Automotive Adhesive Market Trends and Forecast

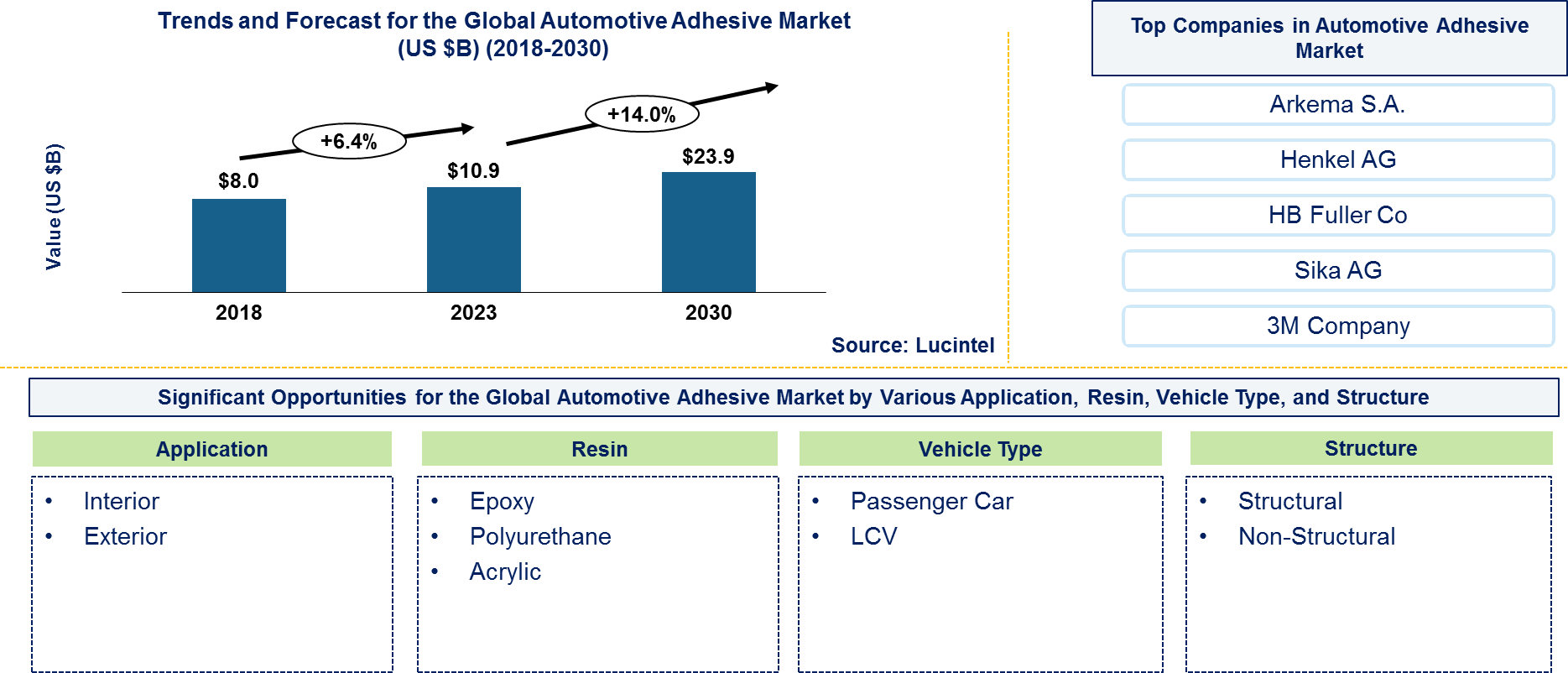

Lucintel finds that the future of the global automotive adhesive market looks promising with opportunities in passenger car and light commercial vehicles. The global automotive adhesive market is expected to reach an estimated $24 billion by 2030 with a CAGR of 11% from 2024 to 2030. The major drivers for this market are increasing demand for lightweight materials in vehicle manufacturing and replacement of mechanical fasteners with adhesives to make vehicles lighter and to meet higher fuel economy requirements.

Automotive adhesives are specialized bonding agents used extensively in the automotive industry for joining components together. They play a crucial role in modern vehicle manufacturing, providing structural integrity, vibration damping, sealing against environmental elements, and enhancing overall vehicle performance and safety. Automotive adhesives are formulated to meet stringent performance requirements, including durability, temperature resistance, and compatibility with various substrates. Acrylic polymers are commonly used in automotive adhesives due to their excellent weather resistance, UV stability, and bonding strength. Polyurethane adhesives offer high flexibility, impact resistance, and strong bonding properties. Epoxy resins provide high strength, chemical resistance, and dimensional stability.

• Lucintel forecasts that polyurethane adhesive will remain the largest segment due to its low price, durability, and performance.

• Adhesives for passenger car will remain the largest segment due to the growth in production of small and compact cars.

• Asia Pacific will remain the largest market and it is also expected to witness the highest growth over the forecast period due to growth in automotive industry in China, Japan, India, and other Asian countries.

Country wise Outlook for Automotive Adhesive Market

The automotive adhesive market is witnessing substantial growth globally, driven by increased demand from passenger car and light commercial vehicles. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major automotive adhesive producers in USA, Germany, China, India, Japan, and Brazil.

Emerging Trends of Automotive Adhesive Market

The automotive adhesive marketÄX%$%Xs size has been expanding rapidly, driven by the increasing adoption of adhesive in various automotive applications. The market size is influenced by factors such as increasing use of composites and lightweight materials in automotive vehicles and development of advanced bonding technologies. The market size is estimated to continue its upward trajectory as industries across the globe seek to improve performance, efficiency, and sustainability.

Emerging trends in automotive adhesive market are shaping its future applications and market dynamics:

• Light weighting Initiatives: To enhance fuel efficiency and meet strict emission standards, the automotive industry is increasingly prioritizing lightweight cars. Specialized adhesives capable of bonding dissimilar materials efficiently and still retaining their structural strength are required for light-weight materials such as aluminum, carbon fiber reinforced polymers (CFRP) and composites. Traditional mechanical fastenings are replaced by adhesives that reduce weight and increase vehicle performance.

• Advanced Bonding Technologies: Automotive assembly processes have moved towards advanced bonding technologies such as structural adhesives, double-sided tapes, liquid gaskets among others. Compared to conventional welding or mechanical fastening methods, structural adhesions provide higher bonding strength durability as well as fatigue resistance. Design flexibility is possible through these technologies thus reducing assembly time while at the same time guaranteeing safety and reliability of the entire vehicle.

• Environmental Sustainability: It is an increasing trend towards making sustainable adhesive with lower VOC emissions and minimized environmental footprint Adherents made from renewable feed stock like bio-based glues plus water based formulations keep gaining attention because they have environmentally friendly properties as well as adherence to strict environmental regulations. The chemical industry is investing in green chemistry approaches and recyclable adhesive technologies so as to promote circular economy principles which will result in reduced carbon footprint of the automotive industry.

• Adhesive Customization and Application Expertise: Customized adhesive solutions aimed at meeting specific performance criteria have been sought by the car OEMs and suppliers. Automotive stakeholders work closely with adhesive manufacturers to develop bonding solutions for advanced materials and achieve efficient processes that will be compatible with automated assembly systems.

• Global Market Expansion and Localization: The global expansion of the automobile adhesive market is accompanied by increased investments in production facilities as well as distribution networks which ensure provision of services within regional markets efficiently. Localization strategies support such efforts to expedite delivery, minimize supply chain vulnerability and conform to local regulations while building up global automotive manufacturing centers

A total of 157 figures / charts and 132 tables are provided in this 250 -page report to help in your business decisions. Sample figures with some insights are shown below.

Recent Developments in the Automotive Adhesive Market

Recent developments in the automotive adhesive market reflect ongoing advancements in technology, expanding applications across industries, and evolving consumer needs.

• Advanced Bonding Solutions: Modern cars are built with specific needs in mind. Car adhesive manufacturers have shifted their focus towards creating advanced adhesives that cater to the vehicle assembly industry’s latest requirements. High tenacity structural adhesives which replace traditional welding and mechanical fastening techniques are part of these solutions, thus reducing weight, enhancing car rigidity and improving crashworthiness. Invention of adhesive formulations has brought about compatibility with different types of substrates such as metals, composites and plastics while at the same time increasing bonding strength as well as durability.

• Electric Vehicle (EV) Applications: The demand for adhesives that can withstand high temperatures, provide electrical insulation, and support the unique assembly requirements of EV components is rising due to the growing market share of electric vehicles (EVs). Adhesive solutions for battery pack assembly, thermal management systems, and electronic component bonding are being developed to enhance performance, safety, and reliability in electric vehicle platforms.

• Sustainability Initiatives: Environmental sustainability is a key focus area in the automotive adhesive market. Companies in this sector are getting involved in developing eco-friendly glues with less VOC emissions; made from biobased materials that can be recycled. Not only do sustainable adhesive solutions comply with stringent environmental regulations but they also contribute towards reducing automotive manufacturing processes’ carbon footprint.

• Smart Adhesive Technologies: Adhesives which have electromagnetic interference (EMI) shielding capabilities as well as efficient thermal management functions are essential for integrating smart technologies and sensor systems into vehicles. Smart adhesive technology development involves connectivity enabled by such improvements allowing enhanced signal integrity within integrated driver assistance applications like ADAS systems up to autonomous driving applications.

• Collaborations and Partnerships: Innovation is being fueled by strategic collaborations between manufacturers of adhesives, automotive OEMs and research institutions leading to accelerated development of next generation adhesive solutions. As regards partnering there is co-engineering formulation activities where other areas involve joint R&D projects, and embedding of adhesive technology into new vehicle platforms. These partnerships are meant to improve customization of products, optimize manufacturing processes and address specific concerns in the industry.

• Global Market Expansion: Automotive adhesives suppliers are expanding worldwide through investments in production facilities, distribution networks and technical support capabilities. To serve regional market requirements, meet local regulations and enhance ties with global auto manufacturers and parts suppliers, automotive adhesive firms are adopting localization strategies.

Strategic Growth Opportunities for Automotive Adhesive Market

Technological advances, regulatory changes and evolving consumer preferences will create strategic growth opportunities for the automotive adhesive market. Below are the key strategic growth opportunities for automotive adhesive:

• Shift to Light Weighting: To improve fuel efficiency and meet regulatory standards for emissions, automakers are increasingly striving towards lightening their cars. Lightening initiatives in automotive industry require advanced adhesives capable of replacing traditional joining techniques such as welding and mechanical fasteners. Automotive manufacturers prefer using adhesives because they lighten the weight, enhance structural integrity, increase design flexibility.

• Electric Vehicles (EVs)’ Rising Demand: Automotive adhesives have a significant growth opportunity in moving toward electric and hybrid vehicles. Electric vehicles need specialized adhesives which can withstand high temperatures, provide electrical insulation and support battery packs assembly, electronic components, thermal management systems among other things. Adhesive producers are working on solutions that will satisfy the unique needs of EV platforms; this is contributing to market enlargement.

• Smart Automotive Technologies Advancements: Adhesives meant for integration of smart technologies like sensors, Advanced Driver Assistance Systems (ADAS), connectivity among others should have specific characteristics like EMI shielding properties, thermal management attributes and durability. Adhesive suppliers are innovating with smart adhesive technologies that enable electronics seamless integration while improving signal transmission resulting to better vehicle performance and safety.

• Sustainability & Environmental Compliance: Environmental sustainability is becoming more important for both automotive OEMs and consumers themselves. Companies need adhesives with fewer VOC emissions, bio-based formulations or recyclable materials since these are more demanded today than ever before. In order to reduce the carbon footprints of their manufacturing process in response to regulation requirements adhesive manufacturers create sustainable production methods including environment friendly adhesives.

• Emerging Markets & Global Expansion: Car adhesive manufacturers are expanding into emerging markets characterized by rapid urbanization industrialization and increased motor vehicle production rates. Strategic investments in production facilities, distribution networks and local partnerships position suppliers well to respond to regional market requirements, enhance supply chain resilience and take advantage of growth opportunities within Asia Pacific region (APAC), Latin America (LATAM) or Middle East (ME) for that matter.

• Collaboration and Co-engineering Initiatives: Partnerships between adhesive manufacturers, automotive OEMs and research institutions facilitate innovation and rapid development of customized adhesives solutions. This allows suppliers to perform co-development by tailoring adhesive formulations for specific application needs, optimizing manufacturing processes as well as ensuring that the new materials used in vehicles are compatible with the latest vehicle designs.

• Technological Innovations & Product Differentiation: Continued investment in research and development enables adhesive manufacturers to introduce technologically advanced products with superior bonding strength, durability, and performance characteristics. Innovations in adhesive chemistry, application methods, and curing technologies enhance product differentiation and competitiveness in the automotive adhesive market.

Automotive Adhesive Market Driver and Challenges

Automotive adhesive play a crucial role in a wide range of applications due to their unique properties and versatile functionalities. The changing market dynamics are being driven by light weight initiatives and technological advancement. However, challenges like cost consideration and compatability to sustain growth and innovation in automotive adhesive market. The factors responsible for driving the automotive adhesive market include:

Light weighting Initiatives: Aluminum, composites and high strength steel are some of the lightweight materials that have increasingly become popular in automotive manufacturing. This has been done to enhance fuel efficiency and decrease emissions. Joining these light materials together instead of the traditional welding and mechanical fasteners is made possible by adhesives which play a significant role. The resultant trend towards light weighting therefore drives the demand for advanced adhesives that keep strong bonding properties while reducing overall vehicle weight.

Technological Advancements: Advances in adhesive formulations, bonding technologies, and application methods continue to improve performance, durability, and reliability of automotive adhesives. Innovations in adhesive chemistry enable manufacturers to develop products with improved flexibility, vibration damping ability or resistance to corrosion or thermal management properties as required by modern vehicle designs.

Electric and Hybrid Vehicle Adoption: Adhesive components used should be able to support battery packs, electric motors as well as electronic assemblies; they should withstand higher temperatures and provide electrical insulation necessary for the assembly of electric vehicles. Instead of contributing solely to impart structural integrity and safety on EVs, automobile adhesives also bring about integration of sophisticated systems geared towards better functionality and efficacy.

Safety and Performance Requirements: Adhesives make vehicles safer through improving crash performance, structural rigidity, and occupant protection because they distribute stress more uniformly thereby reducing fatigue failure risks on joints between components or body panels as well as making them last longer in general. As well adhesives are responsible for reduction in noise levels within cars leading to less vibrations meaning smoother rides.

Challenges facing the automotive adhesive market are:

• Cost Considerations: In some cases costs involved in using such adhesive materials can be higher compared with mechanical fastening techniques like those applied during welding processes used initially. Adhesive usage therefore incurs an extra cost at first though it may lead to long term savings such as reduced weight or even better car performance but all this depends on their production scale among other parameters considered by the automotive industry.

• Process Integration and Compatibility: One of the challenges to be addressed is adhesion’s integration into existing fabrication methods while also being compatible with various substrates, surface treatments and assembly techniques. Adhesives must meet strict process specifications, curing conditions as well as production timeline but shouldn’t compromise on manufacturing efficiency or product quality.

• Regulatory Compliance: In addition, there are regulatory standards put in place for adhesives manufacturers which aim at controlling VOCs emissions, dealing with hazardous substances and ensuring that workplaces are safe. However this has become harder as time goes on because formulation of a glue becomes more complicated due to needing some of these chemicals making up the final composition thus complying with set rules becomes more complex each year that passes.

• Material Compatibility and Joining Technologies: Thus, dissimilar materials, composites, or substrates can hardly provide optimal bonding because they have varying surface energy parameters, chemical makeup or thermal expansion coefficients. Thus research and development efforts should continue being channeled towards developing glues exhibiting strong adhesion across diverse material combinations as well as compatibility with sophisticated joining technologies utilized for example laser welding or riveting.

In summary therefore there are so many drivers behind the growth of this market; these include light weighting initiatives; technological advancements; electric vehicle adoption; safety requirements among others. However to take advantage of such opportunities in the market place we need to look at cost implications related challenges along with their solutions like process integration barriers; additionally durability is one important thing when considering about regulations governing VOC emission during production stages; finally material compatibility may affect the use of some adhesives in specific joints.

Automotive Adhesive Suppliers and their Market Shares

In this globally competitive market, several key players such as Henkel, 3M, H.B. Fuller, Arkema, Sika, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at helpdesk@lucintel.com. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report on “Automotive Adhesive Leadership Report".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies automotive adhesive companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the automotive adhesive companies profiled in this report includes.

• Henkel AG

• The 3M Company

• H.B. Fuller Company

• Arkema

• Sika AG

These companies have established themselves as leaders in automotive adhesive industry, with extensive product portfolios, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within automotive adhesive market are evolving, with the entry of new players and the emergence adhesive technologies. Additionally, collaborations between raw material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Automotive Adhesive Market by Segment

Major segments of automotive adhesive experiencing growth include interior and exterior applications, contribute to enhancing the properties of automotive adhesive in terms of strength, durability, chemical resistance, and other specialized characteristics. This advancement is crucial in meeting the increasingly complex demands of environmental protection, waste containment, and industrial applications.

This automotive adhesive market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including resin type, vehicle type, application, and structure. The report offers insights into regional dynamics, highlighting the major markets for automotive adhesive and their growth potentials. The study includes trends and forecast for automotive adhesive market through 2030, segmented by resin type, vehicle type, application, structure, and region as follows:

By Resin Type [Volume (M lbs) and Value ($M) Analysis for 2018 – 2030]:

• Epoxy

• Polyurethane

• Acrylic

• Others

By Vehicle Type [Volume (M lbs) and Value $M Analysis for 2018 – 2030]:

• Passenger Cars

• Light Commercial Vehicles

By Application [Volume (M lbs) and Value $M Analysis for 2018 – 2030]:

• Interior

• Exterior

By Structure [Volume (M lbs) and Value $M Analysis for 2018 – 2030]:

• Structural

• Non-Structural

By Region [Volume (M lbs) and Value $M shipment analysis for 2018 – 2030]:

• North America

o USA

o Mexico

o Canada

• Europe

o Germany

o Spain

o France

o Russia

o UK

• Asia Pacific

o China

o Japan

o India

o South Korea

• The Rest of the World

o Brazil

o Turkey

Features of Automotive Adhesive Market

Market size estimates: Automotive adhesive market size estimation in terms of value ($B) shipment and volume (M lbs).

Trend and forecast analysis: Market trend (2018-2023) and forecast (2024-2030) by region, resin, vehicle, application, and structure type.

Segmentation analysis: Automotive adhesive market size by resin, vehicle type, application, and structure in terms of value and volume shipment.

Regional analysis: Automotive adhesive market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth opportunities: Analysis on growth opportunities in different applications and regions in the automotive adhesive market.

Strategic analysis: This includes M&A, new product development, and competitive landscape in the automotive adhesive market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

FAQ

Q1. What is the automotive adhesive market size?

Answer: The global automotive adhesive market is expected to reach an estimated $24 billion by 2030.

Q2. What is the growth forecast for automotive adhesive market?

Answer: The automotive adhesive market is expected to grow at a CAGR of 11% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the automotive adhesive market?

Answer: The major drivers for this market are increasing demand for lightweight materials in vehicle manufacturing and replacement of mechanical fasteners with adhesives to make vehicles lighter and to meet higher fuel economy requirements.

Q4. What are the major applications or end use industries for automotive adhesive?

Answer: Exterior automotive is the major application for automotive adhesive market.

Q5. What are the emerging trends in automotive adhesive market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include increasing use of composites and lightweight materials in vehicles and new silicone-based electrically conductive adhesives in various automotive applications, and increasing applications of two component polyurethane adhesives.

Q6. Who are the key automotive adhesive companies?

Answer: Some of the key automotive adhesive companies are as follows:

• Henkel AG

• The 3M Company

• H.B. Fuller Company

• Arkema

• Sika AG

Q7.Which automotive adhesive structure segment will be the largest in future?

Answer: Lucintel forecasts that structural automotive will remain the largest segment and it is expected to witness the highest growth over the forecast period.

Q8: In automotive adhesive market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 7 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global automotive adhesive market by resin type (epoxy, polyurethane, acrylic and others), vehicle type (passenger car and light commercial vehicle), application (interior and exterior), structure (structural and non-structural), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the automotive adhesive market?

Q.5 What are the business risks and threats to the automotive adhesive market?

Q.6 What are the emerging trends in automotive adhesive market and the reasons behind them?

Q.7 What are the changing demands of customers in the automotive adhesive market?

Q.8 What are the new developments in the automotive adhesive market? Which companies are leading these developments?

Q.9 Who are the major players in automotive adhesive market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in automotive adhesive and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M&A activity has occurred in the last 5 years and what has its impact been on the industry?

For any questions related to automotive adhesive market or related to automotive adhesive market share, automotive adhesive market analysis, automotive adhesive market size, automotive interior adhesives, and automotive sealants and adhesives, write to Lucintel analysts at helpdesk@lucintel.com. We will be glad to get back to you soon.