ASEAN Automotive Composites Market Trends and Forecast

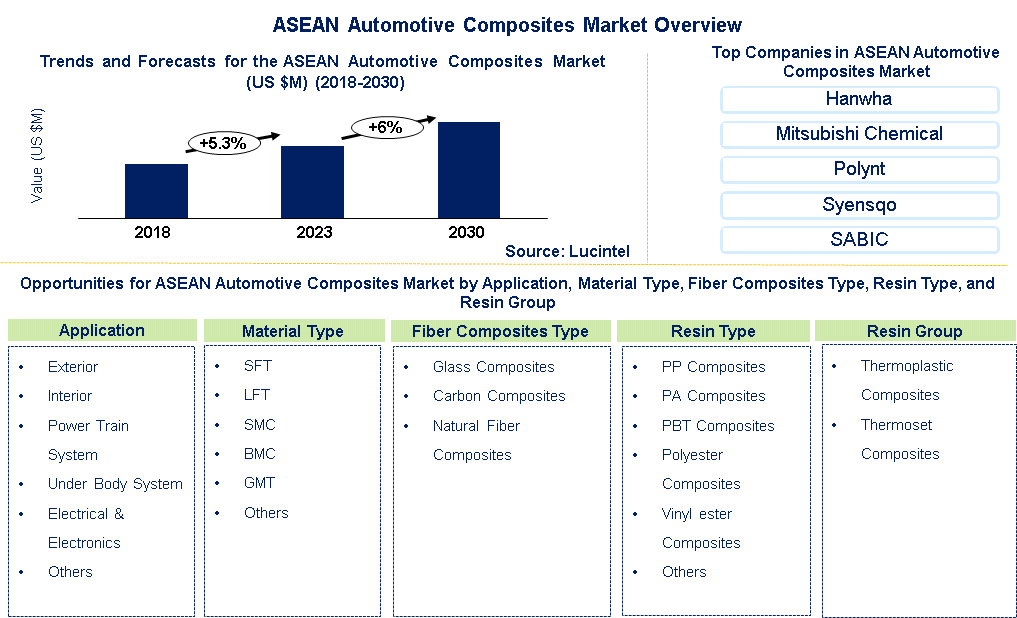

Lucintel finds that future of the ASEAN automotive composites intermediate material market looks promising with opportunities in exterior, interior, power train systems, under body systems, and electrical and electronics application. The ASEAN automotive composites material market is expected to grow with a CAGR of 6% 2024 to 2030. The major drivers for growth in this market are increasing demand for lightweight parts with high performance benefits in the automotive industry.

Automotive composites are made from a wide range of raw materials which include primarily of resins like unsaturated polyester resins, epoxy resins and vinyl ester resins that play a role as the binding agents. Among these are glass fibers, carbon fibers, natural fibers (such as jute or hemp), and aramid fibers used to reinforce this resin so that it withstands better loads. Likewise, fillers such as calcium carbonate talc or mica can be incorporated in order to improve mechanical properties and reduce costs. The pricing of automotive composites is influenced by factors like raw material costs, manufacturing complexity and market demand trends. In general terms, composites compare favorably with conventional materials such as metals because they are ‘lightweight’, thereby contributing to improved fuel economy and performance although specific price comparisons depend on applications and regional market conditions.

-

Lucintel forecasts that SFT will remain the largest segment by value and volume and will experience the highest growth over the forecast period because it offers corrosion resistance, insulation properties, low susceptibility to moisture and high mechanical properties.

-

Power train system industry will remain the largest application and exterior application segment is expected to witness the highest growth over the forecast period due to increasing demand for composite components in automotive industry.

Country wise Outlook for the ASEAN Automotive Composites Market

Emerging Trends in the ASEAN Automotive Composites Market

Emerging trends in ASEAN automotive composites are shaping its future applications and market dynamics:

-

Integration of Smart Composites: Integration of smart functionalities such as sensors and self-monitoring capabilities in composites to enhance safety, durability, and performance in automotive applications.

-

Electric Vehicle (EV) Integration: Government incentives such as tax breaks on green energy products and consumer preferences for sustainable transportation solutions drive the use of composites in electric vehicles for weight reduction and farther range.

-

Adoption of Advanced Manufacturing Technologies: Automating composite manufacturing processes by integrating automation and robots to improve efficiency reduce costs and ensure uniformity of quality.

-

Sustainability Initiatives: This has resulted in environmental regulations that necessitate eco-friendly composites made from recyclable materials using bio-based resins.

-

Increasing Use of Lightweight Materials: Examples include carbon fiber-reinforced composites (CFRP) which have been widely used in aerospace industry to improve fuel economy as well as to enhance vehicle performance.

-

Functional Integration: These functional properties include electromagnetic shielding, acoustic insulation or thermal management that helps to optimize vehicle performance while ensuring passenger comfort.

These trends highlight ASEAN's evolving automotive composites market towards lightweight, sustainable, technologically advanced materials to meet the demands of a growing automotive sector.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the ASEAN Automotive Composites Market

Recent developments in ASEAN automotive composites by highlighting ongoing innovations and advancements across different sectors

-

Expansion of Capacity: Rising demand has fueled the increase in automotive composite production capacities in some ASEAN countries like Malaysia, Thailand and Indonesia.

-

Progress in Technology: Improvement of manufacturing methods that include automated lay-up; RTM (Resin Transfer Molding) and compression molding to enhance process efficiency and better product quality.

-

The Cooperation and Partnership: Besides, ASEAN manufacturers have also ventured into joint ventures with international car makers to produce unique products using advanced materials for automobile industry.

-

Lightweighting is Key: The emphasis on lighter materials such as carbon fiber composites and hybrid composites has risen in order to improve fuel economy and performance.

-

Initiatives Promoting Environmentalism: These companies use recyclable materials and bio-resins to manufacture eco-friendly composites that would match global environmental targets as well as customers’ preferences.

Strategic Growth Opportunities for ASEAN Automotive Composites Market

The ASEAN automotive composites market has various strategic growth opportunities because of changing consumer tastes, regulatory modifications and advancement in manufacturing technologies.

-

Emphasis is Placed on Lightweight Materials: Nowadays, ASEAN automobile makers are opting for weight-saving materials such as composites due to the increasing focus on fuel economy and reduced emissions. In contrast to conventional materials like steel and aluminum, composites can save a lot of weight leading to improved vehicle efficiency and performance. As countries of ASEAN continue following international emission norms and customers’ preferences for greener vehicles.

-

Growing Infrastructure Development: Automotive sector growth in ASEAN countries especially highways, bridges and urban transportation systems among others depend heavily on ongoing infrastructure development. Increasingly, infrastructure uses composites due to their durability including corrosion resistance, design flexibility etc. Thus composite manufacturers get another outlet through which they can expand their market instead of being limited solely into automotive applications.

-

Technological Advancements: The progress in manufacturing processes together with advancements in composite materials has improved their performance attributes thereby making them more viable for application in automotive industry. Cost reductions or gain efficiencies have been achieved through innovations such as automated manufacturing, hybrid composites and sustainable materials therefore this is what makes them attractive more than ever before even to the automotive OEMs located within the ASEAN region.

-

Local Manufacturing & Supply Chain Integration: Localizing operations not only supports regional economic development but also makes ASEAN manufacturers in global automotive industry more competitive. Setting up local manufacturing facilities combined with supply chain integration within ASEAN countries could help reduce lead times as well as logistics costs associated with automotive composites.

-

Collaboration and Partnerships: By forming alliances between automotive OEMs, composite manufacturers, research institutions and government entities, technology development for the market adoption of composites in ASEAN can be accelerated. What comes into play here are joint ventures (JVs) that enable them to exchange knowledge, transfer technology, access funding hence promote innovation process and also facilitate market expansion.

In conclusion, the ASEAN automotive composites market is predicted to grow as a result of focus on light weighting trends; electric vehicle uptake; infrastructure projects; technological advances; local manufacturing drives; strategic partnerships. Businesses that take full advantage of these opportunities stand to become major players within the dynamic ASEAN automotive landscape serving both domestic and foreign markets with innovative composite solutions.

ASEAN Automotive Composites Market Drivers and Challenges

The ASEAN automotive composites market is at a fork in the road due to different factors that are shaping its growth direction. Automotive producers in Southeast Asia have seen an increase in demand for light weight materials such as composites, as they strive to meet strict regulatory norms on fuel efficiency and emissions. These composites deliver a significant reduction in weigh plus enhanced vehicle performance and design flexibility. But there are some problems such as reducing costs, supply chain complexities, compliance with regulations and manufacturing intricacies amid these drivers. Therefore, it is important for participants who want to optimize these prospects or surmount challenges within this changing marketplace to comprehend the dynamics underpinning them

The key drivers for the ASEAN automotive composites market include:

-

Regulations for Fuel Efficiency and Emissions: Stricter fuel efficiency and emissions regulations are necessitating that automakers in ASEAN turn to lightweight materials such as composites that decrease vehicle weight for better fuel mileage and reduced emissions.

-

Rise in Vehicle Production: This region is the automotive manufacturing center with Thailand, Indonesia, and Malaysia serving as the major producers. Hence, there is an increased demand of composites used in the components and structures of vehicles by both passenger cars and commercial vehicles.

-

Progress in Composite Technologies: Continuous improvements in composite materials, methods of making them and designing capabilities have made these products more performing as well as cheap hence their widespread application to automotive industries.

-

Demand for Improved Vehicle Performance: Users desire enhanced safety, performance or even comfort features at least. Such needs are readily addressed by automotive composites through providing strength, stiffness, and design flexibility for the requirements.

-

Focus on Lightweighting: Light weighting is now a priority for many automobiles OEMs for meeting regulatory requirements or customers’ preferences towards vehicles having high fuel economy; therefore, achieving these reduction targets heavily relies on composites like CFRPs (Carbon Fiber Reinforced Polymers) & GFRPs (Glass Fiber Reinforced Polymers.

The key challenges in the ASEAN automotive composites market include:

-

Cost Implications: Composite materials could cost more than traditional ones like steel and aluminum. This means that the manufacturing processes should be low cost and there needs to be economies of scale so as to make mass –producing automotive composites a profitable venture for ASEAN nations.

-

Supply Chain Constraints: Establishment of a dependable composite raw material and technology supply chain is still a challenge in some ASEAN countries. This may affect production time frame and costs since they heavily rely on importation of materials and technologies.

-

Manufacturing Complexities: Composite materials require specific manufacturing methods, procedures, or equipment. To effectively produce integrations of composites into automotive manufacturing process, investments will have to be made by ASEAN manufacturers in training as well as infrastructure.

-

Design and Integration Challenges: When incorporating composites into vehicle designs without sacrificing performance, safety or cost effectiveness; original equipment manufacturers (OEMs) must liaise with their suppliers, designer’s etcetera… This can become very complex leading to wastage of time.

-

Regulatory Compliance: For automotive applications with composite materials, substantial testing as well as validation process is required before they meet regional and international standards for their safety requirements which are extensive. There are also complexities associated with regulatory compliance when one is adopting automotive composites at large-scale level within this region.

A full of potential opportunity driven by laws, technology advancements and client demands for more energy effective and sustainable cars is an ASEAN automotive composites market. The use of light weight composites offers the chance to meet these requirements with their attendant benefits such as improved fuel economy, better performance as well as innovative design. For this reason, it can be said that obstacles like high costs, regulatory hurdles and restricted supply chains require comprehensive attention across the entire sector. If innovation, cooperation and strategic investments are used in addressing these challenges, then stake holders will unlock all potentials in automotive composites found in ASEAN promoting the global auto industry’s sustainability and competitiveness.

ASEAN Automotive Composites Suppliers and Their Market Shares

In this ASEAN automotive composites market, several key players such as Hanwha, Mitsubishi Chemical Advanced Materials, Polynt Group, Syensqo, and SABIC, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players Contact Us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies ASEAN automotive composites companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the ASEAN automotive composites companies profiled in this report include

These companies have established themselves as leaders in ASEAN automotive composites industry with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within ASEAN automotive composites market are evolving, with the entry of new players and the emergence of innovative technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

ASEAN Automotive Composites Market by Segment

The ASEAN automotive composites market is witnessing significant growth across several key segments. Carbon fiber composites are in high demand due to their ability to reduce vehicle weight while enhancing fuel efficiency and performance, particularly in lightweight vehicles. Glass fiber composites continue to expand, valued for their cost-effectiveness and versatility in various automotive applications. Thermoplastic composites are gaining traction for their recyclability, impact resistance, and suitability for complex automotive components. With the rise of electric vehicles (EVs), there is a growing integration of composites to reduce vehicle weight and increase battery efficiency, supported by regional incentives and environmental regulations. Moreover, advancements in manufacturing technologies such as resin transfer molding (RTM) and automated processes are enhancing production efficiency and enabling the production of high-quality automotive composites in the ASEAN region. These trends underscore a dynamic shift towards lightweight, sustainable, and technologically advanced materials in ASEAN's automotive sector

The study includes trends and forecast for the ASEAN automotive composites market by application, material type, fiber composites type, resin type, resin group, and country as follows:

By Application [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

By Material Types [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

By Fiber Composites Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

By Resin Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

By Resin Group [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

By Country [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

-

Malaysia

-

Thailand

-

Vietnam

-

Indonesia

-

Others

Features of ASEAN Automotive Composites Market

-

Market Size Estimates: ASEAN automotive composites market size estimation in terms of value ($M) and volume (M lbs).

-

Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments.

-

Segmentation Analysis: Market size by application, material type, fiber composites type, resin type, resin group, and country.

-

Growth Opportunities: Analysis of growth opportunities in different application, material type, fiber composites type, resin type, resin group, and country for the ASEAN automotive composites market.

-

Strategic Analysis: This includes M&A, new product development, and competitive landscape for the ASEAN automotive composites market.

-

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in ASEAN automotive composites market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the growth forecast for ASEAN automotive composites market?

Answer: The ASEAN automotive composites market is expected to grow at a CAGR of 6% from 2024 to 2030.

Q2. What are the major drivers influencing the growth of the ASEAN automotive composites market?

Answer: The major drivers for growth in this market are increasing demand for lightweight parts with high performance benefits in the automotive industry.

Q3. What are the major applications or end use industries for ASEAN automotive composites market?

Answer: Power train and interior are the major applications for ASEAN automotive composites.

Q4. What are the emerging trends in ASEAN automotive composites market?

Answer: Emerging trend, which have a direct impact on the dynamics of the industry, include integration of smart composites, electric vehicle integration, adoption of advanced manufacturing technologies, sustainability initiatives, lightweight materials.

Q5. Who are the key the ASEAN automotive composites companies?

Answer: Some of the key the ASEAN automotive composites companies are Hanwha, Mitsubishi Chemical Advanced Materials, Polynt , Syensqo, SABIC, Avient etc.

Q6.Which ASEAN automotive composites material type segment will be the largest in future?

Answer: Lucintel forecasts that SFT is expected to remain the largest material type segment by volume over the forecast period because it offers corrosion resistance, insulation properties, low susceptibility to moisture and high mechanical properties.

Q7. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 10 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the ASEAN automotive composites market by application (exterior, interior, power train systems, under body systems, electrical and electronics, and others), material type (SFT (short fiber thermoplastic), LFT (long fiber thermoplastic), SMC (sheet molding compound), BMC (bulk molding compound), and GMT (glass mat thermoplastic), and other), fiber composites type (glass fiber, carbon fiber and natural fiber), resin type (PP (polypropylene), PA (polyamide), PBT (Polybutylene Terephthalate), polyester, vinyl ester and others), resin group (thermoplastic, thermoset), and country (Malaysia, Thailand, Vietnam, Indonesia, and others)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.4 What are the business risks and threats to the market?

Q.5 What are the emerging trends in this market and the reasons behind them?

Q.6 What are the changing demands of customers in the market?

Q.7 What are the new developments in the market? Which companies are leading these developments?

Q.8 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.9 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.10 What M & A activities have taken place in the last 5 years in this market?