Coatings in the Aerospace Market Trends and Forecast

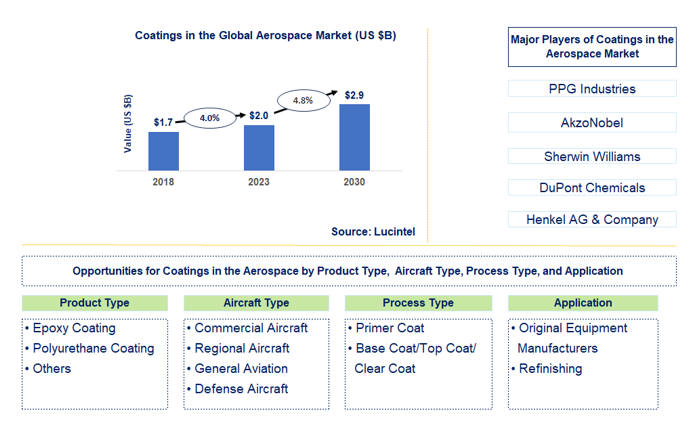

The future of the coatings in the global aerospace market looks promising with opportunities in the original equipment manufacturer and refinishing markets. The coatings in the global aerospace market is expected to reach an estimated $2.9 billion by 2030 with a CAGR of 4.8% from 2024 to 2030. The major drivers for this market are increasing production of commercial and military aircraft, along with the expansion of existing fleets, growing emphasis on improving fuel efficiency and reducing the environmental impact of aircraft operations, and innovations in aerospace coating technologies.

The raw materials that are used include specialized polymers like epoxy resins and polyurethanes, pigments (for colour and protection from UV), solvents (for viscosity control), additives such as anti-corrosive agents and flame retardants for durability and adhesion, while in some cases nanoparticles are used to enhance certain properties of the coating like scratch resistance or thermal management. These ingredients are subject to severe evaluation and approval so as to meet the performance, endurance and safety requirements in aerospace. the price comparison of aerospace coatings differs depending on factors like application complexity, performance requirements, regulatory compliance among others. On average, aerospace coatings have higher prices than general industrial ones due to their specific formulations, strict quality control measures as well as meeting the aviation industry standards including certification by relevant bodies. Technological advancements economy of scale and level of customization sought after for particular aircraft models also affect the price competitiveness.

• Lucintel forecasts that epoxy coating is expected to witness higher growth over the forecast period.

• Within this market, original equipment manufacturer is expected to witness the higher growth.

The raw materials that are used include specialized polymers like epoxy resins and polyurethanes, pigments (for colour and protection from UV), solvents (for viscosity control), additives such as anti-corrosive agents and flame retardants for durability and adhesion, while in some cases nanoparticles are used to enhance certain properties of the coating like scratch resistance or thermal management. These ingredients are subject to severe evaluation and approval so as to meet the performance, endurance and safety requirements in aerospace. the price comparison of aerospace coatings differs depending on factors like application complexity, performance requirements, regulatory compliance among others. On average, aerospace coatings have higher prices than general industrial ones due to their specific formulations, strict quality control measures as well as meeting the aviation industry standards including certification by relevant bodies. Technological advancements economy of scale and level of customization sought after for particular aircraft models also affect the price competitiveness.

• Lucintel forecasts that epoxy coating is expected to witness higher growth over the forecast period.

• Within this market, original equipment manufacturer is expected to witness the higher growth.

Country Wise Outlook for Coatings in the Aerospace Market

Coatings in aerospace market is witnessing substantial growth globally, driven by increasing demand for coatings that provide effective corrosion resistance. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major coatings in aerospace producers in key regions: the USA, UK, China, India, and Brazil.

Emerging Trends for Coatings in the Aerospace Market

• Advanced Materials and Nanotechnology: Coatings are made with nanomaterials to enhance durability, scratch resistance, and corrosion protection while lightening the weight of an object and ensuring good fuel economy.

• Environmentally Friendly Coatings: Coatings that have few VOC emissions and are made from sustainable raw materials will be designed to meet stricter environmental regulations. Again, these coatings will help achieve sustainability goals.

• Smart Coatings: Applications for such coatings include self-repairing functionalities, anti-icing capabilities as well as sensors for real-time monitoring of both structural or environmental conditions.

• High-Performance Functional Coatings: Demand for guards against corrosion as well as wear but also have extra features like thermal control, electromagnetic shielding among others which make an object move more efficiently through a fluid medium.

• Digitalization and Industry 4.0: To enhance efficiency, reduce wastage and ensure uniformity in performance across aerospace manufacturing and maintenance operations, digital technologies can be used in application, monitoring and quality control stages of coating processes.

A more than 150-page report is developed to help in your business decisions. Sample figures with some insights are shown below.

Recent Development in Coatings in the Aerospace Market

• AkzoNobel Aerospace Coatings: Developed a new generation of eco-friendly coatings that offer improved durability and reduced environmental impact, meeting stringent aerospace industry regulations.

• PPG Industries: Introduced a specialized series of coatings designed to enhance the fuel efficiency of aircraft by reducing drag through improved surface smoothness and aerodynamics.

• Sherwin-Williams Aerospace Coatings: Launched a high-performance coating system that provides exceptional corrosion resistance and durability for both commercial and military aircraft, extending maintenance intervals and lifecycle.

• Henkel: Collaborated with aerospace manufacturers to develop advanced composite surface treatments and coatings that enhance bonding strength and structural integrity, crucial for lightweight aircraft designs.

Strategic Growth Opportunities for Coatings in the Aerospace Market

Some key strategic growth opportunities for this market include:

Advanced Performance Coatings: This involves development of coatings with improved qualities as light materials, high durability, extreme temperature resistance and also corrosion and erosion protection which is very important in aerospace applications.

Expansion in Maintenance, Repair, and Overhaul (MRO): It calls for offering coatings for aircraft maintenance and refurbishment to address the necessity of a durable protective solution that can last long.

Innovations in Functional Coatings: The aim is at developing functional coatings with specific capabilities such as anti-icing, anti-static, self-healing properties among others to enhance operational efficiency and safety in aerospace operations.

Adoption of Sustainable Coatings: These include eco-friendly coatings that produce minimal harmful effects on the environment while adhering to strict standards focusing on bio-based materials & low-VOC formulations.

Collaboration and Partnerships: Forging strategic alliances with aerospace manufacturers, research institutions or regulatory authorities; this enables us to innovate more quickly; it helps meet industry’s requirements; it assists to penetrate markets expeditiously.

These are the strategic growth opportunities that show how much differentiation can be achieved in the field of advanced coatings technology within the aerospace sector by specifically addressing challenges faced within an industry as well as ensuring performance needs are met through tight regulation.

Coatings in the Aerospace Market Driver and Challenges

Performance Enhancement: Coatings boost aircraft performance by reducing drag, improving aerodynamics and guarding against elements such as corrosiveness and abrasedion.

Regulatory Compliance: There are strict regulations put in place that require coating to be used in order to meet safety requirements, environmental demands as well as durability specifications for aerospace use.

Maintenance and Lifecycle Management: By preventing wear and degradation, coatings extend the life of aircraft components also reduces maintenance downtime while lowering operational costs.

Technological Advancements: For example smart coatings, advancement of coating technologies like nanocoating has improved functionality by enabling self-healing properties besides anti-icing capabilities among others.

Environmental Sustainability: The move towards using eco-friendly coatings that limit volatile organic compound (VOC) emissions and decrease environmental footprint fits well with the sustainable aviation priorities.

Challenges in coatings in aerospace market are:

Cost and Complexity: This is due to the requirement for high-performance materials as well as complex application processes which makes developing and applying specialized aerospace coatings costly endeavors.

Durability and Performance: Maintaining their effectiveness under extreme conditions including temperature variations, UV exposure or high altitude environments poses a number of technical challenges for coatings operating on aerospace platforms.

Regulatory Compliance: The need for continuous adherence to evolving standards makes it complicated; difficult and involving more so when dealing with safety measures, environmental impact issues or durability aspects that must meet stringent regulatory requirements.

Technological Barriers: However significant research & development investment is required before advancing new types of these products having advanced characteristics such as weight reduction, multi-functionality among others.

Coatings in the Aerospace Suppliers and Their Market Shares

In this globally competitive market, several key players such as TPPG Industries, AkzoNobel, Sherwin Williams, DuPont Chemicals Company, Henkel AG & Company, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players contact us. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies coatings in the aerospace companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of coatings in the aerospace companies profiled in this report include-

• PPG Industries

• AkzoNobel

• Sherwin Williams

• DuPont Chemicals Company

• Henkel AG & Company

These companies have established themselves as leaders in the coatings in the aerospace industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the coatings in the aerospace market are evolving, with the entry of new players and the emergence of innovative coatings in the aerospace technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Coatings in the Aerospace Market by Segment

Coatings in the aerospace industry comprise significant segments that are growing, among them being eco-friendly coatings meant to adhere to strict environmental requirements and at the same time be able to resist corrosions and wear. At the same time, there is a growing market niche for specialized military and defense coatings which are propelled by global rise in defense allocation as well as the demand for coating civil aviation planes that have stealth features capable of resisting harsh environmental conditions. Equally important is an increase in smart coatings with features such as self-repairing properties, anti-icing characteristics and real-time monitoring sensors hence improving aircraft efficiency and safety. Lastly, commercial aircraft interior coatings have grown so as to enhance comfort levels of passengers while increasing airplane aesthetics due to more demands being made on customization of passenger’s experiences in air transport. These segments demonstrate various opportunities available within the sector of coating manufacturing aimed at promoting innovation and responding to emerging needs within the aviation sector.

Coatings in the Aerospace Market by Product Type [Value from 2018 to 2030]:

• Epoxy Coating

• Polyurethane Coating

• Others

Coatings in the Aerospace Market by Aircraft Type [Value from 2018 to 2030]:

• Commercial Aircraft

• Regional Aircraft

• General Aviation

• Defense Aircraft

Coatings in the Aerospace Market by Process Type [Value from 2018 to 2030]:

• Primer Coat

• Base Coat/Top Coat/Clear Coat

Coatings in the Aerospace Market by Application [Value from 2018 to 2030]:

• Original Equipment Manufacturers

• Refinishing

Coatings in the Aerospace Market by Region [Value from 2018 to 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Coatings in the Global Aerospace Market

Market Size Estimates: Coatings in the aerospace market size estimation in terms of value ($B).

Trend and Forecast Analysis: Market trends (2018 to 2023) and forecast (2024 to 2030) by various segments and regions.

Segmentation Analysis: Coatings in the aerospace market size by various segments, such as product type, aircraft type, process type, application, and region in terms of value ($B).

Regional Analysis: Coatings in the aerospace market breakdown by North America, Europe, Asia Pacific, and Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different product types, aircraft types, process types, applications, and regions for coatings in the aerospace market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape of coatings in the aerospace market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in carbon fiber or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the coatings in the aerospace market size?

Answer: The global coatings in the aerospace market is expected to reach an estimated $2.9 billion by 2030.

Q2. What is the growth forecast for coatings in the aerospace market?

Answer: The global coatings in the aerospace market is expected to grow with a CAGR of 4.8% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the coatings in the aerospace market?

Answer: The major drivers for this market are increasing production of commercial and military aircraft, along with the expansion of existing fleets, growing emphasis on improving fuel efficiency and reducing the environmental impact of aircraft operations, and innovations in aerospace coating technologies.

Q4. What are the major segments for coatings in the aerospace market?

Answer: The future of the coatings in the aerospace market looks promising with opportunities in the original equipment manufacturer and refinishing markets.

Q5. Who are the key coatings in the aerospace market companies?

Answer: Some of the key coatings in the aerospace companies are as follows:

• PPG Industries

• AkzoNobel

• Sherwin Williams

• DuPont Chemicals Company

• Henkel AG & Company

Q6. Which coatings in the aerospace market segment will be the largest in future?

Answer: Lucintel forecasts that epoxy coating is expected to witness higher growth over the forecast period.

Q7. In coatings in the aerospace market, which region is expected to be the largest in next 5 years?

Answer: North America is expected to witness the highest growth over the forecast period.

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% customization without any additional cost.

This report answers following 11 key questions:

Q.1. What are some of the most promising, high-growth opportunities for coatings in the aerospace market by product type (epoxy coating, polyurethane coating, and others), aircraft type (commercial aircraft, regional aircraft, general aviation, and defense aircraft), process type (primer coat and base coat/top coat/clear coat), application (original equipment manufacturers and refinishing), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which segments will grow at a faster pace and why?

Q.3. Which region will grow at a faster pace and why?

Q.4. What are the key factors affecting market dynamics? What are the key challenges and business risks in this market?

Q.5. What are the business risks and competitive threats in this market?

Q.6. What are the emerging trends in this market and the reasons behind them?

Q.7. What are some of the changing demands of customers in the market?

Q.8. What are the new developments in the market? Which companies are leading these developments?

Q.9. Who are the major players in this market? What strategic initiatives are key players pursuing for business growth?

Q.10. What are some of the competing products in this market and how big of a threat do they pose for loss of market share by material or product substitution?

Q.11. What M&A activity has occurred in the last 5 years and what has its impact been on the industry?

For any questions related to Coatings in the Aerospace Market Market, Coatings in the Aerospace Market Market Size, Coatings in the Aerospace Market Market Growth, Coatings in the Aerospace Market Market Analysis, Coatings in the Aerospace Market Market Report, Coatings in the Aerospace Market Market Share, Coatings in the Aerospace Market Market Trends, Coatings in the Aerospace Market Market Forecast, Coatings in the Aerospace Market Companies, write Lucintel analyst at email: helpdesk@lucintel.com. We will be glad to get back to you soon.