Base Epoxy Resin Market Trends and Forecast

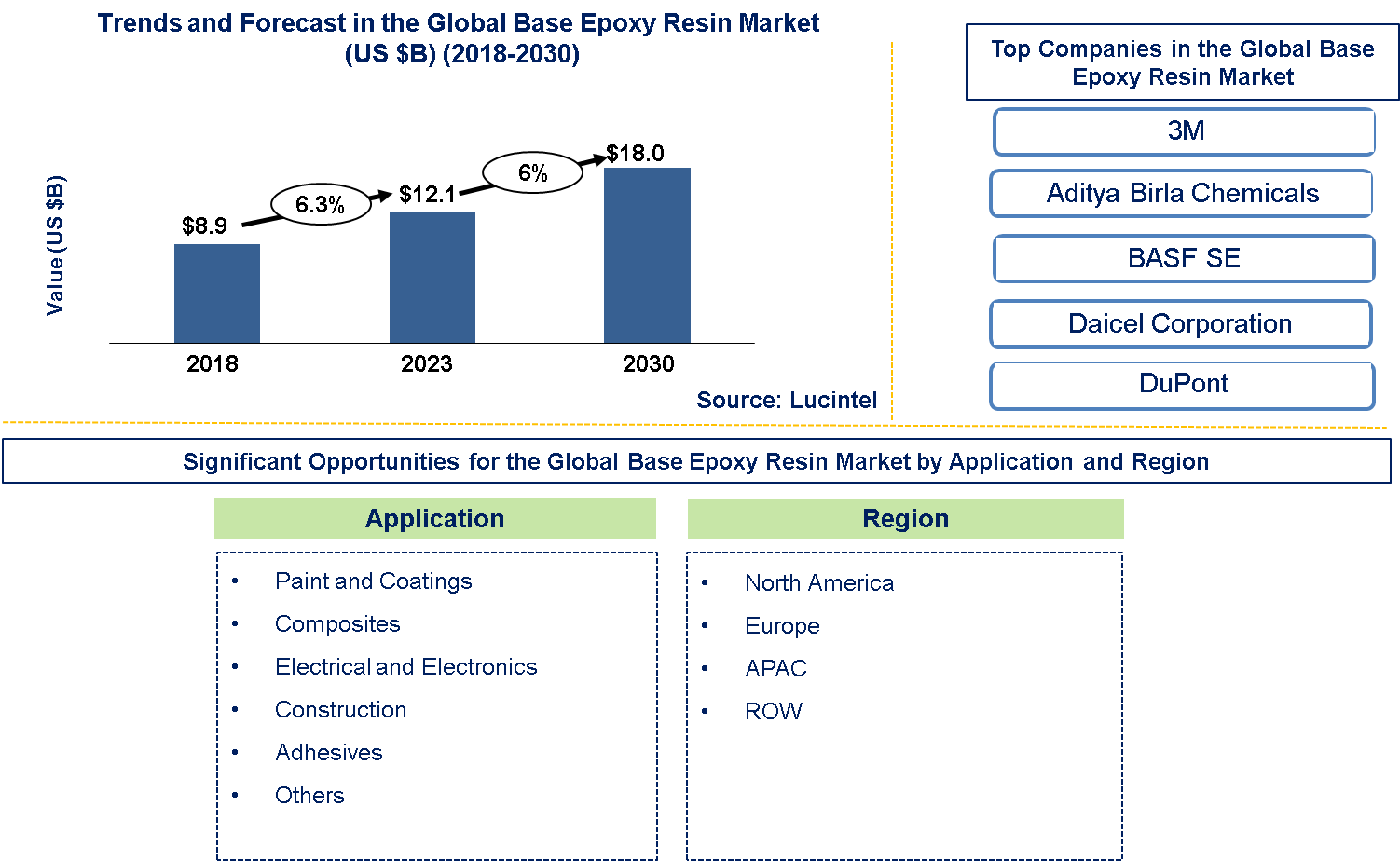

Lucintel finds that the future of the base epoxy resin market looks promising with opportunities in the paint and coatings, composites, electrical and electronics, construction, and adhesives industries. The global base epoxy resin market is expected to reach an estimated value of $18 billion with a growing CAGR of 6% from 2023 to 2030. The major drivers for this market are rise in infrastructure projects, and growth in automotive and electrical & electronics industries.

Base epoxy resins rely on crucial raw materials like bisphenol-A (BPA) and epichlorohydrin, essential for forming the resin backbone. Modifications may involve reagents such as phenols or amines, with solvents like methanol or acetone aiding processing. Catalysts like acids or bases facilitate polymerization. Prices fluctuate based on raw material costs, production efficiency, and global demand, favoring economies of scale for larger manufacturers. Regional production capacities and regulatory factors further influence pricing strategies amidst market dynamics like supply chain disruptions and technological advancements.

• Lucintel forecasts that paint and coatings will remain the largest application segment over the forecast period due to growth in new infrastructure projects and increasing demand for protection of concrete floors in the industrial and commercial facilities.

• Asia Pacific is expected to remain the largest region over the forecast period due to presence of large number of end users of base epoxy resin.

Country wise Outlook for the Base Epoxy Resin Market

The base epoxy resins market is witnessing substantial growth, driven by increased demand from various industries. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major base epoxy resin market producers in key regions. China, USA, Germany, and India.

Emerging Trends in the Base Epoxy Resin Market

Emerging trends in base epoxy resin market are shaping its future applications and market dynamics:

1. Waterborne Epoxy Resins: Waterborne epoxy resins are now trending due to their low volatile organic compound (VOC) content and environmental friendliness. They find applications in coatings, adhesives, and composites which have made them safer and easier to work with.

2. Epoxy Resins for 3D Printing: Possibilities of using epoxy resin in 3D printing (additive manufacturing) continue to grow owing to developments in resin formulations and printing technologies. By doing this its possible to create complex intricate parts with high surface finish grade and good mechanical properties

3. Smart Coatings and Adhesives: Epoxies are crucial compounds that form smart coatings and adhesive materials that have self-healing capability against corrosion or other forms of deterioration caused by microbial attacks among others things. These products serve the automotive sector or marine application in health care where efficiency and reliability play a key role.

4. Nanotechnology Integration: The incorporation of nanotechnology into epoxy resin formulations enhances mechanical strength, barrier properties, functionality etc. They also prove useful for lightweight structures (nanocomposite epoxy resins); protective coatings; high performance composites and so forth.

5. Digitalization and Industry 4.0: Digitalization is changing the epoxy resin market through advancements in process control, predictive maintenance, and quality assurance. The industry 4.0 technologies enhance the efficiency of production while reducing waste as well as maintaining consistency during the manufacturing process by use of resins.

6. Functional Modifications: This includes innovations whereby specific properties such as flame retardancy, thermal stability, UV resistance, electrical conductivity among others were improved upon by varying the structure of an epoxy resin. Particular compositions suit different industry sectors from electronics to infrastructure requirements.

7. Bio-based Epoxy Resins: The use of bio-based epoxy resins derived from renewable sources such as plant oils, sugars, and lignin is becoming increasingly popular. These resins decrease the level of dependency on non-renewable fossil fuels as well as lessen carbon footprints.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Base Epoxy Resin Suppliers

Recent developments in base epoxy resin market by various companies highlight ongoing innovations and advancements across different sectors:

1. Capacity expansions: Demand in coatings, adhesives, electrical laminates and composites for applications are driving a need for capacity expansion from major manufacturers.

2. Technological Innovations: Regulatory pressures and consumer demand for eco-friendly products have led to advances in epoxy resin formulations that include low volatile organic compound (VOC) and sustainable options.

3. Strategic Partnerships and Acquisitions: Strategic partnerships and acquisitions by companies are geared towards strengthening their position in the market, expanding their product portfolio as well as improving on their technological capability.

4. Market Consolidation: Mergers and acquisitions are aimed at enhancing market presence with a view to increase operational efficiency through consolidation activities.

5. Application Diversification: This is due to their excellent mechanical properties and versatility, which has seen a surge in the number of new applications where epoxy resins are used like 3D printing, electronics aerospace or even automotive sectors.

6. Regional Developments: Environmental regulations affecting production processes have caused changes in regulatory framework affecting consumption patterns.

Strategic Growth Opportunities for Global Base Epoxy Resin Market

1. Development in the Construction and Infrastructure Industries: The usage of epoxy resins is common in the construction industry for purposes such as flooring, adhesives, coatings, and civil engineering applications. As worldwide infrastructure development continues particularly in emerging markets, there is an increasing request for durable and high performance materials. This can be capitalized on by companies that offer epoxy resin systems to increase structural integrity, durability and sustainability.

2. Technological Improvements in Electronics and Electrical Fields: The electronics industry are among the users of epoxy resins which are suitable for encapsulation, insulation and printed circuit boards (PCBs). With fast growth in electronics manufacturing and increased need for miniaturization and reliability; a good opportunity exists to come up with Epoxy formulations that meet strict performance requirements like heat resistance characteristics as well as electrical insulation properties.

3. New Applications are Coming Up in Aerospace Manufacturing Sector: In aerospace industry epoxy resins are indispensable because they form part of composite materials used to make aircraft components; they also serve as coatings over metallic surfaces using this material helps reduce weight of aircrafts hence reducing fuel consumption without compromising safety. However with regard to enhanced performance, improved fuel efficiency, emission reduction there has been a huge demand for advanced epoxy resin systems that will possess high strength-to-weight ratios while meeting rigorous safety standards & regulations.

4. Increased Demand within Wind Energy Industry: Wind energy sector rely on epoxy resins due to their excellent mechanical properties and durability when making wind turbine blades. Therefore rapid global flows into renewable energies specifically wind power generation present opportunity to innovate more efficient blade designs involving epoxy resin formulations that improve performance minimize maintenance cost saving resulting from their longer operational lives.

5. Medicinal And Healthcare Spheres: Due to biocompatibility and sterilizability qualities possessed by these types of polymers they have found wide applications particularly in medical devices and dental materials among others . Owing to an aging population together with escalating health care costs worldwide, there is a requirement for epoxy based medical materials that are superiorly performing, safe and reliable.

6. Emphasis on Eco-friendly and Sustainable Epoxy Resins: Sustainability has become a key driver of market growth. Companies are increasingly focusing on research and development of bio-based epoxy resins that use renewable feedstocks. Inventing green formulations which reduce the environmental loads as well as meet regulatory demands can be done in order to make such firms more attractive to environmentally friendly consumers.

Base Epoxy Resin Market Drivers and Challenges

Robust growth is being experienced in the base epoxy resin market due to its versatile applications across industries such as construction, automotive, aerospace, electronics and wind energy among others. Key drivers include increasing demand for durable coatings, adhesives and composites besides advancing technology and sustainability initiatives. Nonetheless, there are also considerable challenges facing the market that range from raw material price volatility and control pressures to rival materials competition and technical intricacies.

The key drivers for the base epoxy resin market include:

1. Construction and Infrastructure are increasingly in demand: Base epoxy resins are important for manufacturing coatings, adhesives and structural applications which are durable for construction works, civil engineering, infrastructure projects.

2. Automotive and Aerospace Industries Expansion: The growth of composites and lightweight materials in the automotive and aerospace industries has increased the demand for epoxy resins because of their strength to weight ratios and flexibility.

3. Electronics & Electrical Applications: Driven by technology advancements as well as electronic devices’ innovations, Epoxy Resins play a vital role in the encapsulation of electronic components such as printed circuit boards (PCBs) along with electrical insulations.

4. Wind Energy Adoption: With the world’s attention shifting towards renewable sources of energy epoxy resins have found immense use in wind turbine blade production.

5. Emerging Applications: Growth in sectors like marine coatings, healthcare, and sports equipment manufacturing expands the market for base epoxy resins.

The challenges in the base epoxy resin market include:

1. Raw material price volatility: Price fluctuations on raw materials including bisphenol A (BPA) and epichlorohydrin affect production costs as well as profit margins.

2. Environmental And Regulatory Pressures: Manufacturers must invest in sustainable production processes plus products due to increasing regulations on chemical emissions, waste disposal and sustainability.

3. Competition from substitutes: The availability of alternative resins and materials such as polyurethanes alongside phenolic resin undermines base epoxy resin market share.

4. Technical Challenges: In different applications stringent performance requirements can be technically demanding i.e. durability, temperature stability; chemical resistance among others.

5. Disruption In Supply Chain: Global supply chain disruptions including raw material shortages plus transportation issues impacts delivery timelines coupled with production schedules

6. Market Consolidation: Increasing consolidation amongst major players combined with market saturation particularly across some segments intensifies competition pressure coupled with pricing.

A solid epoxy resin market is a growing one as there are increasing applications of the product in vital industries all over the globe. Innovation and strategic adaptation to market dynamics will be important despite challenges such as fluctuations in raw material prices, regulatory requirements and competitive pressures. In order to deal with these challenges ahead of them and make use of the various key growth drivers, it means that navigating complexities would help stakeholders take advantage of shifting demand for base epoxy resins worldwide.

Base Epoxy Resin Suppliers and Their Market Shares

In this Global competitive market, several key players such as 3M, Aditya Birla Chemicals, BASF SE, Daicel Corporation, and DuPont etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To

Base Epoxy Resin Market by Segment

The areas of the market where demand is rising for epoxy resin on a global scale include coatings, adhesives, electrical & electronics, composites and automotive applications. Expansion of coatings results from growing need in construction and industrial sector. Adhesives get support from an increasing number of uses in packaging and motor industries. The growth in electrical & electronics industry can be attributed to expanding electronic devices as well as renewable energy applications. Among other things, Composites are on an increase across aerospace, automotive and marine industries while epoxy resins used in automotive applications are driven by lightweighting trends and durability requirements.

Base Epoxy Resin Market by Application [Volume (M lbs) and $M shipment analysis for 2018 – 2030]:

• Paint and Coatings

• Composites

• Electrical and Electronics

• Construction

• Adhesives

• Others

Base Epoxy Resin Market by Region [Volume (M lbs) and $M shipment analysis for 2018 – 2030]:

• North America

o US

o Canada

o Mexico

• Europe

o Germany

o The United Kingdom

o France

o Russia

• Asia Pacific

o China

o Japan

o India

o South Korea

• The Rest of the World

Global Base Epoxy Resin Market

• Market Size Estimates: Base epoxy resin market size estimation in terms of value ($B) and volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by application

• Regional Analysis: Base epoxy resin market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different applications and regions for the base epoxy resin market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the base epoxy resin market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in base epoxy resin market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ_

Q1. What is the base epoxy resin market size?

Answer: The global base epoxy resin market is expected to reach an estimated $18.0 billion by 2030

Q2. What is the growth forecast for base epoxy resin market?

Answer: The base epoxy resin market is expected to grow at a CAGR of 6% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the base epoxy resin market?

Answer: The major drivers for this market are growing demand in construction and infrastructure, expansion in automotive and aerospace industries, and adoption in wind energy.

Q4. What are the major applications or end use industries for base epoxy resin?

Answer: Paint and coatings and composites are the major end use industries for facial cleanser.

Q5. What are the emerging trends in base epoxy resin market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include waterborne epoxy resins, epoxy resins for 3d printing, smart coatings and adhesives, nanotechnology integration, and digitalization and industry 4.0 .

Q6. Who are the key base epoxy resin companies?

Answer: Some of the key base epoxy resin companies are as follows:

• 3M

• Aditya Birla Chemicals

• BASF SE

• Daicel Corporation

• DuPont

• Hexion

• Huntsman

• NAMA Chemicals

• NAN YA Plastic Corp.

• Olin Corporation

Q8: In base epoxy resin market, which region is expected to be the largest in next 7 years?

Answer:Asia Pacific is expected to remain the largest region and witness the highest growth over next 7 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global base epoxy resin market by application (paint and coatings, composites, electrical and electronics, construction, adhesives, and others) and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?