Aerospace Foam Market Trends and Forecast

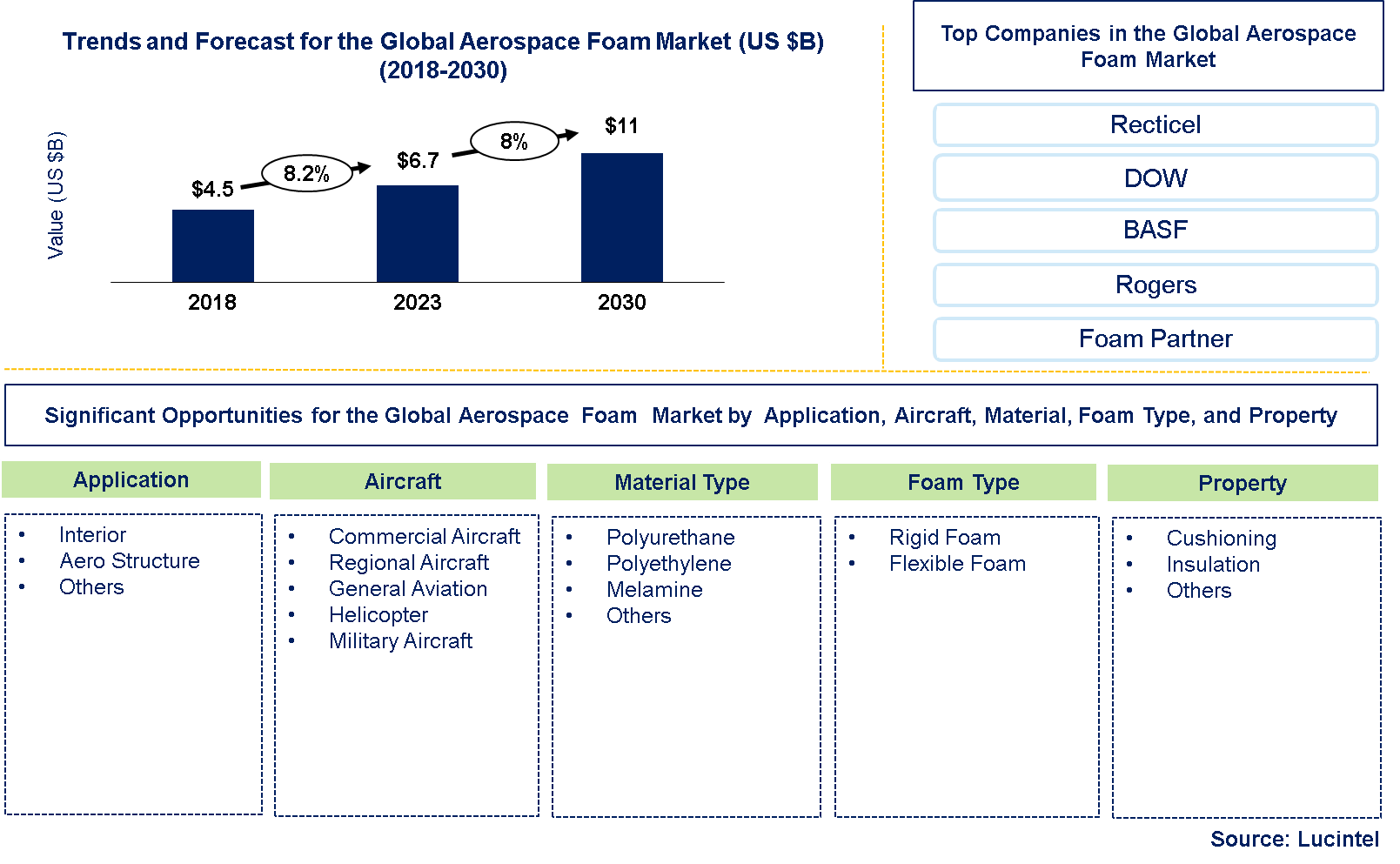

Lucintel finds that the future of the aerospace foam manufacturing market looks good with opportunities in the commercial aircraft, regional aircraft, general aviation, helicopter, and military aircraft applications. The aerospace foam market is expected to reach an estimated 11 billion by 2030 with a CAGR of 8% from 2023 to 2030. The major drivers for this market are increases in aircraft delivery, and retrofitting of aircraft interiors.

Usually, aerospace foam is made out of light-weight, strong polyurethane, polyethylene or other specialized polymers that are ideal for airplane interiors, insulation and structural use. The cost of aerospace foams changes as per the specific type and usage but it’s usually more expensive than traditional ones due to how stringent quality requirements in aviation ensure strict safety standards and quality control processes during manufacturing. However, the slightly high prices are worth due to the excellent qualities that come with this material such as being fire-resistant, having good thermal insulation properties as well as having low weight which will lead to a higher price for this product on the competitive aerospace materials market.

• Lucintel forecasts that the interior segment is likely to remain the largest market during the forecast period due to large amount of foam used in aircraft seats and cabin insulation. Within the aerospace foam market, commercial aircraft is the largest segment by aircraft type.

• Within this market by material type, polyurethane foam is expected to remain the largest market over the forecast period because it offers the most versatile properties such as ability to formulate in a wide range of stiffness, hardness, and densities.

• By foam type, the flexible foam segment is expected to be the largest segment because flexible foam can be transformed in almost any shapes and firmness; it provides cushioning and insulating properties. Flexible foam is used in aircraft seats, carpets, cabin insulation, duct insulation, gaskets, and seals.

• Europe will remain the largest region by value and by volume during the forecast period due to high demand for newer aircraft and the replacement of an aging fleet.

Country wise Outlook for the Aerospace Foam Market

The aerospace foam market is witnessing substantial growth globally, driven by increased demand from various industries such as sports. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major aerospace foam producers in key regions: the USA, EU, China, India, and Brazil.

Emerging Trends in the Aerospace Foam Market

Emerging trends in the aerospace foam market shaping its future applications and market dynamics:

• Advancements in Lightweight Materials: This particular market has seen a shift towards more advanced lightweight materials such as closed-cell polyurethane foams and specialty polymers that help meet the strict weight reduction goals of aircraft design.

• Focus on Fire Resistance and Safety: There is an increasing focus on developing fire resistant foam materials which are able to comply with the stringent aviation safety regulations so that passenger and crew members can be safer in case of fire outbreak during the flight time.

• Integration of Advanced Insulation Properties: Thus, aerospace foams have lately become better in terms of their thermal properties and noise damping features since these greatly matter for passengers’ comfort; it also helps to minimize noise levels hence enhance overall passenger experience.

• Taking major Sustainability Initiatives: Moreover, sustainable foam solutions are gaining popularity among players in this industry due to commitment by the aerospace sector aimed at minimizing its environmental footprint. These entail eco-friendly foams that have least impacts on their environment throughout their life cycles.

• Technological Innovations: Innovations in foam manufacturing processes, such as additive manufacturing (3D printing) and advanced molding techniques, are enabling the production of complex foam shapes and structures tailored to specific aerospace applications

In conclusion, increasing concerns on weight reduction in aerospace applications will continue driving growth in the industry. Ultimately, there’s a need for enhanced safety features, sustainable solutions and technological innovation in the market.

A total of 49 figures / charts and 42 tables are provided in this 159 page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments by the Aerospace Foam Market

Recent developments in aerospace foam market highlighting ongoing innovations and advancements across different sectors:

• Innovative Materials: Aerospace foam manufacturers are increasingly concentrating on inventing and making available novel materials, such as lightweight closed-cell polyurethane (PU) foams and special polymers. These materials give a better level of thermal and acoustic insulation that leads to the improvement of cabin temperature, which consequently results in aircraft energy efficiency.

• Safety Enhancements: There is an increasing focus on improving the flame retardance and safety properties in aerospace foam materials. Company research efforts should ensure that foam products provide effective fire protection and smoke suppression capabilities while complying with stringent aviation safety requirements.

• Technological Integration: Foam manufacturing techniques have advanced to include automated production procedures and additive manufacturing (3D printing), which has disrupted the aerospace foam market. Through these technologies, foam structures can be customized in terms of shapes to optimize performance while maintaining low production costs.

• Sustainability Initiatives: Aerospace foam manufacturers are increasingly using environmentally friendly practices and materials to reduce their environmental footprints. This includes developing eco-friendly foam solutions with improved recyclability or biodegradability thus aligning with industry trends relating towards sustainability and corporate social responsibility.

• Market Expansion & Collaboration: Corporations grow by expanding their market presence through strategic collaborations, partnerships or mergers aimed at enhancing their product portfolios as well as global reach. These initiatives are meant to capitalize on increasing demand for aerospace products in regions like Asia-Pacific or Latin America that present emerging market opportunities.

Strategic Growth Opportunities for Aerospace Foam Market

• Aircraft Interiors: The demand for lightweight materials that increase passenger comfort and operational efficiency is driving the significant potential for growth in aircraft interior applications such as seat, cabin insulation and decorative panels.

• Structural Components: Aerospace foams are increasingly used in structural components such as sandwich panels and composite structures, offering weight savings and structural reinforcement benefits in aircraft wings, fuselage, and rotor blades.

• Spacecraft and Satellite Applications: The expanding space exploration sector presents opportunities for aerospace foams in spacecraft interiors, thermal protection systems, and payload fairings, where lightweight and thermal insulation properties are critical.

• Military and Defense: Ballistic protection, flotation capabilities, soundproofing are some of the ways foam materials are used in naval vessels, military aircrafts among other defense applications making it one of the most important sectors where these products are used.

• Emerging Markets: Exploration of emerging markets in Asia-Pacific and Latin America for aerospace foam applications is expected to grow, driven by increasing aerospace investments, expanding commercial aviation fleets, and rising demand for luxury and executive jets

Aerospace Foam Market Drivers and Challenges

The role of the Aerospace Foam Market is very crucial in the modern aviation, which is driven by desire for light weight materials, better safety and technological innovation. In aircrafts, Aerospace foams are used in interiors, insulation as well as structural components that result to enhanced fuel efficiency, passenger wellbeing and operational efficiency. Nonetheless, this ever-changing market comes with a set of challenges including high production costs, strict regulations and meeting sustainability targets among others. Therefore it is vital for stakeholders to recognize how growth occurs and what difficulties must be faced to survive in the aerospace industry’s intricate labyrinth.

The key drivers for the Aerospace Foam Market

• Demand for Lightweight Materials: There is an urge for lightweight materials in the aerospace industry to save fuel as well as reduce operational costs. Aerospace foams, known for their high strength-to-weight ratios, are a significant contributor towards achieving weight reduction targets in aircraft design.

• Increasing Aircraft Production: The surge in commercial aircraft production fueled by increasing air travel demand and fleet expansion contributes to the demand for aerospace foams. These materials form part of aircraft interiors, insulation, and structural components among others propelling growth of the aerospace industry.

• Stringent Safety and Comfort Standards: Aerospace foams are essential for meeting stringent safety and comfort standards in aircraft interiors. They provide thermal and acoustic insulation, fire resistance, and impact absorption capabilities, enhancing passenger safety and comfort during flight.

• Advancements in Material Science: The continued improvements in material science include development of innovative foam formulations, as well as manufacturing techniques that further expand the performance capabilities of aerospace foams. This ensures that there is continuous improvement on the overall performance, durability, and thermal stability.

• Technological Innovations: Advanced manufacturing technologies such as additive manufacturing (3D printing) have allowed for intricate foam structures with precise geometries to be made. Design flexibility is therefore improved together with customization which optimizes production efficiency.

The key challenges for the Aerospace Foam Market

• High Cost of Materials and Production: Aerospace foam materials are typically subject to high costs and specialized manufacturing methods, thus increasing the cost of production compared with other traditional materials. However, despite advances in the technology of production, it is difficult to achieve cost-efficiency.

• Complex Regulatory Compliance: Compliance with stringent aviation safety regulations and certification processes is crucial but challenging for aerospace foam manufacturers. Meeting regulatory requirements for fire resistance, toxicity levels, and performance standards adds complexity and cost to product development.

• Environmental Concerns: The demand for sustainable alternatives in the aerospace sector has increased pressure on developing ecologically friendly foams which have little environmental footprint. Nevertheless, dealing with issues about foam disposal, its recyclability and environmental footprint persists.

• Technical Performance Requirements: Aerospace foams should always meet specific technical performance requirements such as thermal stability, durability under extreme conditions; aging and degradation resistance among others. These performance standards can be continually achieved or maintained by producers.

• Supply Chain Disruptions: In addition to geopolitical factors and economic uncertainties that disrupt raw material supply chains, there may be impacts on availability and price of aerospace foam materials. Hence, risk management within supply chains and ensuring that there is continuity of supply are essential for industry players.

Just to conclude, within the aerospace industry, the aero space Foam Market has been found as a point where necessity connects with innovation. There remain challenges regarding costs, regulations and environmental implications; however this facts keep evolving because of continuous advancement in material science market demand and manufacturing technologies. Moving forward these researches must be carried out collaboratively with technological advancements and sustainable practices. As the aerospace sector expands its demands and standards shift; it is evident that suppliers as well as manufacturers of these foams have been strategically positioned to take up this leadership mantle in availing environmentally friendly, safer and more efficient aviation solutions.

Aerospace Foam Market Suppliers and Their Market Shares

In this globally competitive market, several key players such as Recticel, DOW, BASF, Rogers, and Foam partner etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players Contact Us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies aerospace foam market companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the aerospace foam companies profiled in this report include.

• Recticel

• DOW

• BASF

• Rogers

• FXI

• Foam Partner

These companies have established themselves as leaders in the aerospace foam market industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the aerospace foam market are evolving, with the entry of new players and the emergence of innovative carbon fiber technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Aerospace Foam Market by Segment

Some key segments of the aerospace foam market are experiencing a considerable growth, while others have experienced a significant growth. In-flight comfort is improving as more foams are used for aircraft seats, cabin lining and thermal panels to reduce noise and improve overall beauty of cabins. There has been an increased use of aerospace foams in sandwich panels and composite structures that help to reduce weight hence improved fuel efficiency in aircrafts. One can observe that there is growing demand for spacecraft interiors, payload fairings and thermal protections systems made up of foams with high thermal insulation properties required for temperature stability. Ballistic protection, sound insulation and shock absorption are some of the notable uses of aerospace foams in military airplanes, ships, armor-plated cars among others (Wang). Aerospace foams also play an important role in reducing weight while still meeting high safety and performance standards necessary for commercial aviation. Thus, the above industries’ demands for light-weight high-performance materials fueled by foam technology advancement present key drivers for these growing segments.Some key segments of the aerospace foam market are experiencing a considerable growth, while others have experienced a significant growth. In-flight comfort is improving as more foams are used for aircraft seats, cabin lining and thermal panels to reduce noise and improve overall beauty of cabins. There has been an increased use of aerospace foams in sandwich panels and composite structures that help to reduce weight hence improved fuel efficiency in aircrafts. One can observe that there is growing demand for spacecraft interiors, payload fairings and thermal protections systems made up of foams with high thermal insulation properties required for temperature stability. Ballistic protection, sound insulation and shock absorption are some of the notable uses of aerospace foams in military airplanes, ships, armor-plated cars among others (Wang). Aerospace foams also play an important role in reducing weight while still meeting high safety and performance standards necessary for commercial aviation. Thus, the above industries’ demands for light-weight high-performance materials fueled by foam technology advancement present key drivers for these growing segments.

Aerospace Foam Market by Aircraft [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Commercial Aircraft

• Regional Aircraft

• General Aviation

• Helicopter

• Military Aircraft

Aerospace Foam Market by Material Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Polyurethane

• Polyethylene

• Melamine

• Others

Aerospace Foam Market by Application [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Interior

• Aero structure

• Others

Aerospace Foam Market by Foam Type [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Rigid Foam

• Flexible Foam

Aerospace Foam Market by Property [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Cushioning

• Insulation

• Others

Aerospace Foam Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Aerospace Foam Market

• Market Size Estimates Aerospace foam market size estimation in terms of value ($M) and volume ( M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: The aerospace foam market size by various segments, such as by aircraft, material type, application, foam type, property, and regions in terms of value

• Regional Analysis Aerospace foam market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different segments aircraft, material type, application, foam type, property.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for aerospace foam market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in aerospace foam market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

Frequently Asked Questions (FAQ)

Q1. What is the composite cardboard tube in the packaging market usage?

Answer: The consumption of aerospace foam market is expected to reach an estimated $11 billion by 2030.

Q2. What is the growth forecast for aerospace foam market?

Answer: The use of aerospace foam market is expected to grow at a CAGR of 8% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the use of aerospace foam market?

Answer: The major drivers for this market are increases in aircraft delivery, and retrofitting of aircraft interiors.

Q4. What are the major applications of aerospace foam market?

Answer: Commercial aircraft is the major segment by aircraft type for aerospace foam.

Q5. What are the emerging trends in aerospace foam market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, includes advancements in lightweight materials, focus on fire resistance and safety, integration of advanced insulation properties, taking major sustainability initiatives, and technological innovations.

Q6. Who are the key companies of aerospace foam market?

Answer: Some of the key aerospace foam companies in the global transportation composites market are as follows:

• Recticel

• DOW

• BASF

• Rogers

• FXI

• Foam Partner

Q7.Which will be the largest segment in the future in the g aerospace foam market usage?

Answer: Lucintel forecasts that Commercial aircraft will remain the largest segment over the forecast period,

Q8: In terms of aerospace foam market, which region is expected to be the largest in the next five years?

Answer: Europe is expected to remain the largest region, and ROW is projected to witness the highest growth over the next five years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following key questions

Q.1 What are some of the most promising, high-growth opportunities for the global aerospace Foam market by application (interior, aero structure, and others), aircraft (commercial aircraft, regional aircraft, general aviation, helicopter, and military aircraft), material type (polyurethane, polyethylene, melamine, and others), foam type (rigid foam and flexible foam), property (cushioning, insulation, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?