Automotive Composite Suspension Components Market Trends and Forecast

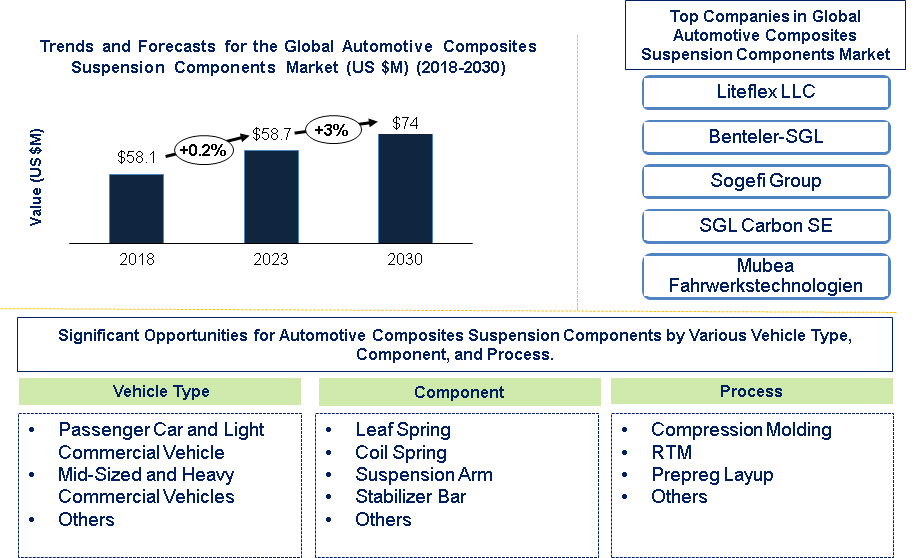

Lucintel finds that the future of the composites intermediate material in the global automotive market looks promising with opportunities in the markets of passenger cars and light commercial vehicles, and medium & heavy commercial vehicles market. The global automotive composites suspension components market is expected to reach an estimated $74 million by 2030 with a CAGR of 3% from 2023 to 2030. The major drivers for this market are growth in automotive production and increasing demand for lightweight materials to achieve high fuel efficiency and reduce carbon emissions.

The composite components of the automotive suspension are usually made from carbon fiber, fiberglass, and epoxy resin and in some cases additional reinforcements such as kevlar. These materials offer high strength-to-weight ratios and good resistance to corrosion. The manufacturing processes usually involve processes like prepreg layup, resin transfer molding (RTM), compression molding among others. Composite suspension components tend to be more expensive than conventional materials such as steel and aluminum because of the raw materials cost and production methods. On the other hand, they have superior performance advantages that can make it justified at least for luxury or performance vehicles when priced higher.

• Lucintel forecasts that passenger cars and light commercial vehicles will remain the largest and witness the highest growth over the forecast period due to increasing penetration of composite leaf springs to reduce vehicle weight.

• Leaf springs will remain the largest segment and witness the highest growth over the forecast period because composite leaf springs are lighter weight and offer better durability compared to steel springs.

• Europe will remain the largest region by value and volume over the forecast period due to stringent government regulations to increase fuel efficiency and lower carbon emissions.

Country wise Outlook for the Automotive Composites Suspension Components Market

The automotive composites suspension components market is witnessing substantial growth globally, driven by increased demand from various industries such as passenger car and light commercial vehicle, medium and heavy commercial vehicle and others. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major automotive composites suspension components producers in key regions: the USA, Germany, China, Brazil, and India.

Emerging Trends in the Automotive Composites Suspension Components Market

Emerging trends in the automotive composites suspension components shaping its future applications and market dynamics:

• Enhanced Utilization of Carbon Fiber Reinforced Polymers (CFRP): The automotive industry is progressively embracing CFRP for suspension components as a result of its exceptional strength-to-weight ratio, thereby improving vehicle performance, fuel economy and reducing emissions.

• Smart Materials Integration: Composite suspension components that incorporate smart materials with the ability to heal themselves and sense damage can last long and are more robust, provide real-time monitoring and maintenance of the system; thus reducing downtime and making the entire car safer.

• Hybrid Composites Development: By blending different fibers including glass and carbon ones in hybrid composites, it becomes possible to strike a balance between cost, weight and performance leading to hi-tech suspension systems more affordable for wider applications across different vehicle types ranging from top end sports vehicles to entry level consumer cars.

• Technological Advances in Manufacturing Process: Innovations realized in manufacturing processes such as Automated Fiber Placement (AFP) or 3D printing have led to efficient production of complex composite suspension components which further results in increased precision, reduced material wastage as well as faster production cycles.

• Sustainability Orientation: The industry is moving towards using recycled materials and developing environmentally friendly resins and fibers that aim at minimizing the impact on environment due to composite suspension parts so that they can be positioned globally in line with sustainability goals.

These trends indicate a shift towards more sustainable, innovative, and technologically advanced solutions in the automotive composites suspension components industry to meet evolving consumer and regulatory demands globally.

A total of 139 figures / charts and 110 tables are provided in this 209-page report to help in your business decisions. Sample figures with some insights are shown below. To learn the scope, benefits, companies researched, and other details of the global automotive suspension market report, please download the report brochure.

Recent Developments in the Automotive Composites Suspension Components Market

Recent developments in global automotive composites suspension components market which highlights ongoing innovations and advancements across different sectors.

• Advanced Composite Materials: They are currently coming up with new formulas for carbon fiber composites that have enhanced properties such as increased impact resistance, better fatigue performance and a lower weight to give a better overall suspension performance.

• 3D Printing and Additive Manufacturing: In order to allow more design flexibility, rapid prototyping, and reduced time-to-market, these processes are increasingly becoming used for manufacturing lightweight, intricate parts of suspension system.

• Nanomaterials Integration: The use of nanomaterials such as graphene in composite matrices has been able to alter the mechanical properties, thermal conductivity and this is improving the durability towards higher performances of suspension components.

• Automated Production Processes: Adoption of automated processes like robotic fiber placement and resin transfer molding is improving production efficiency by saving on labor costs, reducing material wastage, enhancing accuracy and consistency across all stages of manufacture.

• Smart Suspension Systems: These could facilitate predictive vehicle maintenance through the development of smart composites that feature embedded sensors capable of real-time monitoring for structural health assessment.

Strategic Growth Opportunities for Automotive Composites Suspension Components Market

The automotive composites suspension components market is poised for significant expansion, driven by technological advancements and evolving industry demands. As the automotive sector increasingly prioritizes lightweight, durable, and high-performance materials, composite components are becoming essential. This growth is further fueled by the rise of electric vehicles, sustainability initiatives, and smart technology integration. Some key strategic growth opportunities for this market include:

• Electric Vehicles (EVs) Expansion: The shift to EVs provides an important opportunity for growth. Manufacturers of EVs need light weight and high-strength materials that can maximize distance travelled by a unit of fuel or electricity consumed per unit of distance travelled. Thus, the development of composite suspension components is considered necessary both towards improving performance as well as contributing to longer driving ranges.

• Advancements in Material Technology: Ongoing research activities involving composites have led to carpet materials such as hybrid composites and nanocomposites with excellent properties including strength, durability, and thermal resistance. Hence, businesses investing in these advanced materials will be able to gain a competitive advantage over their rivals in terms of having better quality products than them.

• Sustainability Initiatives: Sustainability has become increasingly significant hence the demand for environmentally friendly materials continues to rise. Likewise, the development of recyclable and bio-based composites would comply with regulations while at the same time attracting consumers focused on environmental issues. Companies that prioritize being green can improve their brand reputation attracting new sets of customers.

• Automated and Cost-Effective Manufacturing Processes: Investments into automation manufacturing technologies like robotic fiber placement, 3D printing and advanced resin transfer molding lead to substantial declines in production costs; greater accuracy improvement and ability to scale up production rates among others. The cost structures associated with composite suspension components would then be able to be served more effectively.

• Smart Suspension Systems: Smart composite suspension components which include sensors enable end-users benefit from real-time monitoring, predictive maintenance programs, thereby ensuring valuable vehicle safety measures are put in place concurrently meeting demands created by intelligent vehicles. Consequently this provides value added features within the product offerings required by connected cars and IOT enabled smart transportation systems.

• Strategic Partnerships and Collaborations: Aligning automotive OEMs with material suppliers or research institutions could facilitate technological innovation as well as commercialization thereby speeding up market entry processes. Such collaborations consequently result into new technologies being discovered or developed, enhanced with expertise sharing and faster market entry.

• Focus on Performance and Luxury Vehicles: High performance as well as luxury automobile segments is more inclined to the advanced composite materials because of their focus on performance, weight reduction and top-notch quality. Consequently, this targeting will enhance profit margins and prestige.

Automotive Composites Suspension Components Market Drivers and Challenges

The automotive composites suspension components market has several factors that can be considered as either its drivers or challenges. Some of the major market drivers are light-weight materials usage for improving fuel efficiency and vehicle dynamics and growing adoption of electric vehicles along with material evolution. However, the industry is grappling with high production costs, need for advanced manufacturing techniques, and strict regulatory rules. The equilibrium between these drivers and challenges is very crucial in order to enable companies involved innovate and compete effectively in this ever-changing landscape while ensuring sustainable growth and market penetration.

The factors responsible for driving the automotive composites suspension components market include:

1. Lightweight and High-Performance Materials are in demand: To enhance fuel efficiency and vehicle performance, the automobile industry is increasingly pursuing lightweight materials. Composite suspension components with high strength-to-weight ratios allow for better handling, reduced emissions and improved overall vehicle dynamics; consequently, these are an essential focus for auto manufacturers attempting to satisfy rigid environmental and performance requirements.

2. Growth in Electric Vehicles (EVs): The proliferation of electric vehicles is driving the market demand for light weight parts that extend battery life and improve efficiency. Composite suspension components play a vital role in reducing the weight of vehicles, increasing energy efficiency, fostering high-performance EVs in line with global sustainability goals as well as consumer preferences.

3. Advancements in Composite Material Technology: Innovations on composite materials like carbon fiber reinforced polymers (CFRP) and hybrid composites have resulted into better mechanical features such as increased strength qualities, durability increase and even more resistance to corrosion. These improvements enable faster production of more efficient suspension components capable of withstanding long periods hence meeting the requirement by the automotive industry for enhanced performance characteristics and extended service life.

Challenges in the Automotive Composites Suspension Components Market:

1. High Production Costs: This is owing to the fact that composite suspension component manufacturing uses costly raw materials and sophisticated production techniques, which makes it more expensive than traditional ones. The cost associated with this factor may limit its application in many areas especially those that are operated under tight budgets hence need for continuous improvement of the manufacturing processes and reduction of material costs.

2. Advanced Manufacturing Techniques Needed:

For composite components to be produced, there is a need for specialized manufacturing methods such as automated fiber placement and resin transfer molding (RTM). In terms of capital expenditure, training and maintaining consistent production quality at scale; these advanced techniques require considerable investments in equipment and skilled labor thus posing challenges on manufacturers.

Automotive suspension composites components market is influenced by a dual factor of innovation drive and evolving industry standards. Even though technological advancements and material inventions contribute to the growth of the market by improving performance and efficiency, they also bring along with them complications that include incorporation into existing systems and adherence to stringent safety rules thus making progress be tempered by practicability limitations.

Automotive Composites Suspension Components Suppliers and Their Market Shares

In this globally competitive market, several key players such as, Hendrickson (Liteflex), Sogefi Group, and SGL Carbon SE, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies automotive composites suspension components companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the automotive composites suspension components companies profiled in this report include.

-

Hendrickson Liteflex. LLC

-

Sogefi Group

-

SGL Carbon SE

-

Mubea Hyperco Inc.

-

ARC Industries

These companies have established themselves as leaders in the global automotive composites suspension components industry with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the global automotive composites suspension components market are evolving, with the entry of new players and the emergence of innovative technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Automotive Composite Suspension Components Market by Segment

The automotive composites suspension components sector growth is mainly influenced by the type of vehicle. The demand for lighter weight, high-performance composites that enhance fuel efficiency and driving dynamics has greatly increased in passenger cars and light commercial vehicles. On the other hand, medium and heavy commercial vehicles are now focusing on toughness as well as load carrying capacity which has resulted to more use of advanced composites that increase their strength, while reducing weight. While performance and efficiency are the main concern for passenger cars; durability and longevity are what commercial vehicles value thus spurring growth of composite technologies designed specifically for these unique needs.

This automotive composites suspension components market report provides a comprehensive analysis of the market's current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, include components, vehicle, and process. The report offers insights into regional dynamics, highlighting the major markets for global balsa core material market and their growth potentials. The study includes trends and forecast for the composites in global automotive composites suspension components market by components, vehicle, process and region as follows:

Automotive Composite Suspension Components Market by End Use [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Leaf Spring

• Coil Spring

• Stabilizer Bar

Automotive Composite Suspension Components Market by Vehicle Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Passenger car and light commercial vehicle

• Medium and heavy commercial vehicles

• Others

Automotive Composite Suspension Components Market by Process [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Resin Transfer Molding

• Prepreg Lay Up

• Compression Molding

Automotive Composite Suspension Components Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Automotive Composite Suspension Components Market

• Market Size Estimates: Automotive composite suspension components market size estimation in terms of value ($M) and volume ( M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by components, vehicle, process, and region

• Regional Analysis: Automotive composite suspension components market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different components, vehicle, process, and region for the automotive composites suspension components market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the automotive composites suspension components market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

FAQ

Q1. What is the automotive composites suspension components market size?

Answer: The global automotive composites suspension components market is expected to reach an estimated $74 million by 2030.

Q2. What is the growth forecast for automotive composites suspension components market?

Answer: The automotive composites suspension components market is expected to grow at a CAGR of 3% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the automotive composites suspension components market?

Answer: The major drivers for this market are growth in automotive production and increasing demand for lightweight materials to achieve high fuel efficiency and reduce carbon emissions.

Q4. What are the major applications or end use industries for automotive composites suspension components?

Answer: Passenger cars, light commercial vehicles, and medium & heavy commercial vehicles are the major end use industries for automotive composites suspension components.

Q5. What are the emerging trends in automotive composites suspension components market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, direct impact on the dynamics of the industry, includes development of CFRP leafsprings for heavy commercial vehicles.

Q6. Who are the key automotive composites suspension components companies?

Answer: Some of the key automotive composites suspension components companies are as follows:

-

Hendrickson (Liteflex. LLC)

-

Sogefi Group

-

SGL Carbon SE

-

Mubea

-

Hyperco Inc.

-

ARC Industries

Q7.Which automotive composites suspension components segment will be the largest in future?

Answer: Lucintel forecasts that leaf springs will remain the largest segment and witness the highest growth over the forecast period because composite leaf springs are lighter weight and offer better durability compared to steel springs

Q8: In automotive composites suspension components market, which region is expected to be the largest in next 7 years?

Answer: Europe is expected to remain the largest region over next 7 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 10 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global automotive composites suspension components market by component (leaf spring, coil spring and stabilizer bar), vehicle (passenger car and light commercial vehicle, medium and heavy commercial vehicle and others) process (resin transfer molding, prepreg lay up and compression molding) and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?