in healthcare facilities. The aerospace and defense also rely heavily on lightweight composite cylinders that meet strict security protocols as well as being used in aircraft oxygen and defense applications. These sectors epitomize how the industry needs advanced materials/technologies that would be efficient, safe and sustainable.

Composite Cylinder Market by End Use [Volume (Thousand Units) and Value ($ Million) Analysis from 2018 to 2030]:

-

Gas Carriers and Storage

-

Transportation

-

Life Support

-

Recreation and Others

Composite Cylinder Market By Tank Type [Volume (Thousand Units) and Value ($ Million) Analysis from 2018 to 2030]:

Composite Consumption By Fiber Type [Volume (Million lbs) and Value ($ Million) Analysis from 2018 to 2030]:

-

Glass Fiber Composites

-

Carbon Fiber Composites

-

Aramid Fiber Composites

Composite Cylinder Market By Region [Volume (Thousand Units) and Value ($ Million) Analysis from 2018 to 2030]:

-

North America

-

Europe

-

Rest of the World

Features of Composite Cylinder Market

-

Market size estimates: Global composite cylinder market size estimation in terms of value ($M) and volume (Thousand Units) shipment.

-

Trend and forecast analysis: Market trend (2018-2023) and forecast (2024-2030) by segments and region.

-

Segmentation analysis: Global composite cylinder market size by various segments such as end use, tank type, fiber type, and region.

-

Regional Analysis: Composite cylinder market breakdown by North America, Europe, and the Rest of the World.

-

Growth opportunities: Analysis on growth opportunities in different end use, tank type, fiber type, and region for the composite cylinder market.

-

Strategic analysis: This includes M&A, new product development, competitive landscape, and expansion strategies of composite cylinder in the global composite cylinder market suppliers.

-

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in carbon fiber or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the composite cylinder market size?

Answer:The global composite cylinder market is expected to reach an estimated $1,507 million by 2030.

Q2. What is the growth forecast for composite cylinder market?

Answer:The composite cylinder market is expected to grow at a CAGR of 5% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the composite cylinder market?

Answer: The major drivers for market growth are increasing number of natural gas vehicles (NGVs) and growing demand for lightweight cylinders with higher pressure requirement and greater gas carrying capacity per cylinder.

Q4. What are the major applications or end use industries for composite cylinder?

Answer: Gas carriers and storage and transportation are the major end uses for composite cylinder.

Q5. What are the emerging trends in composite cylinder market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, includes nano-enhanced Composites, intelligent composite cylinders, development of 3D printing, advanced resins systems, and hybrid composites.

Q6. Who are the key composite cylinder companies?

Answer: Some of the key composite cylinder companies are as follows:

-

Luxfer Gas Cylinder

-

Hexagon Composites ASA

-

Quantum Technologies

-

Worthington Cylinders

-

Time Technoplast,

-

Faber Industries S.p.A.,

-

Beijing Tianhai Industry Co.,

-

Ullit

Q7.Which composite cylinder type segment will be the largest in future?

Answer: Lucintel forecasts that type-IV cylinder will remain the largest segment and also expected to witness the highest growth over the forecast period.

Q8: In composite cylinder market, which region is expected to be the largest in next 7 years?

Answer: Europe is expected to remain the largest region and ROW is expected to witness the highest growth over next 7 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report addresses the following 11 questions:

Q.1. What are some of the most promising, high-growth opportunities for global composite cylinder market by end use (gas carriers and storage, transportation, life support, recreation and others), tank type (Type II, Type III, Type IV), composite consumption by fiber type (Glass Fiber Composites, Carbon Fiber Composites and Aramid Fiber Composites), and region (North America, Europe, and the Rest of the World (ROW)?

Q.2. Which products segments will grow at a faster pace and why?

Q.3. Which region will grow at a faster pace and why?

Q.4. What are the key factors affecting market dynamics? What are the drivers, challenges, and business risks in composite cylinder market?

Q.5. What are the business risks and competitive threats in this market?

Q.6. What are emerging trends in this market and the reasons behind them?

Q.7. What are some of the changing demands of customers in composite cylinder market?

Q.8. What are the new developments in the market and which companies are leading these developments?

Q.9. Who are the major players in this market? What strategic initiatives are being taken by key companies for business growth?

Q.10. What are some of the competing products in this market and how big of a threat do they pose for loss of market share by product substitution?

Q.11. What M&A activity has occurred in the last 5 years?

Table of Contents

1. Executive Summary

2. Market Background and Classifications

2.1: Introduction, Background, and Classifications

2.2: Supply Chain

2.3: Industry Drivers and Challenges

3. Market Trends and Forecast Analysis from 2018 to 2030

3.1: Macroeconomic Trends and Forecast

3.2: Global Composite Cylinder Market Trends and Forecast

3.3: Global Composite Cylinder Market by End Use

3.3.1: Gas Carriers and Storage

3.3.2: Transportation

3.3.3: Life Support

3.3.4: Recreation and Other

3.4: Global Composite Cylinder Market by Tank Type

3.4.1: Type II

3.4.2: Type III

3.4.3: Type IV

3.5: Composite Consumption in the Global Composite Cylinder Market by Fiber Type

3.5.1: Glass Fiber Composites

3.5.2: Carbon Fiber Composites

3.5.3: Aramid Fiber Composites

4. Market Trends and Forecast Analysis by Region

4.1: Global Composite Cylinder Market by Region

4.2: North American Composite Cylinder Market

4.3: European Composite Cylinder Market

4.4: Rest of the World Composite Cylinder Market

5. Competitor Analysis

5.1: Product Portfolio Analysis

5.2: Market Share Analysis

5.3: Operational Integration

5.4: Geographical Reach

5.5: Porter’s Five Forces Analysis

6. Growth Opportunities and Strategic Analysis

6.1: Growth Opportunity Analysis

6.1.1: Growth Opportunities for the Global Composite Cylinder Market by End Use

6.1.2: Growth Opportunities for the Global Composite Cylinder Market by Tank Type

6.1.3: Growth Opportunities for the Composite Consumption in the Global Composite Cylinder Market by Fiber Type

6.1.4: Growth Opportunities for the Global Composite Cylinder Market by Region

6.2: Emerging Trends in the Global Composite Cylinder Market

6.3: Strategic Analysis

6.3.1: New Product Development

6.3.2: Capacity Expansion of the Global Composite Cylinder Market

6.3.3: Mergers, Acquisitions and Joint Ventures in the Global Composite Cylinder Market

6.3.4: Certification and Licensing

7. Company Profiles of Leading Players

7.1: Luxfer Gas Cylinder

7.2: Hexagon Composites ASA

7.3: Quantum Technologies

7.4: Worthington Cylinders

7.5: Drägerwerk AG & Co. KGaA

7.6: Time Technoplast

7.7: Faber Industrie S.p.A.

7.8: Beijing Tianhai Industry Co.

7.9: Ullit.

Buy full report or by chapter as follows

Lucintel has been in the business of market research and management consulting since 2000 and has published over 1000 market intelligence reports in various markets / applications and served over 1,000 clients worldwide. This study is a culmination of four months of full-time effort performed by Lucintel's analyst team. The analysts used the following sources for the creation and completion of this valuable report:

-

In-depth interviews of the major players in this market

-

Detailed secondary research from competitors’ financial statements and published data

-

Extensive searches of published works, market, and database information pertaining to industry news, company press releases, and customer intentions

-

A compilation of the experiences, judgments, and insights of Lucintel’s professionals, who have analyzed and tracked this market over the years.

Extensive research and interviews are conducted across the supply chain of this market to estimate market share, market size, trends, drivers, challenges, and forecasts. Below is a brief summary of the primary interviews that were conducted by job function for this report.

Thus, Lucintel compiles vast amounts of data from numerous sources, validates the integrity of that data, and performs a comprehensive analysis. Lucintel then organizes the data, its findings, and insights into a concise report designed to support the strategic decision-making process. The figure below is a graphical representation of Lucintel’s research process.

Please sign in below to get report brochure - Composite Cylinder Market.