3D Printing Materials Market Trends and Forecast

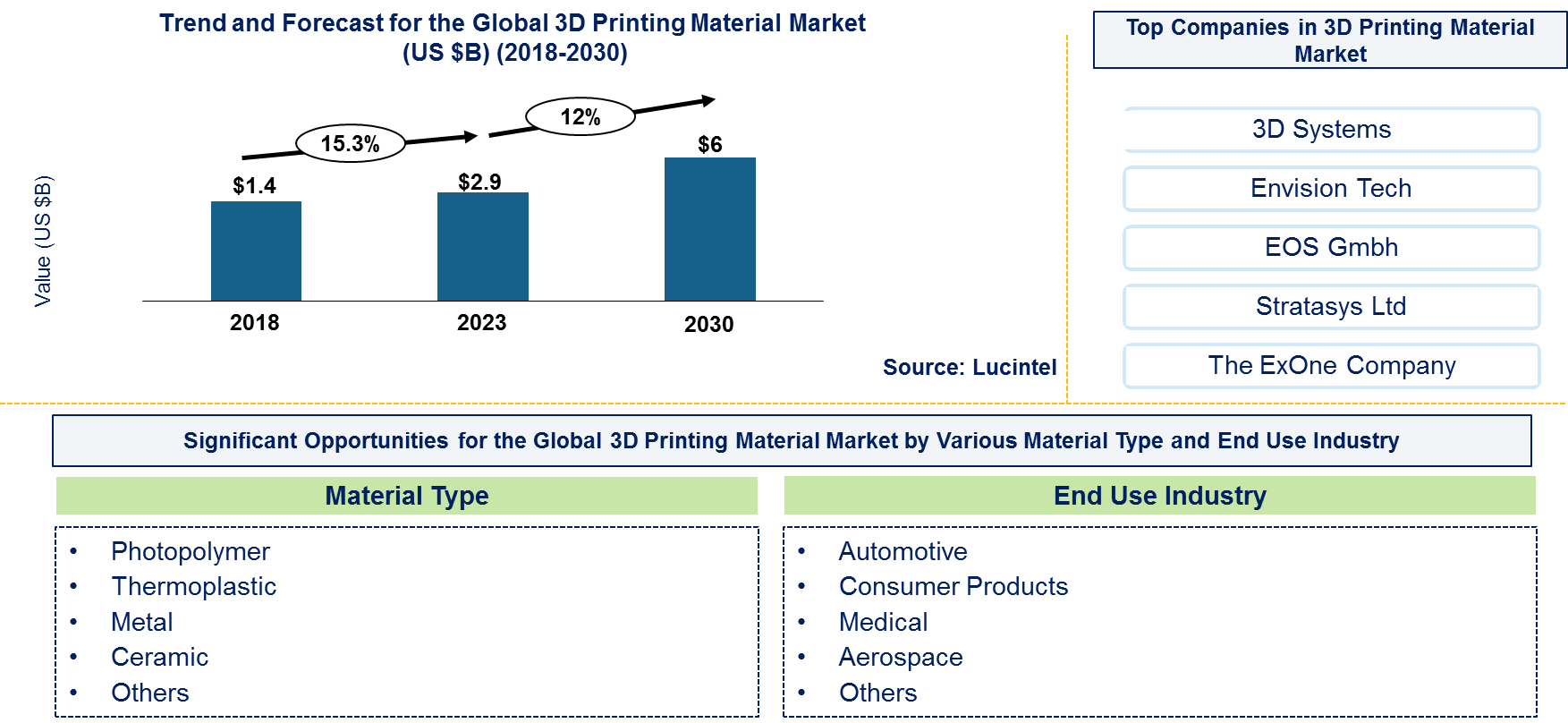

The future of the global 3D printing materials market looks promising with opportunities in the automotive, consumer, medical, and aerospace industries. The global 3D printing material market is expected to reach an estimated $6 billion by 2030 with a CAGR of 12% from 2023 to 2030. The major drivers for this market are rapid acceptance of 3D printing technology from prototyping to final product manufacturing and reduction in manufacturing cost.

3D printing uses various raw materials, which are specifically designed for different printing technologies and purposes. On the other hand, resin-based printing involves liquid photopolymers and filament-based printing makes use of thermoplastics like ABS and PLA. In the metal 3D printing processes titanium and aluminum are used while in ceramic 3D printing use of ceramic powders such as zirconia and alumina is often done. Furthermore, composite blends using materials like zinc have added up to having improved mechanical properties while biomaterials are applied for bio-printing applications. These costs may vary greatly depending on whether the material is a type of plastic, metal or ceramic; if it was made through a process like FDM, SLA or SLM; or what physical attributes were desired in the printed object being created. However, with less cost due to decreased cost related to tooling as well as setup charges compared to traditional manufacturing approaches whereby 3D printed materials can be competitive for prototyping and low volume production runs. Nevertheless for high scale manufacturing; injection molding or CNC machines could be better placed than additive programs.

• Lucintel forecasts that photopolymers will remain the largest material for 3D printing due to the increasing demand in medical, consumer electronic, and aerospace industries.

• Medical industry is expected witness the highest growth during the forecast period due to increasing adoption of 3D printing in medical devices and tissue engineering products.

• Asia Pacific is expected to witness the highest growth over the forecast period due to the growing awareness of 3D printing technology and increasing adoption of 3D printing materials in medical and dental implants

Country wise Outlook for the 3D Printing Materials Market

The 3D printing materials market is witnessing substantial growth globally, driven by increased demand from various industries such as aerospace, automotive, medical, and consumer. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major 3D printing materials producers in key regions: the USA, China, India, Japan, and Germany

Emerging Trends in the 3D Printing Materials Market

Emerging trends in the 3D Printing Materials market shaping its future applications and market dynamics:

• Use of Bio-inks and Gels in Medical Industry: One of the rapidly growing technologies is 3D bioprinting. This was initially marketed by “Organovo,” a San Diego-based company. Organvo has also tried printing pieces of lungs, kidneys, and heart muscles among others.

• Growing Use of Composite Materials: Many composites have been fashioned that bring more advantages than their regular counterparts because they give added strength, suppleness and open new horizons for application in various industries.

• Growing Merger and Acquisition Activities: The leading companies in the 3D printing business are having much merger as well as acquisition activities with an aim or strategy to be industry leader through covering all related fields and materials.

• Growing Application of Carbon-Fiber Reinforced Composites: The carbon fiber reinforced composites (CFRP) are increasingly being used as polymer material in 3D printing. The aerospace industry demands this material because it has a high strength to-weight ratio, higher than composites reinforced with glass and other fibers aramid.

A total of 91 figures / charts and 77 tables are provided in this 284-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments in the 3D Printing Materials Market

Ongoing innovations and advancements in various sectors of the 3D printing materials market which have been highlighted by recent developments:

• Expansion of Material Options: The expansion of the available materials range, and new materials being developed with improved qualities such as toughness, resilience and resistance to temperatures to suit different industries.

• Biocompatible and Medical Grade Materials: Evolution of biomaterials in the healthcare industry for use in medical devices and bioinks for tissue engineering and implants.

• Sustainability Initiatives: Focus on sustainable material sourcing and recycling methods for lower ecological footprints through research on biobased 3D printing feedstocks and recyclable raw polymer powders.

• Metal and Ceramic Materials Advancements: Developments in metal and ceramic powders used for high-performance aerospace, automotive, engineering applications due to better powder quality as well as process improvements in printing technology.

• Customizable and Composite Materials: Innovations made towards producing customizable materials with additives like carbon fibers or nanoparticles added into them making them more efficient mechanically.

Strategic Growth Opportunities for 3D Printing Material Market

Technological advancements, broadening applications across industries and increasing the demand for customized manufacturing solutions have presented opportunities for growth in the 3D printing materials market. Below are some of these opportunities.

Industry Diversification: The use of 3D printing (additive manufacturing) has spread farther than traditional sectors such as aerospace or automotive into healthcare, consumer goods, electronics, and construction. Every industry has its own material requirements which offer a potential for specialized 3D printing materials that serve their respective applications.

Advanced Polymers and Composites: There is a growing demand for high-performance polymers and composite materials capable of meeting stringent performance criteria. For instance, aerospace and automotive industries require materials with superior mechanical strength, heat resistance, chemical inertness and lightweight properties. This creates strategic opportunities to develop advanced polymers like PEEK, PEI; composite materials such as carbon fiber reinforced polymers that can withstand extreme conditions while replacing conventional manufacturing materials.

Metal Powders for Additive Manufacturing: Metal 3D printing is gathering pace because it enables production of geometries with complex shapes having functional parts characterized by high strength-to-weight ratios. Titanium, aluminum, stainless steel and nickel alloys metal powders can be supplied to aerospace industry, medical implants, and automotive application markets where precision, durability, and customization are essential.

Biocompatible Materials for Medical Applications: One of the areas where the growth rate will be steady is healthcare industry in respect to 3D printing materials used in biocompatible polymers and metals utilized in making devices such as medical implants, prosthetics and surgical tools. Innovations on materials like titanium alloys and biodegradable polymers (for example PLA/PCL) have created room for patient-specific implant development thereby improving surgical outcomes.

Customized and On-Demand Manufacturing: Through 3D printing demands can now be met individually; rapid prototyping has become possible as well as decentralize production process creating strategic growth opportunities. These include materials that are conducive to multi-material printing, digital blending of materials, and can build highly complex parts with diverse properties in a single print.

Sustainable Materials and Recycling: There is an increasing focus on sustainability within the 3D printing materials market as demand for environmentally friendly materials and closed loop recycling solutions continue to rise. The development of bio-based filaments, recycled polymers and sustainable manufacturing processes that minimize their impact on the environment while maintaining performance and quality provides opportunities.

Partnerships and Collaborations: Collaboration between material suppliers, manufacturers of 3D printers, research institutions, and end-users facilitate innovation as well as market expansion. Such collaborations provide a platform through which new technologies can be validated hence accelerating material development; they also help validate new applications for this technology while addressing some of the technical challenges facing additive manufacturing.

Regulatory Compliance and Standards: Complying with regulations regarding health, safety or environmental impacts when materials are used in actual markets calls for performance oriented competition among these materials. This presents an opportunity for compliance with health safety environmental regulations without sacrificing performance benefits at the point of use.

By taking advantage of these strategic growth opportunities, the 3D printing materials market can realize its full potential and transform numerous industries through strength, lightness, versatility.

3D Printing Materials Driver and Challenges

3D Printing Materials has a very important role in many industries including automotive, aerospace, consumer, and medical. The changing market dynamics are being driven by the technological advancement, variety of industries using, customization and personalization. However, challenges like material performance and quality and limited material selection.

The factors responsible for driving the 3D printing materials market include:

Technological Advancement: 3D printing technologies are continuously changing with printer improvements, software advances and material development that necessitates the use of new and customized materials. These developments increase the 3D printed parts compatibility range and expand what they can do.

Utilization in Wide Range of Industries: Many industries including aviation, automotive, healthcare, consumer goods, and electronics have adopted 3D printing technology. For every industry there is a need for different materials hence creating a market for specialized materials that meet different people’s requirements and regulatory standards.

Customization and Personalization: The ability of 3D printing to produce on-demand customized complex geometries significantly drives its own demand. Industries look out for such materials like rapid prototyping for tooling as well as end-use parts that are unique to individual customers reducing time-to-market and enhancing product design flexibility.

Sustainability: A growing recognition of eco-friendly nature of 3D printing enhances demand for green 3D printing materials. Through bio-based polymers, recycled filaments plus sustainable manufacturing processes there is way out to minimize carbon footprint thus meeting the requirements set by regulators in relation to sustainability.

Medical & Healthcare Applications: In health care sector materials used in 3D printers before production includes patient-specific implants, prosthetics, surgical guides or medical devices. Biocompatible materials such as titanium alloys and medical grade polymers facilitate personalized medicine innovations which in turn improve patient results.

Cost Efficiency: The costs involved in material costs as well as those incurred during the manufacturing process through the use of any type of printings are reduced when economies scales improve due to maturity levels attained by various types of this form of printings. This aspect makes this technology more competitive against traditional methods used in manufacture for certain applications which grow their respective markets.

Challenges facing the 3D printing materials market are:

Material Performance and Quality: Ensuring the consistency of materials performance, quality, and dependability across different printing technologies and applications is difficult. For instance, changes that happen in material properties like mechanical robustness, heat stability, smoothness or surface texture may impact on part’s functionality and durability.

Limited Material Selection: In comparison to conventional materials the range of 3D printing materials available especially for high-performance applications such as aerospace and automotive is much narrower. Enhancement of properties within new materials and increased variety of options for materializing are the best approaches toward satisfying divergent industry requirements.

Regulatory Compliance: Meeting regulatory needs with regard to material safety, biocompatibility as well as environmental sustainability could be a thorny issue. Thus, various countries have established health & safety guidelines regarding 3D-printing materials, which must meet specific certification standards through rigorous testing procedures.

Technological Constraints: Despite emerging improvements in 3D printing techniques it has its limitations like speed, scalability resolution and compatibility with other substances. Therefore printer capability improvement necessitates research investment so that it can overcome these limitations as well as better material performance in future.

Innovations in the 3D printing materials market are revolutionizing additive manufacturing by advancing materials like high-performance polymers, metals, and biocompatible substances. These innovations cater to diverse industries such as aerospace, automotive, healthcare, and electronics, enhancing product design flexibility and performance. Developments in recyclable and sustainable materials contribute to environmental goals, while smart materials and nanotechnology integration offer enhanced functionalities like shape memory, conductivity, and self-healing properties. Multi-material printing capabilities and advanced simulation software further empower manufacturers to create complex, customized parts efficiently and with improved precision.

3D Printing Materials Suppliers and Their Market Shares

In this globally competitive market, several key players such 3D Systems Corporation, Stratasys, The ExOne Company, Arcam AB (GE), EOS GmbH Electro Optical Systems etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players Contact Us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies 3D printing materials companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the 3D printing materials companies profiled in this report include.

• 3D Systems Corporation

• Stratasys

• The ExOne Company

• Arcam AB (GE)

• EOS GmbH Electro Optical Systems

• Voxeljet AG

• EnvisionTEC GmbH

• Arkema SA

• Hoganas AB

• Materialise NV

• Carpenter Technology

• 3T-AM

These companies have established themselves as leaders in the 3D printing materials industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the 3D printing materials market are evolving, with the entry of new players and the emergence of innovative 3D printing materials technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

3D Printing Materials Market by Segment

The 3D printing materials market is diversified into several key segments based on additive manufacturing technologies. Fused Deposition Modeling (FDM) utilizes thermoplastic filaments for cost-effective prototyping and production. Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) fuse powdered materials using lasers or thermal printheads, ideal for complex, durable parts in nylon and metals. Stereolithography (SLA) and Digital Light Processing (DLP) employ UV light to cure liquid resin, offering high-resolution prints for detailed prototypes. Material Jetting deposits photopolymer droplets, ensuring accuracy and multi-material capabilities. These segments collectively drive advancements in material diversity, performance, and application versatility across various industries.

This 3D printing materials market report provides a comprehensive analysis of the market's current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including material, and end use industry. The report offers insights into regional dynamics, highlighting the major markets for 3D printing materials and their growth potentials. The study includes trends and forecast for global 3D printing materials market by material, end use industry, and region as follows:

Materials Market by Material [Value ($M) and Volume (Tons) Analysis for 2018 – 2030]:

• Photopolymers

• Thermoplastics

• Metals

• Ceramics

• Others

3D Printing Materials Market by End Use Industry [Value ($M) and Volume (Tons) Analysis for 2018 – 2030]:

• Automotive

• Aerospace

• Consumer

• Medical

• Others

3D Printing Materials Market by Region [Value ($M) and Volume (Tons) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of 3D Printing Materials Market

• Market Size Estimates: 3D Printing Materials market size estimation in terms of value ($B)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by material and end use industry

• Regional Analysis: 3D Printing Materials market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different material, end use industry, technology, and regions for the 3D printing materials market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the 3D printing materials market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in 3D printing materials or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the 3D printing materials market size?

Answer: The global 3D printing materials market is expected to reach an estimated $6 billion by 2030.

Q2. What is the growth forecast for 3D printing materials market?

Answer: The 3D printing materials market is expected to grow at a CAGR of 12% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the 3D printing materials market?

Answer: The major drivers for this market are rapid acceptance of 3D printing technology from prototyping to final product manufacturing and reduction in manufacturing cost.

Q4. What are the major applications or end use industries for 3D printing materials?

Answer: Medical is the major end use industries for 3D printing materials.

Q5. What are the emerging trends in 3D printing materials market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include use of bio-inks and gels in the medical industry, increasing use of composite materials and growing application of carbon-fiber reinforced composites.

Q6. Who are the key 3D printing materials companies?

Answer: Some of the key 3D printing materials companies are as follows:

• 3D Systems Corporation

• Stratasys

• The ExOne Company

• Arcam AB (GE)

• EOS GmbH Electro Optical Systems

• Voxeljet AG

• EnvisionTEC GmbH

• Arkema SA

• Hoganas AB

• Materialise NV

• Carpenter Technology

• 3T-AM

Q7.Which 3D printing materials deposit segment will be the largest in future?

Answer: Lucintel forecasts that photopolymers will remain the largest material for 3D printing due to the increasing demand in medical, consumer electronic, and aerospace industries.

Q8: In 3D printing materials market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region and witness the good growth over next 7 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global 3D printing materials market by end use industry (automotive, aerospace, consumer, medical, and others), material (photopolymers, thermoplastics, metals, ceramics, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 7 years in this market?

For any questions related to 3D printing materials market or related to 3D printing materials market share, 3D printing materials market analysis, 3D printing materials market size, 3D printing materials cost, and 3D printing technology, write to Lucintel analysts at helpdesk@lucintel.com. We will be glad to get back to you soon.