Glass Fiber Textile Market Trends and Forecast

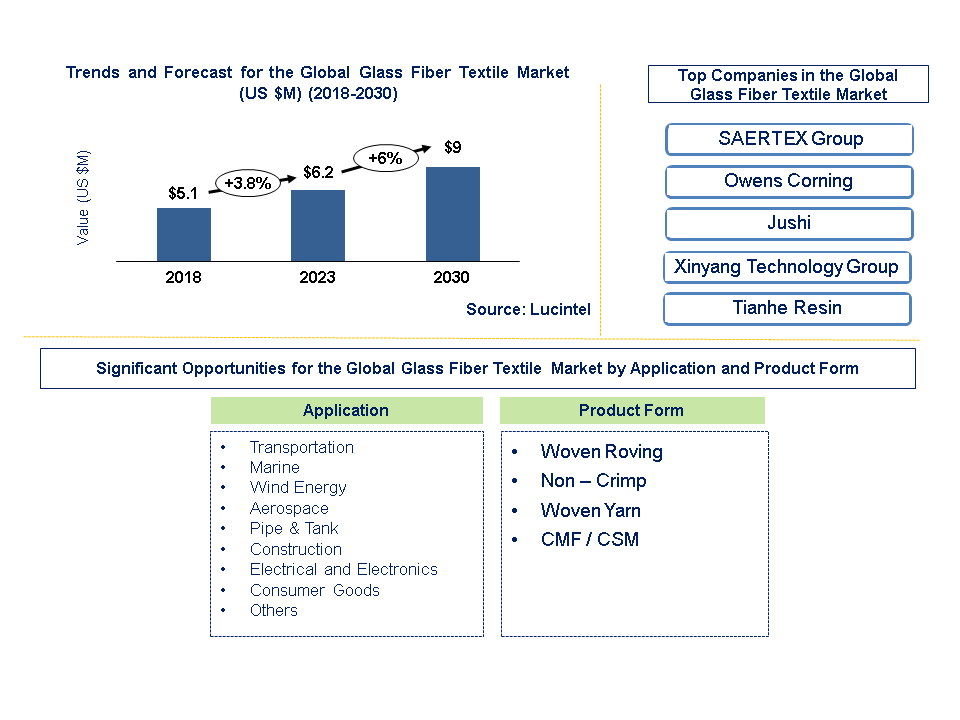

Lucintel finds that the future of the global glass fiber textile intermediate material market looks promising with opportunities in the in transportation, marine, wind energy, aerospace & defense, pipe and tank, construction, electrical and electronics, and consumer goods applications. The global glass fiber textile market is expected to reach an estimated $9 million by 2030 with a CAGR of 6% from 2023 to 2030. The major growth drivers for this market are increasing demand for durable, lightweight, non-corrosive components, continuous demand in Chinese and Indian markets.

Silica (SiO₂), alumina (Al₂O₃), calcium oxide (CaO), boron oxide (B₂O₃), and magnesium oxide (MgO) are among the raw materials typically used in glass fiber textiles. These substances are molten and then extruded through fine nozzles to form continuous glass filaments. The latter can be woven or knitted into textile forms, thereby demonstrating tensile strength, flexibility, as well as resistance to changes in temperature.

Glass fiber textiles are generally cheaper than carbon fibers but more expensive than conventional materials such as cotton or polyester. Glass fiber textiles have optimum cost-effectiveness, considering their properties like endurance, hardiness, and even heat resistance that make them competitive in applications where performance is critical. Nevertheless, there may still be other less effective yet inexpensive alternatives that can be preferred in some price-sensitive markets.

• Lucintel forecasts that wind energy application will remain the largest application. Aerospace & defense is expected to witness the highest growth over the forecast period.

• Woven yarn will remain the largest segment by value over the forecasted period due to growth in electrical and electronic industry. Non-Crimp is expected to witness highest growth over the forecast period.

• APAC is expected to remain the largest region by value and volume due to growth in applications, such as electrical & electronics and wind energy and also it is expected to witness the highest growth over the forecast period.

Country wise Outlook for the Glass Fiber Textile Market

Emerging Trends in the Glass Fiber Textile

Emerging trends in the glass fiber textile market shaping its future applications and market dynamics:

• Increasing Focus on Sustainability Initiatives: There is a growing emphasis on developing eco-friendly glass fiber textiles. Innovations include the use of recycled glass and the development of bio-based resins for composite materials, reducing environmental impact and appealing to eco-conscious consumers and industries.

• Advanced Manufacturing Techniques: Adoption of advanced manufacturing technologies such as 3D weaving and automated fiber placement is on the rise. These techniques enhance production efficiency, reduce waste, and enable the creation of more complex and high-performance textile structures.

• High-Performance Applications: The demand for high-performance glass fibers in aerospace, automotive and wind energy sectors has been increasing. Industries that call for materials with superior strength-to-weight ratios, durability, thermal resistance etc., are driving innovation and market development.

• Smart Textiles: Integration of smart technologies into glass fiber textiles is emerging. These smart textiles can include sensors and electronic components, offering functionalities such as structural health monitoring, temperature regulation, and other responsive behaviors for advanced applications.

These trends indicate a shift towards more sustainable, innovative, and technologically advanced solutions in the glass fiber textile industry to

meet evolving consumer and regulatory demands globally.

A total of 85 figures / charts and 58 tables are provided in this 176-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments in the Glass Fiber Textile Market

Recent developments in global glass fiber textile market which highlights ongoing innovations and advancements across different sectors.

• Innovative Composite Materials: Glass fiber textiles are combined with advanced resins and polymers to make innovative composite materials. These composites have mechanical properties that are better than those of conventional materials, such as enhanced strength, durability, and thermal resistance resulting into an expanded range of their applications in the aerospace, automobile, and construction industries.

• Sustainable Practices: There is a huge move towards sustainability with manufacturers increasingly looking at recycled glass fibers and bio-based resins. This will help reduce the carbon footprint of glass fiber textiles while also offering eco-friendly alternatives for use in numerous sectors where eco-friendly stuffs are needed.

• Improved Manufacturing Techniques: Adoption of state-of-the-art manufacturing approaches like 3D weaving and automated fiber placement is on the rise. These developments enhance efficiency in production processes; reducing wastages as well as allowing complex formation of more complicated textile structures that offer high performance features tailored according to a specific demand of various applications.

• Smart Textiles Development: Incorporating smart technologies into glass fiber textiles is becoming popular. Some latest trends include fabrics embedded sensors for structural integrity monitoring real-time alerts, temperature regulation among other responsive behaviors. These intelligent textiles can be used for safety and maintenance purposes especially in aerospace and building structures

• Fire and Heat Resistant Innovations: The different types of specialized fire retardant glass fiber textiles have been developed. In this direction, these fabrics find wider application in protective garments, industrial operations involving high temperature environment as well as safety equipment.

Strategic Growth Opportunities for Glass Fiber Textile Market

Innovative materials that are sustainable, advanced manufacturing techniques, and increased high-performance uses are the driving forces behind strategic growth opportunities in the glass fiber textile market. The above have reshaped the industry landscape and hence given room for great potential for growth and competitive advantage. Some key strategic growth opportunities for this market include:

• Recycled Glass Fibers: Recycled glass fibers are being developed and used. The use of recycled materials reduces the impact on the environment and is consistent with global sustainability initiatives. Investments in recycling technologies and processes will boost market attractiveness, as well as meet the growing regulatory requirements for greener practices.

• Bio-based Resins: This trend involves using bio-based resins in making glass fiber textiles. These are renewable source based resins that can substitute traditional petrochemical based resins with eco- friendly ones which have been a requirement for sustainable materials across various industries.

• Technological Advancements in Manufacturing: 3D Weaving and Automated production: Technological advancements such as 3D weaving and automated production techniques has improved efficiency and quality of glass fiber textiles. These technologies enable complex textile structures to be created cheaply, reducing waste while expanding application possibilities.

• Enhanced Processing Techniques: High-precision applications require innovative processing techniques like improved impregnation methods & precise cutting tools so that production of glass fiber textiles can be optimized. Such advancements enhance product consistency, performance, fulfilling high precision application needs.

• Expansion into High-Performance Applications: There are significant opportunities presented by increasing demand for lightweight yet durable materials in aerospace industry or automotive sector. Glass fiber textiles exhibit outstanding strength-to-weight ratios along with resistance to heat which make them suitable for use in structural components and safety systems.

Glass Fiber Textile Market Drivers and Challenges

The demand for strong, high-quality materials from the aerospace, car and building industries underpins glass fiber textile market. As sustainable methods advance, along with manufacturing technology the growth is driven by environmentally friendly and productive techniques. Nonetheless, weighty barriers like difficult supply networks, competition from other components in the production process and even costliness in manufacturing hinder its expansion. Consequently, to improve their market share; companies must strike a balance between these push factors and problems faced that can enable them innovate effectively while adapting to the changing needs of this sector.

The factors responsible for driving the glass fiber market include:

1. High-Performance Requirements: The need for glass fiber textiles is determined by their superior mechanical properties which includes; high tensile strength, durability and thermal resistance. These features make them suitable for use in the aerospace, automotive and construction industries where lightweight, strong and heat resistant materials are required. Glass fibers textiles have the needed attributes that drive their uptake and expansion as industries look for performance enhancing materials that enhance safety, fuel economy as well as efficiency.

2. Sustainability Trends: Increasing environmental awareness coupled with regulatory pressures are driving the adoption of sustainable materials. There is an increasing popularity of glass fiber textiles made from recycled glass or biobased resins due to their reduced environmental footprint. By investing in these environmentally friendly options, companies can attract eco-conscious consumers/industries, align themselves with global sustainability objectives and meet stringent regulations thereby improving market competitiveness.

3. Technological Innovations: Manufacturing technologies such as 3D weaving as well as automatic production processes have revolutionized how glass fiber textiles work hence making them more efficient than before. The introduction of these technologies now makes it possible to make sophisticated textile structures that perform better but at the same time generate less waste hence reducing cost implications. Also advanced processing techniques will be able to improve uniformity and quality of products thus enabling them to find wider applications in various high-tech industrial sectors which are experiencing rapidly growing demand.

Challenges in the Glass Fiber Textile Market:

1. Increasing Production Costs: The manufacture of glass fiber textiles involves significant expenditures on raw materials, energy, and state-of-the-art technologies. These may adversely affect pricing, thus making glass fiber textiles less attractive than alternatives like polyester or polypropylene which are cheaper. Manufacturers targeting competitiveness in the market must manage to control within the cost limits.

2. Competition From Other Materials: Alternative carbon fibers and aramid fibers pose a great competition to glass fiber textiles that offer different performance characteristics or serve at lower costs. Glass fiber textiles, while cherished for their strength and heat resistance abilities, however have to compete with such alternatives on various applications. To hold onto market share and satisfy the varying industry needs continuous innovative developments as well as differentiation are needed.

In the glass fiber textile market, growth is dependent on continuous innovation in composite materials and the desire for better performance in tough environments. But it is important to still address production costs and competition from alternatives as leveraging technology and sustainable practices can help overcome them, thereby resulting in further market expansion.

Glass Fiber Textile Suppliers and Their Market Shares

In this globally competitive market, several key players such as, SAERTEX, Owens Corning, Jushi, Xinyang Technology, Tianhe Resin Company, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies global glass fiber textile companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the global glass fiber textile companies profiled in this report includes.

• SAERTEX Group

• Owens Corning

• Jushi Group Co. Ltd

• Xinyang Technology Group

• Tianhe Resin Company Ltd

These companies have established themselves as leaders in the global glass fiber textile industry with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the global glass fiber textile market are evolving, with the entry of new players and the emergence of innovative technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Glass Fiber Textile Market by Segment

In the global market for glass fiber textiles, transportation, wind power, maritime, aerospace, and defense are among the major growing applications. For transportation purposes these fabrics are made lighter but stronger to make them fuel saving and safety enhancing components. This is how wind energy sector benefits from their strength and resistance in turbine blades. Marine makes use of such textiles because they improve the durability of boat hulls as well as resisting corrosion. The aerospace and defense sectors employ glass fiber textiles for high performance components and protective gear. In each case, glass fiber textiles have distinct properties that can be used to meet specific performance or durability requirements leading to growth in these industries.

This glass fiber textile market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, includes application and product form. The report offers insights into regional dynamics, highlighting the major markets for global glass fiber textile market and their growth potentials. The study includes trends and forecast for the composites in global glass fiber textile market by application, product form, and region as follows:

Global Glass Fiber Textile Market by Application [Value ($M) and (M lbs) Analysis for 2018 – 2030]:

• Transportation

• Marine

• Wind Energy

• Aerospace & Defense

• Pipe and Tank

• Construction

• Electrical and Electronics

• Consumer Goods

• Others

Global Glass Fiber Textile Market by Product Form [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• Woven Roving

• Non-Crimp

• Woven Yarn

• CFM/CSM

Global Glass Fiber Textile Market by Region [Value ($M) and Volume (M lbs) Analysis for 2018 – 2030]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

Features of Glass Fiber Glass Textiles Market

• Market Size Estimates: Glass fiber textiles market size estimation in terms of value ($M) and Volume (M lbs)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by application, product type and region

• Regional Analysis: Glass fiber textiles market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different application, product form and regions for the glass fiber textiles market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the glass fiber textiles market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in composites in the global glass fiber textile market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the global glass fiber textile market size?

Answer: The global glass fiber textile market is expected to reach an estimated $9 billion by 2030.

Q2. What is the growth forecast for global glass fiber textile market?

Answer: The global glass fiber textile market is expected to grow at a CAGR of 6% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the global glass fiber textile market?

Answer: The major drivers for this market are increasing demand for durable, lightweight, non-corrosive components, continuous demand in Chinese and Indian markets.

Q4. What are the major applications for global glass fiber textile?

Answer: Electrical and Electronics is the major applications in industries for global glass fiber textile.

Q5. What are the emerging trends in global glass fiber textile market?

Answer: Emerging trends, which have a direct impact on the dynamics of the glass fiber textile industry, includes high-performance textile for wind energy, high tensile glass fiber textile for construction market.

Q6. Who are the key global glass fiber textile companies?

Answer: Some of the key global glass fiber textile companies are as follows:

• SAERTEX Group

• Owens Corning

• Jushi Group Co. Ltd

• Xinyang Technology Group

• Tianhe Resin Company Ltd

Q7. Which global glass fiber textile product segment will be the largest in future?

Answer: Lucintel forecasts that woven yarn global glass fiber textile will remain the largest segment and it is expected to witness the highest growth over the forecast period due to its better cleansing and moisturizing properties

Q8. In global glass fiber textile market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region and North America witness the highest growth over next 7 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high-growth opportunities for the global glass fiber textile market by application(transportation, marine, wind energy, aerospace and defense, pipe and tank, construction, electrical and electronics, consumer goods and others), product form (woven roving, non crimp, woven yarn, CFM/CSM), and region (North America, Europe, Asia Pacific, and Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?