Carbon Fiber Reinforced Plastic Market Trends and Forecast

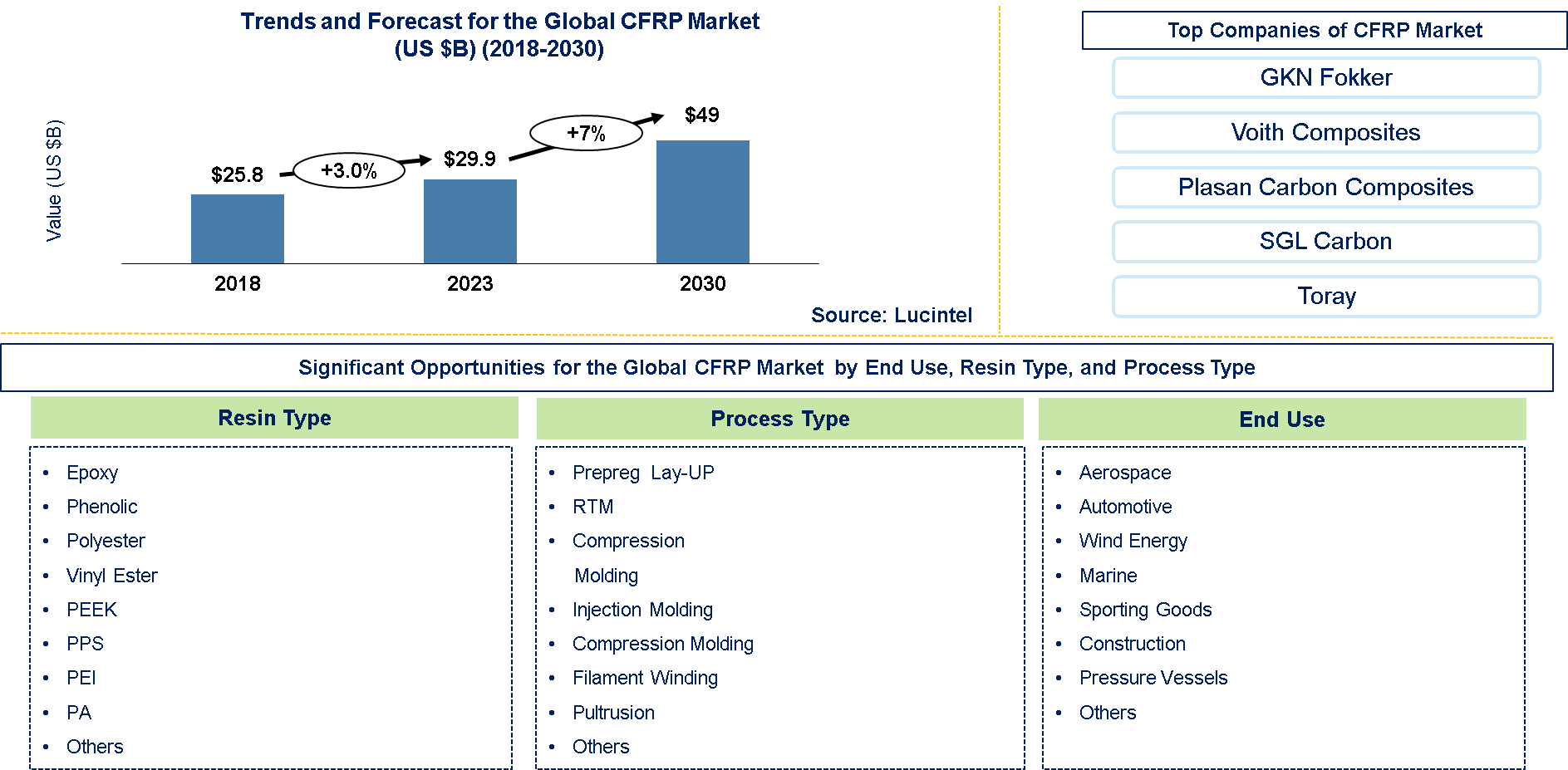

The future of the global carbon fiber reinforced plastic product market looks promising with opportunities in the aerospace, automotive, wind energy, marine, sporting goods, construction, and pressure vessel. The global carbon fiber reinforced plastic market is expected to reach an estimated $49 billion by 2030 with a CAGR of 7% from 2023 to 2030. The major drivers for this market are growing demand for high performance and lightweight composite materials and increasing performance requirements in the various end use industries.

A mixture of carbon fibers and a polymer resin matrix is used in production of carbon fiber reinforced plastics (CFRPs). The fiber-forming polymer precursors, generally PAN or pitch, offer high modulus and tensile strength. The fibers are usually bonded together by a thermosetting polymer (epoxy, polyester or vinyl ester resins) which also distributes the applied load. Furthermore, specific properties of the resultant composite can be heightened by incorporating other constituents and fillers. Due to its greater strength-to-weight ratio, durability and performance, carbon fiber reinforced plastic (CFRP) is generally more costly than other competing materials namely; fiberglass, aluminum and steel. Despite CFRP having a huge advantage in weight reduction and fuel economy, the high costs of producing them makes it a luxury option for industries e.g. aerospace and automotive that prioritize performance over cost considerations.

• Lucintel forecasts that aerospace will remain the largest end use segment over the forecast period due to superior strength-to-weight ratio and increasing demand for composites in the production of aircraft components, such as floor beams, ailerons, vertical stabilizers, elevators, wings, and engine nacelles.

• Epoxy based carbon fiber reinforced plastic will remain the largest segment over the forecast period due to its better chemical and mechanical properties.

• North America is expected to remain the largest region and witness the highest growth over the forecast period due to the growth in aerospace market and increasing use of composite material in aerospace market because of its excellent mechanical properties.

Country wise Outlook for the Carbon Fiber Reinforced Plastic Market

The Carbon Fiber Reinforced Plastic market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major Carbon Fiber Reinforced Plastic producers in key regions: the USA, Germany, China, Japan, France, and Brazil.

Emerging Trends in the Carbon Fiber Reinforced Plastic Market

Emerging trends in the Carbon Fiber Reinforced Plastic Market shaping its future applications and market dynamics:

• Increasing use in Automation Manufacturing: As companies increasingly adopt automated manufacturing processes such as automated fiber placement (AFP) and automated tape laying (ATL), it enhances production efficiency while cutting down on labor expenses. This drive improves the accuracy of carbon fibers’ deposition in producing stronger CFRP components that are at the same time more uniform.

• Advancements in Resin Systems: The evolution of resin systems such as thermoset and thermoplastic matrices for CFRP applications continues to improve material properties including impact resistance, flexibility, and fire retardancy. These changes make it possible for CFRP to be used in a wider range of industries from automotive to renewable energy.

• Recycling and Sustainability Initiatives: A growing focus on sustainability is pushing for research into technologies for recycling CFRP. By doing this, they minimize environmental impacts posed by end-of-life products and also provide low-cost alternative materials against those produced from virgin sources since they promote circular economy principles.

• Integration of Nanotechnology: The inclusion of nanomaterials like carbon nanotubes or graphene within the structure of CFRP improves mechanical properties such as strength, stiffness, etc., making them suitable for aerospace applications, defense industry, high-tech applications where stringent requirements are imposed.

• Expansion in Electric Vehicles (EVs): Explanation: With the rise in electric vehicles comes an increase in demand for lightweight materials like CFRP that can extend battery range or improve vehicle efficiency. In addition to supporting sustainable transportation solutions, EV components including chassis, body panels and battery enclosures require materials with high strength-to-weight ratios which make them ideal candidates for incorporating CFRP technology.

A total of 121 figures / charts and 95 tables are provided in this 223-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Carbon Fiber Reinforced Plastic Market

Recent developments in Carbon Fiber Reinforced Plastic Market by various companies highlight ongoing innovations and advancements across different sectors:

• Growing Use in the Automotive Industry: Automakers are increasingly integrating CFRP in mainstream car models to cut down on weight as well as improve fuel efficiency. Recent alliances between automakers and suppliers of CFRP have resulted in inventive applications such as EVs and high-performance sports cars.

• Advancements in Aerospace Applications: With its higher strength-to-weight ratio, carbon fiber reinforced polymers continue to replace conventional metals in aircraft structures. Recent developments include the use of CFRP on wing elements, sections of the fuselage, and interior panels to minimize total aircraft mass and improve fuel consumption.

• Industrialization of Production Processes: The advent of manufacturing technologies such as automated fiber placement (AFP), automated tape laying (ATL) and resin infusion methods has led to simplification of CFRP production. These improvements reduce costs during production, ensure uniformity in materials and allow for mass-production towards a general market.

• Focus on Sustainable Manufacturing: Throughout the life cycle of CFRP production, companies are investing into sustainable practices that range from sourcing raw materials to recycling at end-of-life. Among these initiatives include using bio-based resins, designing closed-loop recycling processes for CFRP wastes plus reducing carbon footprint during manufacturing operations.

• Integration of Digital Twins and IoT: Using digital twin technology together with Internet of things (IoT) solutions improves process monitoring, quality control as well as predictive maintenance in CFRP manufacture. This leads to improved real-time data analysis which enhances productivity by minimizing material wastage while improving product performance across various industrial uses.

Strategic Growth Opportunities for Global Carbon Fiber Reinforced Plastic Market

Automotive Sector

• Electric Vehicle (EV) Adoption Boom: CFRP adoption on EVs is rising so as to lighten them and sustain battery lives. The car manufacturers have incorporated the carbon fiber-reinforced composites in chassis, body panels and structural components of vehicles to boost their performance and lessen fuel consumption.

• Collaborations for Mainstream Application: They are working together with CFRP suppliers in order to bring about something new into commercial cars. These latest developments are geared towards production scalability as well as cost reduction of CFRP materials which would make them more affordable for mass-market auto brands.

Aerospace Industry

• Advances in Airplane Structures: Carbon fiber reinforced polymers (CFRPs) continue to replace conventional metals in aircraft structures because of their extreme strength-to-weight ratio. The most recent trends show that CFRPs are being used in components such as wings, fuselages and interior panels of aircrafts aimed at improving fuel economy while reducing overall weight.

• Incorporation into Future Commercial Aircraft: Next-generation aircraft programs rely increasingly on CFRP for its superior characteristics. Firms involved are researching on better methods of establishing this by using highly industrialized methods that will meet aerospace requirements to enhance structure durability.

Renewable Energy Sector

• Wind Turbine Blades: This substance is essential when it comes to developing longer wind turbine blades that can capture more energy efficiently. Recent developments focus on the improvement of blade robustness, reduction of maintenance costs, increasing energy yield from wind farms among other aspects.

• Solar Energy Applications: In solar energy applications, structural components made from CFRP have been implemented in order to increase lifespan and decrease weight. Innovators aim at optimizing the use of carbon-fiber reinforced polymer in making solar cells more efficient and long-lasting.

Industrial Applications & Infrastructure

• High-Performance Pipes & Tanks: Industries such as those manufacturing high-performance pipes and tanks use carbon fiber reinforced polymers. The most recent approaches to the use of this material in demanding industrial environments have aimed at enhancing corrosion resistance, durability, and reliability.

• Bridge and Building Construction: CFRP composites are finding increasing applications in infrastructure projects for their high strength-to-weight properties. These include using carbon-fiber reinforced polymer for reinforcement purposes in concrete structures, bridges and seismic retrofitting that would improve on structural life expectancy and toughness.

Consumer Goods & Sporting Equipment

• Sporting Goods & Equipment: For sport bicycles, tennis rackets, golf clubs among other sporting equipment with lightweight properties and durable attributes. Latest developments seek to increase the durability, stiffness as well as the overall performance of goods used by athletes and enthusiasts alike.

• Consumer Electronics: In consumer electronics industry applications, aesthetic appeal is expected from such materials. The latest trends aim at lowering product weight through incorporation of better design features while maintaining its aesthetics including a stylish look and lasting quality necessary to meet consumers’ ever changing tastes.

.

Carbon Fiber Reinforced Plastic Market Drivers and Challenges

The global carbon fiber reinforced plastic market is pivotal in industries requiring corrosion-resistant storage solutions. Driven by benefits like durability and design flexibility, it faces challenges such as high initial costs and logistical complexities. This discussion explores key drivers propelling its growth and significant challenges hindering broader market adoption.

The key drivers for the global Carbon Fiber Reinforced Plastic market include:

1. Weight Reduction in Automotive and Aerospace: The demand for carbon fiber reinforced plastic (CFRP) as a lightweight material is driven by increased regulations to improve fuel economy and reduce emissions. Motor vehicle manufacturers are also incorporating CFRP in their cars to boost performance, minimize fuel consumption and meet sustainability targets.

2. Manufacturing Advancements in Technology: It is now possible to make CFRPs more efficiently using automated systems like automatic fiber placement (AFP) and liquid infusion. Scalable manufacturing of high-performance CFRP components spanning across various sectors becomes possible due to these advancements thereby propelling wider usage variations.

3. Growing Applications in Renewable Energy and Infrastructure: Thus, there is an increasing global market for durable light materials driven by the rising share of renewable energy sources and infrastructure expansion, with civil engineering works accounting for 40% of the total composites market globally. Because of its strength-to-weight ratio, CFRP is employed in wind turbine blades, solar panels, as well as infrastructure projects.

The challenges in the global Carbon Fiber Reinforced Plastic Market include:

1. Costly Production and Raw Material Prices: The production of CFRP is an expensive affair since it uses highly priced raw materials such as carbon fibers and resin systems, not to mention high energy requirements. However, manufacturers have the pressure of being competitive on price which means that managing such expenses can be challenging if not impossible therefore making it harder for them to expand their markets and become profitable.

2. Recycling and Sustainability Concerns: Technological difficulties continue to face recycling efforts in CFPR composites thus raising concerns about waste management and environmental implications. Efficient recycling methods need to be developed while advocating for sustainable practices; these are some of the ways through which firms can cope with regulatory pressures as well as meet consumer preferences for green products.

.

To conclude, despite its technological advancements and growing use in various sectors such as automotive and aerospace, CFRP still faces challenges like high production costs and lack of recycling. Innovation in manufacturing processes and sustainable practices are key to overcoming these obstacles, thereby guaranteeing the sustained development of CFRP as a favoured lightweight, high performance material across industries worldwide.

Carbon Fiber Reinforced Plastic Suppliers and Their Market Shares

In this globally competitive market, several key players such as GKN Fokker, Voith Composites SE & Co. KG, Plasan Carbon Composites, and SGL Carbon etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report on “Carbon Fiber Reinforced Plastic Market Leadership Report".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies carbon fiber reinforced plastic companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the carbon fiber reinforced plastic companies profiled in this report includes.

• GKN Fokker

• Voith Composites SE & Co. KG

• Plasan Carbon Composites

• SGL Carbon

• DowAksa Advanced Composites Holding

• Toray Industries Inc.

• Mitsubishi Chemical Corporation

• Teijin Limited

• Hexcel Corporation

These companies have established themselves as leaders in the global carbon fiber reinforced plastic market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the Carbon Fiber Reinforced Plastic market are evolving, with the entry of new players and the emergence of innovative Carbon Fiber Reinforced Plastic market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Carbon Fiber Reinforced Plastic Market by Segment

Automotive, aerospace and renewable energy are major CFRP growing sectors. For instance, in the automotive sector, EVs have seen an upswing with lightweight components made of CFRP being manufactured at a higher rate. In the aerospace industry, it is crucial for aircraft structures to have CFRP due to its high strength-to-weight ratio. On the other hand, CFRPs play a fundamental role in wind turbine blades as well as solar panels under renewable energy. In conclusion, these segments benefit from the strengths of CFRP such as durability, efficiency and sustainability advantages that encourage more people to use them thus increasing their market.

The study includes a forecast for the global carbon fiber reinforced plastic market by end use, resin type, process type, and region as follows:

Carbon Fiber Reinforced Plastic Market by End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Aerospace

• Automotive

• Wind Energy

• Marine

• Sporting Goods

• Construction

• Pressure Vessel

• Others

Carbon Fiber Reinforced Plastic Market by Resin Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Epoxy

• Phenolic

• Polyester

• Vinyl ester

• PEEK

• PPS

• PEI

• PA

• Others

Carbon Fiber Reinforced Plastic Market by Process Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Prepreg Layup

• RTM

• Injection Molding

• Compression Molding

• Filament Winding

• Pultrusion

• Others

Carbon Fiber Reinforced Plastic Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Carbon Fiber Reinforced Plastic Market

• Market Size Estimates: Carbon fiber reinforced plastic market size estimation in terms of value ($M)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by end use, resin type, process type, and region.

• Regional Analysis: Carbon fiber reinforced plastic market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different end use, resin type, process type, and regions for the carbon fiber reinforced plastic market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the carbon fiber reinforced plastic market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

.

If you are looking to expand your business in carbon fiber reinforced plastic or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the carbon fiber reinforced plastic market size?

Answer: The global carbon fiber reinforced plastic market is expected to reach an estimated $49 billion by 2030.

Q2. What is the growth forecast for carbon fiber reinforced plastic market?

Answer: The carbon fiber reinforced plastic market is expected to grow at a CAGR of 7% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the carbon fiber reinforced plastic market?

Answer: The major drivers for this market are weight reduction in automotive and aerospace, manufacturing advancements in technology, and growing applications in renewable energy and infrastructure.

Q4. What are the major applications or end use industries for carbon fiber reinforced plastic?

Answer: Aerospace, automotive, wind energy, marine, sporting goods, construction, pressure vessel, and others are the major end uses for carbon fiber reinforced plastic.

Q5. What are the emerging trends in carbon fiber reinforced plastic market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include the increasing use in automation manufacturing, advancements in resin systems, recycling and sustainability initiatives, integration of nanotechnology, and expansion in electric vehicles (EVs).

Q6. Who are the key carbon fiber reinforced plastic companies?

Answer: Some of the key carbon fiber reinforced plastic companies are as follows:

• GKN Fokker

• Voith Composites SE & Co. KG

• Plasan Carbon Composites

• SGL Group

• DowAksa Advanced Composites Holding

• Toray Industries Inc.

• Mitsubishi Chemical Corporation

• Teijin Limited

• Hexcel Corporation

Q7. Which carbon fiber reinforced plastic resin segment will be the largest in future?

Answer: Lucintel forecasts that epoxy based resin carbon fiber reinforced plastic will remain the largest segment over the forecast period due to its better chemical and mechanical properties

Q8. In carbon fiber reinforced plastic market, which region is expected to be the largest in next 7 years?

Answer: North America is expected to remain the largest region and witness the highest growth over next 7 years due to the growth in aerospace market and increasing use of composite material in aerospace market because of its excellent mechanical properties.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global carbon fiber reinforced plastic market by end use (aerospace, automotive, wind energy, marine, sporting goods, construction, pressure vessel and others), by process type, by resin type, and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?